Patents

Literature

40results about How to "Moderate reaction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

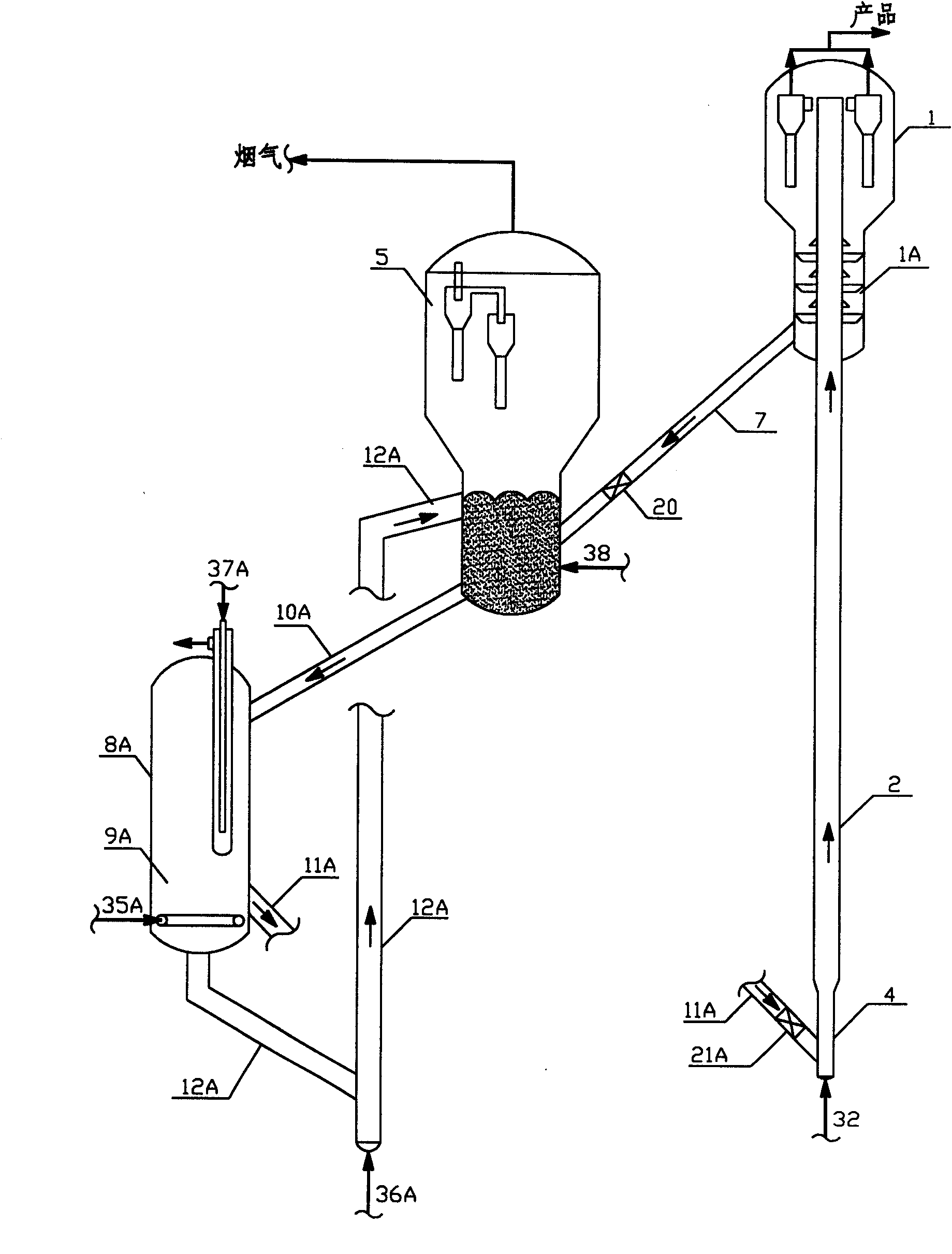

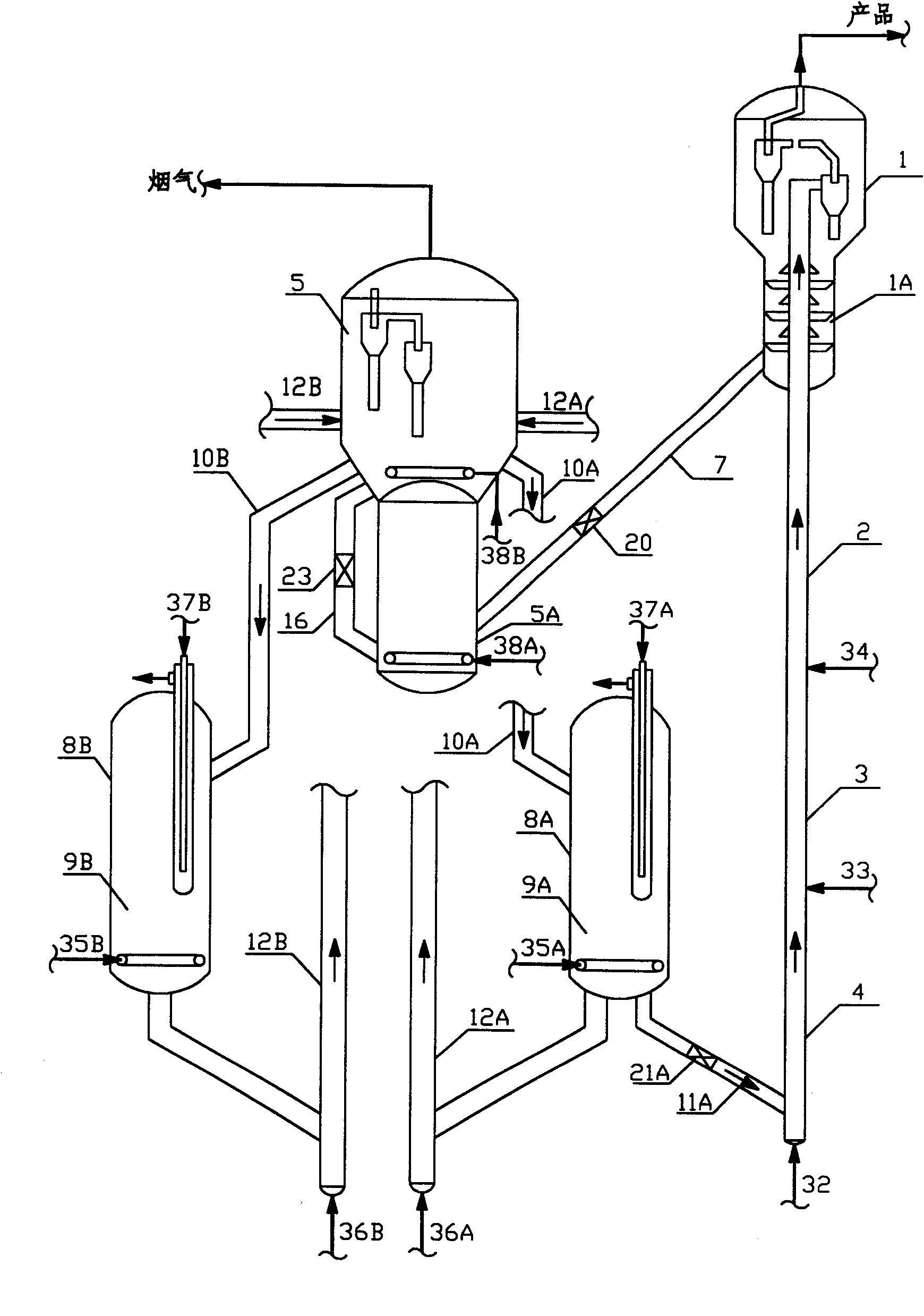

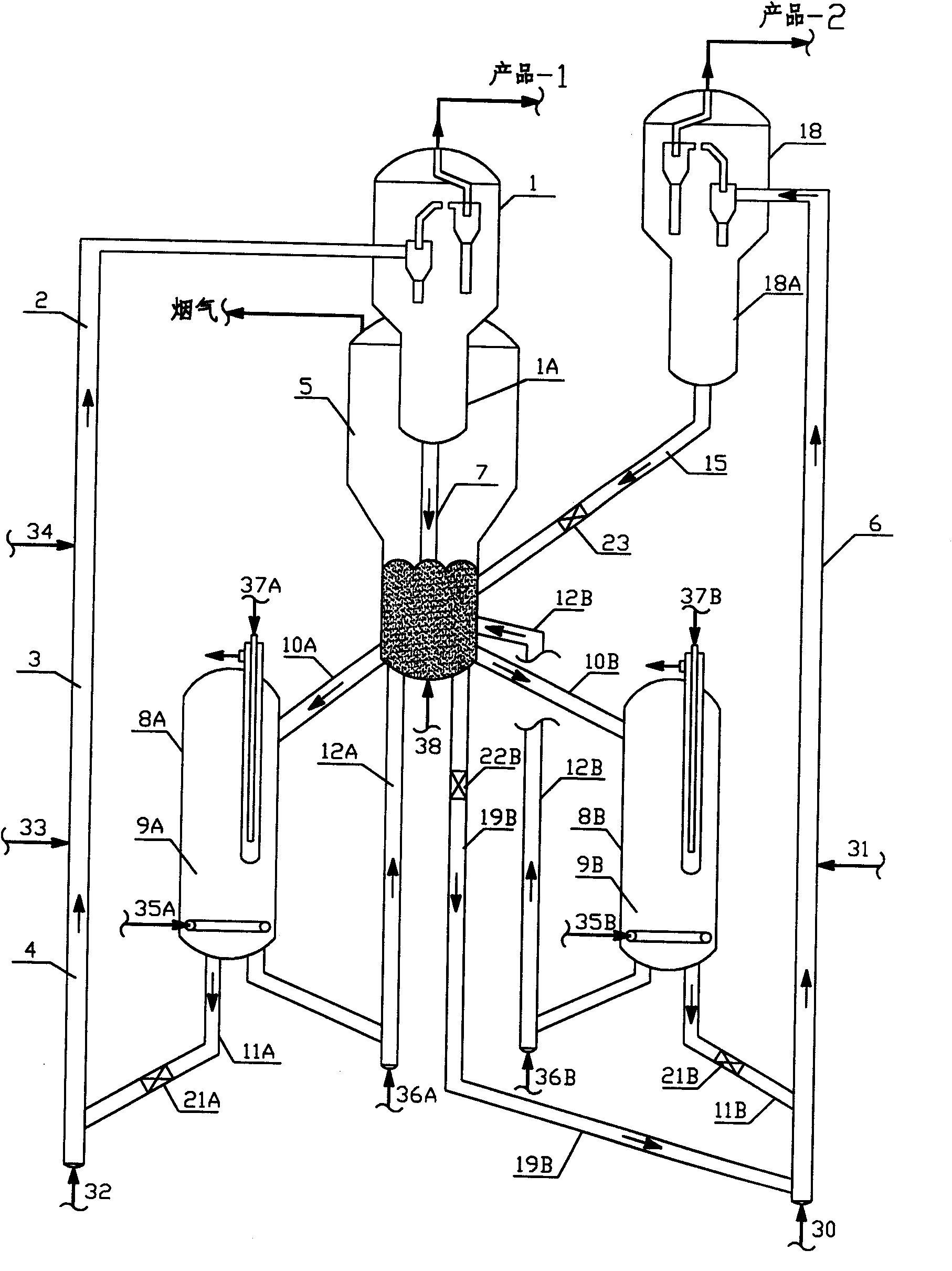

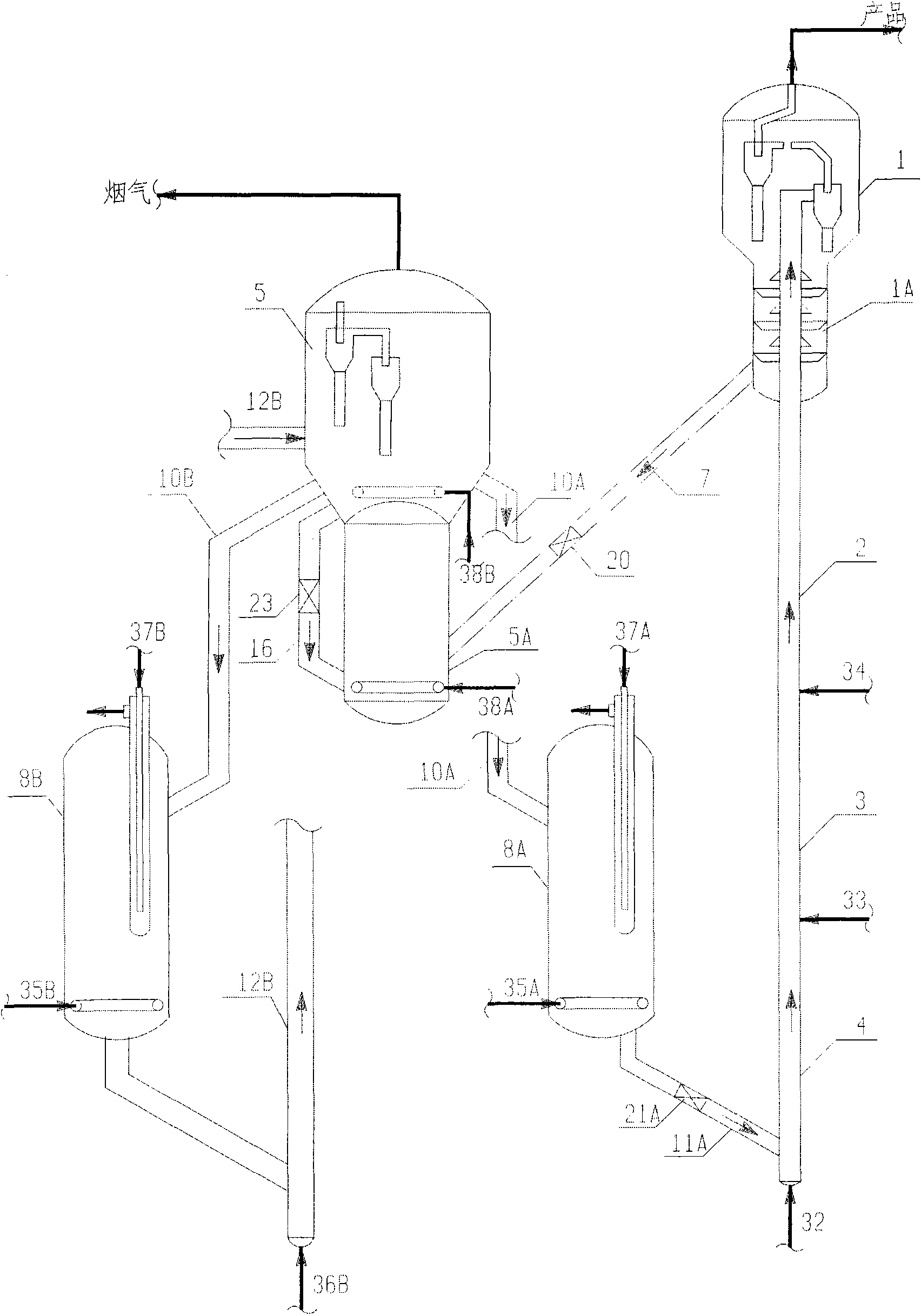

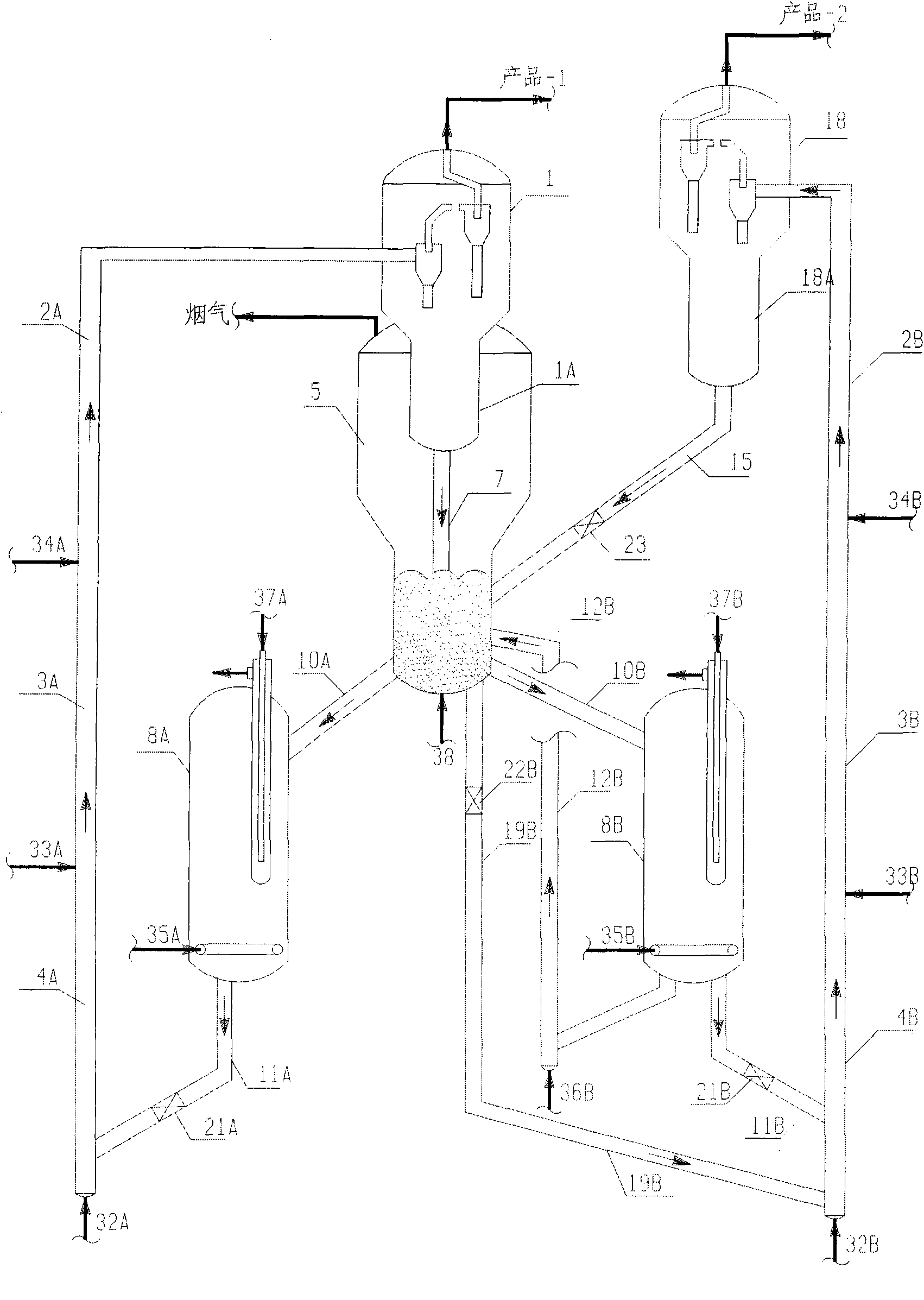

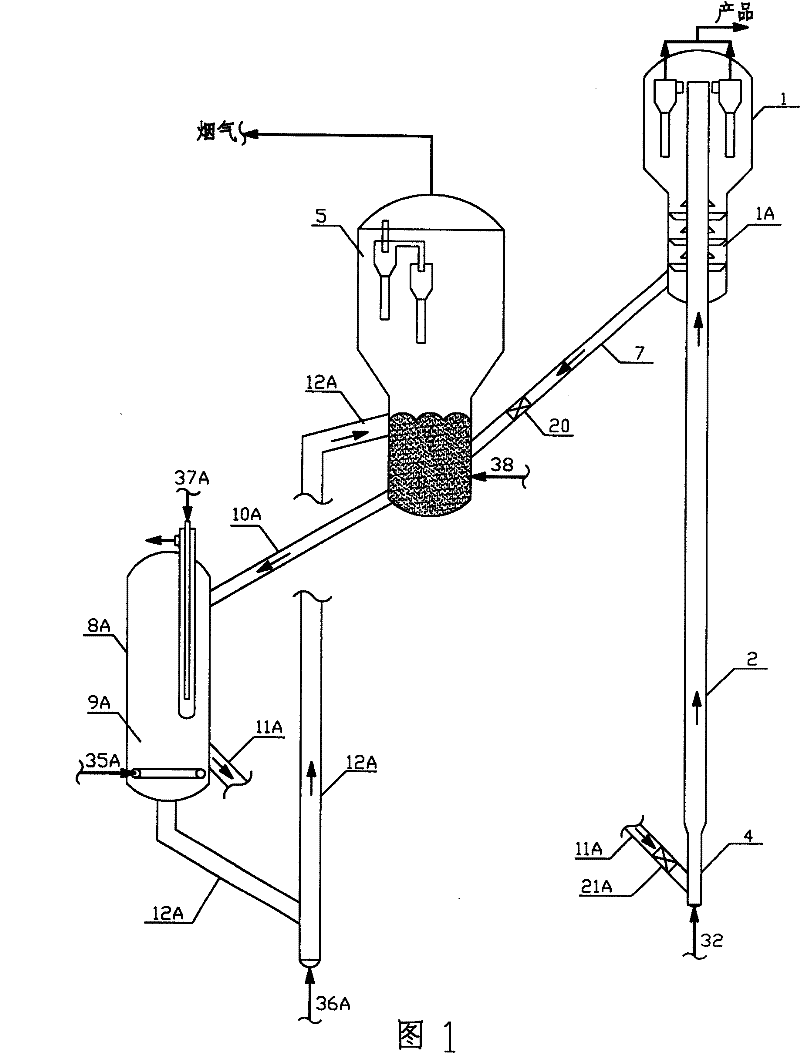

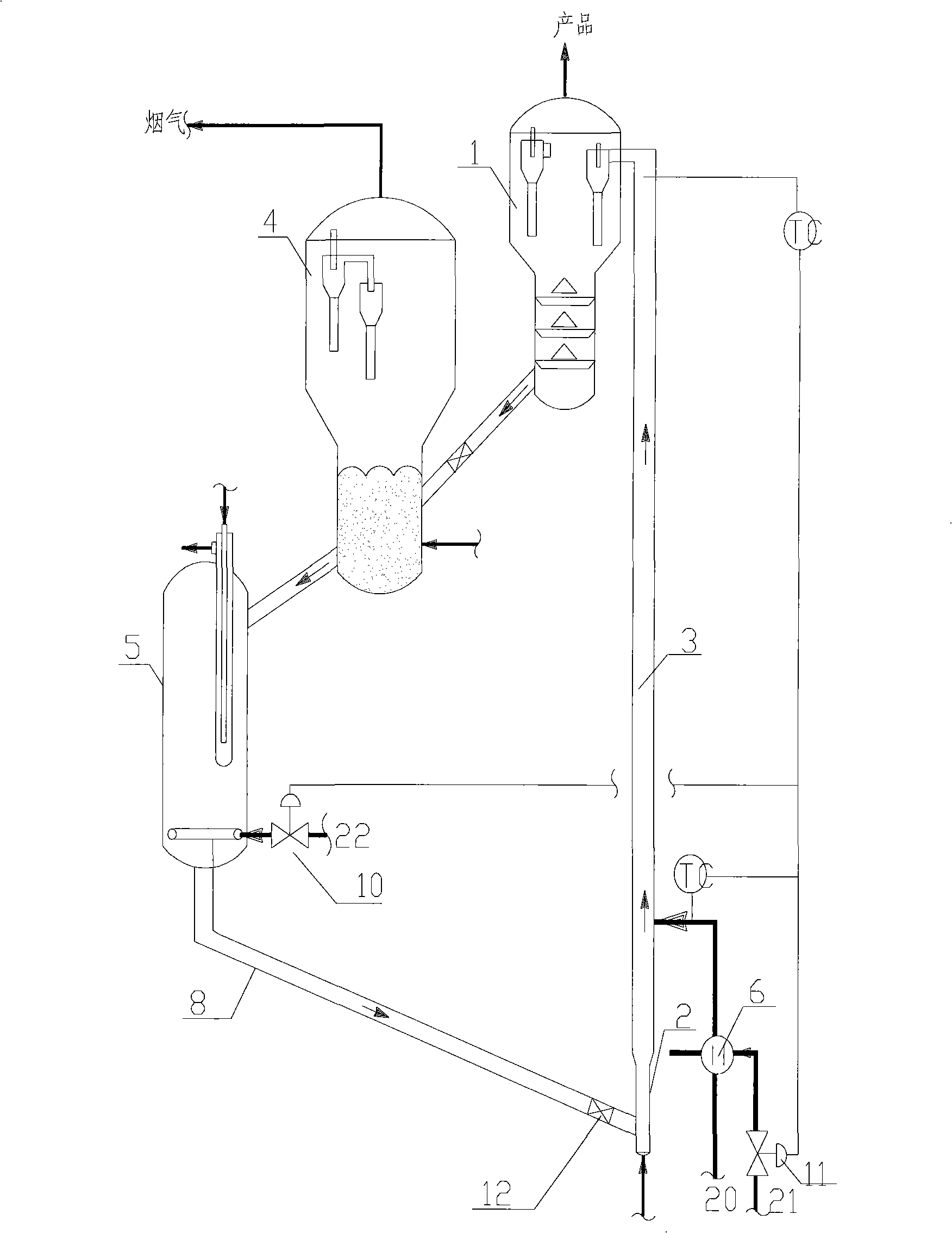

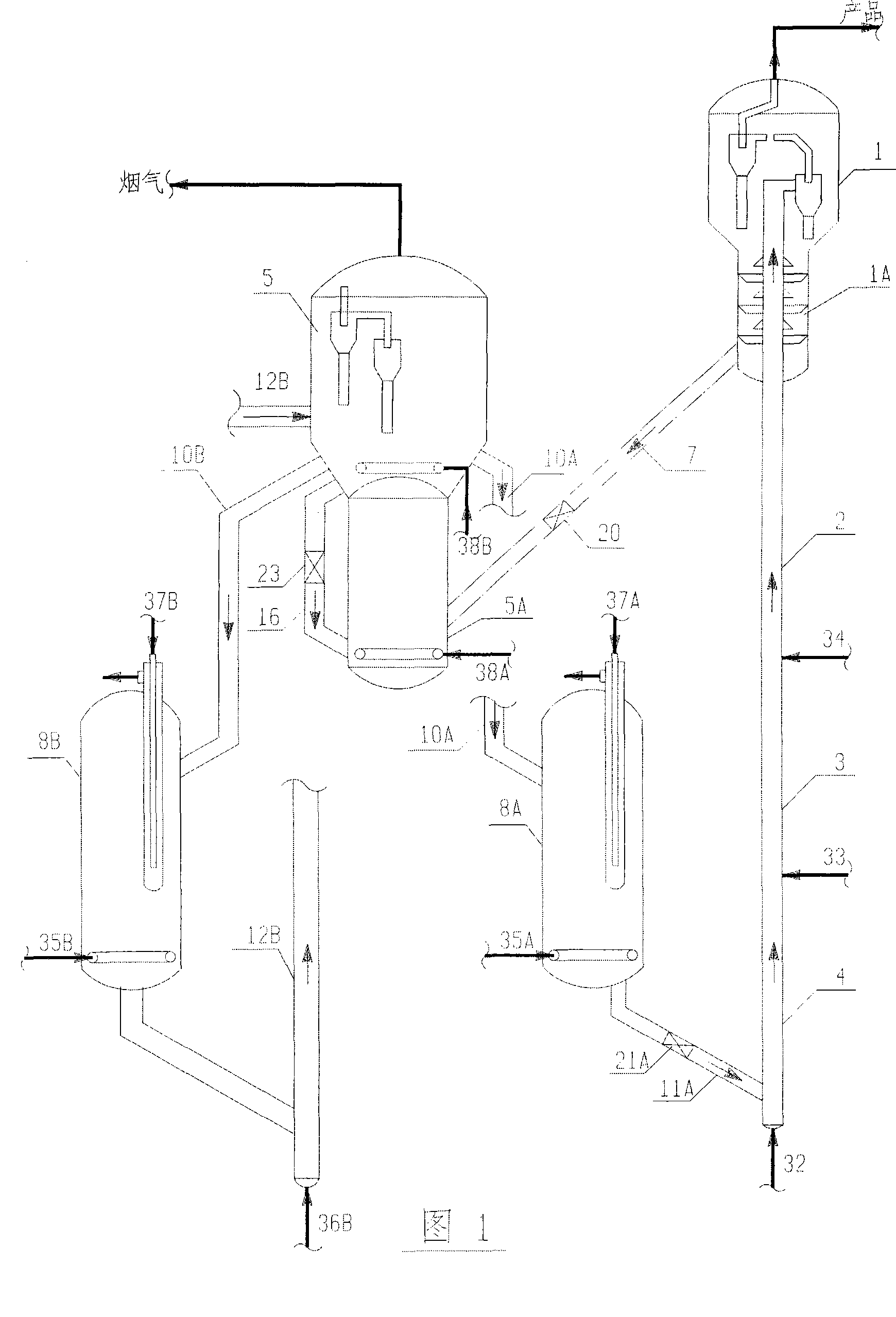

Method and device for circulating cold regenerated catalyst

The invention provides a method for circulating a cold regenerated catalyst and application thereof. A regenerated catalyst from a regenerator is cooled by a catalyst cooler to between 200 and 720DEGC, and is not mixed with a hot regenerated catalyst to directly enter a riser reactor, or is mixed with another part of uncooled hot regenerated catalyst into a mixed regenerated catalyst of which thetemperature is not lower than that of the regenerator to enter the riser reactor; and a hydrocarbon raw material undergoes contact reaction with the catalyst in the riser reactor, the reaction material flow enters a settler for the separation of the catalyst and oil gas, the separated catalyst to be regenerated is subjected to steam stripping in a steam stripping section, and then enters the regenerator for coke burning regeneration, and the regenerated catalyst is cooled and returns to the riser reactor for recycling. The method for circulating the cold regenerated catalyst has wide application, can be used for various fluid catalytic cracking processes comprising resid fluid catalytic cracking, wax oil catalytic cracking, gasoline catalytic conversion upgrading and the like, and also can be sued for other gas-solid reaction processes comprising residual oil pretreatment, fluid coking and the like.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

