Patents

Literature

38results about How to "Raise regeneration temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for catalytic conversion of heavy oil and device thereof

ActiveCN1664074ARaise the preheat temperaturePromote atomizationTreatment with plural serial stages onlyCatalytic transformationPtru catalyst

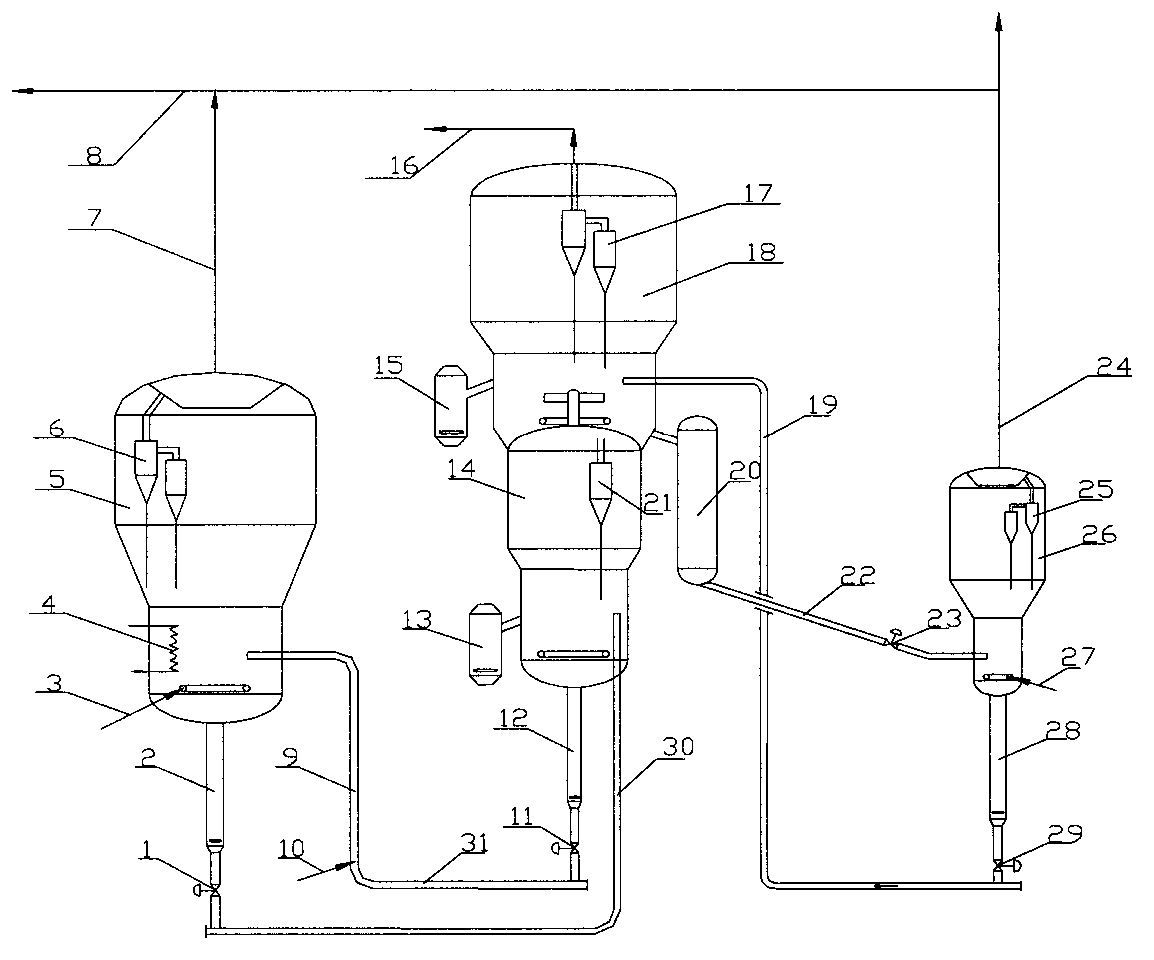

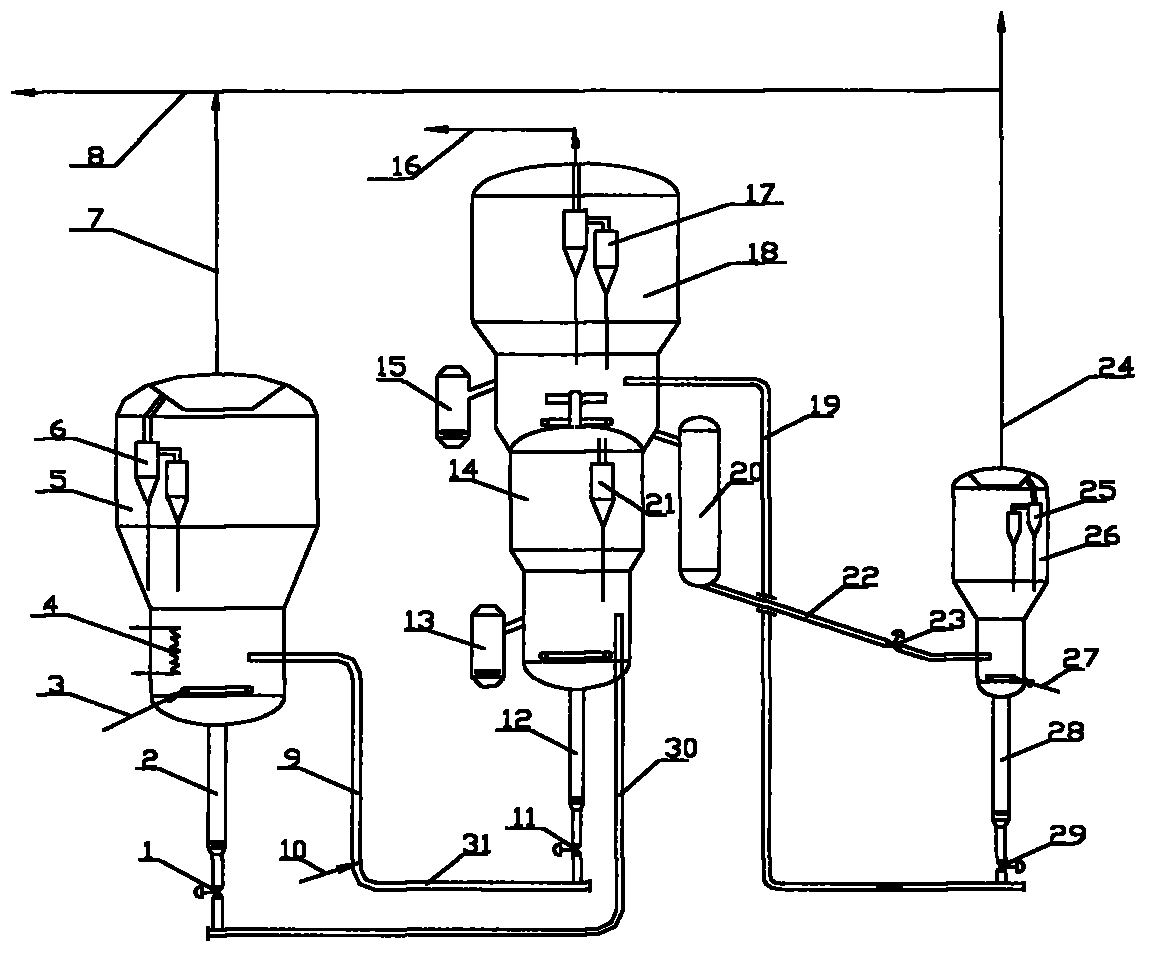

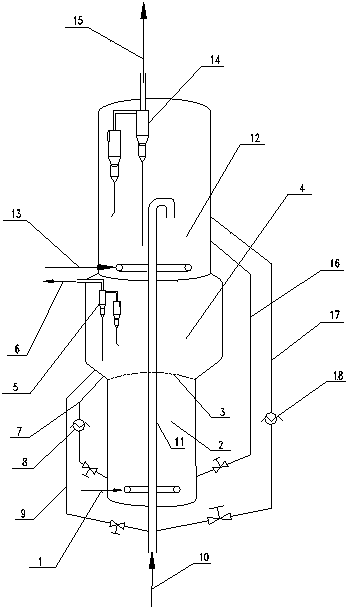

The invention provides a method of heavy raw material catalytic conversion and the device, comprising: the heavy hydrocarbon raw material passing through the first and second reaction area of the raiser reactor and contacting with catalyst for first reaction and second reaction, the reactants entering into the settler for the separation of catalyst and oil gas, steam stripping the separated catalyst through stripping section and introducing it to the reactivator for carbon burning reactivation, the reactivated catalyst returning to the raiser reactor after cooled or directly to the raiser reactor for reuse. After the heavy oil passing through the device said above, the volume content of olefin decreases by 10~40%, octane value increases 0.5~1 units, sulfur content in petrol decreases 10~30% by weight. After the poor petrol passing through the device said above, the volume content of olefin decreases by 10~60%, octane value increases 0.5~40 units, sulfur content in petrol decreases 10~50% by weight.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

