Catalytic cracking method and device capable of increasing propylene yield and improving properties of gasoline

A technology of catalytic cracking and gasoline properties, applied in the direction of catalytic cracking, cracking, petroleum industry, etc., can solve the problems that it is difficult to achieve conversion conditions, and it is difficult to achieve high conversion rate of propylene, so as to achieve the reduction of olefin volume content, sulfur content reduction, The effect of property improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

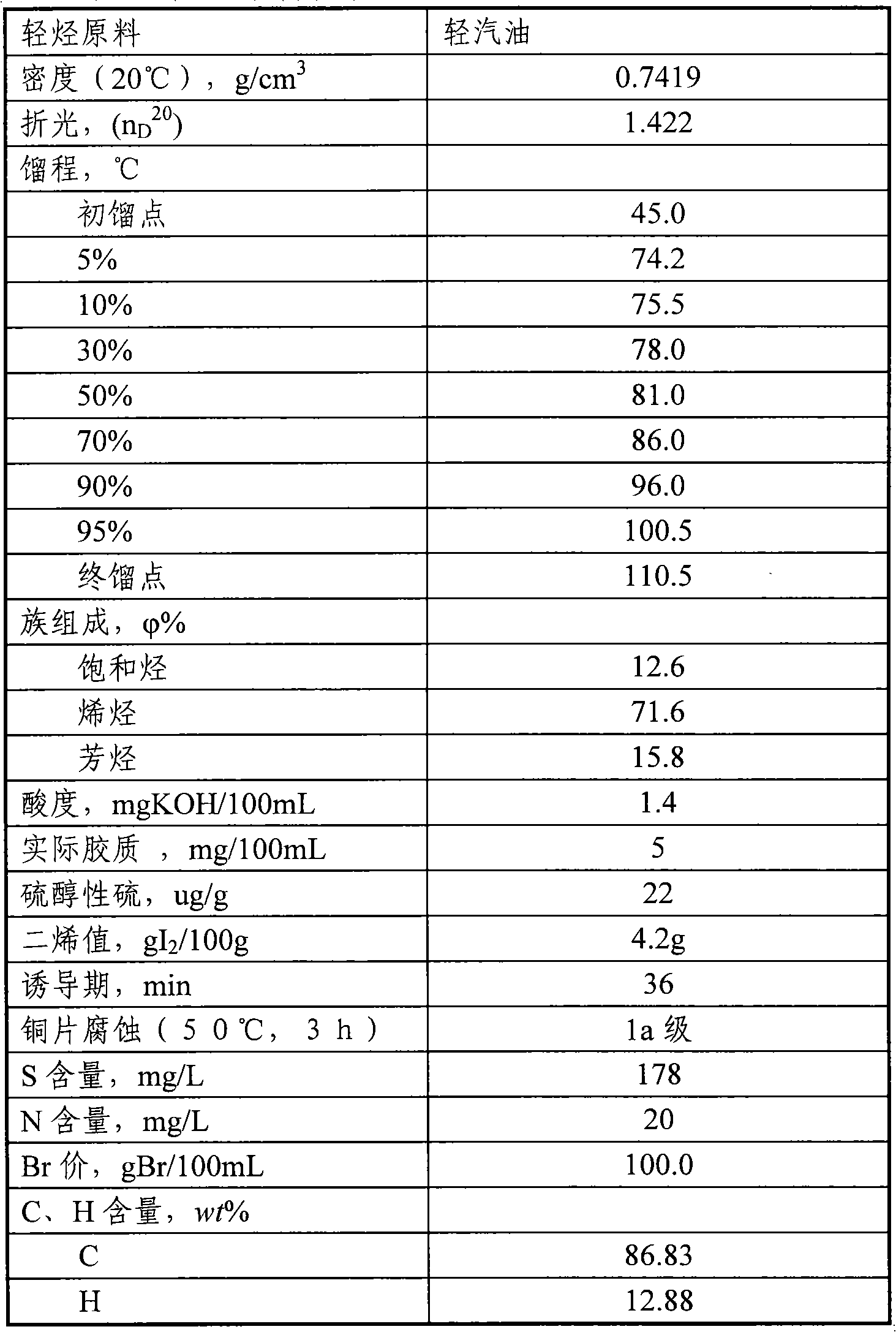

[0041] Example 1 illustrates the effect of the catalytic cracking method provided by the present invention comprising a two-stage riser reaction zone plus a bed reactor to increase propylene production and improve gasoline properties.

