A kind of preparation method and application of calcium carbide slag super early strength admixture

A technology of calcium carbide slag and admixture, applied in the field of building materials, can solve the problems of high production cost of crystal nuclei, complicated process, and coarse crystal growth of hydration products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The specific embodiment of the preparation method of the calcium carbide slag ultra-early strength admixture of the present invention will be provided below. In this specific embodiment, the carbide slag used is from each calcium carbide method for producing acetylene, and the wet mill used is a vertical planetary ball mill, including steps:

[0036] (1) Take 20-60 parts by mass of carbide slag and 0.5-1 part by mass of dispersant, add 80-160 parts by mass of water, mix and stir, and sieve to obtain calcium carbide slag slurry with a particle size of less than 1 mm. The dispersant is used to avoid the aggregation of carbide slag, and specifically, triethanolamine and / or diethanolamine can be used. The solid content of carbide slag used in the present invention is 30% to 95%, and its main mineral component is calcium hydroxide, wherein the calcium oxide content is more than 75%, the silicon oxide content is more than 3%, and the alumina content is more than 1%.

[0037] ...

Embodiment 1

[0048] The concrete steps of this embodiment are as follows:

[0049] (1) 35 parts by mass of carbide slag, 0.8 part by mass of diethanolamine dispersant and 120 parts by mass of water are mixed, stirred and sieved to obtain a calcium carbide slag slurry with a diameter of less than 1 mm, and the solid content of the used carbide slag is 90%.

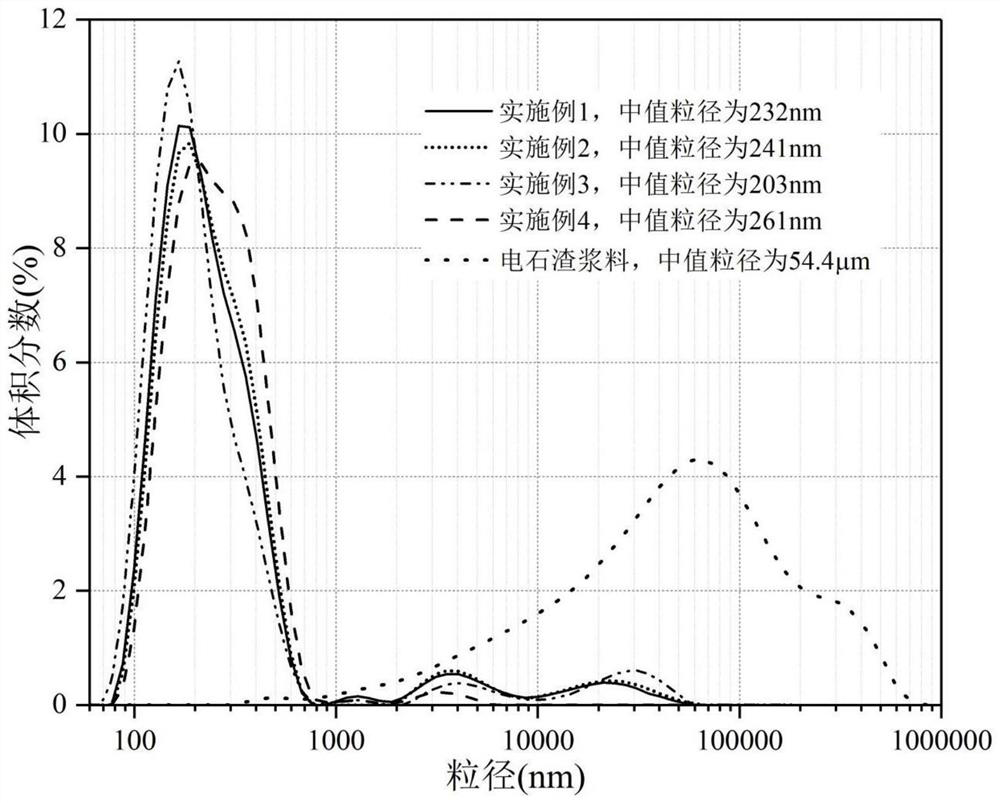

[0050] (2) The calcium carbide slag slurry is mixed with propylene glycol grinding aid, polycarboxylate plasticizer and 300 parts by mass of zirconia balls, placed in a wet mill and ground to a median particle size of 232 nm and a specific surface area of 26560 m 2 / kg, sieve the grinding medium to obtain calcium carbide slag ultrafine slurry. Among them, the dosage of propylene glycol grinding aid is 1‰ of the solid content of calcium carbide slag in the calcium carbide slag slurry, and the dosage of polycarboxylate plasticizer is 17‰ of the solid content of calcium carbide slag in the calcium carbide slag slurry. The ball ratio is ...

Embodiment 2

[0055] The concrete steps of this embodiment are as follows:

[0056] (1) 35 parts by mass of carbide slag, 1 part by mass of diethanolamine dispersant and 90 parts by mass of water are mixed, stirred and sieved to obtain a calcium carbide slag slurry with a diameter of less than 1 mm, and the solid content of the used carbide slag is 90%.

[0057] (2) The calcium carbide slag slurry is mixed with propylene glycol grinding aid, polycarboxylate plasticizer and 300 parts by mass of zirconia balls, placed in a wet mill and ground to a median particle size of 241 nm (specific surface area is 25680 mm m 2 / kg), sieving the grinding medium to obtain calcium carbide slag ultrafine slurry. Among them, the dosage of propylene glycol grinding aid is 1‰ of the solid content of calcium carbide slag in the calcium carbide slag slurry, and the dosage of polycarboxylate plasticizer is 23‰ of the solid content of calcium carbide slag in the calcium carbide slag slurry. The ball ratio is 4:1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com