Preparation method of hydrophobic porous carbon material

A porous carbon material and hydrophobic technology, which is applied in the field of preparation of hydrophobic porous carbon materials, can solve problems such as failure to achieve pore-forming effect, and achieve the effects of facilitating pore-forming effect, increasing contact opportunities, and high activation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

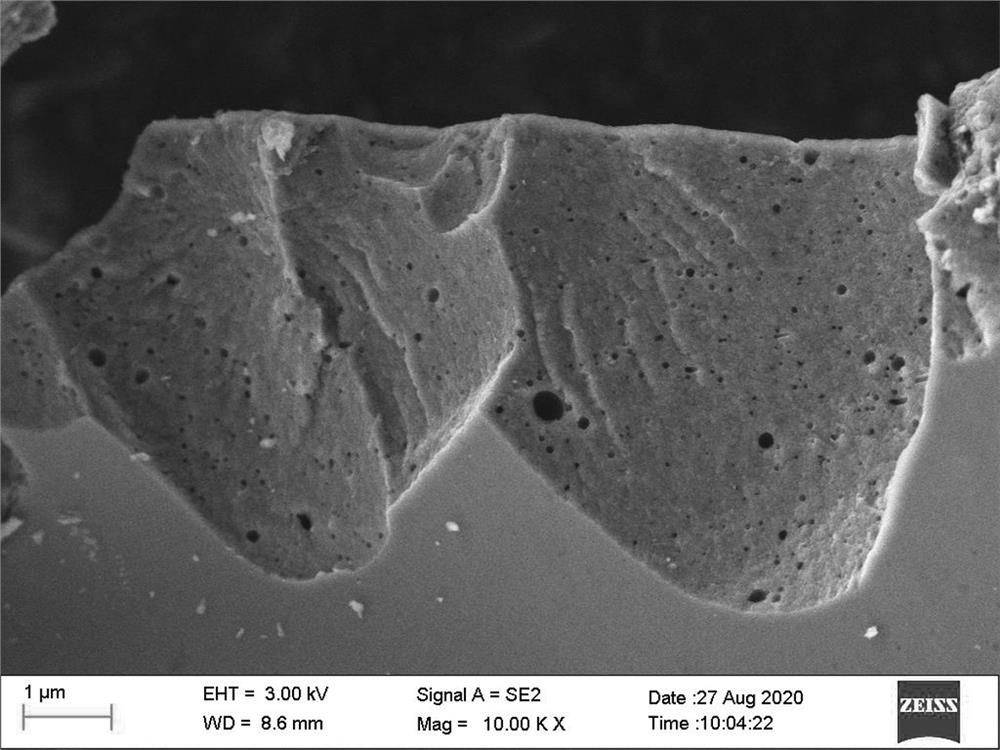

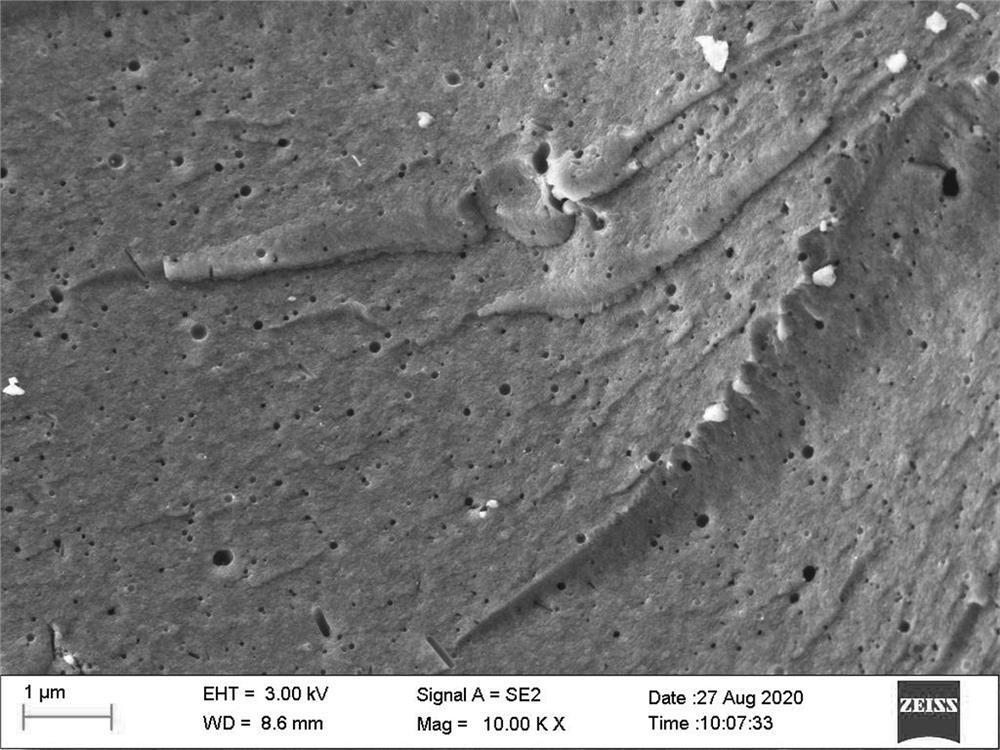

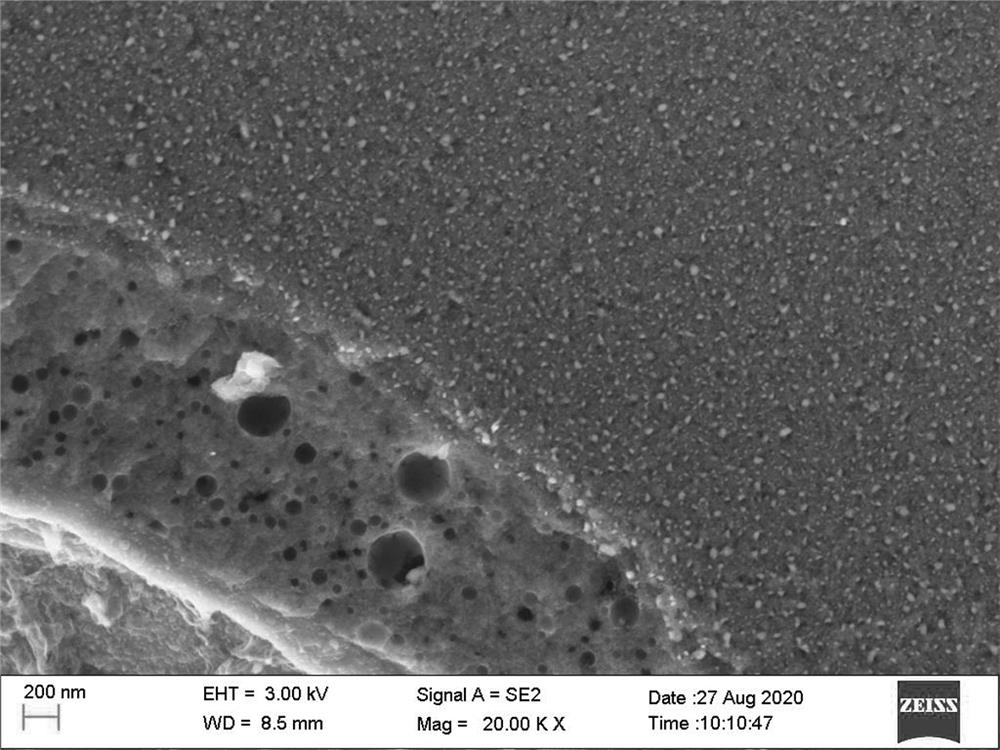

Image

Examples

Embodiment 1

[0036] The preparation method of the hydrophobic porous carbon material of the present embodiment comprises the following steps:

[0037] (1) Pre-emulsify 2g dimethyldivinylsilane, 40g styrene, 10g ethyl acrylate, 0.2g dodecyl glucoside, 0.2g Tween-80 and 60g deionized water in a four-necked flask , under a nitrogen atmosphere, the temperature was raised to 85°C, and 0.2g potassium persulfate aqueous solution (5% w / w) was slowly added dropwise for emulsion polymerization, and kept for 2 hours to obtain silicopropylbenzene latex (SSAL);

[0038] (2) Dissolve 8g of oxalic acid (OA) in 35mL of absolute ethanol to prepare OA solution;

[0039] (3) Mix 40g of SSAL with all the OA solution, stir for 12 hours to form a new emulsion system, and dry at 50°C for 24 hours to obtain a resin matrix (PSO);

[0040] (4) Under an inert atmosphere, the PSO was raised to 700°C at 10°C / min in a tube furnace, and then kept for 1h to obtain a porous carbon product, which was ground to obtain a hy...

Embodiment 2

[0042] The preparation method of the hydrophobic porous carbon material of the present embodiment comprises the following steps:

[0043] (1) Put 3g dimethyl divinyl silane, 40g styrene, 10g butyl acrylate, 0.8g sodium lauryl sulfate, 0.4g polyoxyethylene octylphenol ether-10 and 100g deionized water in four Pre-emulsify in a flask with an argon gas atmosphere, raise the temperature to 88°C, slowly add 0.4g potassium persulfate aqueous solution (5% w / w) dropwise for emulsion polymerization, keep warm for 4 hours, and obtain silicopropylbenzene latex (SSAL);

[0044] (2) Dissolve 10g of oxalic acid (OA) in 40mL of absolute ethanol to prepare OA solution;

[0045](3) Mix 20g of SSAL with all the OA solution, stir for 12 hours to form a new emulsion system, and dry at 70°C for 30 hours to obtain a resin matrix (PSO);

[0046] (4) Under an inert atmosphere, the PSO was raised to 800°C at a rate of 10°C / min in a tube furnace, and then kept for 2 hours to obtain a porous carbon pro...

Embodiment 3

[0048] The preparation method of the hydrophobic porous carbon material of the present embodiment comprises the following steps:

[0049] (1) Put 4g dimethyldivinylsilane, 40g styrene, 10g isooctyl acrylate, 0.8g sodium lauryl sulfate, 0.5g polyoxyethylene octylphenol ether-10 and 100g deionized water in Pre-emulsify in a four-necked flask, raise the temperature to 85°C under a nitrogen atmosphere, slowly add 0.3g potassium persulfate aqueous solution (5% w / w) dropwise for emulsion polymerization, and keep warm for 4 hours to obtain silicopropylbenzene latex (SSAL);

[0050] (2) Dissolve 20g of oxalic acid (OA) in 80mL of absolute ethanol to prepare OA solution;

[0051] (3) Mix 20g of SSAL with all the OA solution, stir for 24 hours to form a new emulsion system, and dry at 80°C for 30 hours to obtain a resin matrix (PSO);

[0052] (4) Under an inert atmosphere, the PSO was raised to 850°C at a rate of 10°C / min in a tube furnace, and then kept for 2 hours to obtain a porous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com