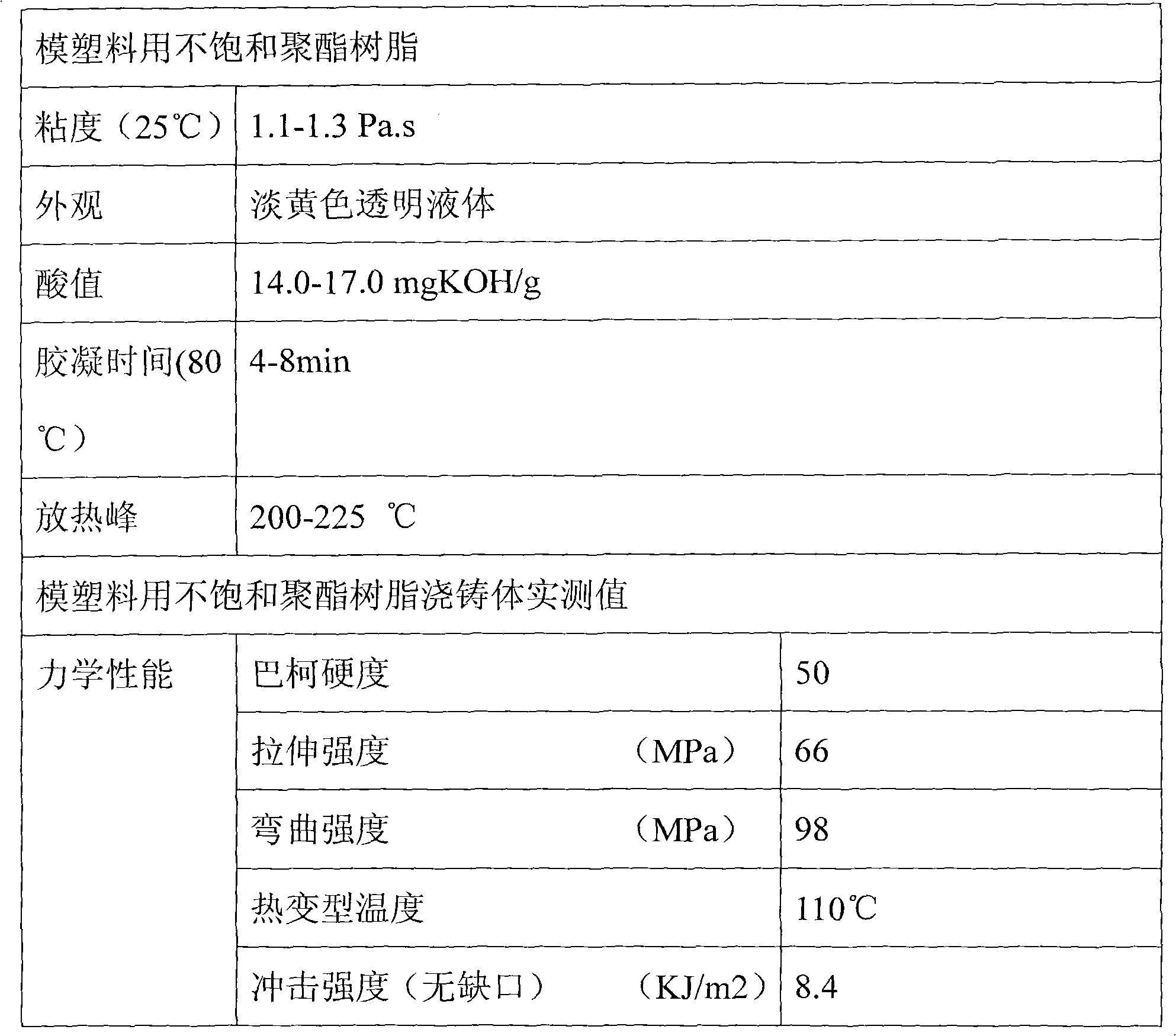

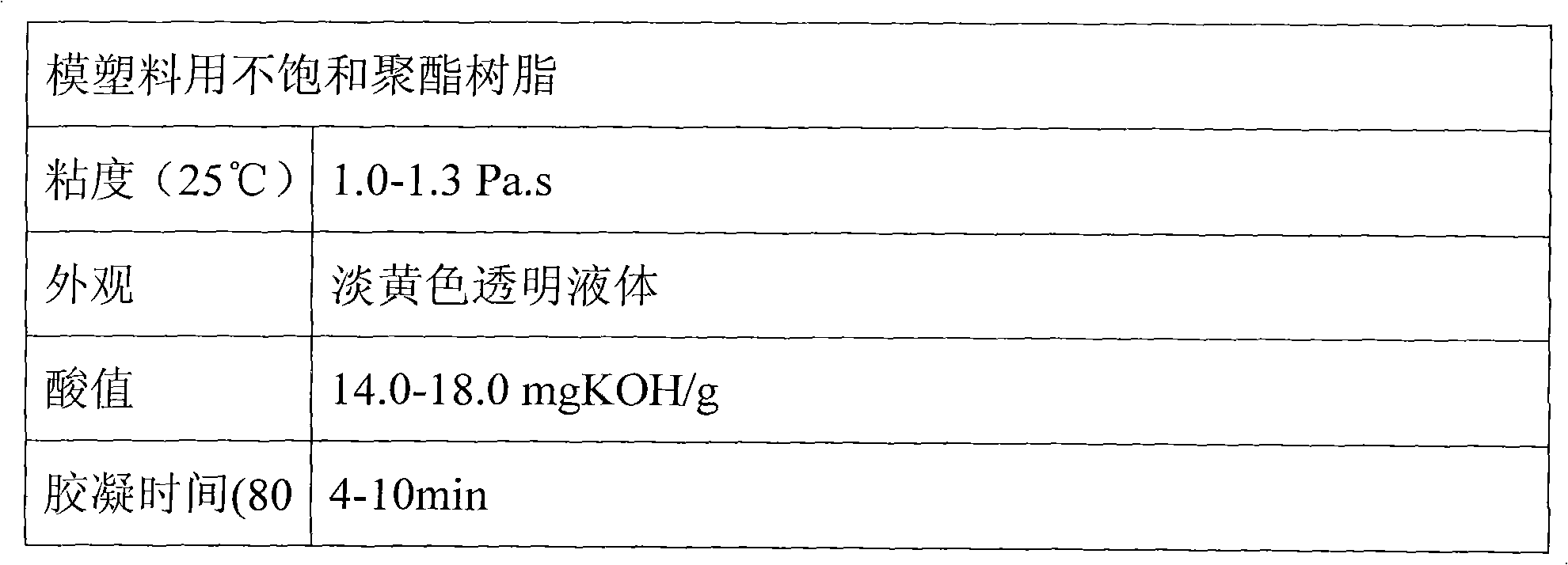

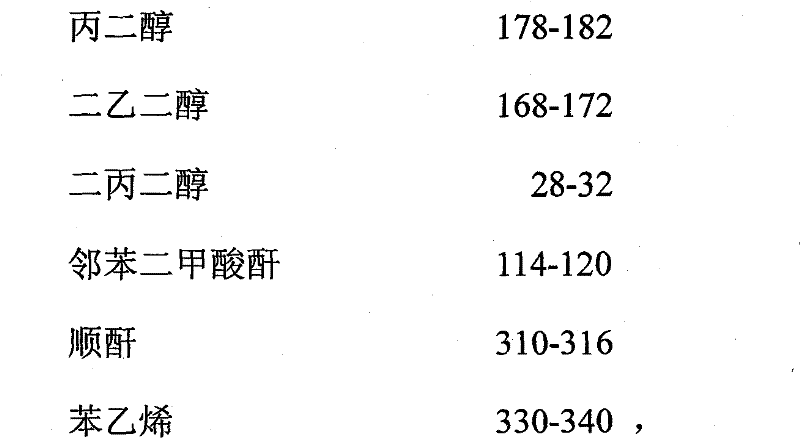

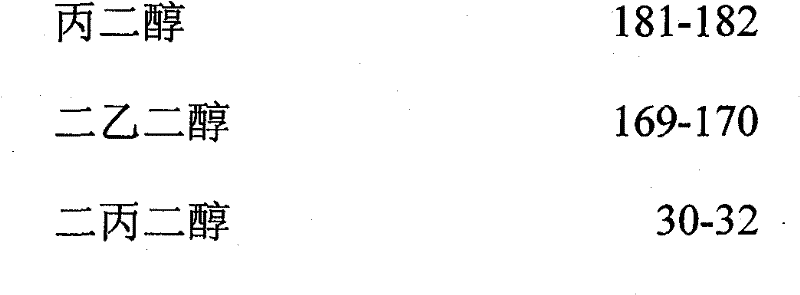

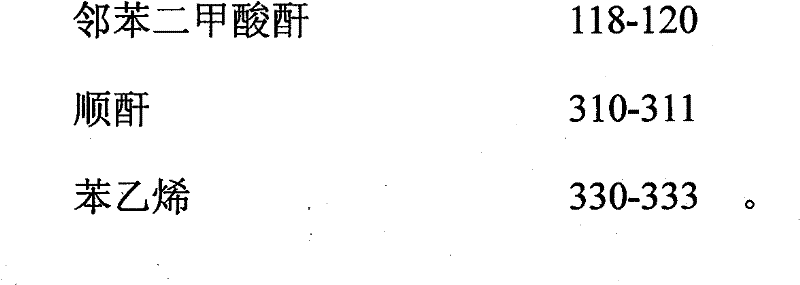

Unsaturated polyester resin for molding compound of auto parts and manufacturing method thereof

The invention relates to a high molecular compound, in particular to an unsaturated polyester resin for molding compound of auto parts, which is prepared by dissolving a reaction product of the condensation reaction of propylene qlycol, diethylene qlycol, dipropylene glycol, phthalic anhydride and cis-butenedioic anhydride into styrene after the condensation reaction is completed. The invention has the advantages that: (1) the resin has good water resistance and flexibility through optimization combination on the premise that the cost of raw materials of the resin is not greatly increased, and products made of the resin have good anti-wet capacity and good mechanical property; (2) the reactivity of the resin is greatly enhanced so as to ensure that the surface of molding compound products after hot press molding has higher luster; (3) the resin is used together with a proper low-profile agent, and enables produced products to achieve zero shrinkage so as to ensure the accuracy of the size of the products; and the resin also can be used together with low-shrinkage agents in polystyrene so as to enhance stainability of the products; and (4) the reaction time can be shortened as well as the energy consumption and the manufacturing cost of the resin can be reduced by adopting phthalic anhydride.