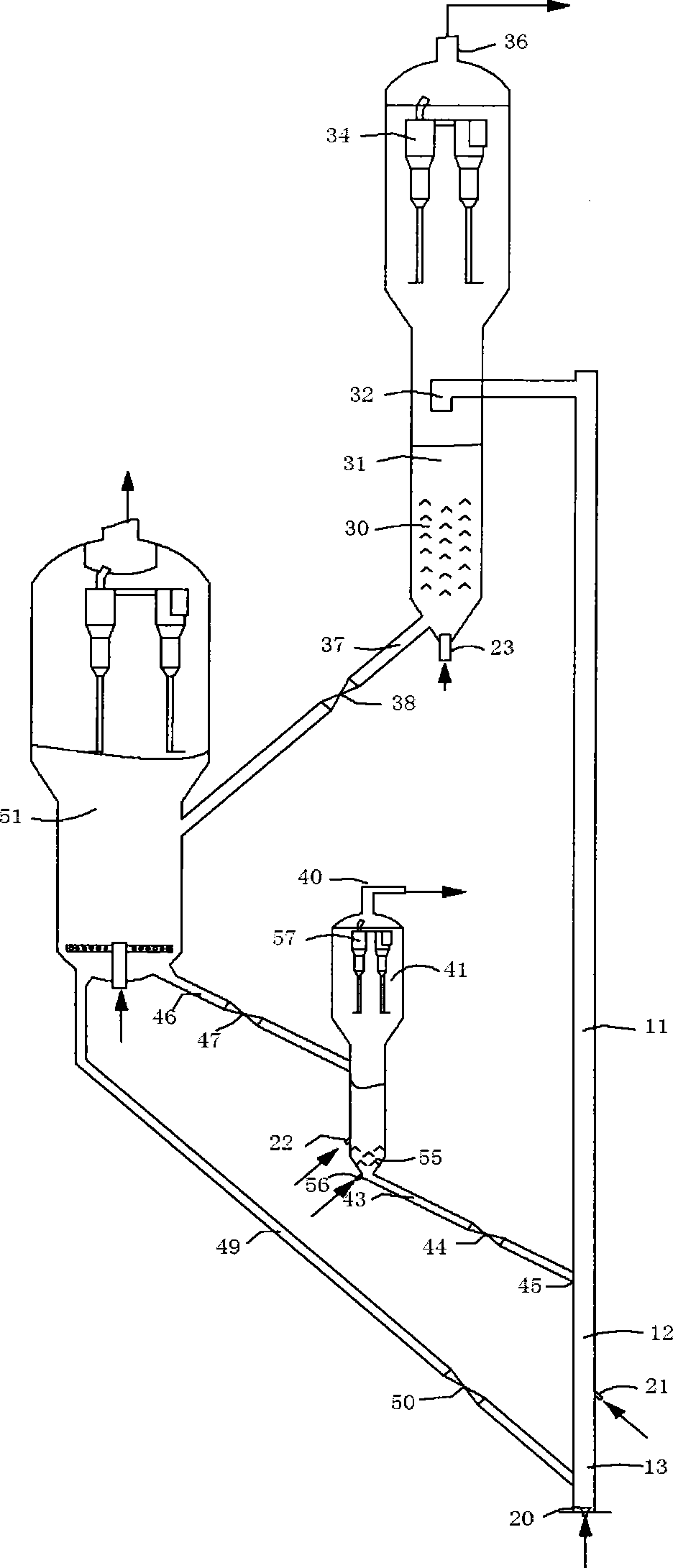

[0042] The test device is a medium-sized catalytic cracking unit, the total length of the main riser is 8 meters, the inner diameter of the first-stage reaction zone of the riser is 18mm, and the inner diameter of the second-stage reaction zone is 21mm; the heights of the first-stage reaction zone and the second-stage reaction zone of the riser are respectively 2.0 m, 6.0m. The bed reactor has an inner diameter of 60mm and a height of 2000mm. The conventional catalytic cracking catalyst MLC-500 with active component Y was used for catalytic conversion of hydrocarbon oil. The reaction process is attached figure 1 As shown, the main operating conditions and product distribution are listed in Table 4 and Table 5, and the properties of product ga...

Embodiment 2

[0045] Example 2 illustrates the effect of the catalytic cracking method provided by the present invention comprising a three-stage reaction zone for increasing propylene production and improving gasoline properties.

