A kind of technological process of producing epichlorohydrin by epoxidation of propylene chloride

The technology of epichlorohydrin and epichlorohydrin tower is applied in the field of production technology of chemical products, and can solve the problems of producing 11 tons of waste water, high equipment investment, lengthy process, etc., and achieve the effect of small loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

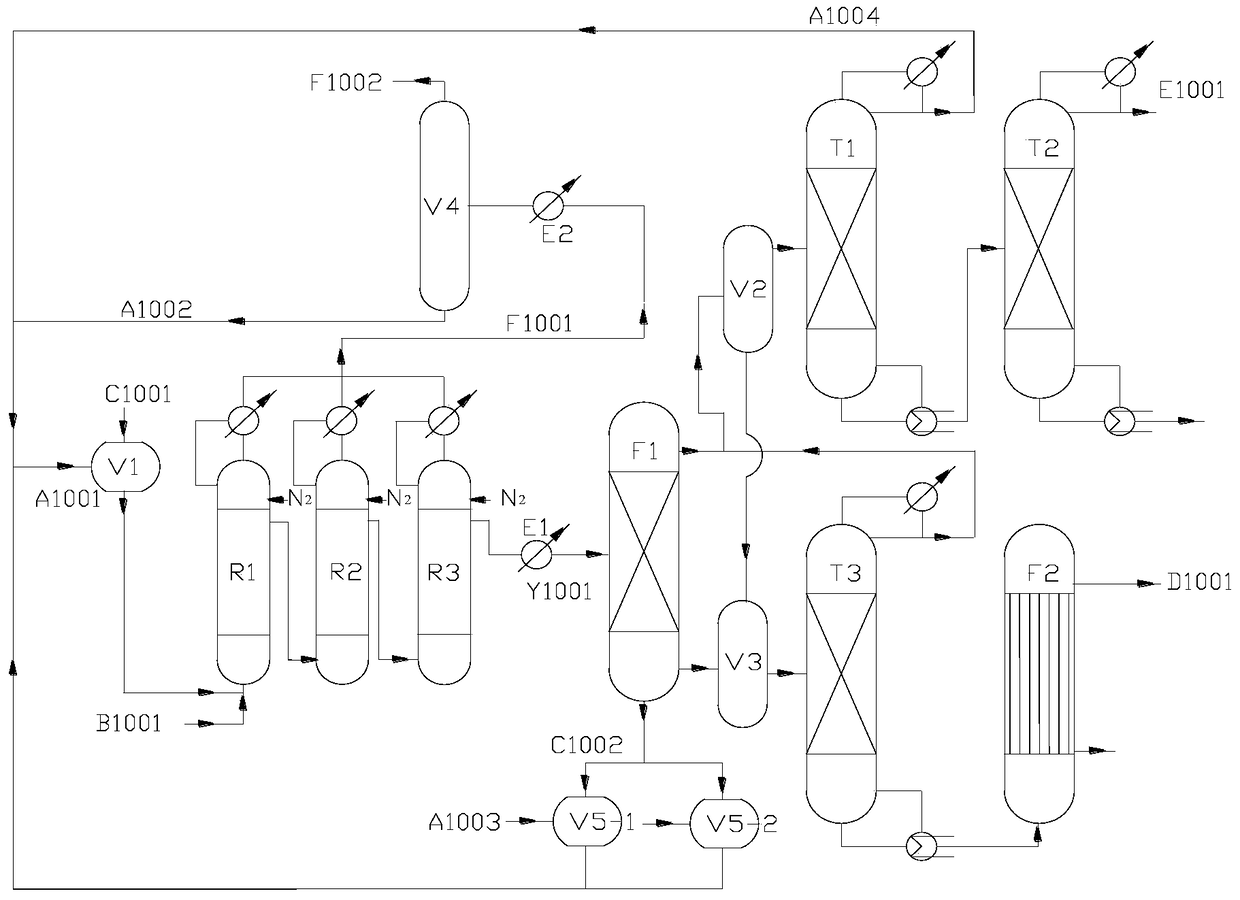

[0057] 1) Through the nitrogen inlets provided on the top of the primary reactor (R1), secondary reactor (R2), and tertiary reactor (R3) to the primary reactor (R1), secondary reactor (R2), Pass into the three-stage reactor (R3) to replace the air in the reactor cavity with nitrogen and keep the continuous feeding of nitrogen and the discharge of tail gas, and set the reaction pressure to 0.75MPa;

[0058] 2) Set the heaters of the primary reactor (R1), secondary reactor (R2), and tertiary reactor (R3) to 65°C, and set the condensation temperature of the top reflux condensation device of the three reactors to 0 ℃; the condensation temperature of the condenser (E2) is set to -5 ℃, and the pressure of the secondary pressurized condensation storage tank (V4) is set to 1.0MPa; the temperature of the reboiler at the bottom of the chloropropene tower (T1) is set to 90 ℃, The temperature of the top reflux condenser is -5°C, and the operating pressure is 0.040MPa; the temperature of t...

