Porous covalent triazine framework hollow microsphere as well as preparation method and application thereof

A technology of covalent triazine and framework, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. The ball is not an independent hollow structure, etc., to achieve the effect of flexible and controllable preparation method, low collapse rate, and high photocatalytic hydrogen production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

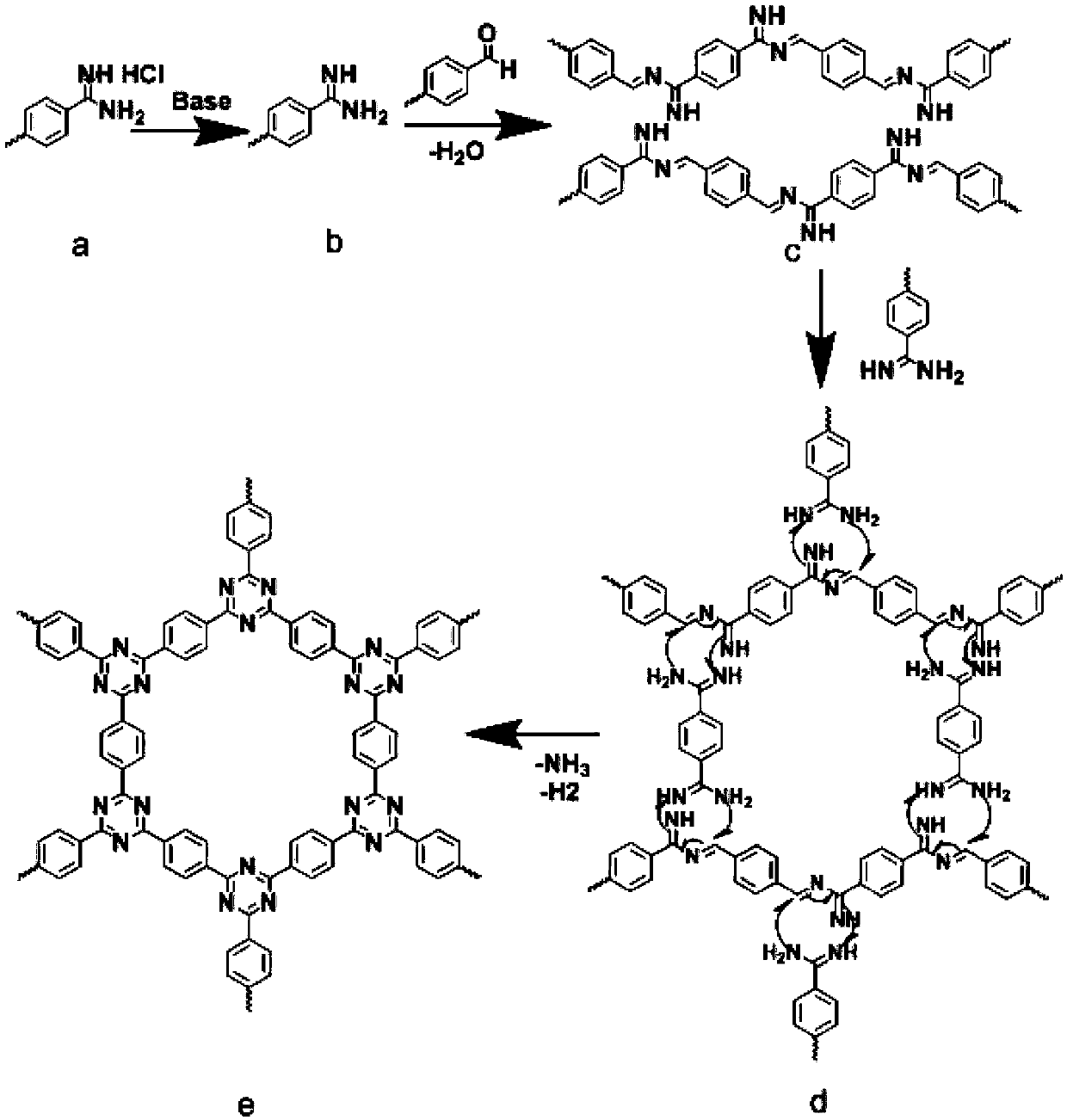

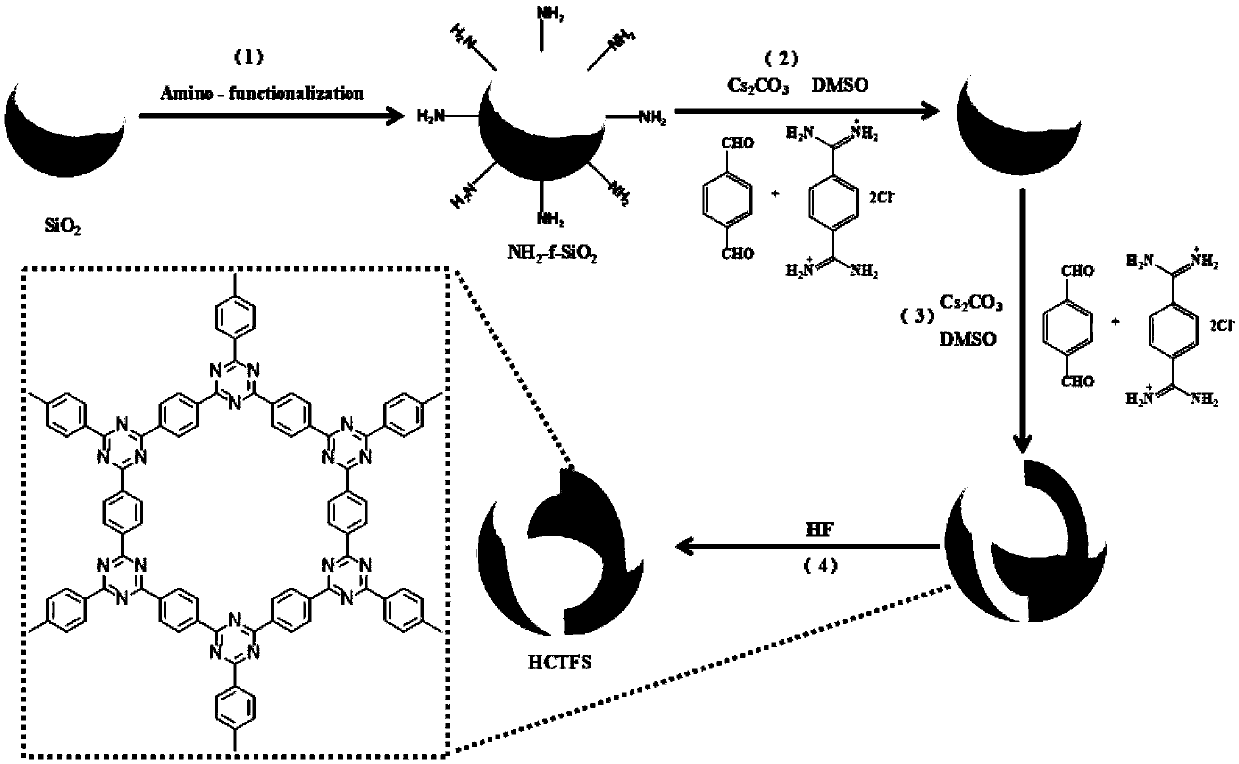

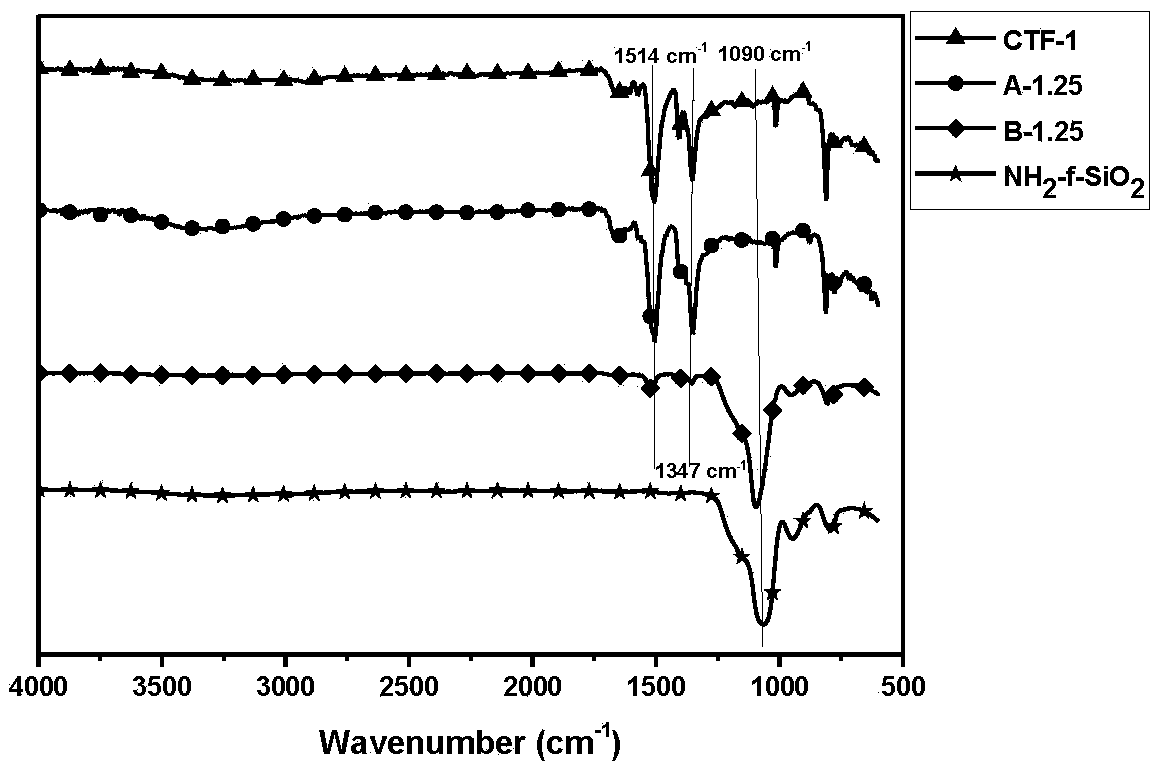

[0052] The preparation method of the porous covalent triazine framework hollow microsphere provided by the invention comprises the following steps:

[0053] (1) Preparation of seed core-shell structure: Mix binary or polyaldehyde or benzyl alcohol monomers with binary or polyamidino monomers, and disperse them in the template suspension. In the presence of a catalyst, the monomers The polycondensation reaction occurs according to the stoichiometric molar ratio, the polycondensation reaction occurs between the aldehyde functional group and amidino functional group according to 1:2, the polycondensation reaction between