Method and apparatus for catalytic upgrading poor gasoline

A low-quality gasoline, catalytic upgrading technology, applied in the field of hydrocarbon oil refining, can solve the problems of limited olefin volume content reduction in gasoline, limited equipment operation flexibility, complex process flow, etc., to achieve reduced sulfur content, wide application, and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

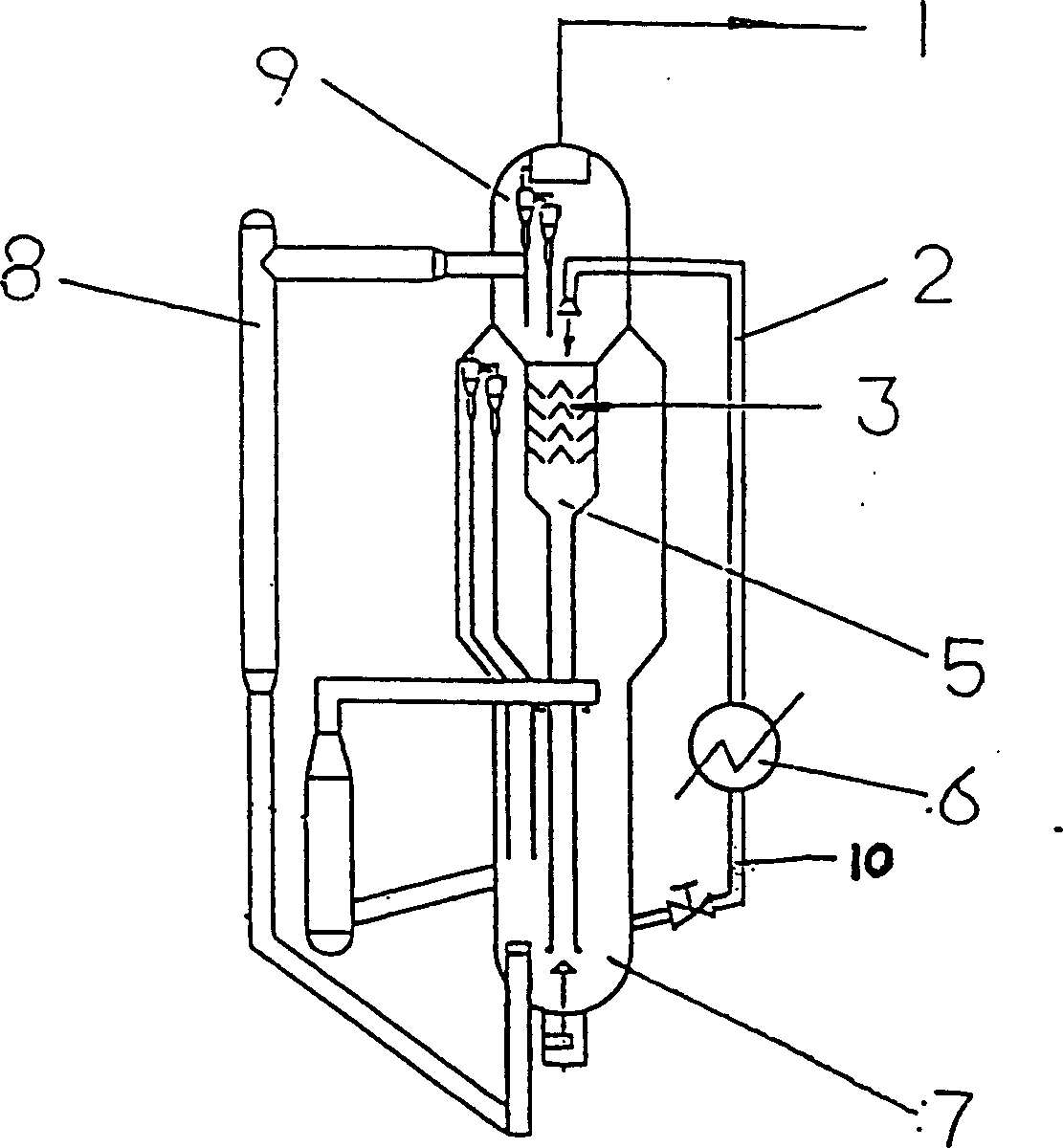

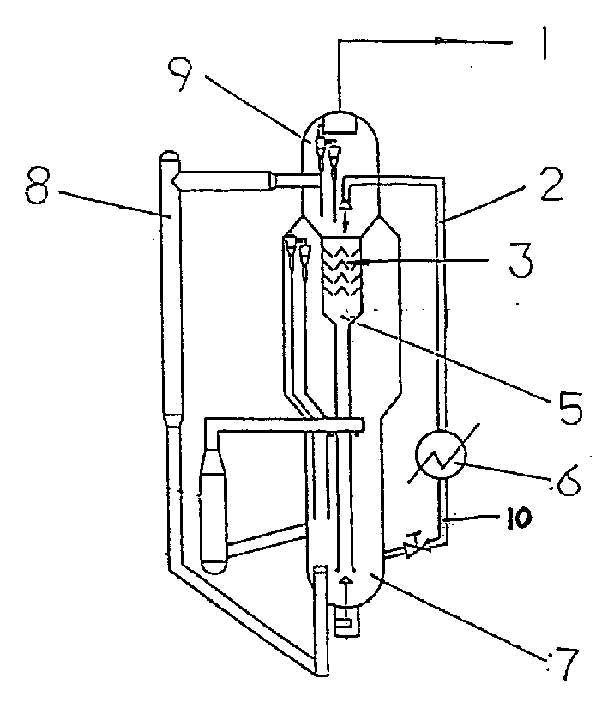

[0025] According to the inferior gasoline catalytic upgrading device of the present invention shown in the accompanying drawings, Daqing atmospheric residual oil catalytic cracking gasoline is upgraded, and the catalytic cracking catalyst adopts LRC-99 industrial balancer. The treatment capacity of the riser is 30 kg / day, and the raw material is Daqing atmospheric residue. The operating conditions and product distribution are shown in Table 1. Daqing atmospheric residue catalytic cracking gasoline to be upgraded enters the stripping section with a treatment capacity of 10 kg / day. The operating conditions and product distribution are shown in Table 2. The properties of gasoline before and after upgrading are shown in Table 3.

[0026] Example

[0027] Example

[0028] Example

Embodiment 2

[0030] According to the low-quality gasoline catalytic upgrading device of the present invention shown in the accompanying drawings, the catalytic cracking gasoline of Zhongyuan atmospheric residue is upgraded, and the catalytic cracking catalyst adopts CC-20D industrial balancer. The processing capacity of the riser is 30 kg / day, and the raw material is pipeline atmospheric residual oil. The operating conditions and product distribution are shown in Table 4; the inferior gasoline enters the stripping section, and the processing capacity is 10 kg / day. The operating conditions and product distribution are shown in Table 5. The comparison of main properties of gasoline products before and after upgrading is shown in Table 6.

[0031] Example

[0032] Example

[0033] Example

Embodiment 3

[0035] On the riser catalytic cracking device of the present invention shown in the accompanying drawings, the pipeline transported normal slag catalytic cracking gasoline is upgraded, and the catalytic cracking catalyst adopts ORBIT-3000 industrial balancer. The treatment capacity of the riser is 30 kg / day, and the raw material is Zhongyuan atmospheric residual oil. The operating conditions and product distribution are shown in Table 7; the processing capacity of inferior gasoline into the stripping section is 10 kg / day. The comparison of main properties of gasoline products before and after is shown in Table 9.

[0036] Example

[0037] Example

[0038] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| dry point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com