Method and device for fluidized catalytic conversion

A fluidized catalysis and catalyst technology, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve the problems of reduced catalyst activity, inability to optimize the operating conditions of the reaction system, and unfavorable catalytic conversion reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

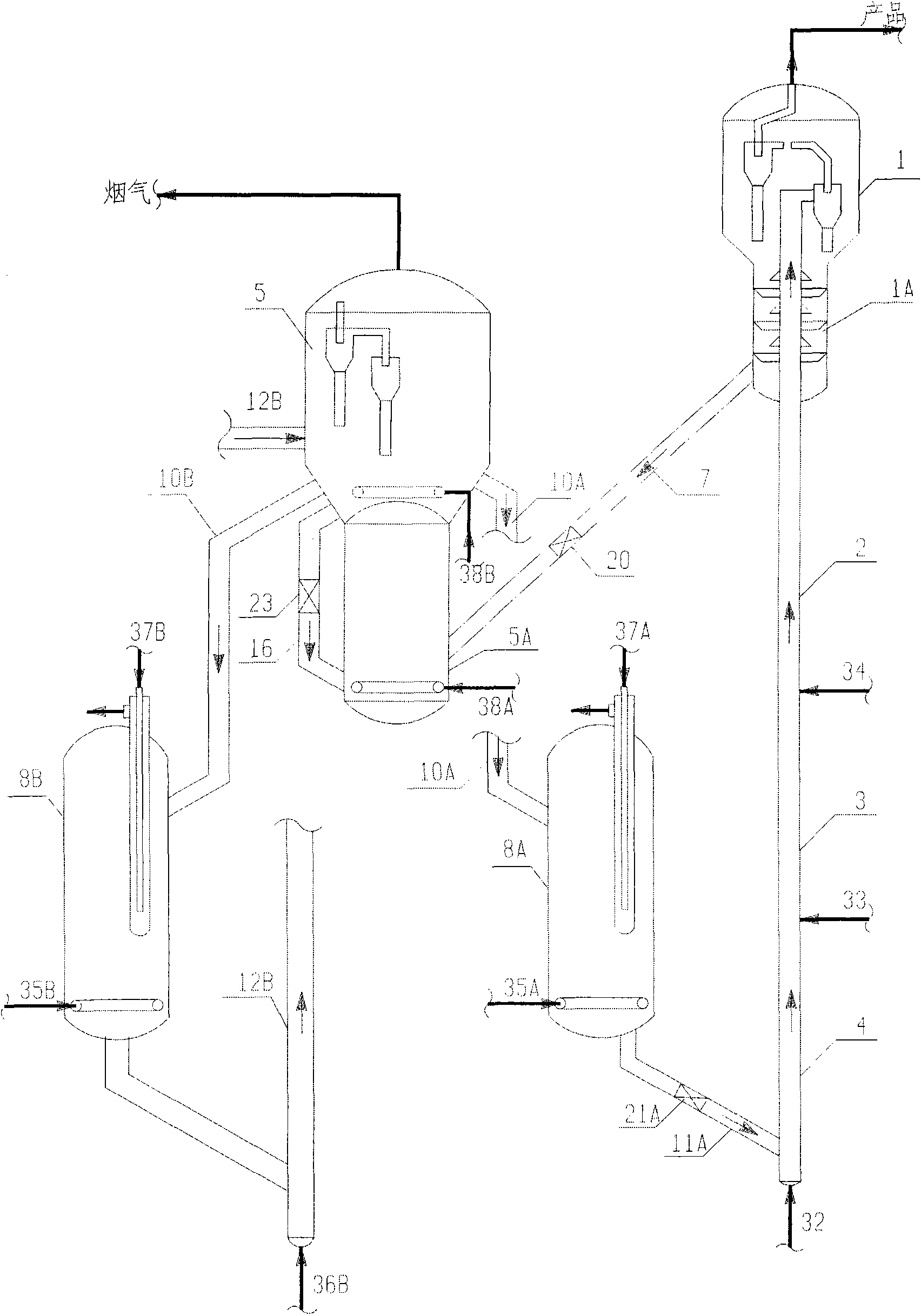

[0172] To verify the effect of the present invention, adopt figure 1 The process flow shown, the process conditions shown in Table 2, the raw materials shown in Table 1, and the CORH catalyst produced by the Changling Refinery Catalyst Plant, and the test results are shown in Table 3.

[0173] In Table 2, Scheme A of the prior art adopts conventional catalytic conversion technology: the temperature of the regenerator catalyst bed is 680°C, and the reaction temperature is 505°C. The raw material temperature is 200°C, and the agent / oil ratio is 6.0. Therefore, the temperature difference between the regenerant and the raw material is 480°C. Solution A of the prior art has the following shortcomings:

[0174] (1) The temperature of the feedstock at 200°C is quite low for the cracking of the residue-containing feedstock.

[0175] (2) Although the temperature of the regenerator meets the regeneration requirements, the temperature is too high when it comes into contact with the raw mater...