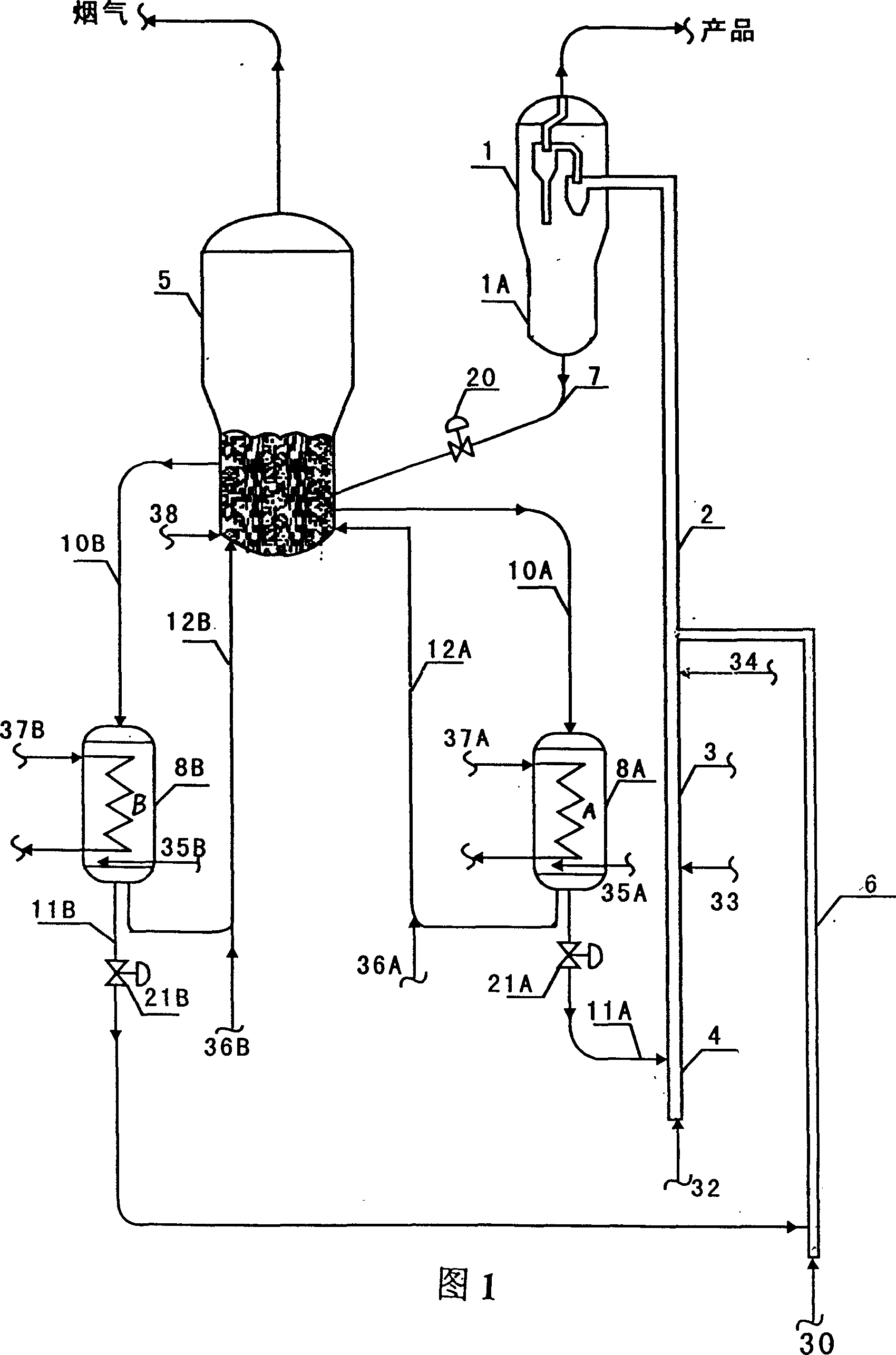

