Catalytic cracking method and device

A catalytic cracking and catalyst technology, used in catalytic cracking, cracking, refining and cracking process treatment only in multi-stage series, etc. The effect of increasing liquid yield and decreasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

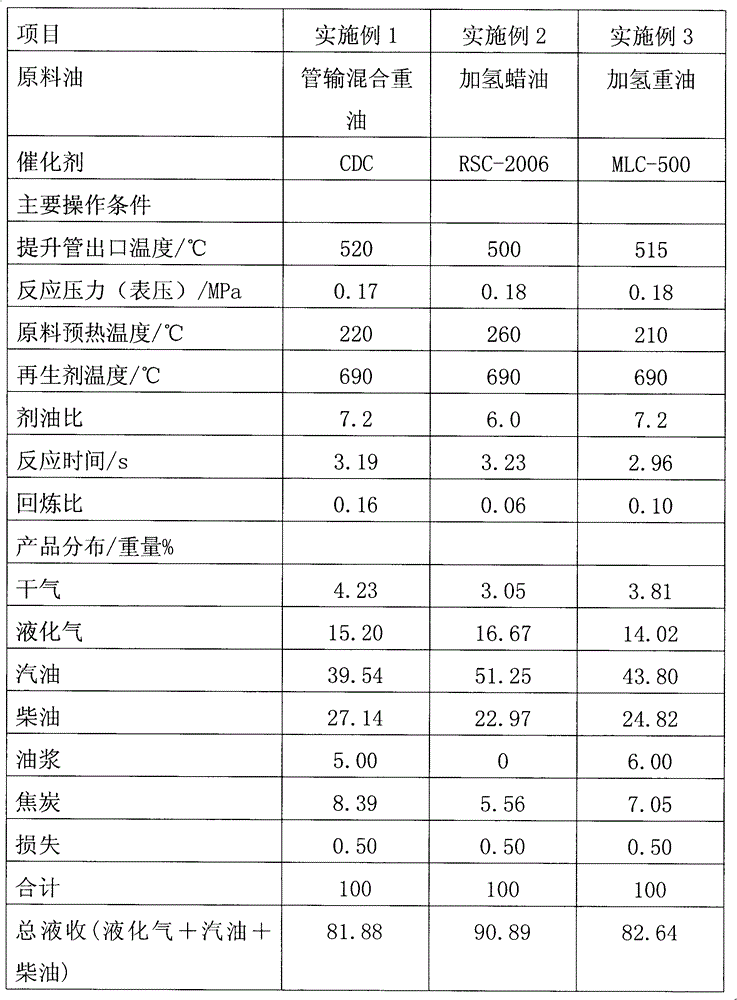

[0034] Embodiment 1 comparative example

[0035] The test is carried out on a common riser catalytic cracking test device. The raw material oil is pipeline transported mixed heavy oil. The main properties are listed in Table 1. The processing capacity is 30 kg / day. It is 62, and the carbon content is 0.05w%. The main operating conditions, product distribution and main properties of the products of the riser reactor are listed in Table 2 and Table 3.

[0036] Embodiment 2 comparative example

[0037] By embodiment 1, the difference is that the raw material oil is hydrogenated wax oil, the main properties are listed in table 1, the processing capacity is 30 kg / day, and the catalyst used in the test is RSC-2006 industrial balancer, and the micro-reaction activity of the balance catalyst is 60 , the carbon content is 0.06w%. The main operating conditions, product distribution and main properties of the products of the riser reactor are listed in Table 2 and Table 3.

Embodiment 3

[0038] Embodiment 3 comparative example

[0039] By embodiment 1, the difference is that the raw material oil is a hydrogenated heavy oil, the main properties are listed in table 1, and the processing capacity is 30 kg / day, and the catalyst used in the test is an MLC-500 industrial balancer, and the micro-reaction activity of the equilibrium catalyst is 63, The carbon content is 0.03w%. The main operating conditions, product distribution and main properties of the products of the riser reactor are listed in Table 2 and Table 3.