Embodiment 2

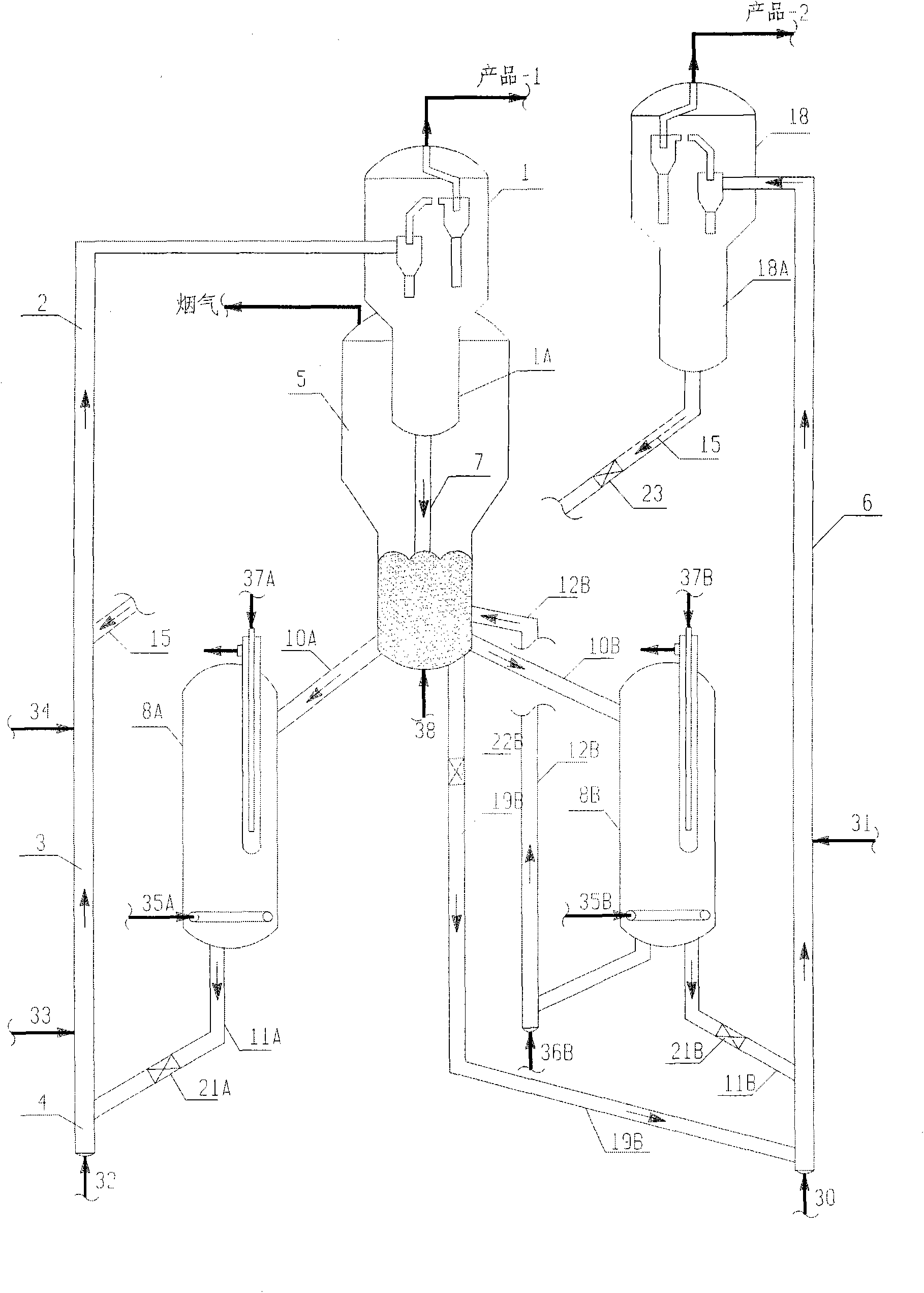

[0185] To verify the effect of the present invention, adopt figure 2 In the process flow shown, the heavy oil riser adopts the process conditions shown in Table 2, the raw materials shown in Table 1, and the CORH catalyst produced by the Changling Refinery Catalyst Plant. The test results are shown in Table 4.

[0186] The results in Table 4 show that the coke and dry gas yield decreased by 2.1%, the olefin volume content in gasoline decreased by 65%, and the octane number (RON) increased by 0.6 units.

[0187] Table 4

[0188]

Product

Plan A

this invention

Plan B

Product yield Wt%

5.2

3.7

LPG

14.4

14.1

Petrol

45.6

49.5

Diesel

23.6

25.1

Oil slurry

3

-

8.2

7.6

Total

100.0

100.0

Gasoline quality

Olefin content V%

37.2

13.6

Aromatic content V%

31.6

37.9

Octane number RON

90.1

90.7

[0189] The raw material of the gasoline riser is catalytically cracked gasoline. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com