Owner:CHANGZHOU HUARUN COMPOSITE MATERIALS +1

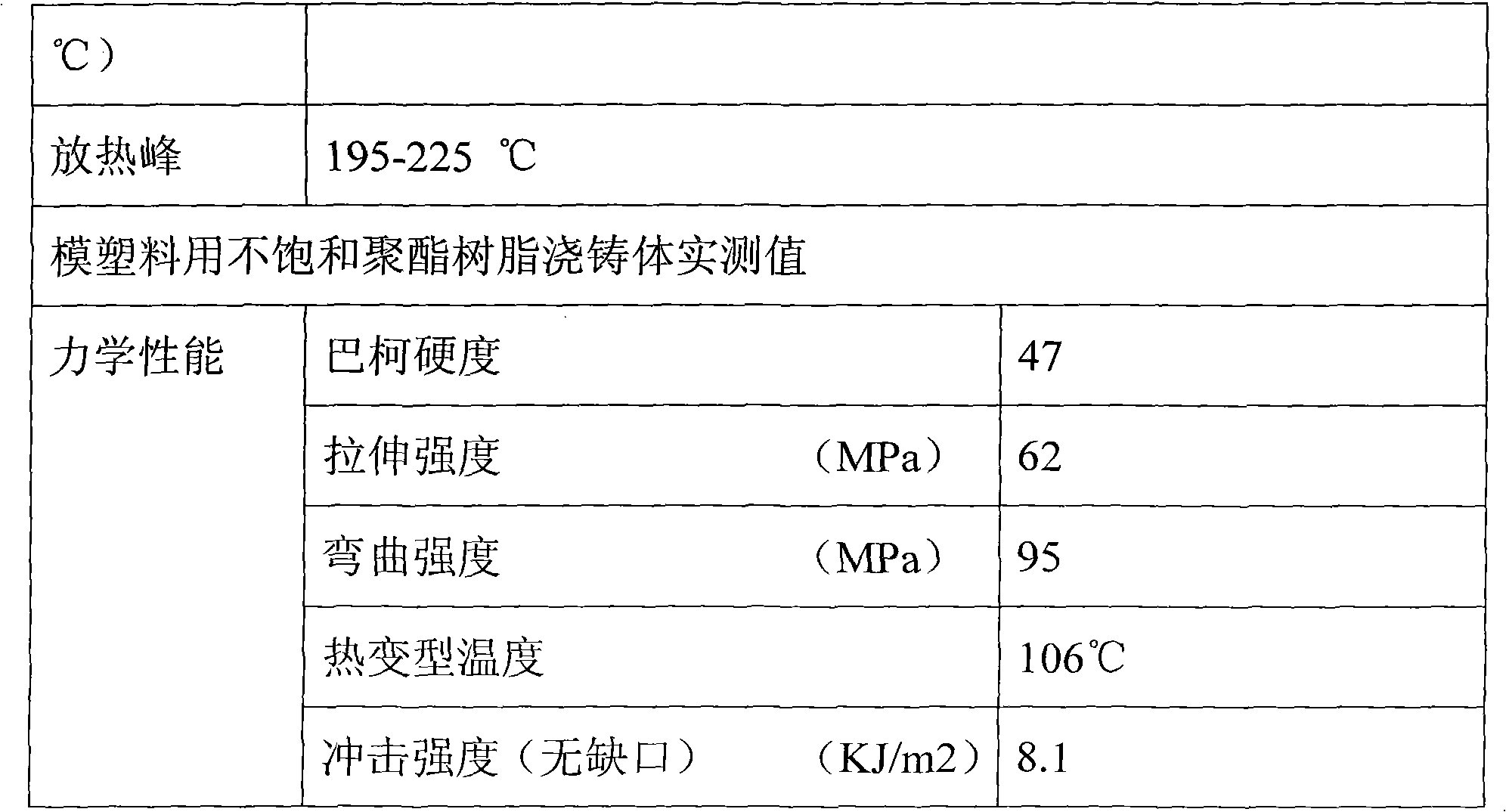

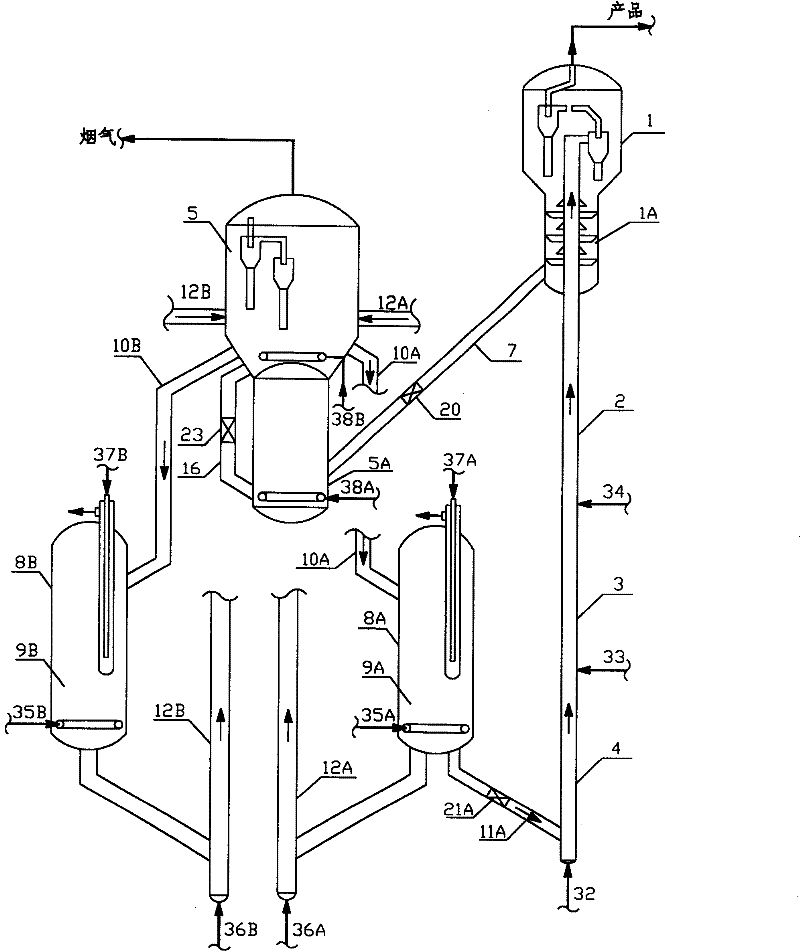

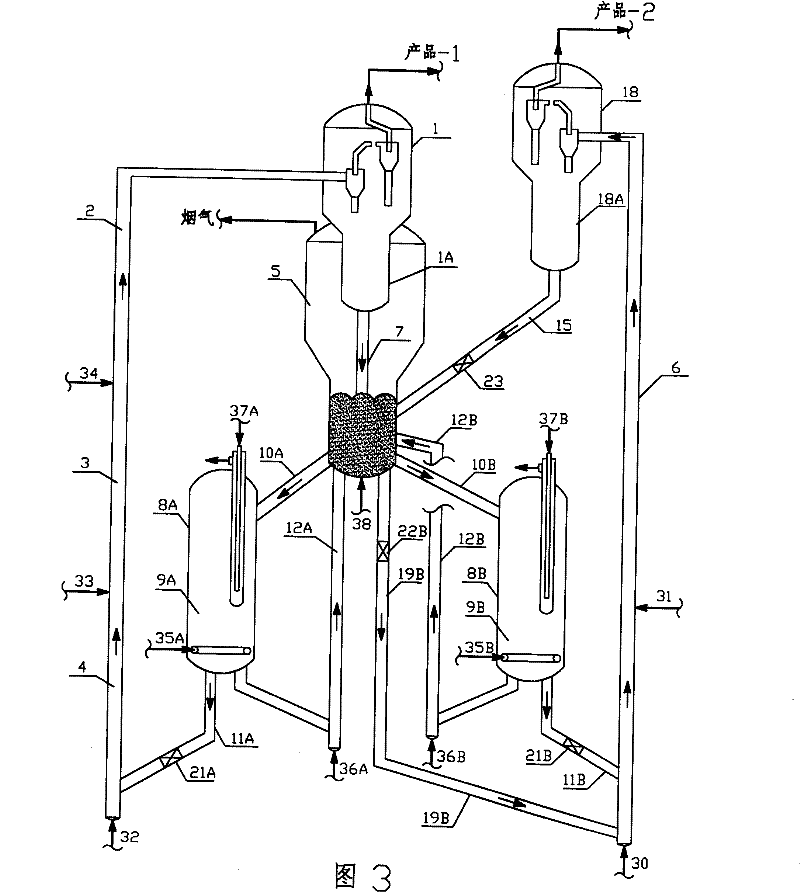

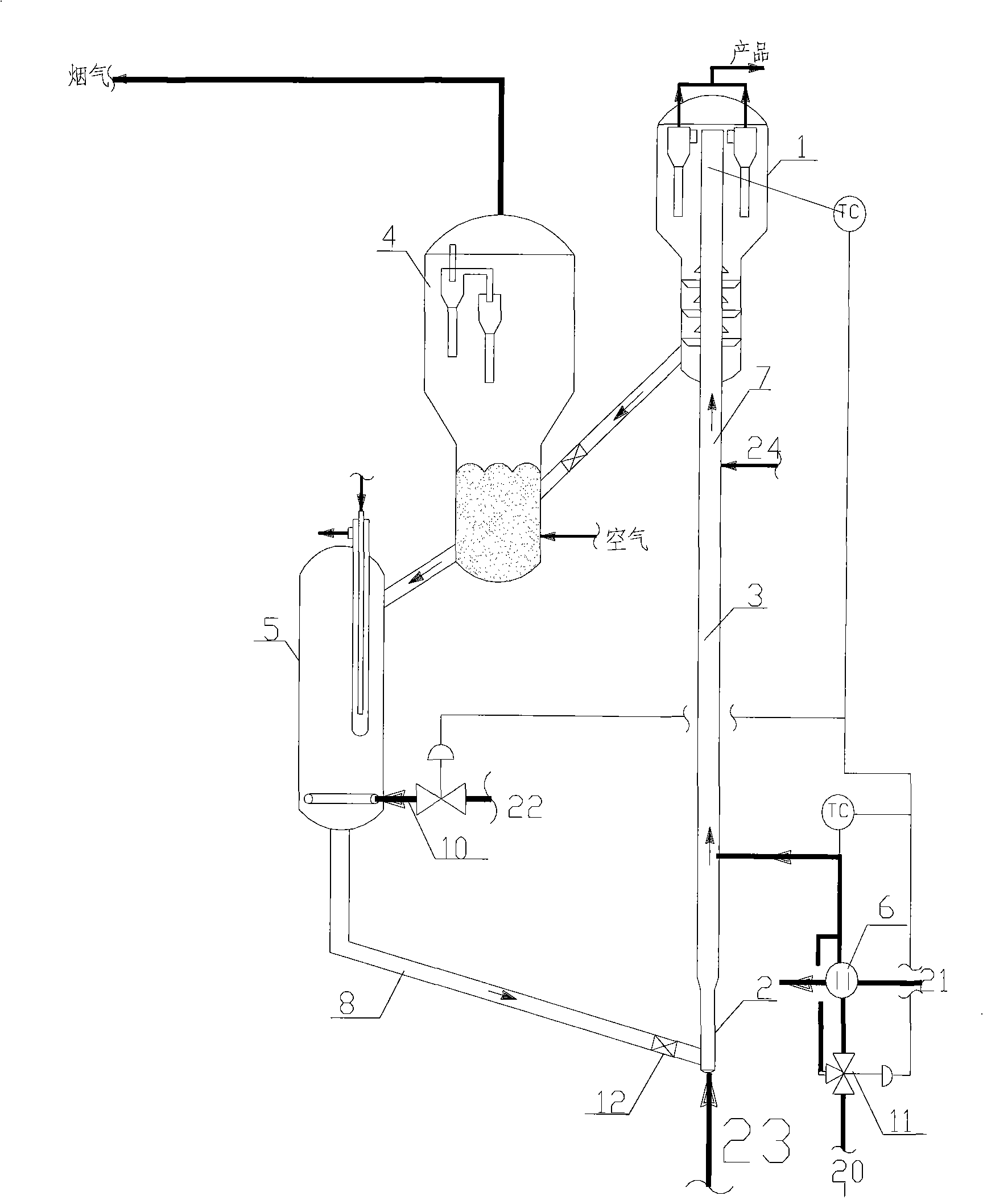

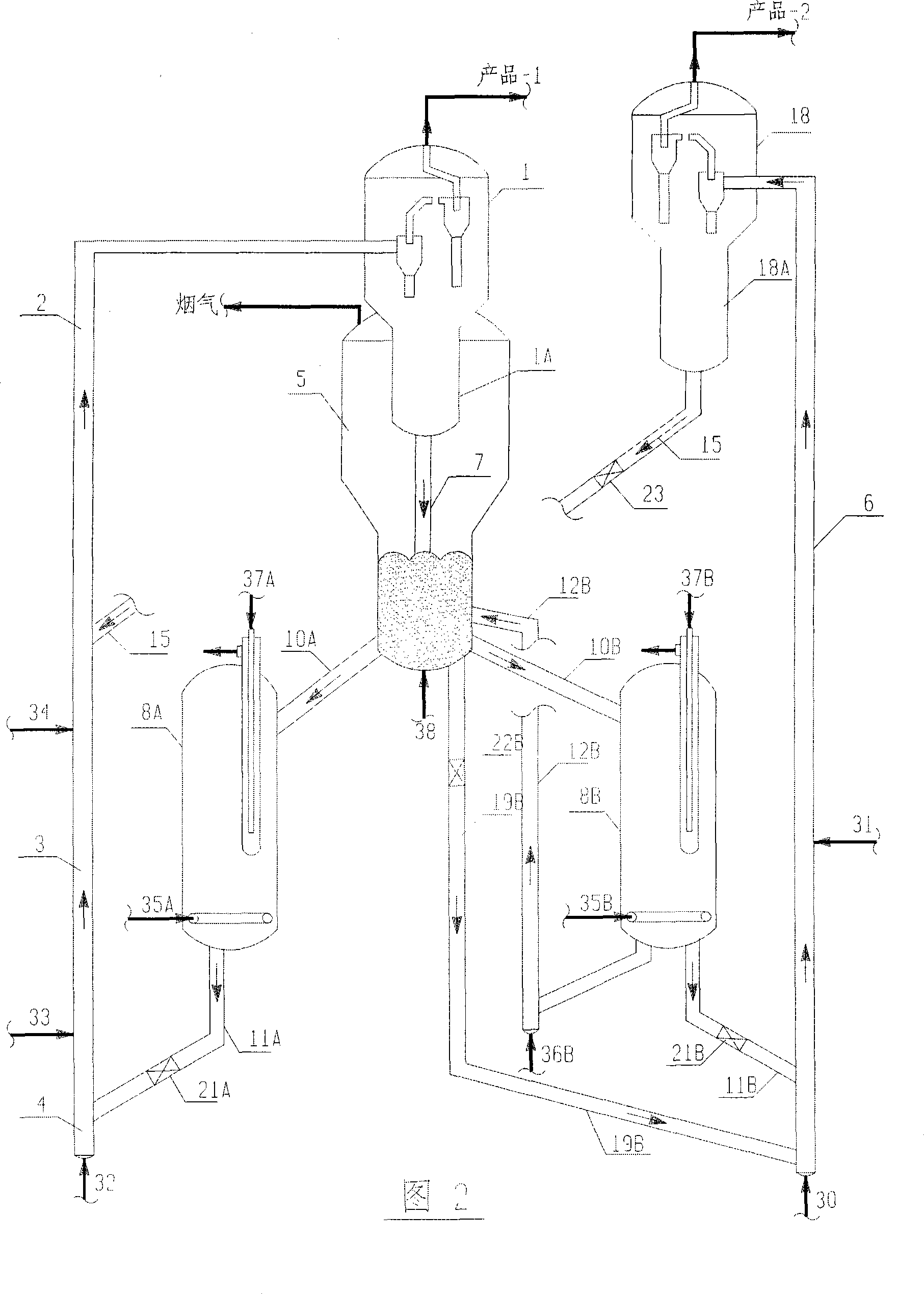

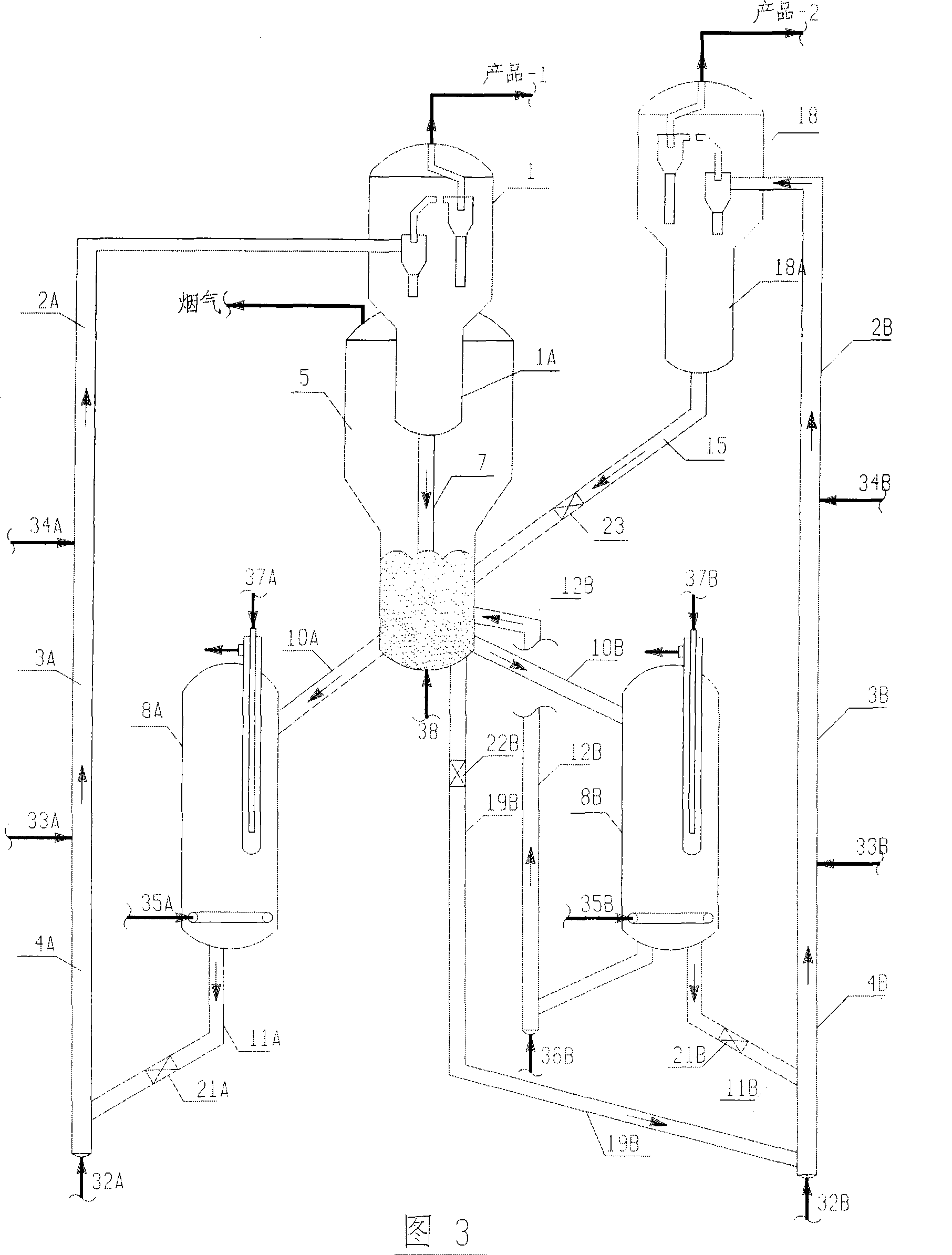

Method and device for fluidized catalytic conversion

ActiveCN101665712AReduce the temperatureRaise the preheat temperatureCatalytic crackingCatalytic transformationContact time

The invention provides a method for catalytic conversion of heavy oil, which comprises a fluidized catalytic conversion process that: heavy hydrocarbon raw materials contacts a catalyst in a riser reactor or fluidized bed reactor to react; the reaction temperature is 400 to 650 DEG C (preferably 480 to 560 DEG C); the reaction pressure is 0.11 to 0.4MPa; the contact time is 0.05 to 5 seconds (preferably 0.1 to 3 seconds); and the weight ratio of the catalyst to the raw materials ( catalyst to oil ratio) generally is 3 to 15, preferably 5 to 12. The reaction products flow in a settler for catalyst and oil gas separation; the separated catalyst to be regenerated is stripped by a stripping section and enters a regenerator for coke burning regeneration; and the regenerated catalyst is cooled or directly returns to the riser reactor to be recycled. The method can solve the problems encountered in the resid-blend ratio improvement and gasoline upgrade and update processes of the prior catalytic conversion.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

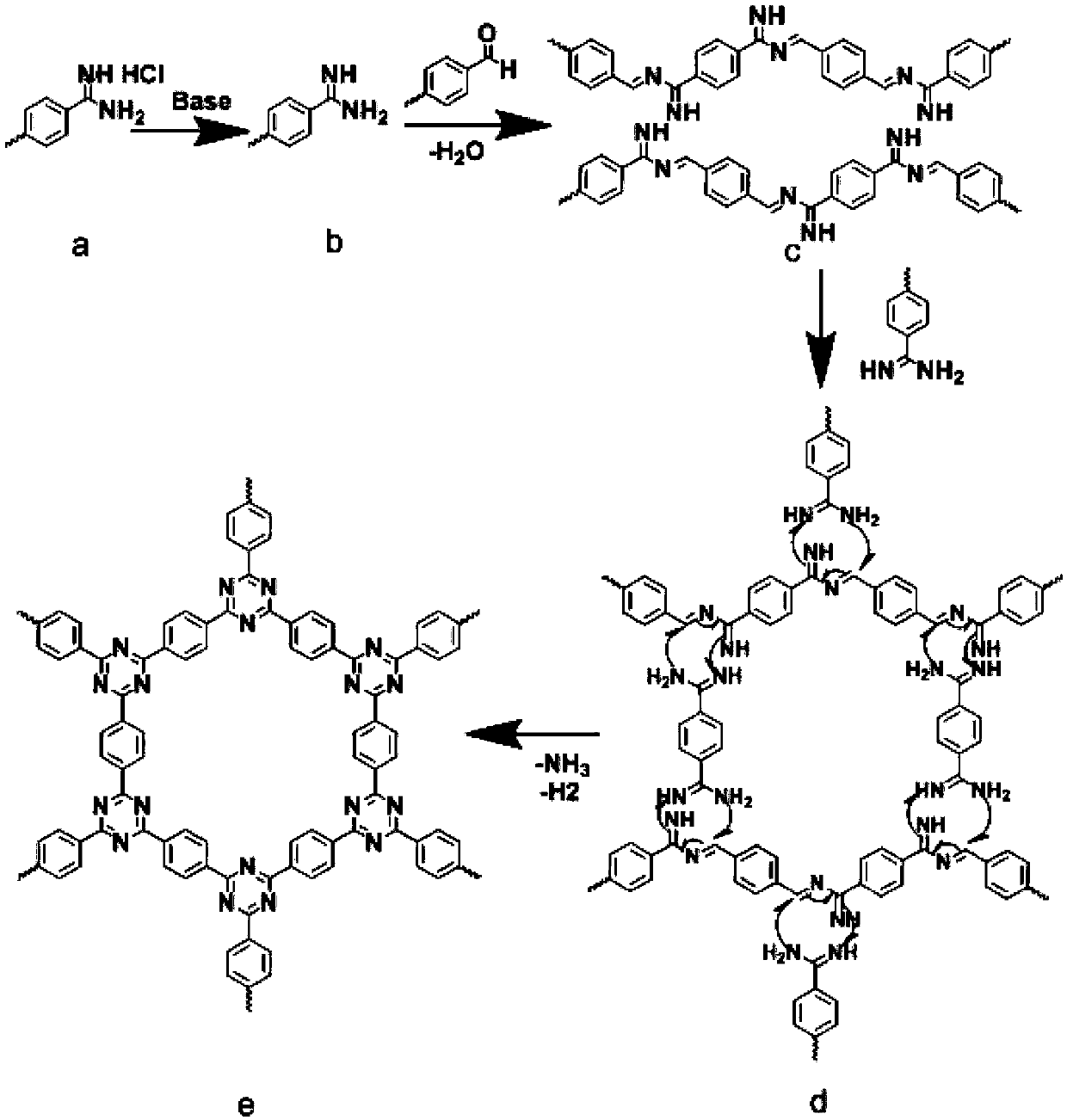

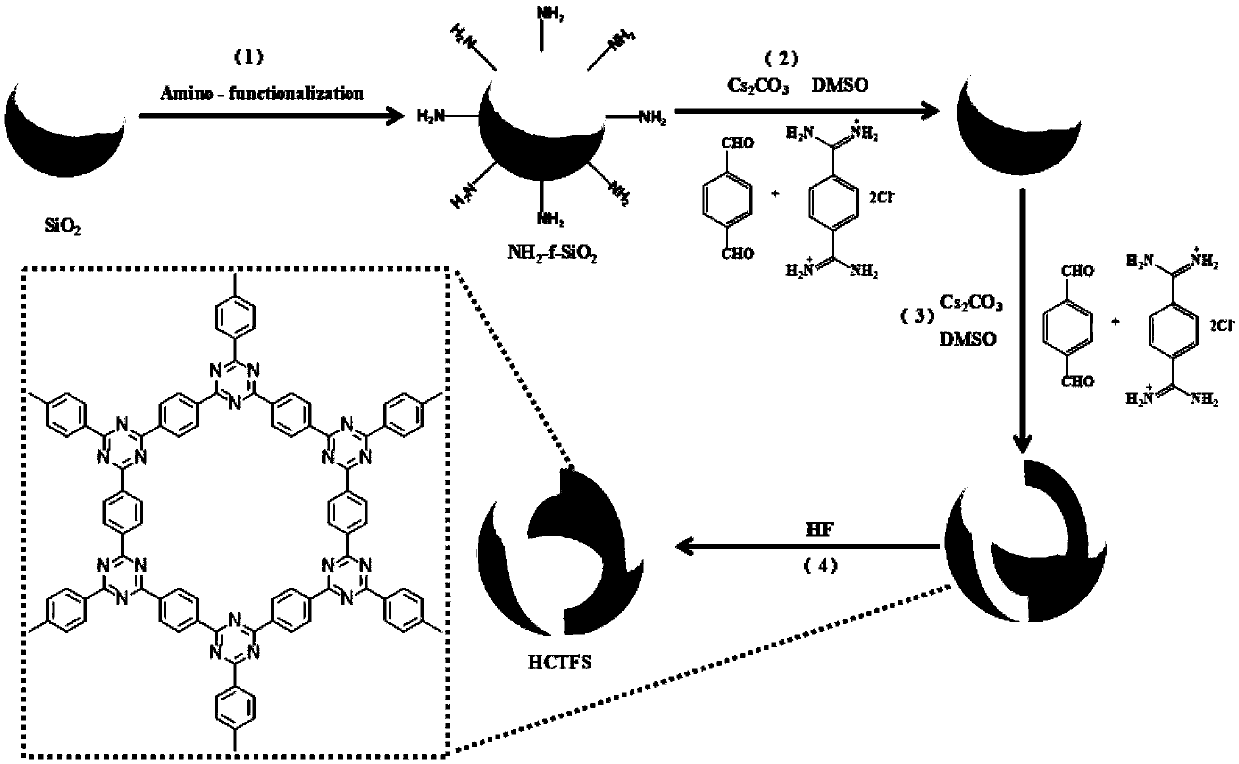

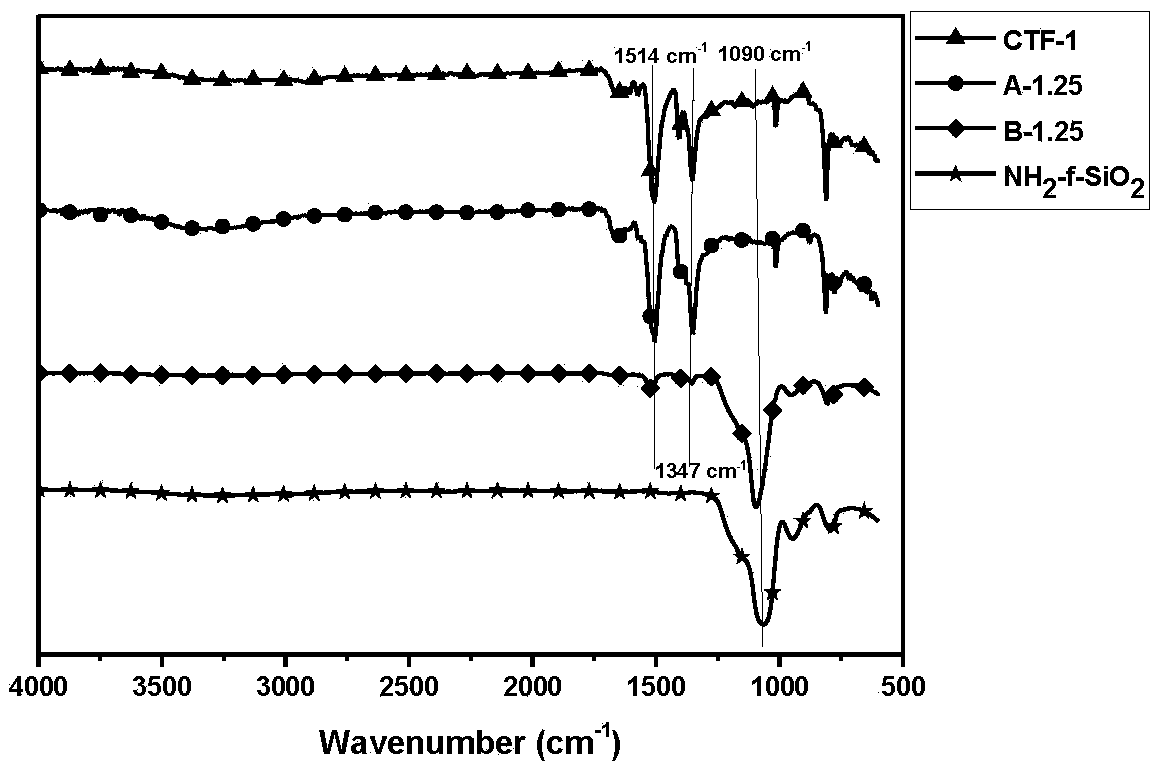

Porous covalent triazine framework hollow microsphere as well as preparation method and application thereof

ActiveCN109627250ADense pore structureStable structureOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChemistryHydrogen production rate

The invention belongs to the technical field of photocatalytic application of new materials, and particularly relates to a porous covalent triazine framework hollow microsphere as well as a preparation method and application thereof, a hard template stepwise polycondensation method is adopted to prepare the porous covalent triazine framework hollow microsphere with stable structure, low collapse rate and independent hollow structure, the porous covalent triazine framework hollow microsphere has excellent photocatalytic hydrogen production performance when being applied to visible light catalytic hydrogen production, thereby solving the technical problems that the covalent triazine framework hollow microsphere is not an independent hollow structure and the hydrogen production rate is poor in the prior art.