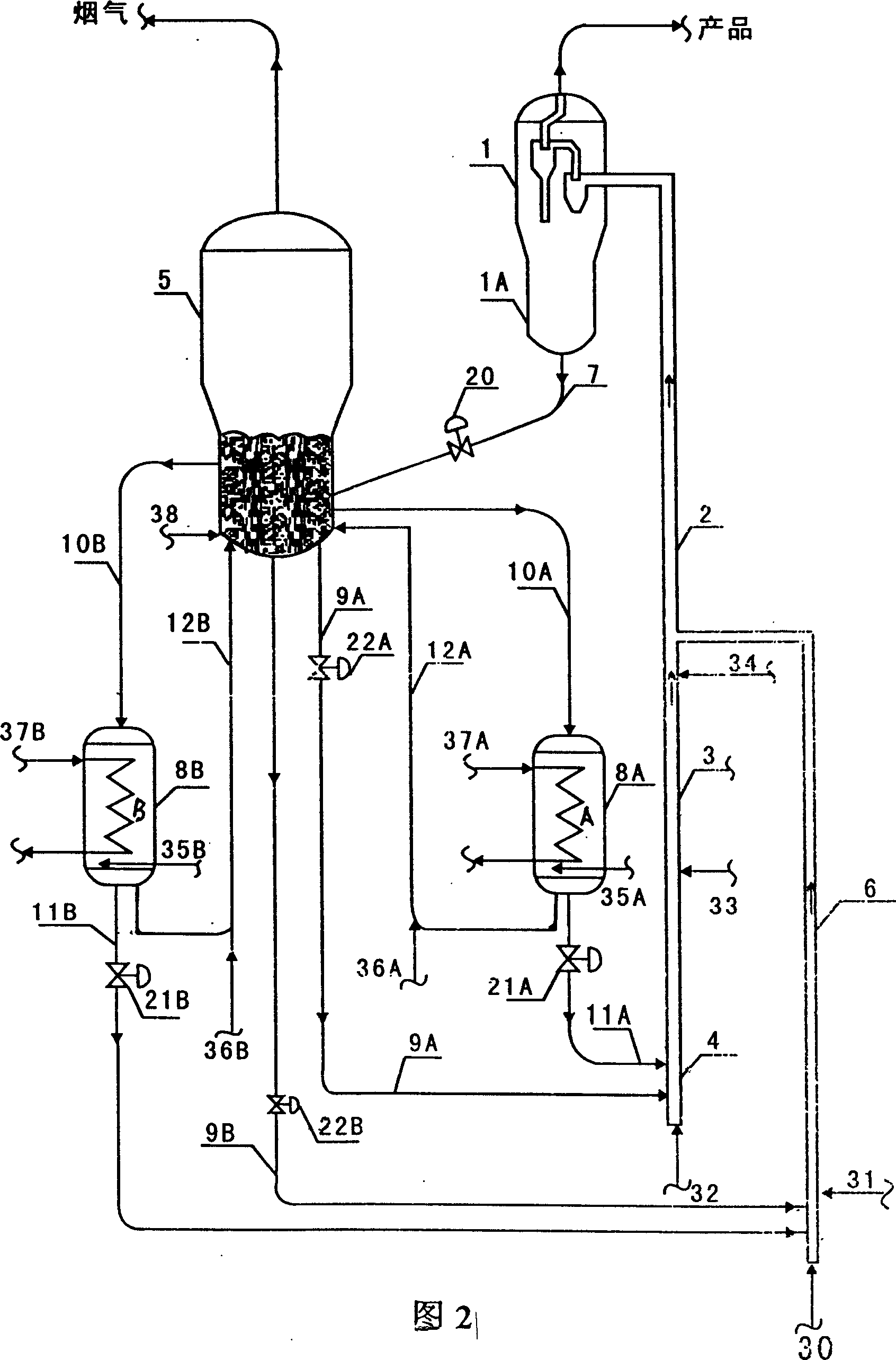

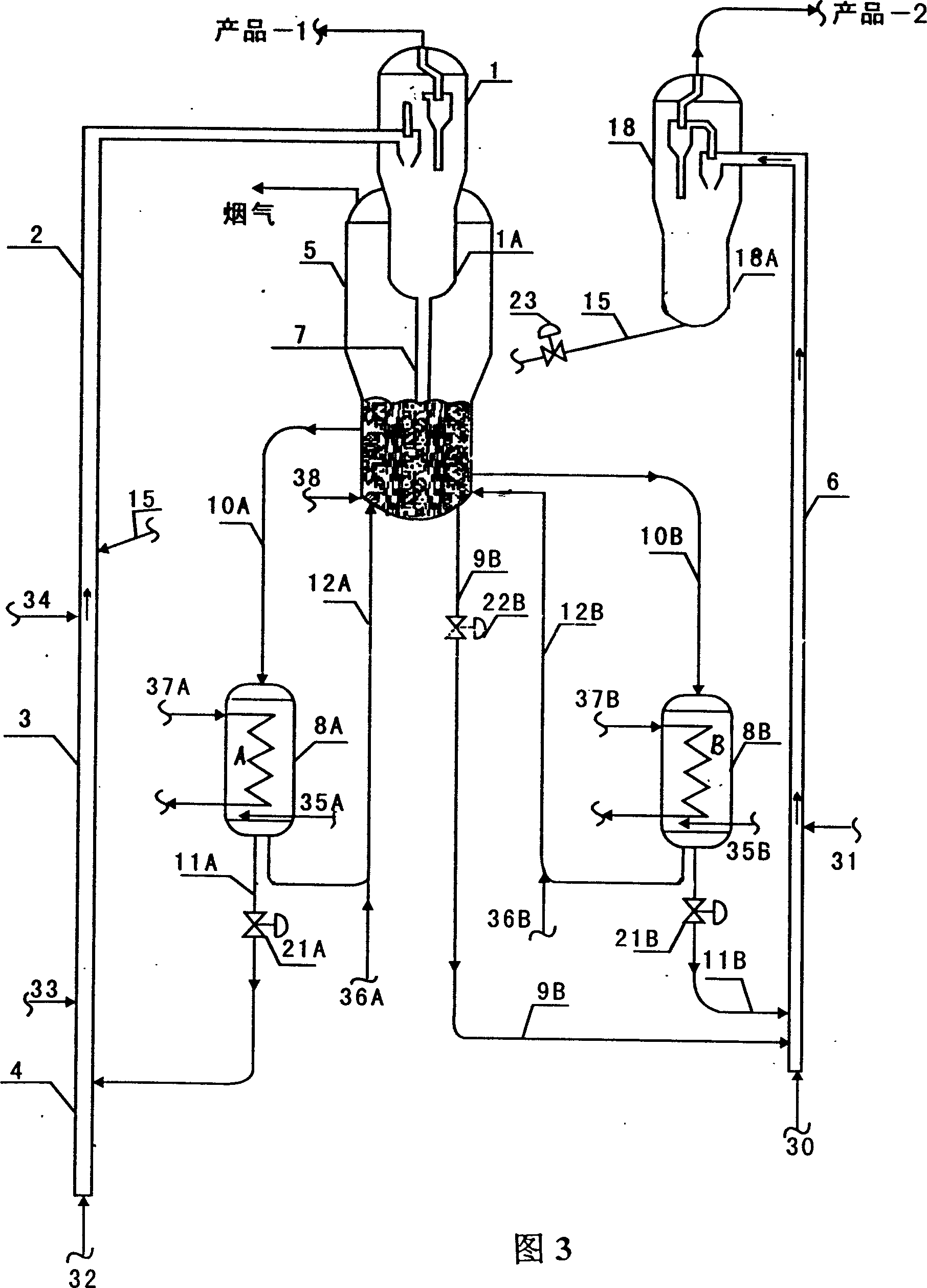