Embodiment 2

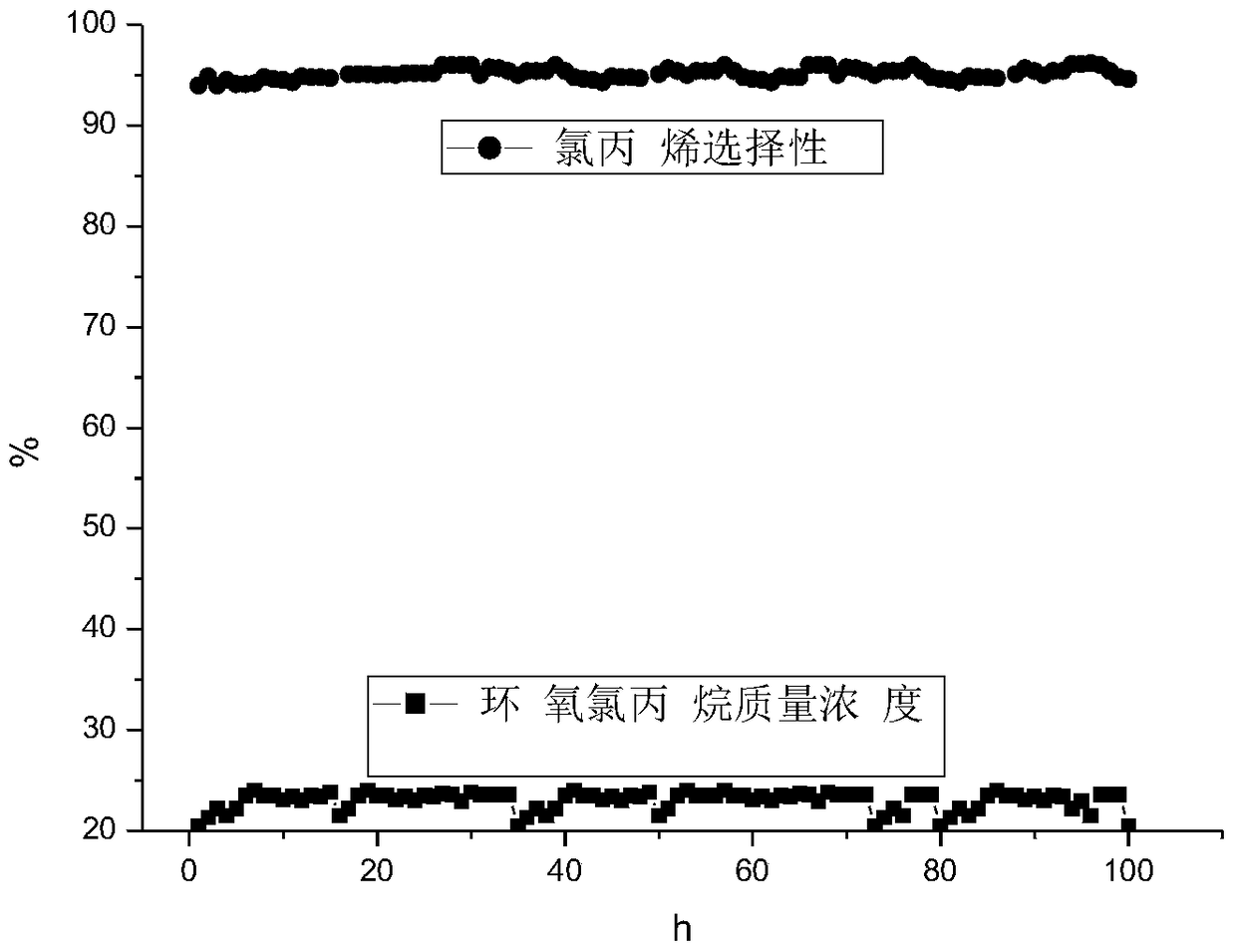

[0067] figure 2 It is a working line obtained by carrying out continuous production for 100 hours according to the process conditions of Example 1, and analyzing the mass concentration of epichlorohydrin in the oil phase of Y1001 and the selectivity of allyl chloride by taking a sample every hour for analysis. It can be seen from the figure that the oil phase of Y1001 The mass concentration of epichlorohydrin in the medium is maintained between 21% and 24%, and the selectivity of chloropropene in the oil phase of Y1001 is greater than 94%, and is maintained at about 95%.