Owner:HUAZHONG UNIV OF SCI & TECH

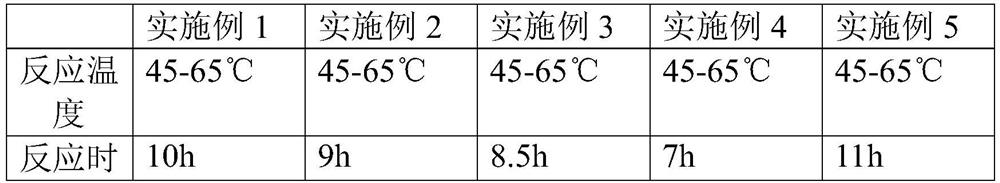

Synthesis method of light stabilizer N,N-bis-(2,2,6,6-tetramethyl-4-piperidyl) isophthalamide

ActiveCN105481759AReduce pollutionEasy to separate and purifyOrganic chemistryPtru catalystMethyl palmoxirate

The invention discloses a synthesis method of light stabilizer N,N-bis-(2,2,6,6-tetramethyl-4-piperidyl) isophthalamide. Isophthaloyl dichloride and 2,2,6,6-tetramethyl-4-piperidyl are taken as raw materials and react in the presence of a catalyst and a solvent, and N,N-bis-(2,2,6,6-tetramethyl-4-piperidyl) isophthalamide is prepared. According to the synthesis method of the N,N-bis-(2,2,6,6-tetramethyl-4-piperidyl) isophthalamide, the separation and purification process is simple, the reaction time is short, the product yield can be higher than 96%, the product purity is higher, the energy consumption is low, the environmental pollution is small, the cost is low, and the method is a more ideal process for industrial production.

Owner:RUDONG JINKANGTAI CHEM CO LTD

Method for preparing polymerization inhibitor (4-benzoyl-2,2,6,6-tetramethylpiperidine-1-nitroxide free radical)

InactiveCN101948421AHigh activityHigh selectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

The invention discloses a method for preparing a polymerization inhibitor (4-benzoyl-2,2,6,6-tetramethylpiperidine-1-nitroxide free radical). 4-benzoyl-2,2,6,6-tetramethylpiperidine and hydrogen peroxide are used as raw materials and reacted in the presence of a composite catalyst to obtain the 4-benzoyl-2,2,6,6-tetramethylpiperidine-1-nitroxide free radical. The method for synthesizing the 4-benzoyl-2,2,6,6-tetramethylpiperidine-1-nitroxide free radical by adopting the composite catalyst simplifies the separation and purification processes, has the advantages of short reaction time, high product yield which reaches over 91 percent of product yield, high product purity, low energy consumption, low environmental pollution and low cost, and is an ideal process for realizing industrialized production.