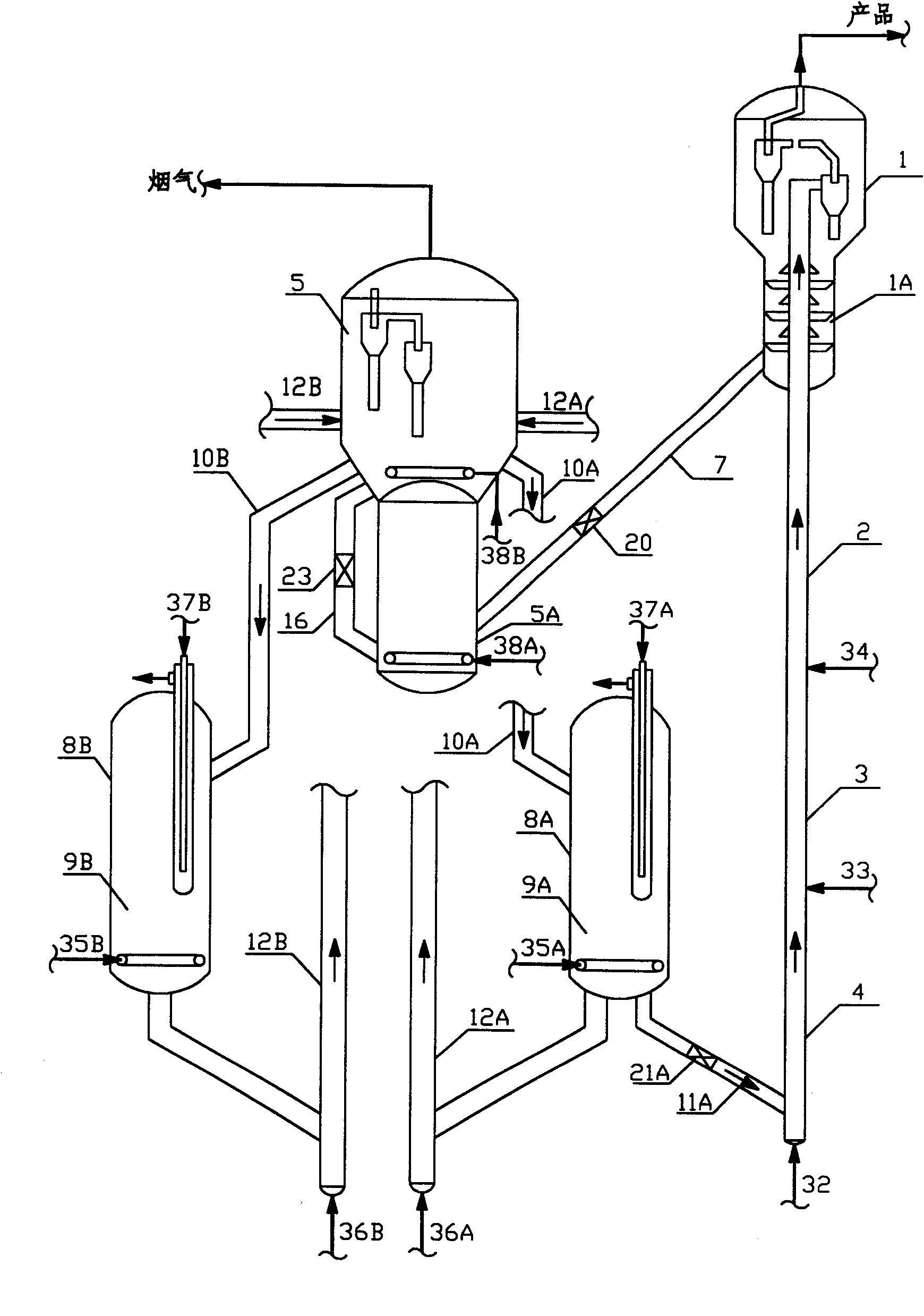