benzyl alcohol functional group and amidino functional group also occurs according to 1:2, control the reaction temperature, and prepare the seeds after the reaction A suspension of a core-shell structure; the shell layer of the seed core-shell structure is a prepolymer of a binary or multiple aldehyde or benzyl alcohol monomer and a binary or multiple amidine mon...

Embodiment 1

[0074] Prepare porous covalent triazine framework hollow microspheres, according to figure 2 The schematic diagram of the steps shown:

[0075] Prepare the target product according to the following steps

[0076] (1) Preparation of a suspension with amino-modified silica as a template with a concentration of 12.5g / L

[0077] Dissolve 1.25g of amino-modified silica in 100ml of dimethyl sulfoxide, and sonicate at room temperature until uniformly dispersed;

[0078] (2) Preparation of prefabricated seed suspension

[0079] Dissolve 0.008g of terephthalaldehyde in the above solution respectively, and stir at 100°C for 12h;

[0080] Then add 0.028g of amidine salt and 0.120g of cesium carbonate to the above reaction system respectively, and react at 100°C for 12h respectively;

[0081] (3) Preparation of the target core-shell structure complex

[0082] Add 0.0592g of terephthalaldehyde to the suspension prepared in step (2), and react at 100°C for 12h;

[0083] Then add 0.20...

Embodiment 2

[0097] Prepare the target product according to the following steps

[0098] (1) Prepare a suspension with amino-modified silica as a template with a concentration of 7.5g / L

[0099] Dissolve 0.75g of amino-modified silica in 100ml of dimethyl sulfoxide, and sonicate at room temperature until uniformly dispersed;

[0100] (2) Preparation of prefabricated seed suspension

[0101] Dissolve 0.008g of terephthalaldehyde in the above solution respectively, and stir at 100°C for 12h;

[0102] Then add 0.028g of amidine salt and 0.120g of cesium carbonate to the above reaction system respectively, and react at 100°C for 12h respectively;

[0103] Add 0.0592g of terephthalaldehyde to the suspension prepared in step (2), and react at 100°C for 12h;

[0104] Then add 0.2072g of amidine and 0.580g of cesium carbonate to the above reaction system, and react at 100°C for 12h.

[0105] (3) post-processing

[0106] First wash 2 times with deionized water, each time for 4-5 hours, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com