Owner:南通惠康国际企业有限公司

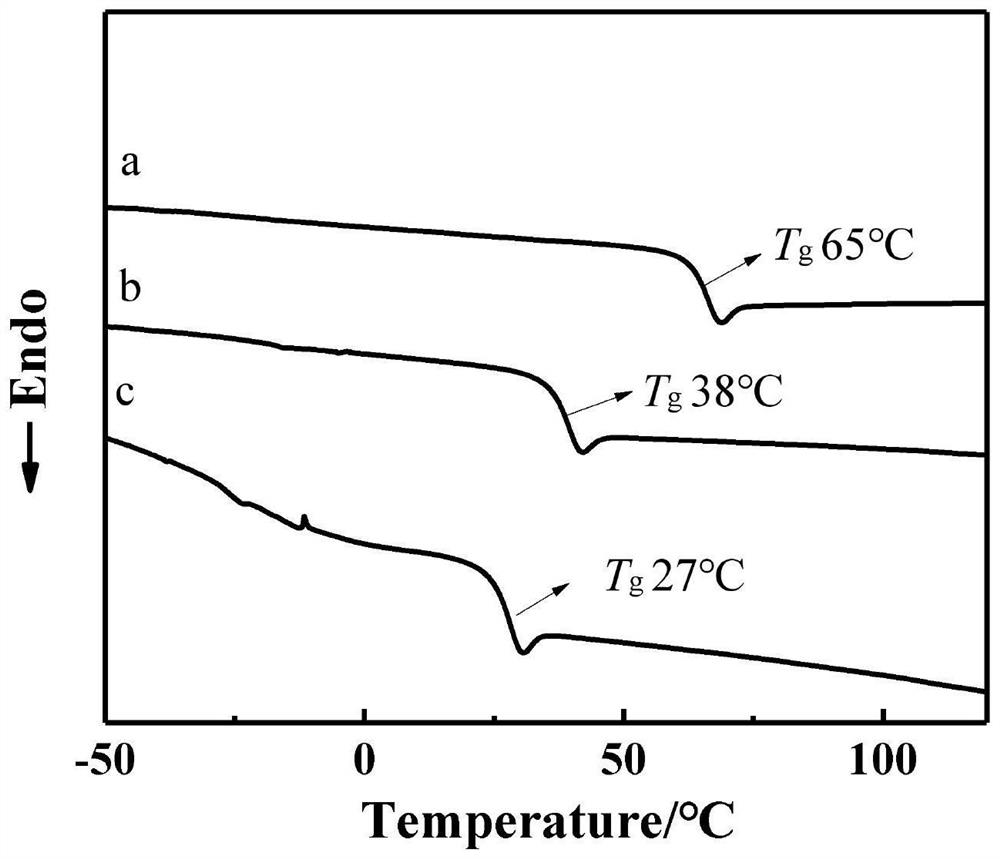

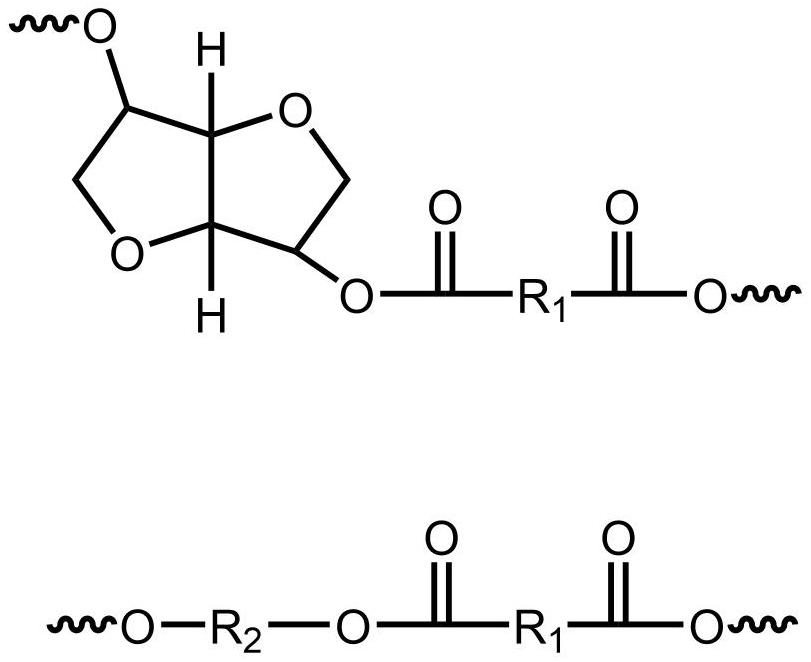

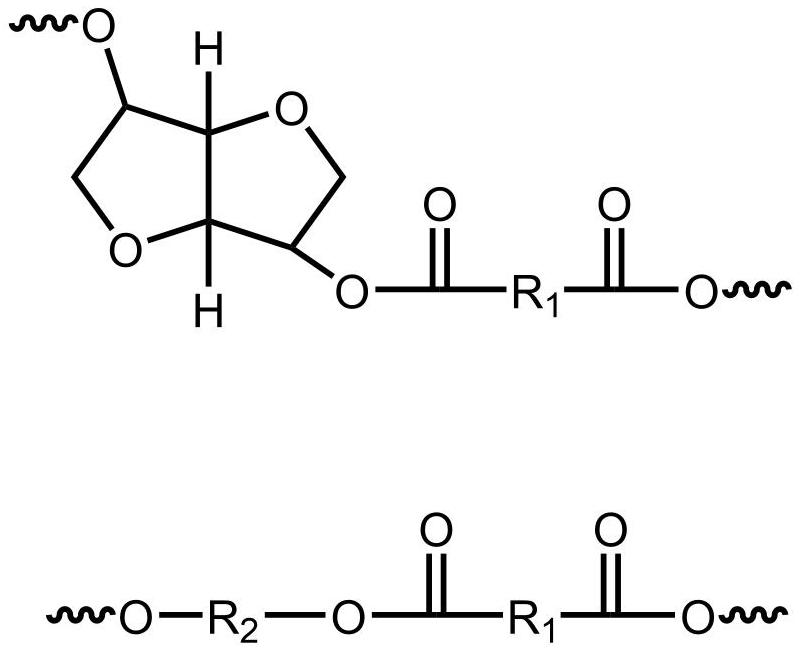

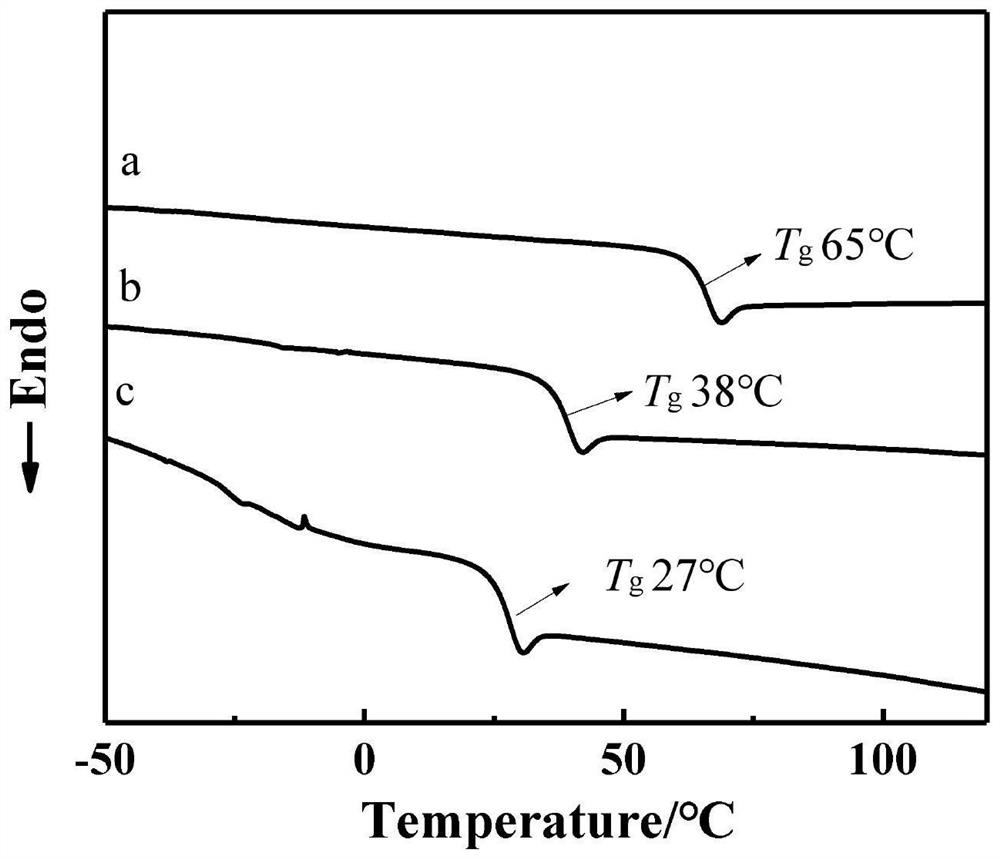

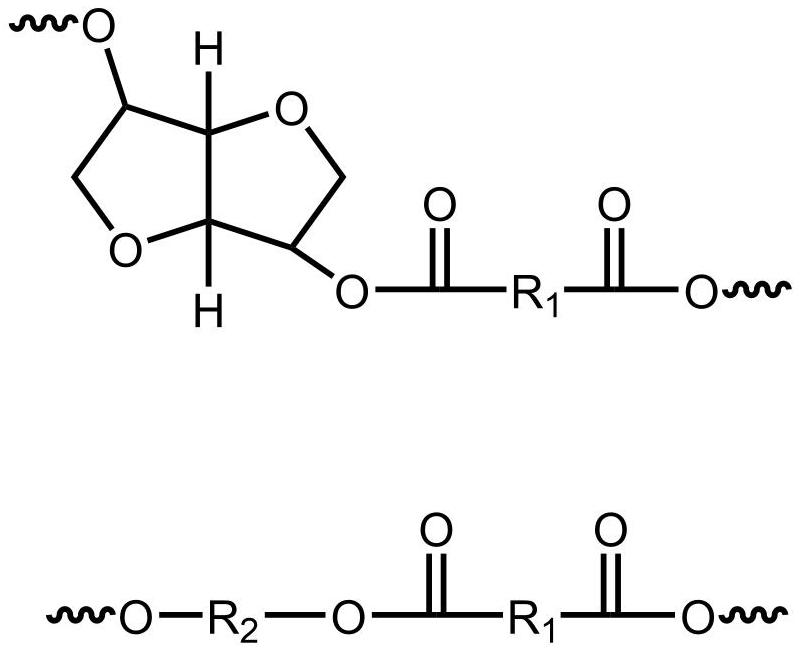

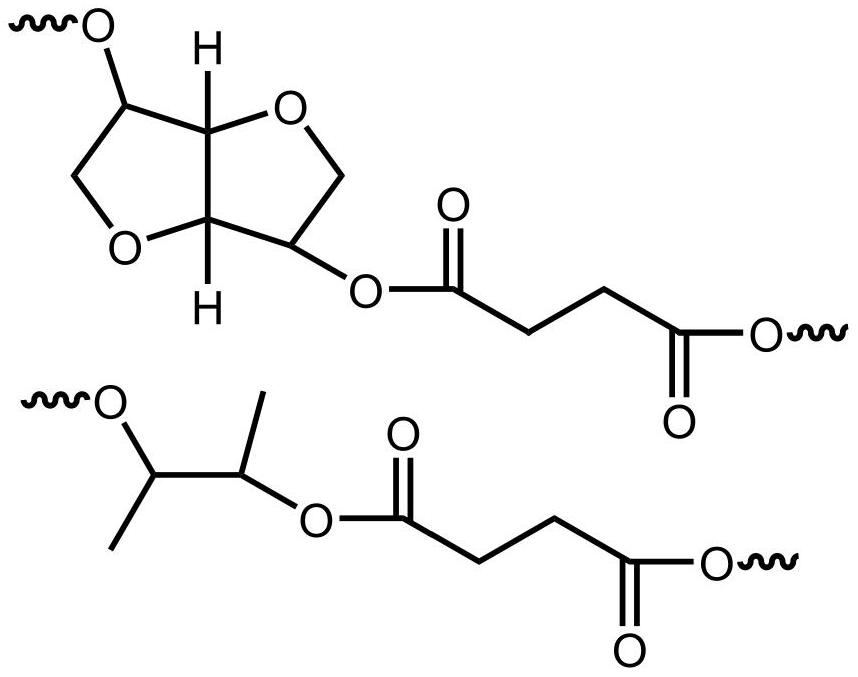

Bio-based degradable polyester resin as well as preparation method and application thereof

ActiveCN112812283AIn line with the principles of productionPromote degradationChewing gumFood ingredient as emulsifierPolymer sciencePolyester resin

The invention provides bio-based degradable polyester resin and a preparation method thereof. The bio-based degradable polyester resin is applied to a bio-based degradable chewing gum base. The bio-based degradable polyester with the glass transition temperature of 15-45 DEG C is synthesized by condensation polymerization of safe, nontoxic and renewable bio-based micromolecular dibasic acid and bio-based micromolecular dihydric alcohol, can provide excellent elasticity and plasticity, has a very high degradation rate, can be used as degradable chewing gum base resin, can ensure good performance of the chewing gum, has the characteristic of bio-based degradability.

Owner:BEIJING UNIV OF CHEM TECH

A kind of method of synthesizing p-bromopropiophenone

InactiveCN102260155AThe separation and purification process is simpleModerate reaction timeCarbonyl compound preparation by condensationChemistryBromobenzoic Acids

The invention discloses a method for synthesizing p-bromopropiophenone, which uses p-bromobenzoic acid and propionic acid as raw materials to prepare p-bromopropiophenone through reaction in the presence of a composite catalyst. The invention adopts a novel composite catalyst to synthesize p-bromopropiophenone, the separation and purification process is simple, the reaction time is short, the yield of the product reaches more than 77%, the obtained product has high purity, low energy consumption, little environmental pollution, and low cost, and is the realization of industrial production an ideal process.

Owner:NANTONG UNIVERSITY

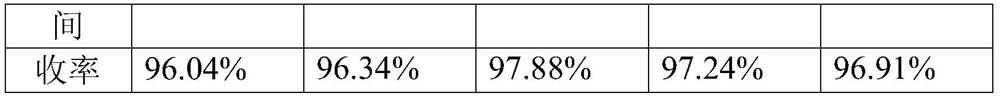

Imidazo-[1,2-c]-quinazolin-3(2H)-one fused-heterocycle compounds and preparation method thereof

ActiveCN103965203ARaw materials are easy to getEasy to operateOrganic chemistrySulfonyl chloridePtru catalyst

The invention discloses imidazo-[1,2-c]-quinazolin-3(2H)-one fused-heterocycle compounds and a preparation method thereof, and discloses a preparation method of fused ring compounds (imidazo[1,2-c]quinazolin-3(2H)-one derivatives). The preparation method comprises the steps that 3 in a general formula is obtained by reacting at the proper temperature in the absence of a solvent or in a proper amount of the solvent under the action of amines 1 and 2 to generate a key intermediate and purifying; in addition, if R2 is -H, 3 can also be obtained by reacting 1 and DMF in the presence of benzene sulfonyl chloride and purifying, and the fused ring compounds represented by a formula are obtained by reacting 3 with 4 at the proper temperature in a proper amount of the solvent. The method has the beneficial effects that 1, the reaction path is short, namely a two-step synthetic method is adopted; 2, two heterocyclic rings are formed by adopting a one-pot method in the reaction of the second step; 3, raw materials are easily available and the operation is convenient; 4, no heavy metal ion catalysts and the like are used in the reaction and the reaction conditions are mild; 5, the reaction time is moderate, the control is easy, the post-treatment is simple, and the product purity and the yield are high; 6, the environment is not polluted and the green chemical concept is fully embodied.

Owner:ASSET SUZHOU PHARMA CO LTD

8, 9-mono and/or di-substituted imidazo[1, 2-c]quinazolin-3(2H)-one fused heterocyclic compound and preparation method thereof

ActiveCN104059075ARaw materials are easy to getEasy to operateOrganic chemistryChemical compoundCombinatorial chemistry

The invention discloses a 8, 9-mono and / or di-substituted imidazo[1, 2-c]quinazolin-3(2H)-one fused heterocyclic compound and a preparation method thereof. The method comprises the steps of: reacting amine 1 and a compound 2 without solvent or in an appropriate solvent under an appropriate temperature to generate a key intermediate, then performing purification to obtain an intermediate 3 shown as the following general formula, or if R3=-H, reacting amine 1 and DMF under the action of benzenesulfonyl chloride and then conducting purification to obtain the intermediate 3, and then reacting the intermediate 3 with a compound 4 in an appropriate solvent under an appropriate temperature to obtain a fused ring compound 5 shown as the following general formula. The method provided by the invention has the advantages that: 1. the reaction route is short, i.e. a two-step synthesis method; 2. the fused ring compound with two heterocycles is formed in step 2 by a one-pot technique; 3. the raw materials are easily available, and the operation is convenient; 4. the reaction has no need for any heavy metal ion catalyst and the like, and the reaction conditions are mild; 5. the reaction time is moderate, the reaction is easy to control, the post-treatment is simple, and the product has high purity and yield; and 6. the method has no pollution to the environment, thus fully reflecting the concept of green chemistry.

Owner:ASSET SUZHOU PHARMA CO LTD

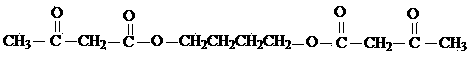

Preparing method for organic intermediate diacetoacetic acid (1,4-butanediol) ester

InactiveCN103819340AThe separation and purification process is simpleModerate reaction timePreparation from ketenes/polyketenesAcetoacetic acidPolymerization

The invention discloses a preparing method for organic intermediate diacetoacetic acid (1,4-butanediol) ester, which includes the following steps: using ketene dimer and 1,4-butanediol as raw materials, and reacting to obtain the diacetoacetic acid (1,4-butanediol) ester after the addition of a catalyst, a polymerization inhibitor and a solvent. During the synthesis of the diacetoacetic acid (1,4-butanediol) ester, the separation and purification process is simple, the reaction time is short, the product yield reaches 91% above, the product purity is higher, the energy consumption is low, environmental pollution is low, the cost is low, and the preparing method is an ideal technology for the realization of industrial production.

Owner:NANTONG UNIVERSITY

Synthetic method for 5-bromo-imidazo[1, 2-A]pyrimidine-3-carboxylate and corresponding acid thereof

InactiveCN105061433AHigh yieldRaw materials are easy to getOrganic chemistryCarboxylic saltPhotochemistry

The invention discloses a synthetic method for for 5-bromo-imidazo[1, 2-A]pyrimidine-3-carboxylate and corresponding acid thereof. The synthetic method comprises: taking a compound as shown in formula (1) as a raw material, and reacting the raw material with a compound as shown in formula (2) to generate a compound as shown in formula (3); and reacting the compound as shown in formula (3) with alpha ester of halogenated acid, and purifying to obtain the 5-bromo-imidazo[1, 2-a]pyrimidine-3-carboxylate; and hydrolyzing and acidifying the 5-bromo-imidazo[1, 2-a]pyrimidine-3-carboxylate to obtain 5-bromo-imidazo[1, 2-a]pyrimidine-3-carboxylic acid. The synthetic method disclosed by the invention is short in synthesis route and high in yield, and raw materials are easily available.