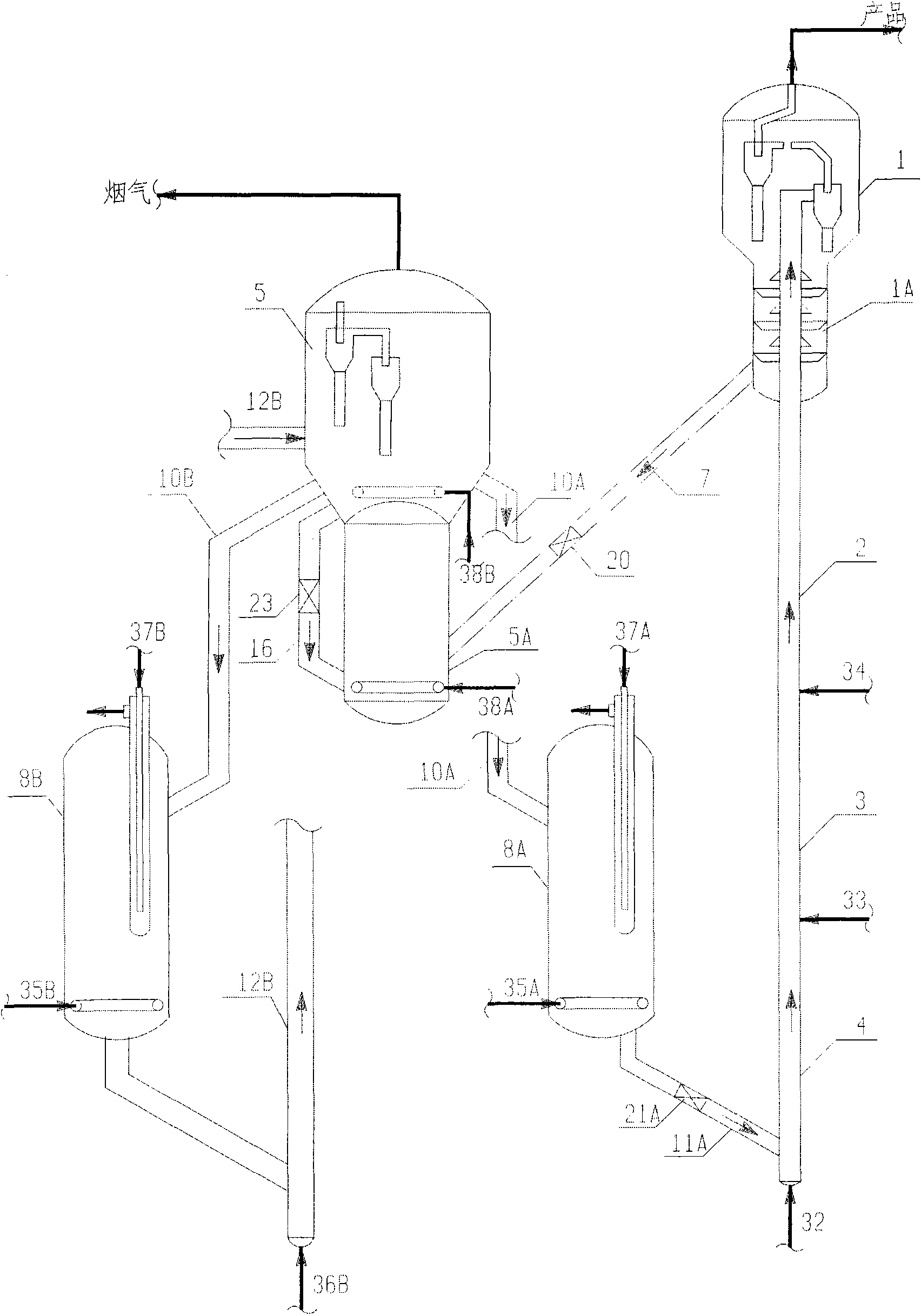