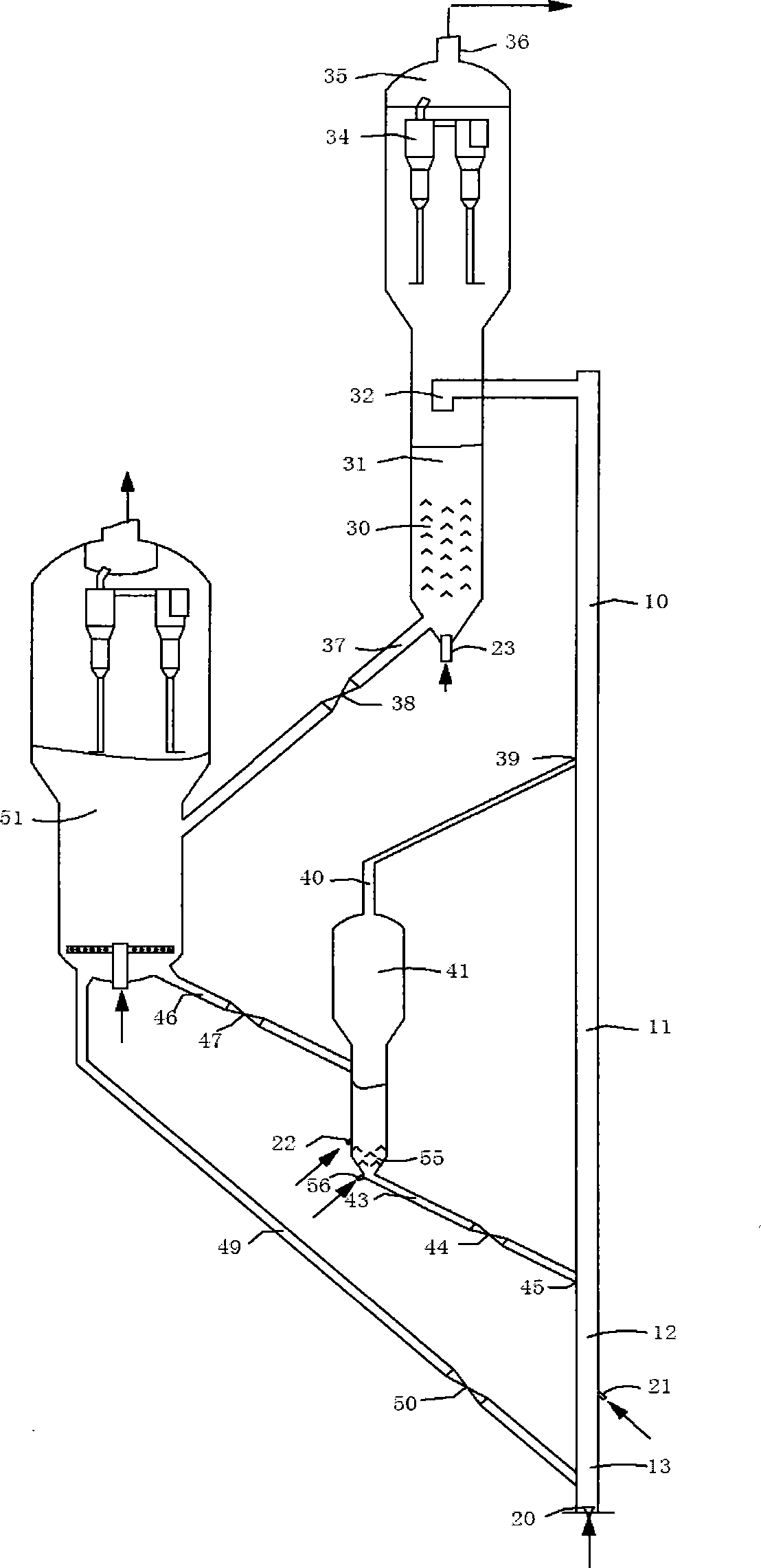

[0046] The test device is a medium-sized catalytic cracking unit. The total length of the main riser is 8 meters. The heights of the zone and the third-stage reaction zone are 2.0m, 4.0, and 2.0m, respectively. The bed reactor has an inner diameter of 60mm and a height of 2000mm. Catalytic cracking catalyst CRP-1 with both Y-type zeolite and ZSM-5 zeolite was used for catalytic conversion of hydrocarbon oil. The reaction process is attached figure 2 As shown, the heavy raw material is introduced into the riser for reaction, and the light raw material is introduced into the bed reactor for reaction. The catalyst properties, heavy raw material properties and light raw material properties are shown in Table 1, Table 2 and Table 3 respectively. The main operatin...

Embodiment 3

[0049] Example 3 illustrates the effect of the catalytic cracking method provided by the present invention comprising a three-stage reaction zone for increasing propylene production and improving gasoline properties.

[0050] The test device is a medium-sized catalytic cracking device, and the structures of the main riser and the bed reactor are the same as in Example 2. Catalyst is with embodiment 2. The reaction process is attached figure 2 As shown, the main operating conditions and product distribution are listed in Table 4 and Table 5, and the properties of product gasoline are listed in Table 6.

[0051] It can be seen from Table 5 and Table 6 that the liquefied gas yield is 32.16wt%, the propylene yield is 15.2wt%, the gasoline olefin volume content is 30.2%, the sulfur content is 202ug / g, and the research octane number is 94.8.

[0052] Table 1 Catalyst properties

[0053] catalyst

MLC-500

CRP-1

MA

64

64

RE 2 o 3 , wt%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| research octane number | aaaaa | aaaaa |

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com