Owner:HENAN VIOLET TECH CO LTD

Method and device for circulating cold regenerated catalyst

ActiveCN101665713BReduce the temperatureRaise the preheat temperatureCatalytic crackingEthylene productionWaxGasoline

The invention provides a method for circulating a cold regenerated catalyst and application thereof. A regenerated catalyst from a regenerator is cooled by a catalyst cooler to between 200 and 720DEG C, and is not mixed with a hot regenerated catalyst to directly enter a riser reactor, or is mixed with another part of uncooled hot regenerated catalyst into a mixed regenerated catalyst of which the temperature is not lower than that of the regenerator to enter the riser reactor; and a hydrocarbon raw material undergoes contact reaction with the catalyst in the riser reactor, the reaction material flow enters a settler for the separation of the catalyst and oil gas, the separated catalyst to be regenerated is subjected to steam stripping in a steam stripping section, and then enters the regenerator for coke burning regeneration, and the regenerated catalyst is cooled and returns to the riser reactor for recycling. The method for circulating the cold regenerated catalyst has wide application, can be used for various fluid catalytic cracking processes comprising resid fluid catalytic cracking, wax oil catalytic cracking, gasoline catalytic conversion upgrading and the like, and also can be sued for other gas-solid reaction processes comprising residual oil pretreatment, fluid coking and the like.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

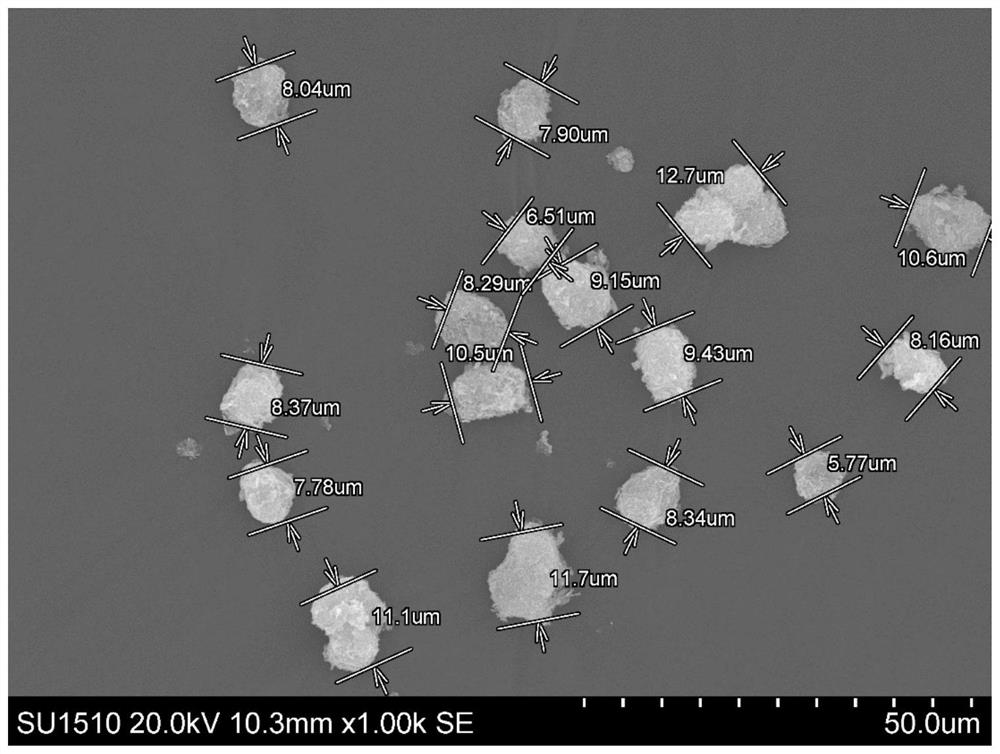

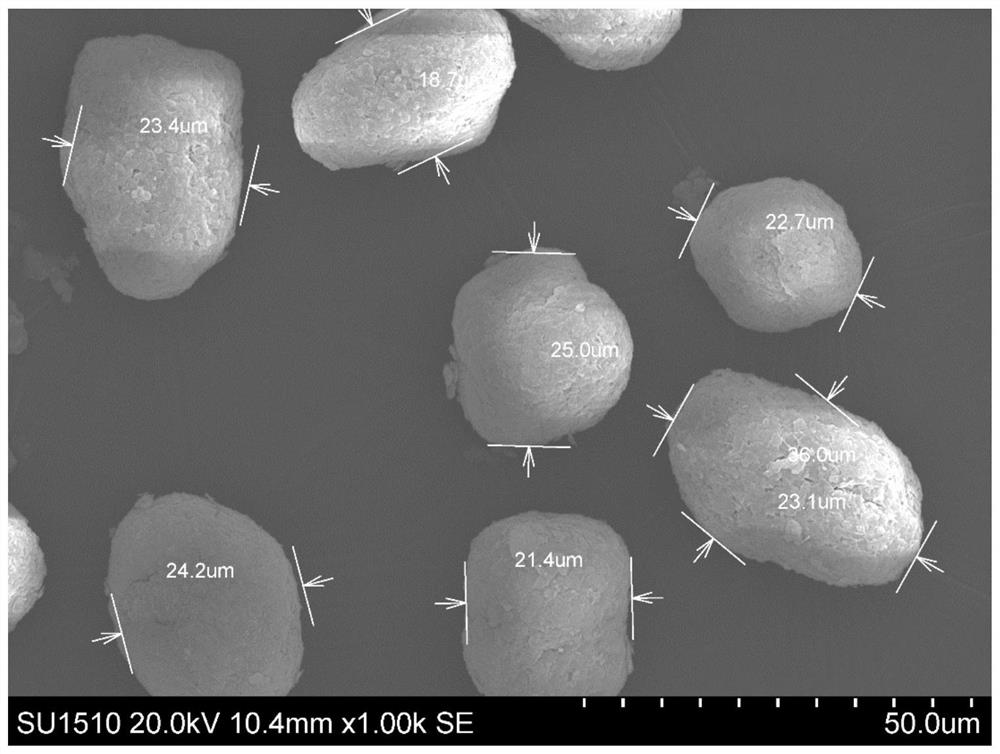

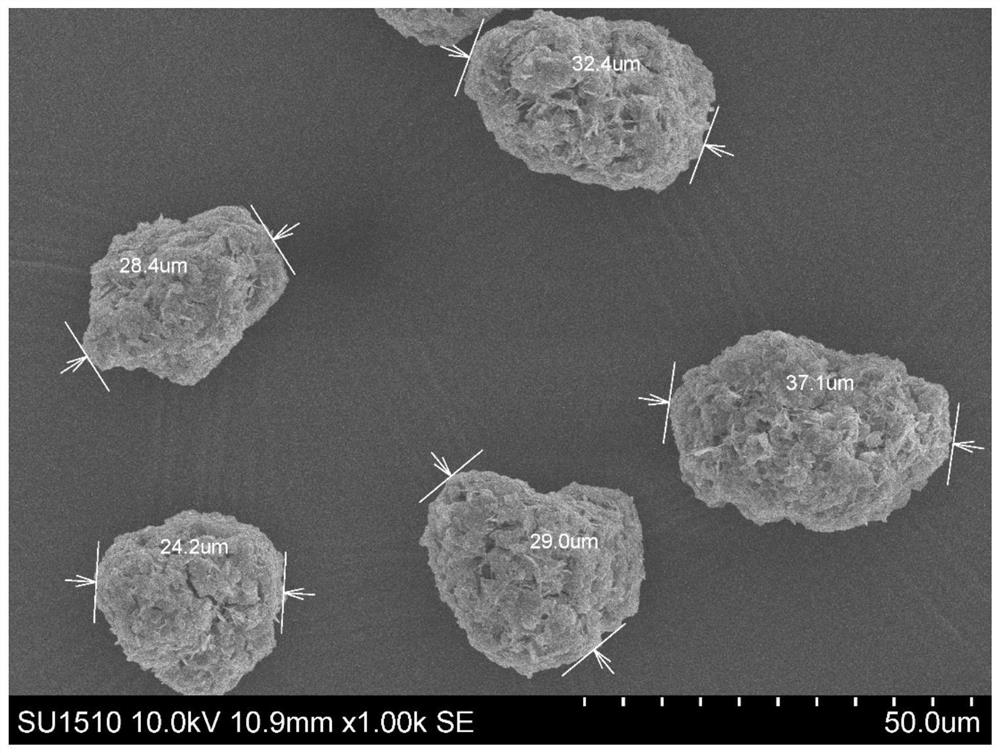

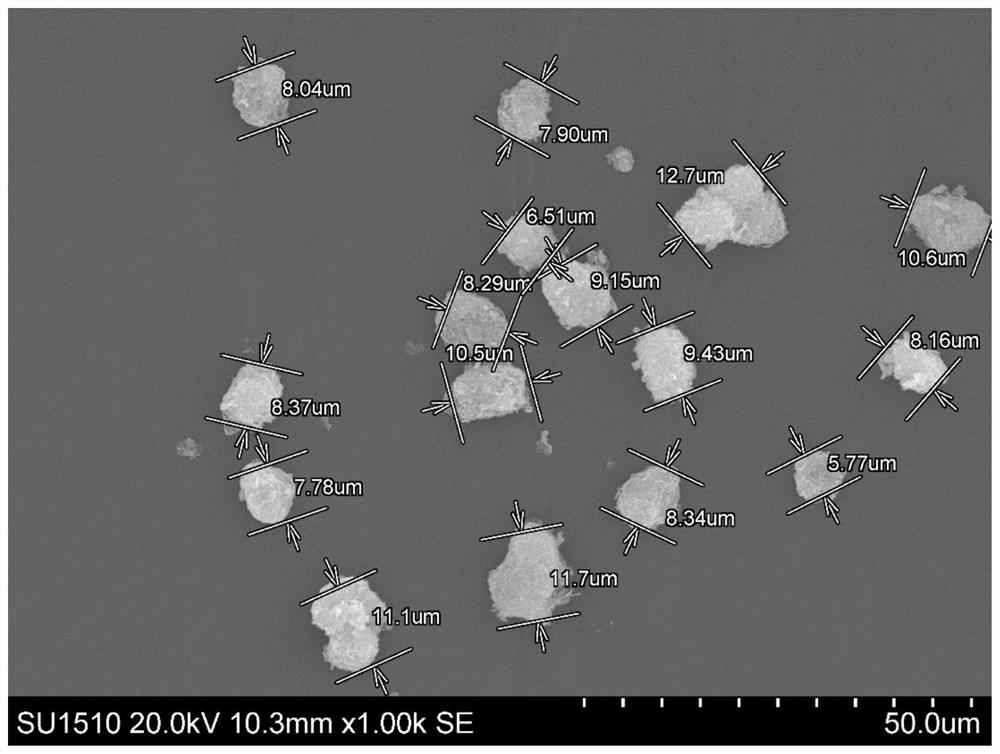

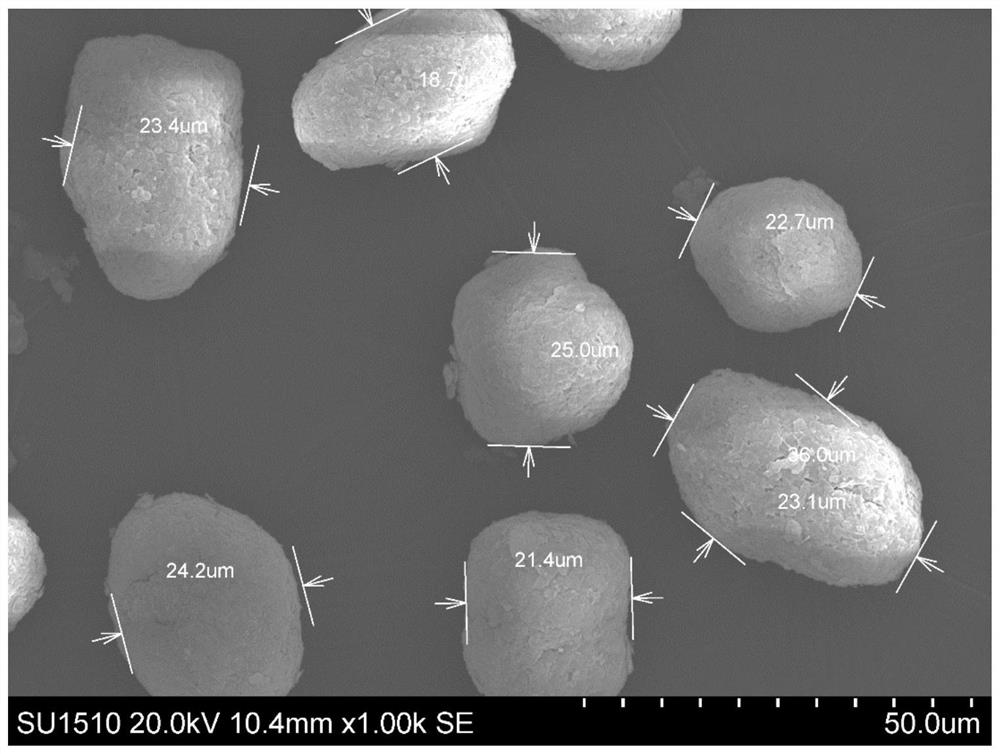

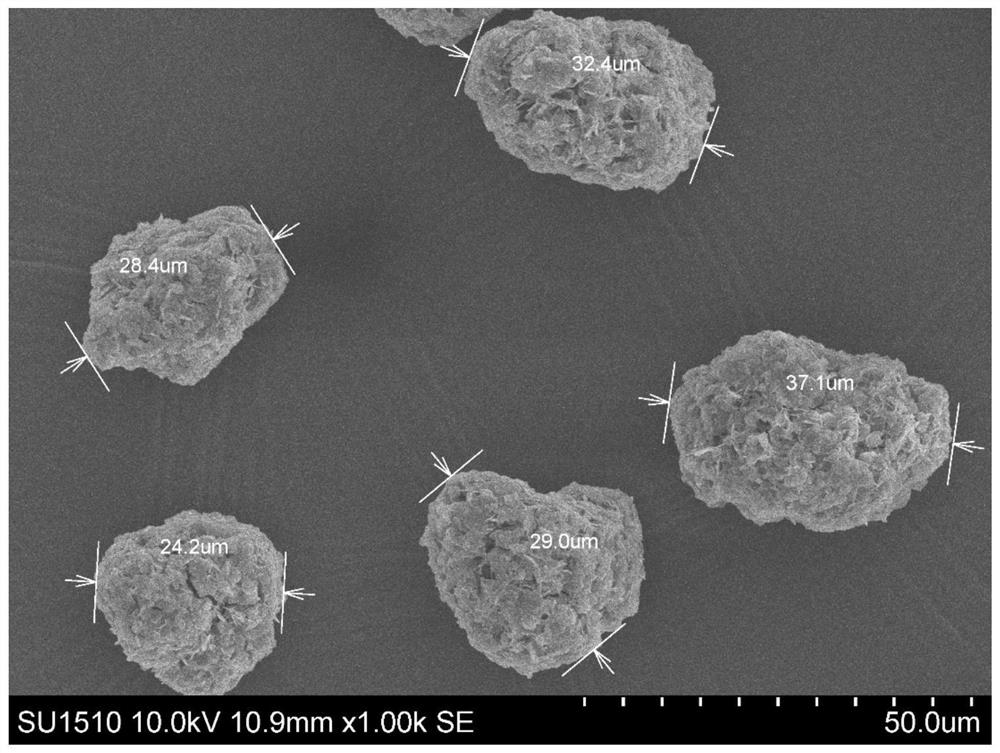

Preparation method of spherical magnesium diethoxylate

ActiveCN112299984AParticle size controllableUniform particle sizeOrganic compound preparationCarboxylic acid salt preparationAlcoholActive agent

The invention provides a method for preparing magnesium diethoxylate, which comprises the following steps of: by using metal spherical magnesium powder and absolute ethyl alcohol as raw materials, adding elemental iodine and a cosolvent to prepare spherical magnesium diethoxylate. The particle size of the obtained spherical magnesium diethoxylate ranges from 1 micron to 200 microns, and the span of particle size distribution is smaller than 3. The cosolvent is added into the reaction system, the particle size of the obtained magnesium diethoxylate can even reach 5 [mu] m to 15 [mu] m, and compared with a traditional method of adding a surfactant, silicone oil or span and the like, the method has the advantages that the cosolvent is easier to remove, impurity residues are avoided, and post-treatment is more convenient. The method has the advantages of low reaction temperature, stable reaction, short reaction time and no discharge of environment-unfriendly substances, and is suitable forlarge-scale industrial production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