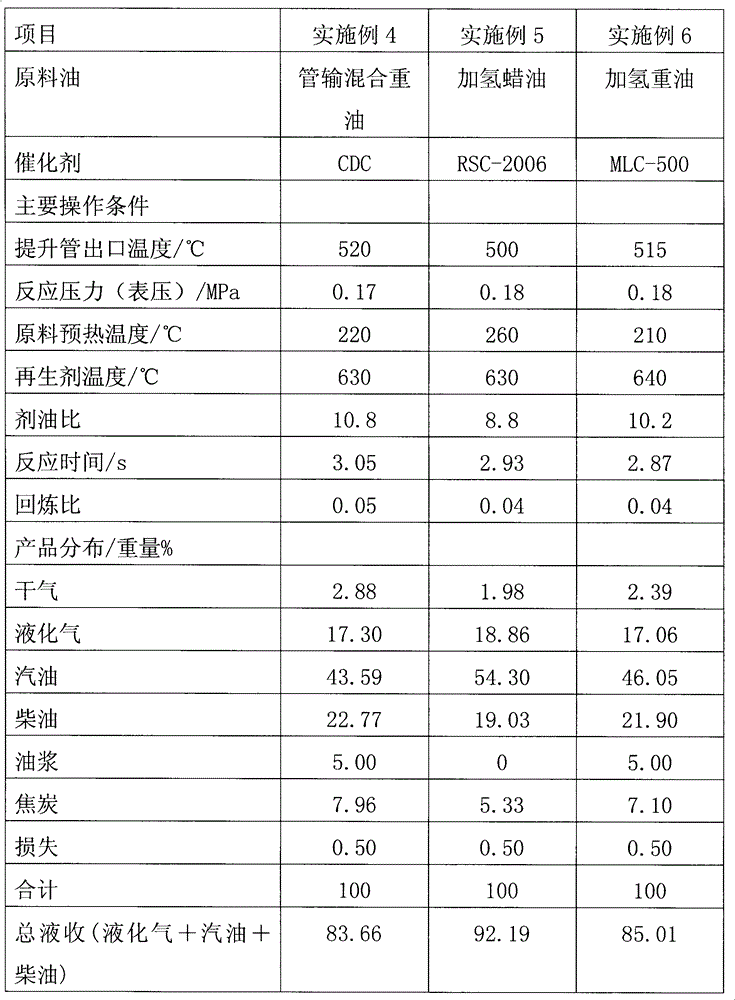

Embodiment 4

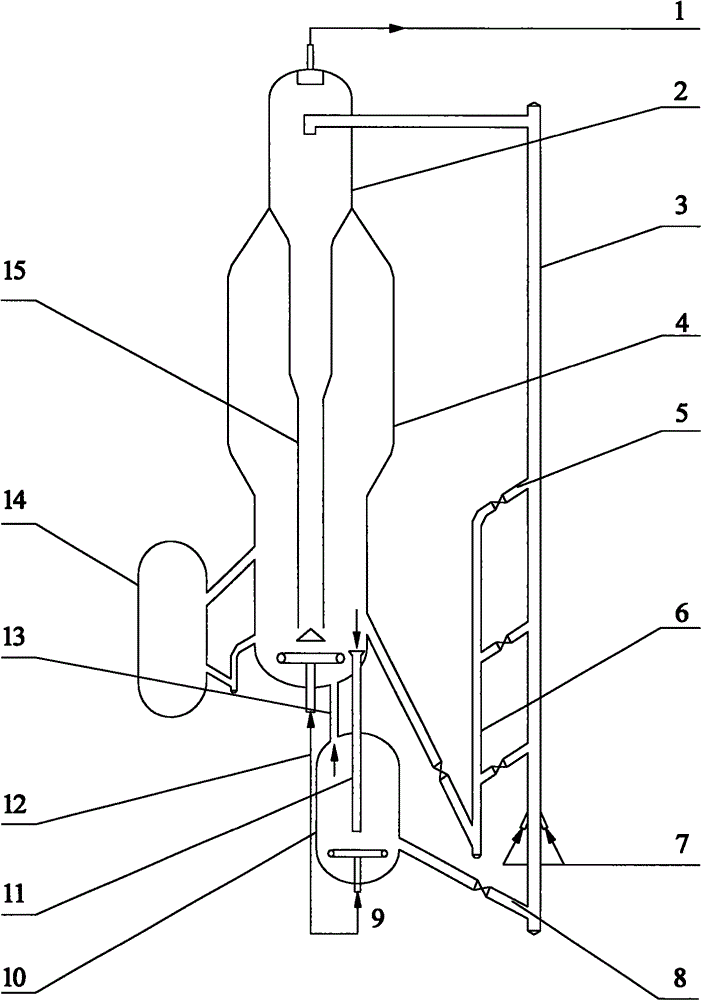

[0041] in such as figure 1 Test is carried out on the catalytic cracking test device shown, and processing capacity is 30 kilograms / day, and stock oil, catalyzer are identical with embodiment 1, and the main operating conditions of riser reactor, product distribution and the main character of product are listed in table 4 and table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com