Wood cutting machinery favorable for clearing wood dust

A cutting machine and cutting machine technology, applied in wood processing equipment, special forming/shaping machines, forming/shaping machines, etc., can solve the problem of inconvenient transportation and reuse of sawdust waste, inability to effectively reduce the labor intensity of staff, Can not effectively guarantee the health of the staff and other issues, to achieve the effect of easy reuse, reduce labor intensity, and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

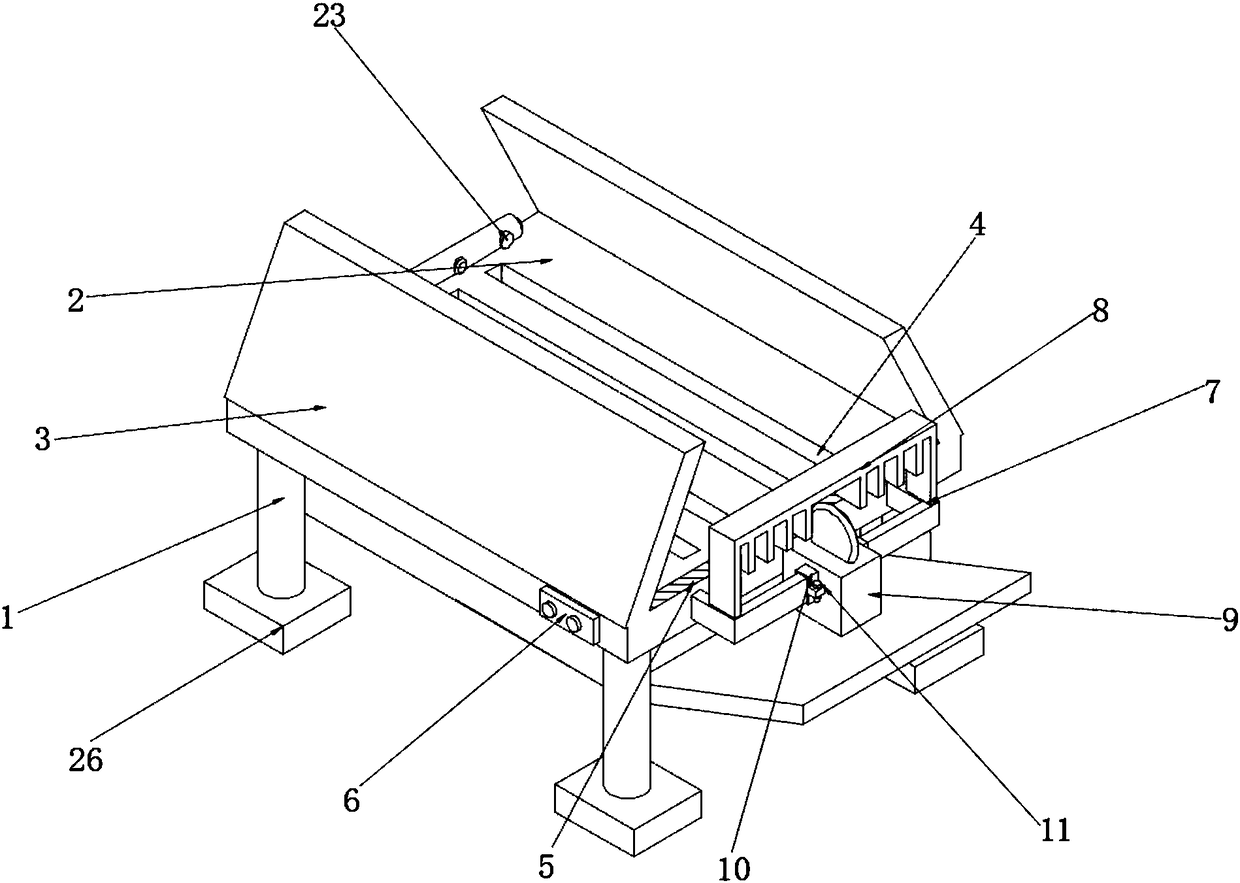

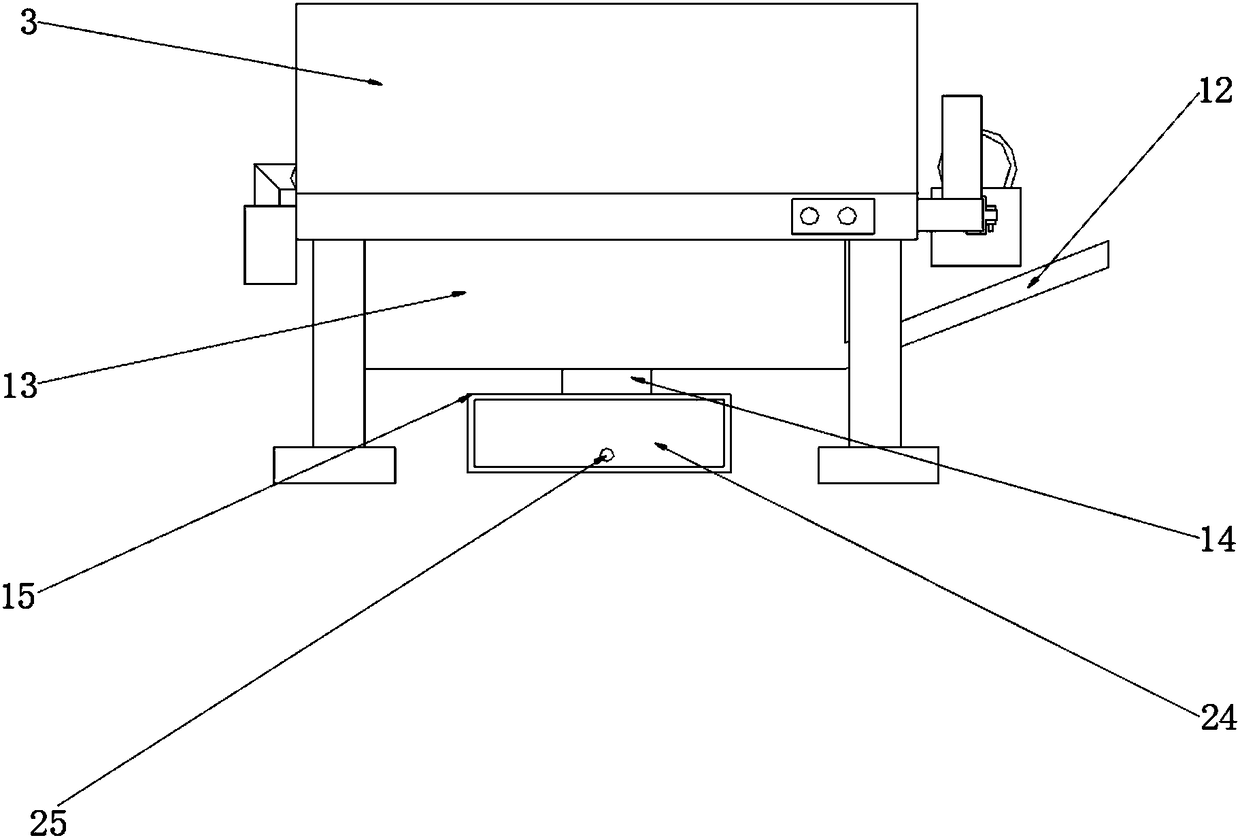

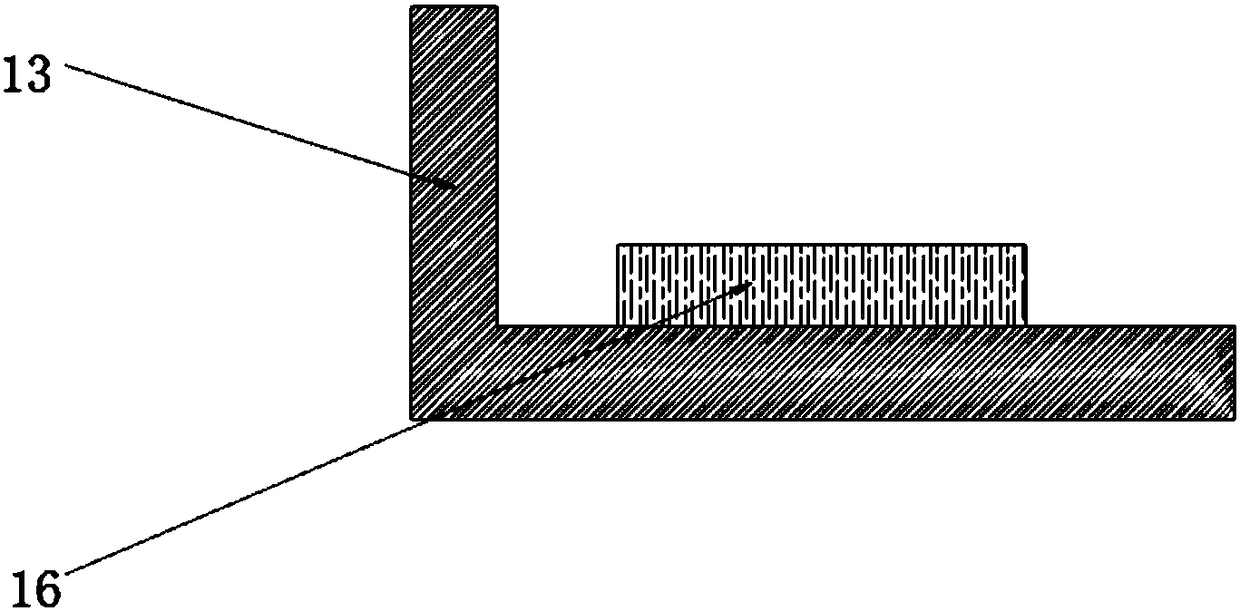

[0022] Example: such as Figure 1-6 As shown, the present invention provides a technical solution, a wood cutting machine that is convenient for cleaning sawdust, including a bracket 1, a base 2, a baffle 3, a drain 4, a scale 5, a control panel 6, a sliding rod 7, and a brush 8 , cutting machine 9, buckle 10, fixing bolt 11, slide plate 12, collection box 13, feeding pipe 14, waste box 15, cyclone dust collector 16, pressure plate 17, servo motor 18, positioning rod 19, threaded rod 20, Air pump 21, air duct 22, nozzle 23, side door 24, handle 25 and shock absorber 26, base 2 is installed on the top of support 1, shock absorber 26 is installed around the bottom of support 1, and baffles are arranged on both sides of base 2 3. There is a drain 4 on the top of the base 2, a scale 5 is installed on one end of the base 2, a sliding rod 7 is installed on one side of the base 2, a cutting machine 9 is sleeved on the outside of the sliding rod 7, and buckles 10 are installed on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com