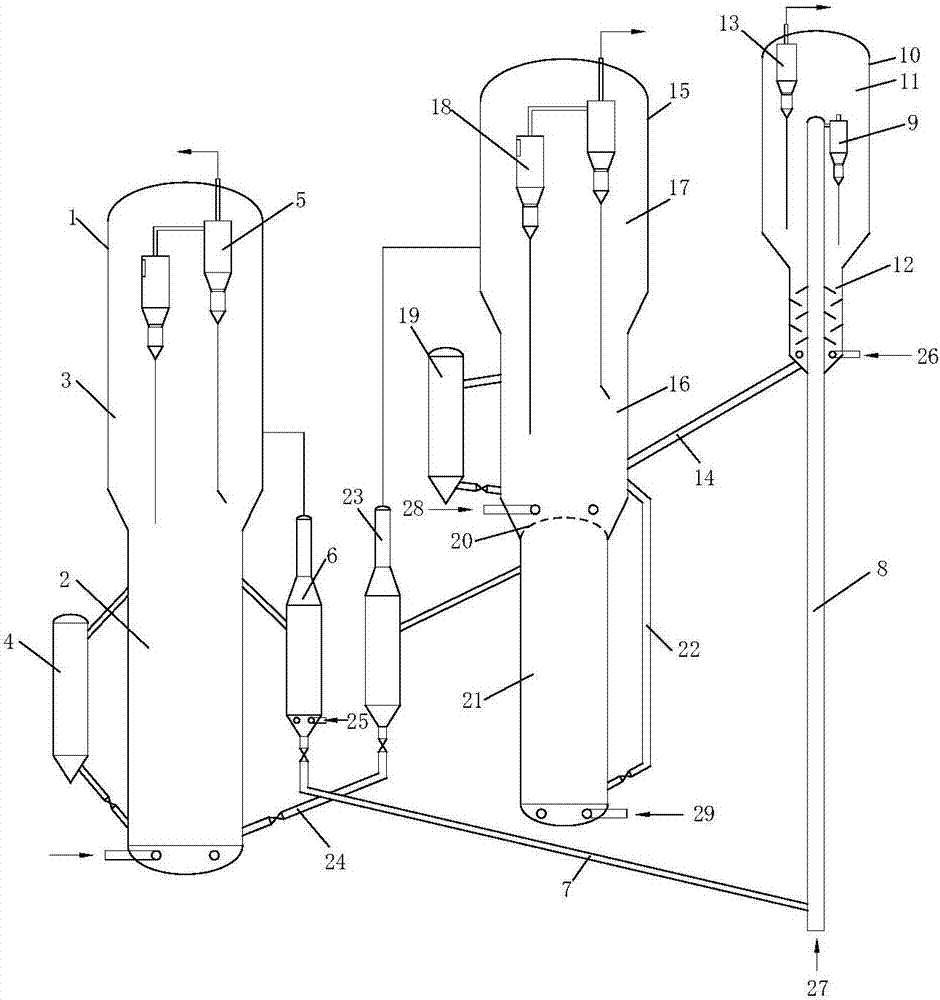

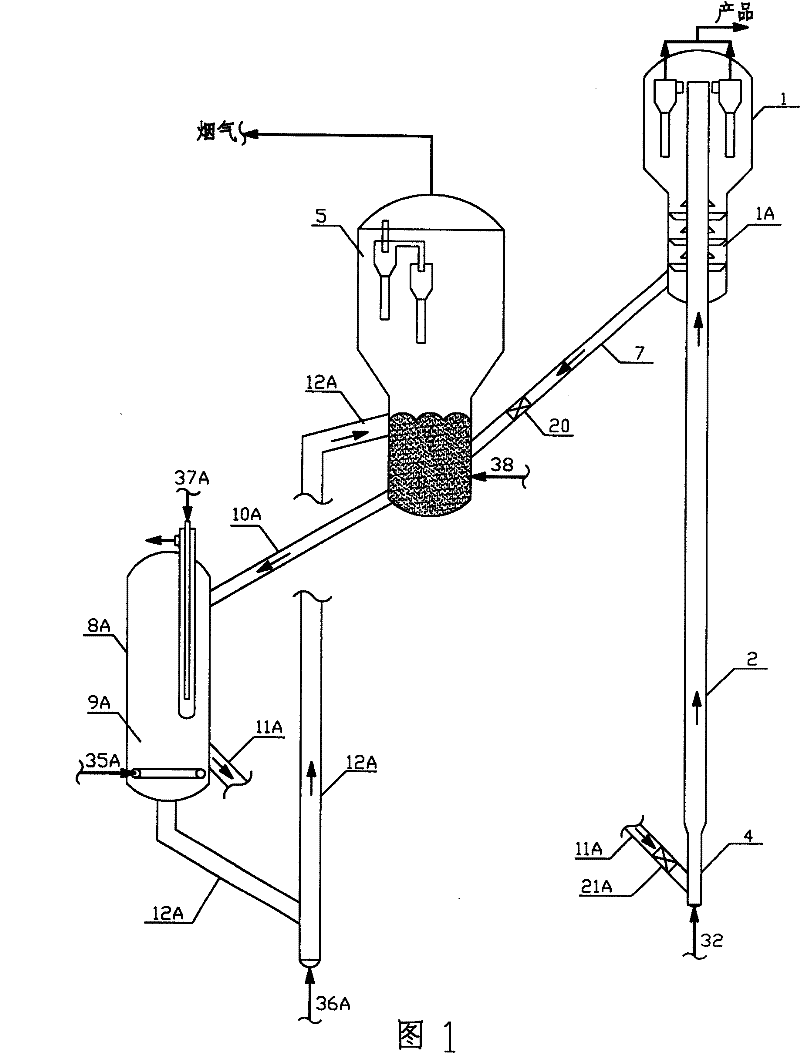

