Method for preparing red mud building material product based on compound microorganism technology

A microbial technology and composite microbial technology, applied in the field of red mud building materials, can solve problems such as red mud pollution, and achieve the effects of extending the industrial chain, reducing land occupation problems, and improving the rate of hydration reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

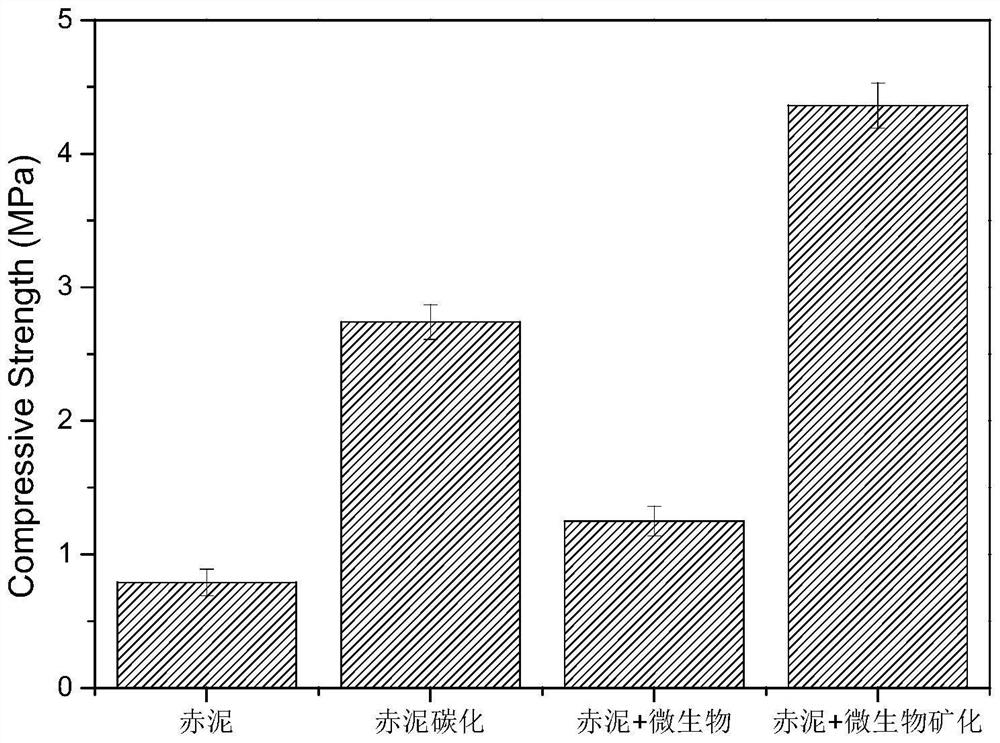

Image

Examples

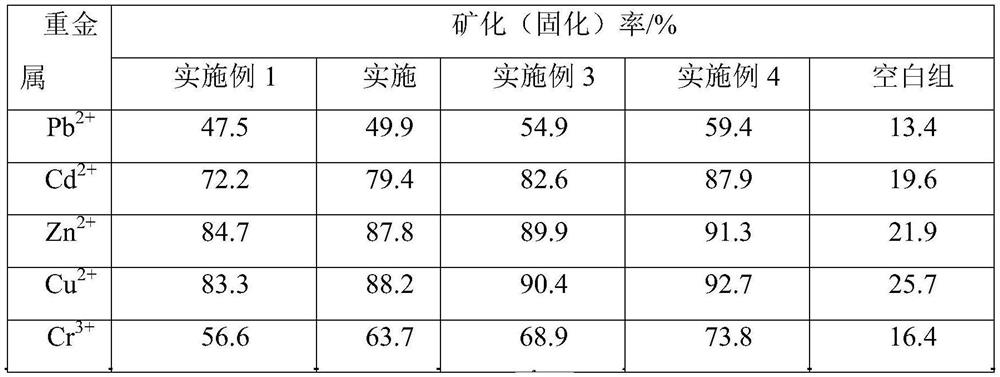

Embodiment 1

[0026] The method for preparing red mud building material products based on composite microbial technology comprises the following steps:

[0027] 1) Mix red mud and steel slag according to the ratio in Table 1 to obtain a composite cementitious material;

[0028] 2) mixing Bacillus colloidus, Bacillus subtilis and Bacillus acetic acid in a mass ratio of 1:1:1 to 2:1:1 to obtain a composite microorganism;

[0029] 3) According to the ratio in Table 1, add composite cementitious material, water, sand and composite microorganisms and mix thoroughly, stir evenly to obtain a slurry, then pour the slurry into a mold and vibrate to form it to obtain a test piece;

[0030] 4) Put the test piece in an environment with a relative humidity of 60% and a temperature of 20°C for 30 hours to remove the mold to obtain a sample, place the sample in an environment with a relative humidity of 98% and a temperature of 20°C for standard curing for 3 days, and put it in a relative The red mud bui...

Embodiment 2

[0034] The method for preparing red mud building material products based on composite microbial technology comprises the following steps:

[0035] 1) Mix red mud and steel slag according to the ratio in Table 1 to obtain a composite cementitious material;

[0036] 2) mixing Bacillus colloidus, Bacillus subtilis and Bacillus acetic acid in a mass ratio of 1:1:1 to obtain a composite microorganism;

[0037] 3) According to the ratio in Table 1, add composite cementitious material, water, sand and composite microorganisms and mix thoroughly, stir evenly to obtain a slurry, then pour the slurry into a mold and vibrate to form it to obtain a test piece;

[0038] 4) Put the test piece in an environment with a relative humidity of 63% and a temperature of 22°C for 48 hours to remove the mold to obtain a sample, place the sample in an environment with a relative humidity of 99% and a temperature of 22°C for standard curing for 5 days, and put it in a relatively The red mud building m...

Embodiment 3

[0040] The method for preparing red mud building material products based on composite microbial technology comprises the following steps:

[0041] 1) Mix red mud and steel slag according to the ratio in Table 1 to obtain a composite cementitious material;

[0042] 2) mixing Bacillus colloidus, Bacillus subtilis and Bacillus acetic acid in a mass ratio of 2:1:1 to obtain a composite microorganism;

[0043] 3) According to the ratio in Table 1, add composite cementitious material, water, sand and composite microorganisms and mix thoroughly, stir evenly to obtain a slurry, then pour the slurry into a mold and vibrate to form it to obtain a test piece;

[0044] 4) Put the test piece in an environment with a relative humidity of 61% and a temperature of 18°C for 30 hours to remove the mold to obtain a sample, place the sample in an environment with a relative humidity of 96% and a temperature of 21°C for standard curing for 4 days, and put it in a relative The red mud building m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com