Unsaturated polyester resin for molding compound of auto parts and manufacturing method thereof

A polyester resin and auto parts technology, applied in the field of unsaturated polyester resin, can solve the problems of controlling the shrinkage rate of the product to the expected value, the high price of isophthalic acid, and the poor quality of orthophthalic acid, etc. , to achieve the effects of reduced shrinkage, high exothermic peak temperature, and increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

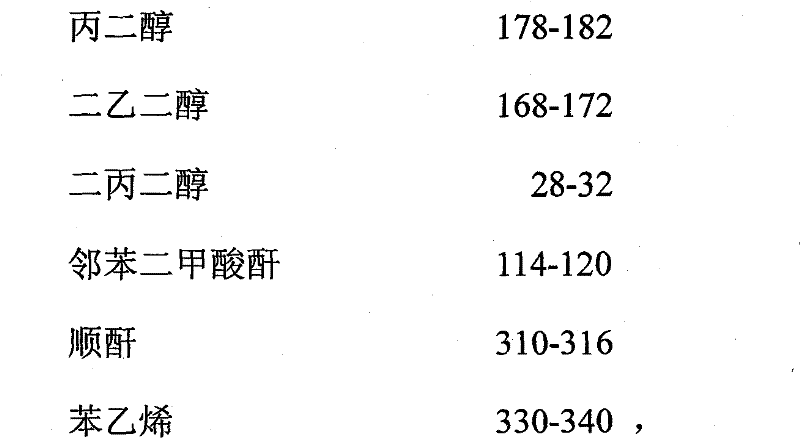

[0032] Synthesize the unsaturated polyester resin used for auto parts molding compound according to the following raw materials and production method, the specific formula of raw materials is:

[0033] Propylene glycol 181g

[0034] Diethylene glycol 170g

[0035] Dipropylene glycol 31g

[0036] Phthalic anhydride 119g

[0037] Maleic anhydride 311g

[0038] Styrene 330g;

[0039] The concrete synthetic steps are:

[0040] (1) Add propylene glycol, diethylene glycol and phthalic anhydride in the 1000ml four-necked bottle;

[0041] (2) Stir and heat up to effluent, control the temperature of the distillation head to not exceed 103°C, and the reaction temperature to not exceed 190°C until the acid value is 30-40mgKOH / g;

[0042] (3) After cooling down to 160°C, add dipropylene glycol and maleic anhydride;

[0043] (4) Continue to heat up, control the head temperature below 103°C, and the reaction temperature below 200°C until the acid value of the reactant is less than 30...

Embodiment 2

[0047] Adopt the method for making as described in embodiment 1 to synthesize the unsaturated polyester resin that is used for auto parts molding compound, the concrete formula of raw material is:

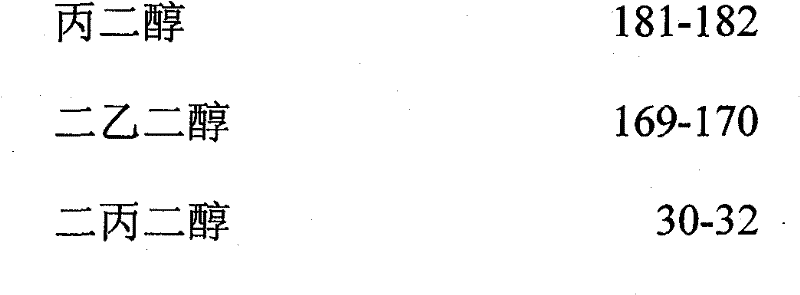

[0048] Propylene glycol 182g

[0049] Diethylene glycol 169g

[0050] Dipropylene glycol 30g

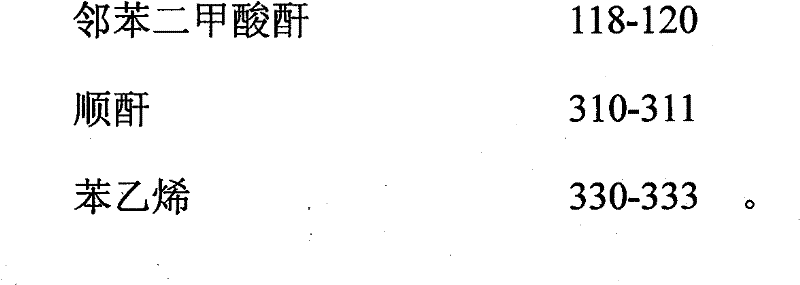

[0051] Phthalic anhydride 120g

[0052] Maleic anhydride 310g

[0053] Styrene 333g

[0054] The resin that embodiment 1,2 makes has following table characteristic:

[0055]

Embodiment 3

[0057] Adopt the method for making as described in embodiment 1 to synthesize the unsaturated polyester resin that is used for auto parts molding compound, the concrete formula of raw material is:

[0058] Propylene glycol 178g

[0059] Diethylene glycol 171g

[0060]Dipropylene glycol 29g

[0061] Phthalic anhydride 118g

[0062] Maleic anhydride 316g

[0063] Styrene 335g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com