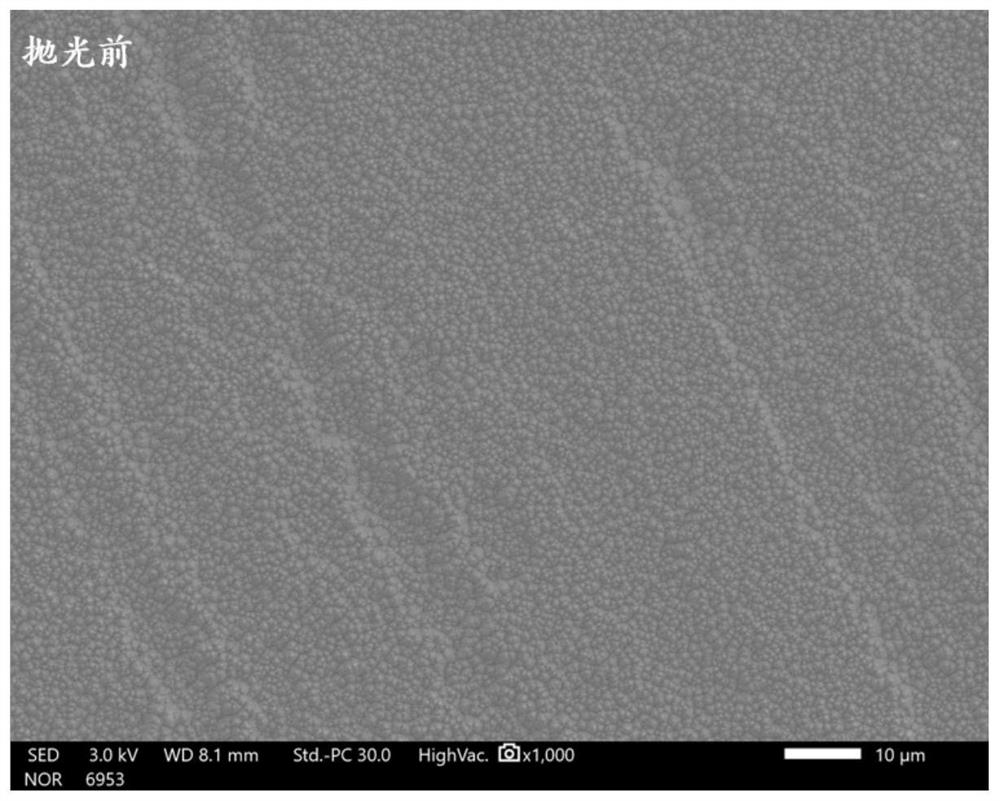

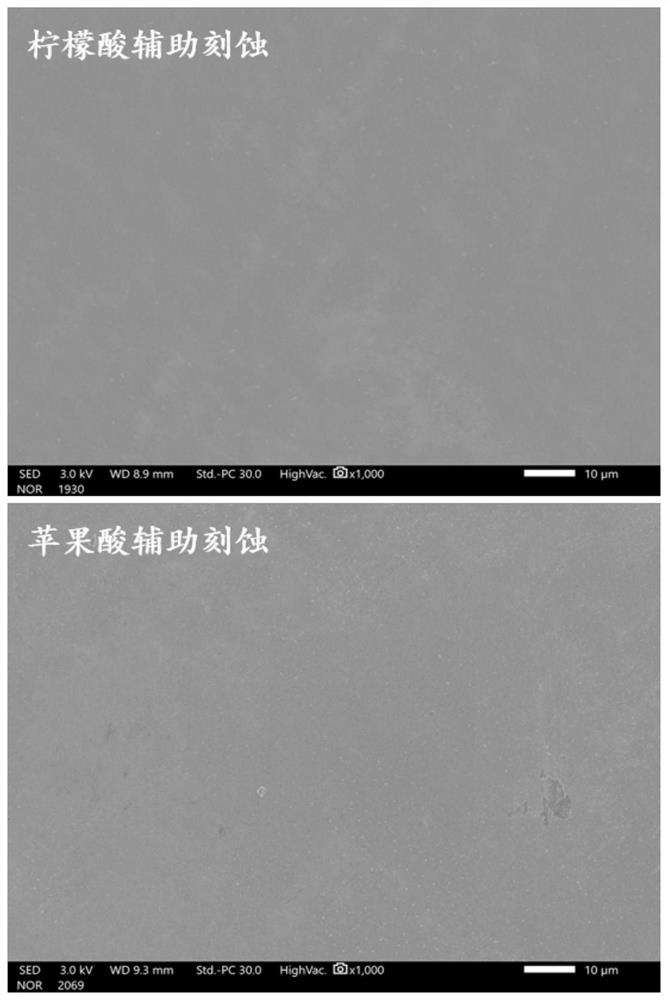

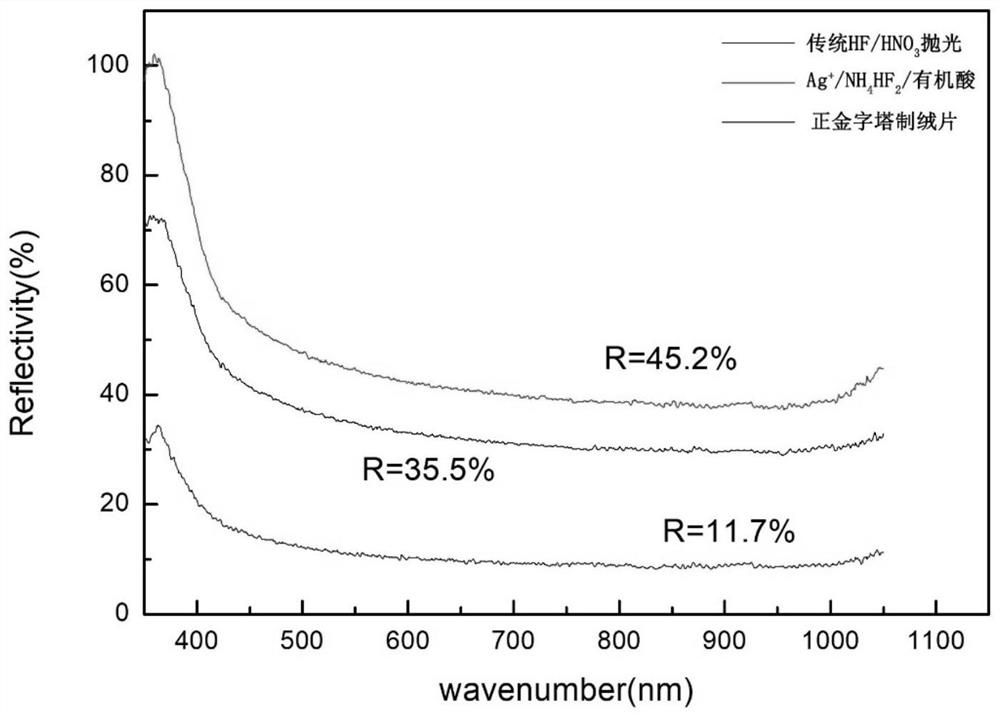

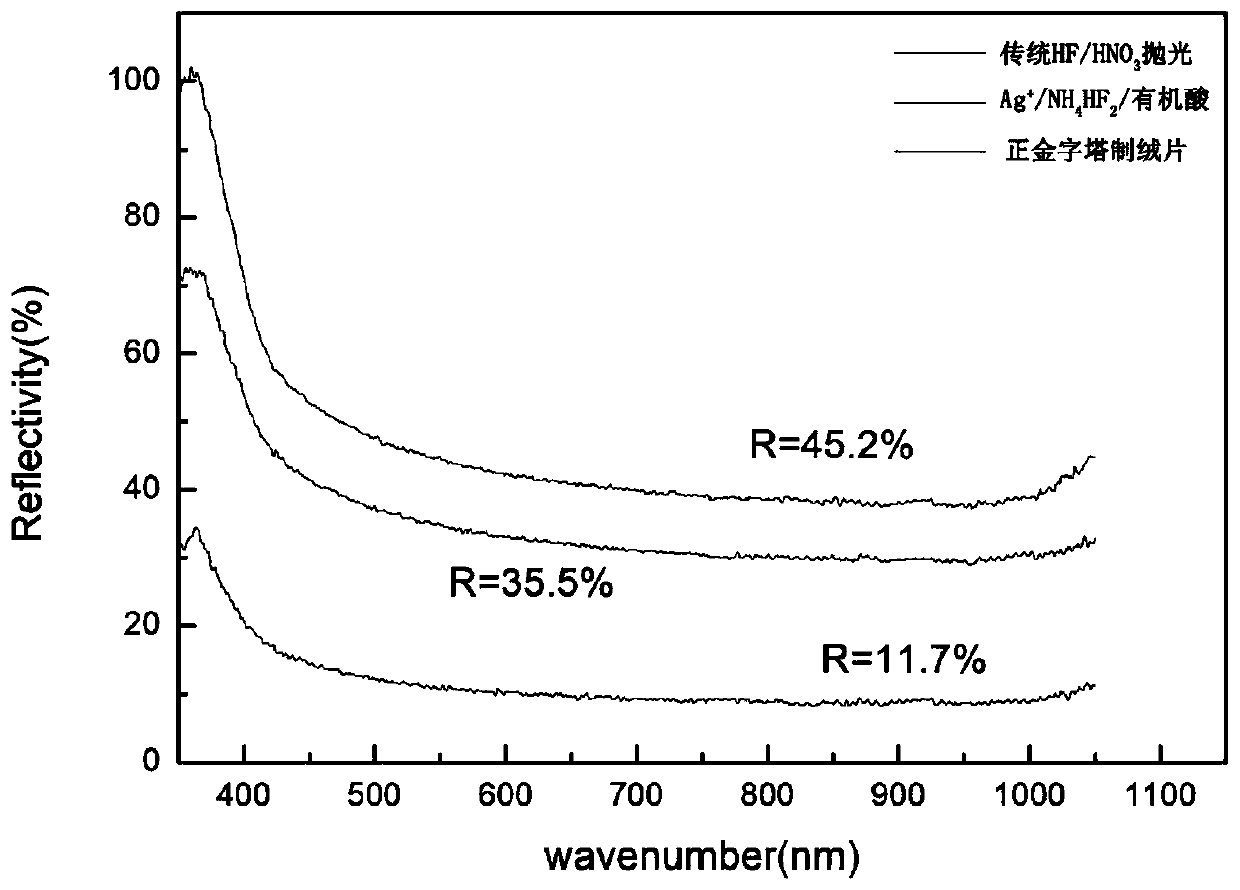

A kind of metal ion assisted non-nitric acid polishing method

InactiveCN110820048BComponents are safe and stableReduce consumptionPolycrystalline material growthAfter-treatment detailsOrganic acidPhysical chemistry

The invention relates to the technical field of monocrystalline silicon solar cells. A metal ion-assisted non-nitric acid polishing method comprises the following steps that S1, a polishing solution is prepared, specifically, 1.5 ml / L-5ml / L of a silver nitrate solution, 0.1%-5% of an organic acid, 0.5%-5% of ammonium bifluoride, 10%-40% of hydrogen peroxide and other components are sequentially dissolved into balance deionized water to be evenly mixed; s2, heating and polishing are conducted, specifically, the polishing solution obtained in the step S1 is heated to 55-70 DEG C, a monocrystalline textured wafer is placed in the polishing solution to be polished, and the polishing time is within 90-360 s; and S3, cleaning is performed, specifically, the monocrystalline textured wafer polished in the S2 is cleaned. The metal ion assisted non-nitric acid polishing method can solve the problems of low reflectivity, poor stability and high consumption at present.

Owner:NANJING NAXIN NEW MATERIAL

Biodegradable gum base elastomer and preparation method thereof

ActiveCN102408549BIn line with the general principles of productionGood physical and mechanical processing propertiesChewing gumElastomerPolymer science

Owner:BEIJING UNIV OF CHEM TECH

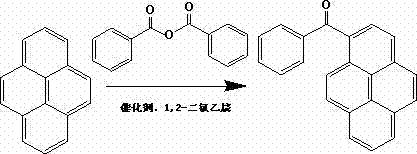

One-step synthesis method of 1-benzoylpyrene

ActiveCN103086860AHigh yieldLow yieldOrganic-compounds/hydrides/coordination-complexes catalystsCarbonyl compound preparation by condensationPesticideEnvironmental chemistry

The invention discloses a method for synthesizing an organic synthesis intermediate compound 1-benzoylpyrene having high yield and high selectivity through the catalytic Friedel-Crafts acylation reaction of condensed aromatic pyrene and benzoic anhydride by using cheap, accessible and hydrostable aluminum phosphotungstate and supported aluminum phosphotungstate as a catalyst and using non-polar solvent 1,2-dichloroethane as solvent. The 1-benzoylpyrene is widely used in multiple fields such as medicine, pesticide, dye and the like. The method is simple in reaction, convenient to operate, short in reaction time, low in reaction temperature, low in energy consumption and satisfactory in catalyst reusability, thus conforming to the requirements for greenness and environmental protection in the world at present.

Owner:JIANGSU UNIV

A kind of bio-based degradable polyester resin and its preparation method and application

ActiveCN112812283BIn line with the principles of productionPromote degradationChewing gumFood ingredient as emulsifierPolymer sciencePolyester resin

The invention provides a bio-based degradable polyester resin and a preparation method thereof, and applies the bio-based degradable polyester resin to a bio-based degradable chewing gum base. The invention adopts the polycondensation of bio-based small molecule dibasic acid and bio-based small molecule diol which is safe and non-toxic and derived from renewable sources, and synthesizes bio-based degradable polyester with a glass transition temperature of 15-45°C. It can provide excellent elasticity and plasticity, and has a high degradation rate. It can be used as a degradable chewing gum base resin, which can not only ensure good performance of the chewing gum itself, but also has biodegradable characteristics.

Owner:BEIJING UNIV OF CHEM TECH

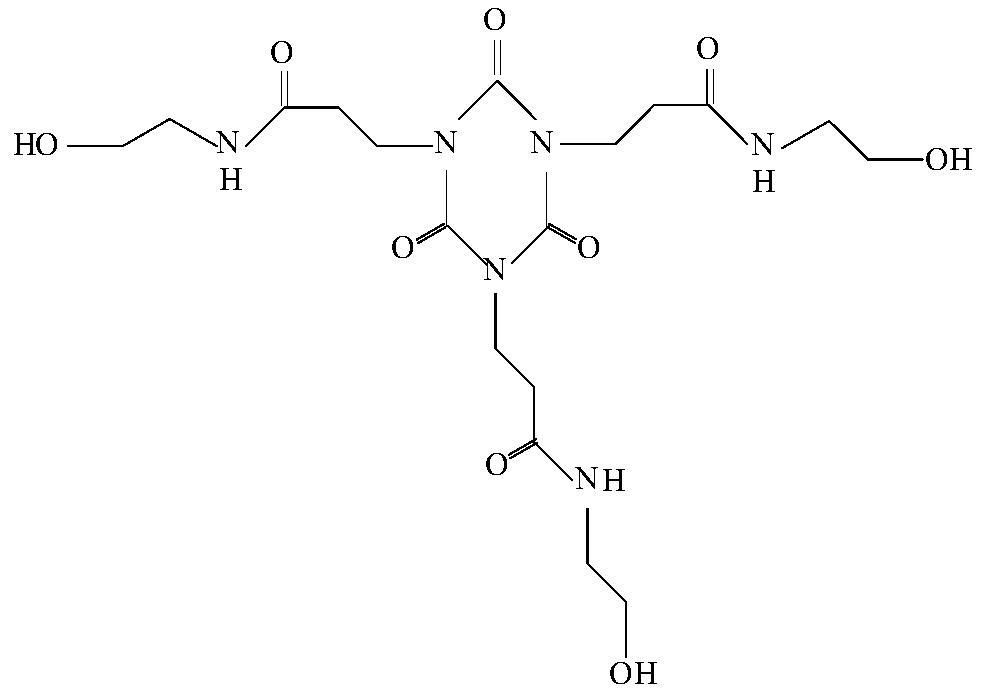

Preparation method of n,n,n-tris(n'-hydroxyethyl-3'-propionic acid amido)-1,3,5-triazine

The invention provides a method for preparing a curing agent intermediate N,N,N-tris(N'-hydroxyethyl-3'-propionic acid amido)-1,3,5-triazine, which uses N,N ,N‑tris(3'‑methyl propionate)‑1,3,5‑triazine and monoethanolamine are used as raw materials, and the curing agent intermediate N,N,N‑ Tris(N'-hydroxyethyl-3'-propionamido)-1,3,5-triazine. The present invention synthesizes curing agent intermediate N,N,N-tris(N'-hydroxyethyl-3'-propionic acid amido)-1,3,5-triazine, the separation and purification process is simple, the reaction time is short, and the product The yield can reach more than 96%, the product has high purity, less energy consumption, less environmental pollution and low cost, and is an ideal process for realizing industrialized production.

Owner:JIANGSU XINLU CHEM NEW MATERIAL

A kind of preparation method of spherical diethoxymagnesium

ActiveCN112299984BParticle size controllableUniform particle sizeOrganic compound preparationCarboxylic acid salt preparationChemical industryAnhydrous ethanol

The invention provides a method for preparing diethoxymagnesium, which comprises using metal spherical magnesium powder and absolute ethanol as raw materials, adding iodine simple substance and a cosolvent to prepare spherical diethoxymagnesium. The particle size range of the obtained spherical diethoxymagnesium is 1-200um, and the span of the particle size distribution is less than 3; by adding a co-solvent to the reaction system, the particle size of the obtained diethoxymagnesium can even reach 5um-15um, and Compared with the traditional method of adding surfactant, silicone oil or spar, the method is easier to remove the cosolvent, has no residue of impurities, and is more convenient for post-processing. The method of the present invention has lower reaction temperature, stable reaction and shorter reaction time. Short, no environmentally unfriendly substance discharge, suitable for large-scale industrial production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Imidazo-[1,2-c]-quinazolin-3(2H)-one fused-heterocycle compounds and preparation method thereof

ActiveCN103965203BRaw materials are easy to getEasy to operateOrganic chemistrySulfonyl chloridePtru catalyst

The invention discloses imidazo-[1,2-c]-quinazolin-3(2H)-one fused-heterocycle compounds and a preparation method thereof, and discloses a preparation method of fused ring compounds (imidazo[1,2-c]quinazolin-3(2H)-one derivatives). The preparation method comprises the steps that 3 in a general formula is obtained by reacting at the proper temperature in the absence of a solvent or in a proper amount of the solvent under the action of amines 1 and 2 to generate a key intermediate and purifying; in addition, if R2 is -H, 3 can also be obtained by reacting 1 and DMF in the presence of benzene sulfonyl chloride and purifying, and the fused ring compounds represented by a formula are obtained by reacting 3 with 4 at the proper temperature in a proper amount of the solvent. The method has the beneficial effects that 1, the reaction path is short, namely a two-step synthetic method is adopted; 2, two heterocyclic rings are formed by adopting a one-pot method in the reaction of the second step; 3, raw materials are easily available and the operation is convenient; 4, no heavy metal ion catalysts and the like are used in the reaction and the reaction conditions are mild; 5, the reaction time is moderate, the control is easy, the post-treatment is simple, and the product purity and the yield are high; 6, the environment is not polluted and the green chemical concept is fully embodied.

Owner:ASSET SUZHOU PHARMA CO LTD

2H-imidazo[1,2-C] quinazoline-3-one compound with optical activity and preparation method thereof

InactiveCN104327086ANo pollution in the processRaw materials are easy to getOrganic chemistrySulfonyl chloridePtru catalyst

The invention discloses a 2H-imidazo[1,2-C] quinazoline-3-one compound with optical activity and a preparation method thereof. The preparation method comprises the steps of reacting to generate a key intermediate shown in the formula in the specification at appropriate temperature in the absence of solvent or in an appropriate solvent under the actions of amine 1 and a compound 2, wherein when R2 is -H, the intermediate 3 can be generated by the amine 1 and DMF under the action of benzene sulfonyl chloride, and the intermediate 3 can be obtained through separation and purification; and reacting the intermediate 3 with alpha amino-acid ester 4 or 4' at appropriate temperature in an appropriate solvent, and purifying to obtain quinazolinone compounds 5 and 6 shown in the formula in the specification. The reaction route is short, the two-step synthesis method is adopted, the raw materials are easily available, the operation is convenient, no any heavy metal ionic catalyst and the like are added during reaction, the product has high purity and high yield, no environment pollution is caused, and the green chemistry concept is fully embodied.