Embodiment 3

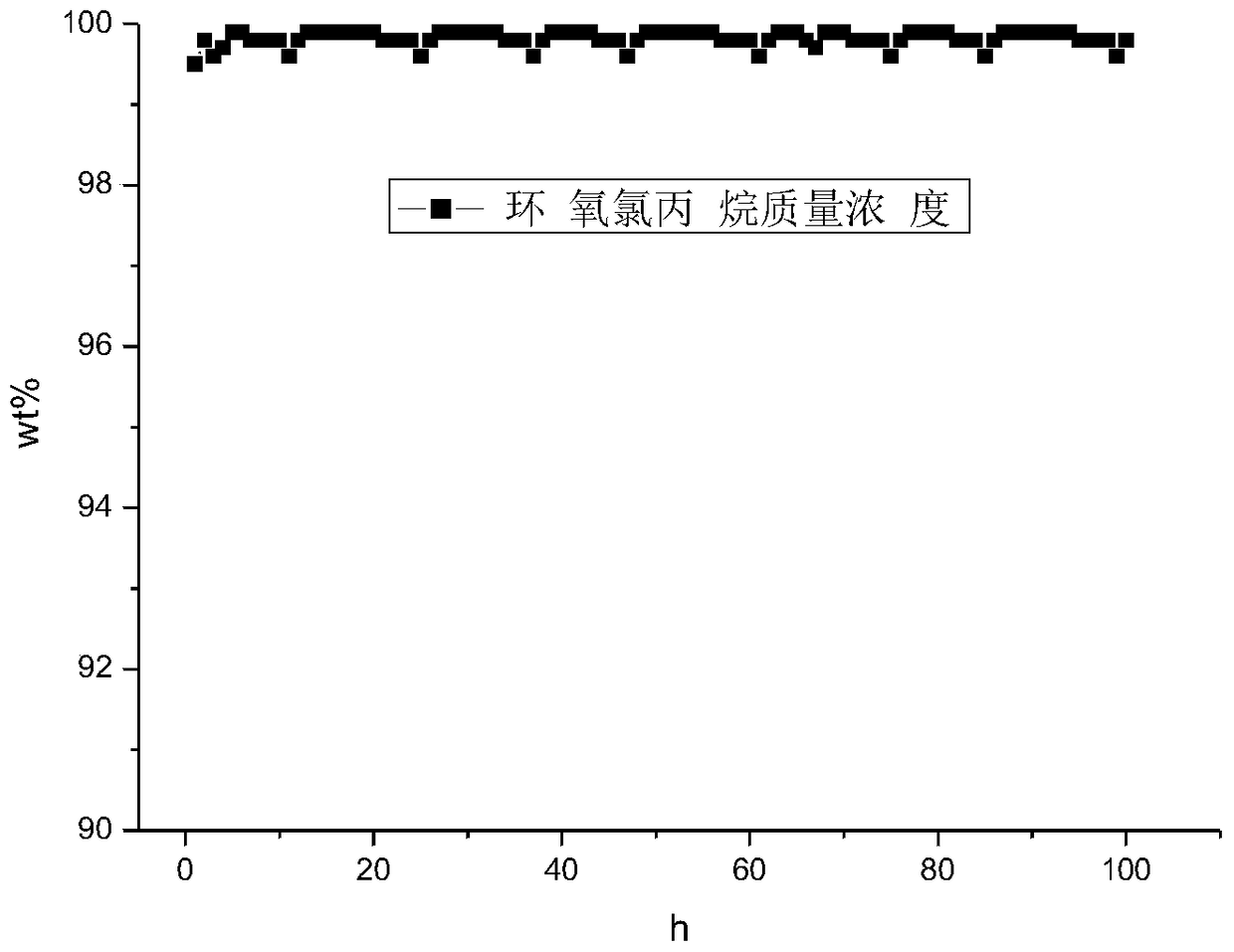

[0069] image 3 It is to carry out 100 hours of continuous production according to the process conditions of embodiment 1, and the epichlorohydrin tower output E1001 product epichlorohydrin mass concentration is carried out to take a sample every hour and analyze the working line that obtains, as seen from the figure, the product epoxy chlorohydrin The mass concentration of chloropropane reaches above 99.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com