Owner:SHANDONG ENG & TECH INST OF LUNAN COAL CHEM ENG

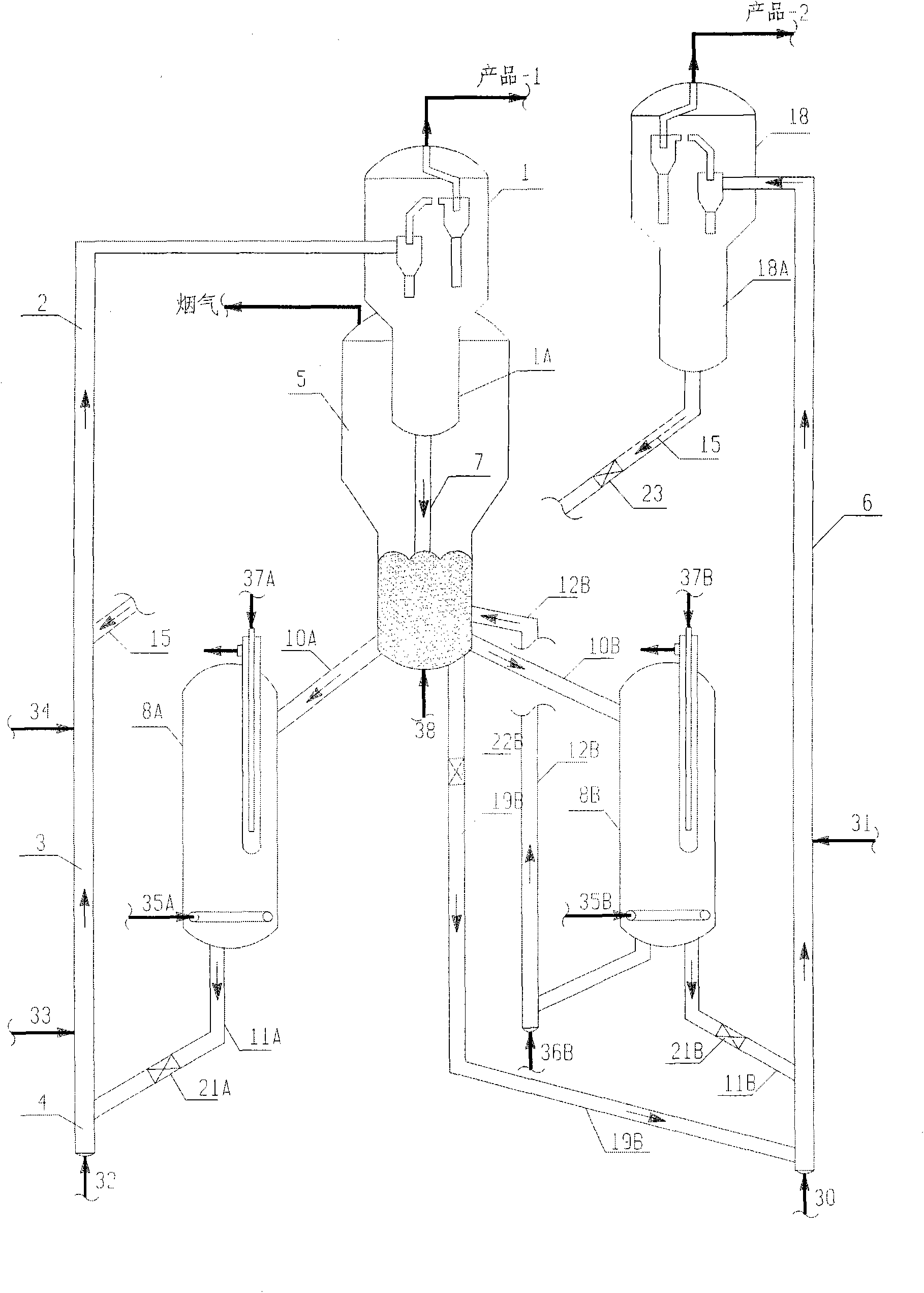

Fluid catalytic conversion feeding preheating and reaction temperature control method

ActiveCN101838545BEasy to operateThe number of catalyst active centers is stableCatalytic crackingHydrocarbon from oxygen organic compoundsRecyclable catalystReaction temperature

Owner:李群柱

2,3,5-position substituted imidazol[1,2-c]-thiophene[2,3-e]pyrimidin-7(8h)one heterocyclic compound and its synthesis method

ActiveCN105541865BHas antitumor activityStrong inhibitory activityOrganic active ingredientsOrganic chemistryChemical compoundCombinatorial chemistry

The invention discloses a 2,3,5-substituted imidazole[1,2-c]-thiophene[2,3-e]-7(8H)keto heterocyclic compound of which the structure is shown as a formula (I) shown in the description. The invention also discloses a preparation method of the compound and application of the compound in preparing antineoplastic drugs. The 2,3,5-substituted imidazole[1,2-c]-thiophene[2,3-e]-7(8H)keto heterocyclic compound provided by the invention adopts a two-step synthesis method, a one-pot reaction is adopted for forming two heterocyclic rings, the reaction material is easily obtained, the operation is convenient, the reaction condition is mild, the reaction time is moderate, the control is easy, the after-treatment is simple, the purity and yield of a product are high, and the compound and the synthetic method thereof have the advantages of being less in operation step, high in yield, free of reagents such as phosphorus, low in toxicity, convenient to operate and the like.

Owner:山东益康药业股份有限公司

A kind of water-in-oil type anionic polyacrylamide emulsion and method thereof

ActiveCN109503756BImprove solubilityImprove salt resistanceDrilling compositionEthyl groupSodium sulfate

Owner:东营市诺尔化工有限责任公司

Metal ion assisted non-nitric acid polishing method

InactiveCN110820048AComponents are safe and stableReduce consumptionPolycrystalline material growthAfter-treatment detailsElectrical batterySingle crystal

The invention relates to the technical field of monocrystalline silicon solar cells. A metal ion-assisted non-nitric acid polishing method comprises the following steps that S1, a polishing solution is prepared, specifically, 1.5 ml / L-5ml / L of a silver nitrate solution, 0.1%-5% of an organic acid, 0.5%-5% of ammonium bifluoride, 10%-40% of hydrogen peroxide and other components are sequentially dissolved into balance deionized water to be evenly mixed; s2, heating and polishing are conducted, specifically, the polishing solution obtained in the step S1 is heated to 55-70 DEG C, a monocrystalline textured wafer is placed in the polishing solution to be polished, and the polishing time is within 90-360 s; and S3, cleaning is performed, specifically, the monocrystalline textured wafer polished in the S2 is cleaned. The metal ion assisted non-nitric acid polishing method can solve the problems of low reflectivity, poor stability and high consumption at present.

Owner:NANJING NAXIN NEW MATERIAL

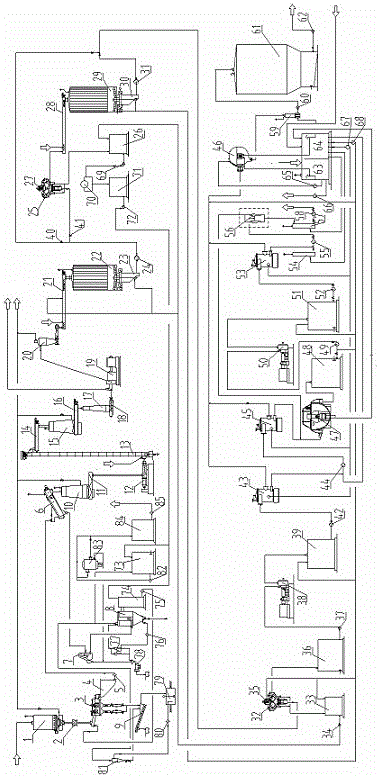

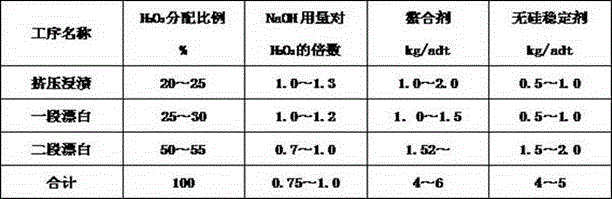

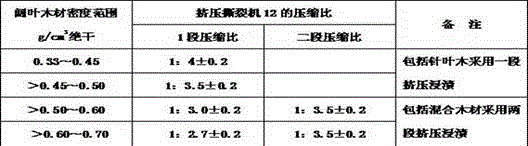

A chemical mechanical pulping process

ActiveCN104711880BImprove purification qualityIncrease productivityPretreatment with water/steamWashing/displacing pulp-treating liquorsFiberCardboard

The invention discloses a chemi-mechanical pulp manufacturing technology which includes the step of wood chip washing, the step of extruding and dipping, the step of pulp grinding, bleaching and pulp washing, the step of screening, purifying and regrinding of pulp residues, the step of pulp condensation and storage, the step of water circulating use and the step of chemical application and control. In the step of extruding and dipping, the extruding and dipping technology and an extruding and tearing device are used, heated and softened wood chips are evenly squashed in the texture direction, air in the wood chips and extracts affecting bleaching are discharged, it is ensured that the wood chips evenly absorb bleaching chemical liquid to be in a saturated state, fibers are promoted to be in the best moist and expanded state, and accordingly separation of the wood chips and fibrillation of the fibers are facilitated. The chemi-mechanical pulp manufacturing technology is wide in raw material application range and successfully combines the advantages that chemical pulp is high in strength and mechanical pulp is high in yield, produced bleached pulp can be used for newsprint, high-grade toilet paper, facial tissues, high-grade culture and printing paper, coating paper, light paper, white paper boards, food package paper and the like, and development prospects are wide.

Owner:WENRUI MACHINERY SHANDONG

Unsaturated polyester resin for molding compound of auto parts and manufacturing method thereof

The invention relates to a high molecular compound, in particular to an unsaturated polyester resin for molding compound of auto parts, which is prepared by dissolving a reaction product of the condensation reaction of propylene qlycol, diethylene qlycol, dipropylene glycol, phthalic anhydride and cis-butenedioic anhydride into styrene after the condensation reaction is completed. The invention has the advantages that: (1) the resin has good water resistance and flexibility through optimization combination on the premise that the cost of raw materials of the resin is not greatly increased, and products made of the resin have good anti-wet capacity and good mechanical property; (2) the reactivity of the resin is greatly enhanced so as to ensure that the surface of molding compound productsafter hot press molding has higher luster; (3) the resin is used together with a proper low-profile agent, and enables produced products to achieve zero shrinkage so as to ensure the accuracy of the size of the products; and the resin also can be used together with low-shrinkage agents in polystyrene so as to enhance stainability of the products; and (4) the reaction time can be shortened as wellas the energy consumption and the manufacturing cost of the resin can be reduced by adopting phthalic anhydride.

Owner:CHANGZHOU HUARUN COMPOSITE MATERIALS +1

Method and device for fluidized catalytic conversion

ActiveCN101665712BReduce the temperatureRaise the preheat temperatureCatalytic crackingCatalytic transformationPtru catalyst

The invention provides a method for catalytic conversion of heavy oil, which comprises a fluidized catalytic conversion process that: heavy hydrocarbon raw materials contacts a catalyst in a riser reactor or fluidized bed reactor to react; the reaction temperature is 400 to 650 DEG C (preferably 480 to 560 DEG C); the reaction pressure is 0.11 to 0.4MPa; the contact time is 0.05 to 5 seconds (preferably 0.1 to 3 seconds); and the weight ratio of the catalyst to the raw materials ( catalyst to oil ratio) generally is 3 to 15, preferably 5 to 12. The reaction products flow in a settler for catalyst and oil gas separation; the separated catalyst to be regenerated is stripped by a stripping section and enters a regenerator for coke burning regeneration; and the regenerated catalyst is cooled or directly returns to the riser reactor to be recycled. The method can solve the problems encountered in the resid-blend ratio improvement and gasoline upgrade and update processes of the prior catalytic conversion.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

2,3,5-substituted imidazole[1,2-c]-thiophene[2,3-e]-7(8H)keto heterocyclic compound and synthetic method thereof

ActiveCN105541865AHas antitumor activityStrong inhibitory activityOrganic active ingredientsOrganic chemistrySynthesis methodsKetone

The invention discloses a 2,3,5-substituted imidazole[1,2-c]-thiophene[2,3-e]-7(8H)keto heterocyclic compound of which the structure is shown as a formula (I) shown in the description. The invention also discloses a preparation method of the compound and application of the compound in preparing antineoplastic drugs. The 2,3,5-substituted imidazole[1,2-c]-thiophene[2,3-e]-7(8H)keto heterocyclic compound provided by the invention adopts a two-step synthesis method, a one-pot reaction is adopted for forming two heterocyclic rings, the reaction material is easily obtained, the operation is convenient, the reaction condition is mild, the reaction time is moderate, the control is easy, the after-treatment is simple, the purity and yield of a product are high, and the compound and the synthetic method thereof have the advantages of being less in operation step, high in yield, free of reagents such as phosphorus, low in toxicity, convenient to operate and the like.

Owner:山东益康药业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Imidazo-[1,2-c]-quinazolin-3(2H)-one fused-heterocycle compounds and preparation method thereof Imidazo-[1,2-c]-quinazolin-3(2H)-one fused-heterocycle compounds and preparation method thereof](https://images-eureka.patsnap.com/patent_img/4322aa2d-5e74-4ab0-a8d6-98c3a98ef469/115656DEST_PATH_IMAGE007.PNG)

![Imidazo-[1,2-c]-quinazolin-3(2H)-one fused-heterocycle compounds and preparation method thereof Imidazo-[1,2-c]-quinazolin-3(2H)-one fused-heterocycle compounds and preparation method thereof](https://images-eureka.patsnap.com/patent_img/4322aa2d-5e74-4ab0-a8d6-98c3a98ef469/192998DEST_PATH_IMAGE002.PNG)

![Imidazo-[1,2-c]-quinazolin-3(2H)-one fused-heterocycle compounds and preparation method thereof Imidazo-[1,2-c]-quinazolin-3(2H)-one fused-heterocycle compounds and preparation method thereof](https://images-eureka.patsnap.com/patent_img/4322aa2d-5e74-4ab0-a8d6-98c3a98ef469/26161DEST_PATH_IMAGE005.PNG)

![8, 9-mono and/or di-substituted imidazo[1, 2-c]quinazolin-3(2H)-one fused heterocyclic compound and preparation method thereof 8, 9-mono and/or di-substituted imidazo[1, 2-c]quinazolin-3(2H)-one fused heterocyclic compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/de973cb7-90b6-4617-b26b-f875af448513/106121DEST_PATH_IMAGE010.PNG)

![8, 9-mono and/or di-substituted imidazo[1, 2-c]quinazolin-3(2H)-one fused heterocyclic compound and preparation method thereof 8, 9-mono and/or di-substituted imidazo[1, 2-c]quinazolin-3(2H)-one fused heterocyclic compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/de973cb7-90b6-4617-b26b-f875af448513/131845DEST_PATH_IMAGE011.PNG)

![8, 9-mono and/or di-substituted imidazo[1, 2-c]quinazolin-3(2H)-one fused heterocyclic compound and preparation method thereof 8, 9-mono and/or di-substituted imidazo[1, 2-c]quinazolin-3(2H)-one fused heterocyclic compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/de973cb7-90b6-4617-b26b-f875af448513/320648DEST_PATH_IMAGE006.PNG)

![Synthetic method for 5-bromo-imidazo[1, 2-A]pyrimidine-3-carboxylate and corresponding acid thereof Synthetic method for 5-bromo-imidazo[1, 2-A]pyrimidine-3-carboxylate and corresponding acid thereof](https://images-eureka.patsnap.com/patent_img/05073000-23af-4393-bdf5-ac6be52debf2/1.PNG)

![Synthetic method for 5-bromo-imidazo[1, 2-A]pyrimidine-3-carboxylate and corresponding acid thereof Synthetic method for 5-bromo-imidazo[1, 2-A]pyrimidine-3-carboxylate and corresponding acid thereof](https://images-eureka.patsnap.com/patent_img/05073000-23af-4393-bdf5-ac6be52debf2/BDA0000767107870000021.PNG)

![Synthetic method for 5-bromo-imidazo[1, 2-A]pyrimidine-3-carboxylate and corresponding acid thereof Synthetic method for 5-bromo-imidazo[1, 2-A]pyrimidine-3-carboxylate and corresponding acid thereof](https://images-eureka.patsnap.com/patent_img/05073000-23af-4393-bdf5-ac6be52debf2/BDA0000767107870000022.PNG)

![Imidazo-[1,2-c]-quinazolin-3(2H)-one fused-heterocycle compounds and preparation method thereof Imidazo-[1,2-c]-quinazolin-3(2H)-one fused-heterocycle compounds and preparation method thereof](https://images-eureka.patsnap.com/patent_img/3d00c764-716e-452c-b787-d359924ed97e/115656DEST_PATH_IMAGE007.PNG)

![Imidazo-[1,2-c]-quinazolin-3(2H)-one fused-heterocycle compounds and preparation method thereof Imidazo-[1,2-c]-quinazolin-3(2H)-one fused-heterocycle compounds and preparation method thereof](https://images-eureka.patsnap.com/patent_img/3d00c764-716e-452c-b787-d359924ed97e/192998DEST_PATH_IMAGE002.PNG)

![Imidazo-[1,2-c]-quinazolin-3(2H)-one fused-heterocycle compounds and preparation method thereof Imidazo-[1,2-c]-quinazolin-3(2H)-one fused-heterocycle compounds and preparation method thereof](https://images-eureka.patsnap.com/patent_img/3d00c764-716e-452c-b787-d359924ed97e/26161DEST_PATH_IMAGE005.PNG)

![2H-imidazo[1,2-C] quinazoline-3-one compound with optical activity and preparation method thereof 2H-imidazo[1,2-C] quinazoline-3-one compound with optical activity and preparation method thereof](https://images-eureka.patsnap.com/patent_img/3e45c87e-8f43-4858-90c3-38963825a9eb/173821DEST_PATH_IMAGE003.PNG)

![2H-imidazo[1,2-C] quinazoline-3-one compound with optical activity and preparation method thereof 2H-imidazo[1,2-C] quinazoline-3-one compound with optical activity and preparation method thereof](https://images-eureka.patsnap.com/patent_img/3e45c87e-8f43-4858-90c3-38963825a9eb/216981DEST_PATH_IMAGE002.PNG)

![2H-imidazo[1,2-C] quinazoline-3-one compound with optical activity and preparation method thereof 2H-imidazo[1,2-C] quinazoline-3-one compound with optical activity and preparation method thereof](https://images-eureka.patsnap.com/patent_img/3e45c87e-8f43-4858-90c3-38963825a9eb/250864DEST_PATH_IMAGE006.PNG)

![2,3,5-position substituted imidazol[1,2-c]-thiophene[2,3-e]pyrimidin-7(8h)one heterocyclic compound and its synthesis method 2,3,5-position substituted imidazol[1,2-c]-thiophene[2,3-e]pyrimidin-7(8h)one heterocyclic compound and its synthesis method](https://images-eureka.patsnap.com/patent_img/535b188e-13f0-4d75-893f-d893d253843a/BDA0000918378950000011.png)

![2,3,5-position substituted imidazol[1,2-c]-thiophene[2,3-e]pyrimidin-7(8h)one heterocyclic compound and its synthesis method 2,3,5-position substituted imidazol[1,2-c]-thiophene[2,3-e]pyrimidin-7(8h)one heterocyclic compound and its synthesis method](https://images-eureka.patsnap.com/patent_img/535b188e-13f0-4d75-893f-d893d253843a/BDA0000918378950000021.png)

![2,3,5-position substituted imidazol[1,2-c]-thiophene[2,3-e]pyrimidin-7(8h)one heterocyclic compound and its synthesis method 2,3,5-position substituted imidazol[1,2-c]-thiophene[2,3-e]pyrimidin-7(8h)one heterocyclic compound and its synthesis method](https://images-eureka.patsnap.com/patent_img/535b188e-13f0-4d75-893f-d893d253843a/BDA0000918378950000022.png)

![2,3,5-substituted imidazole[1,2-c]-thiophene[2,3-e]-7(8H)keto heterocyclic compound and synthetic method thereof 2,3,5-substituted imidazole[1,2-c]-thiophene[2,3-e]-7(8H)keto heterocyclic compound and synthetic method thereof](https://images-eureka.patsnap.com/patent_img/9271843e-aa32-4696-b5b1-56f0e17bfd38/BDA0000918378950000011.PNG)

![2,3,5-substituted imidazole[1,2-c]-thiophene[2,3-e]-7(8H)keto heterocyclic compound and synthetic method thereof 2,3,5-substituted imidazole[1,2-c]-thiophene[2,3-e]-7(8H)keto heterocyclic compound and synthetic method thereof](https://images-eureka.patsnap.com/patent_img/9271843e-aa32-4696-b5b1-56f0e17bfd38/BDA0000918378950000021.PNG)

![2,3,5-substituted imidazole[1,2-c]-thiophene[2,3-e]-7(8H)keto heterocyclic compound and synthetic method thereof 2,3,5-substituted imidazole[1,2-c]-thiophene[2,3-e]-7(8H)keto heterocyclic compound and synthetic method thereof](https://images-eureka.patsnap.com/patent_img/9271843e-aa32-4696-b5b1-56f0e17bfd38/BDA0000918378950000022.PNG)