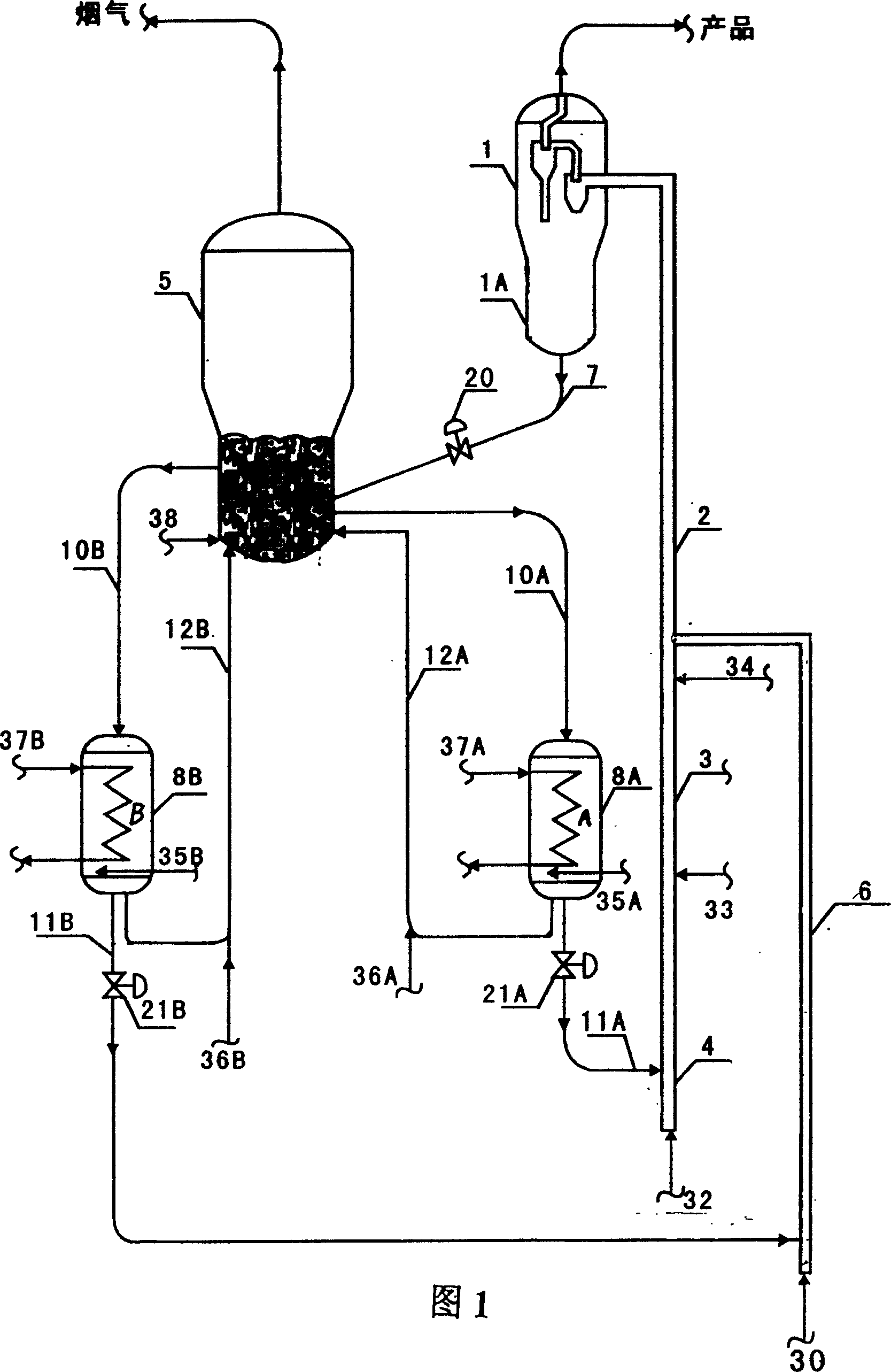

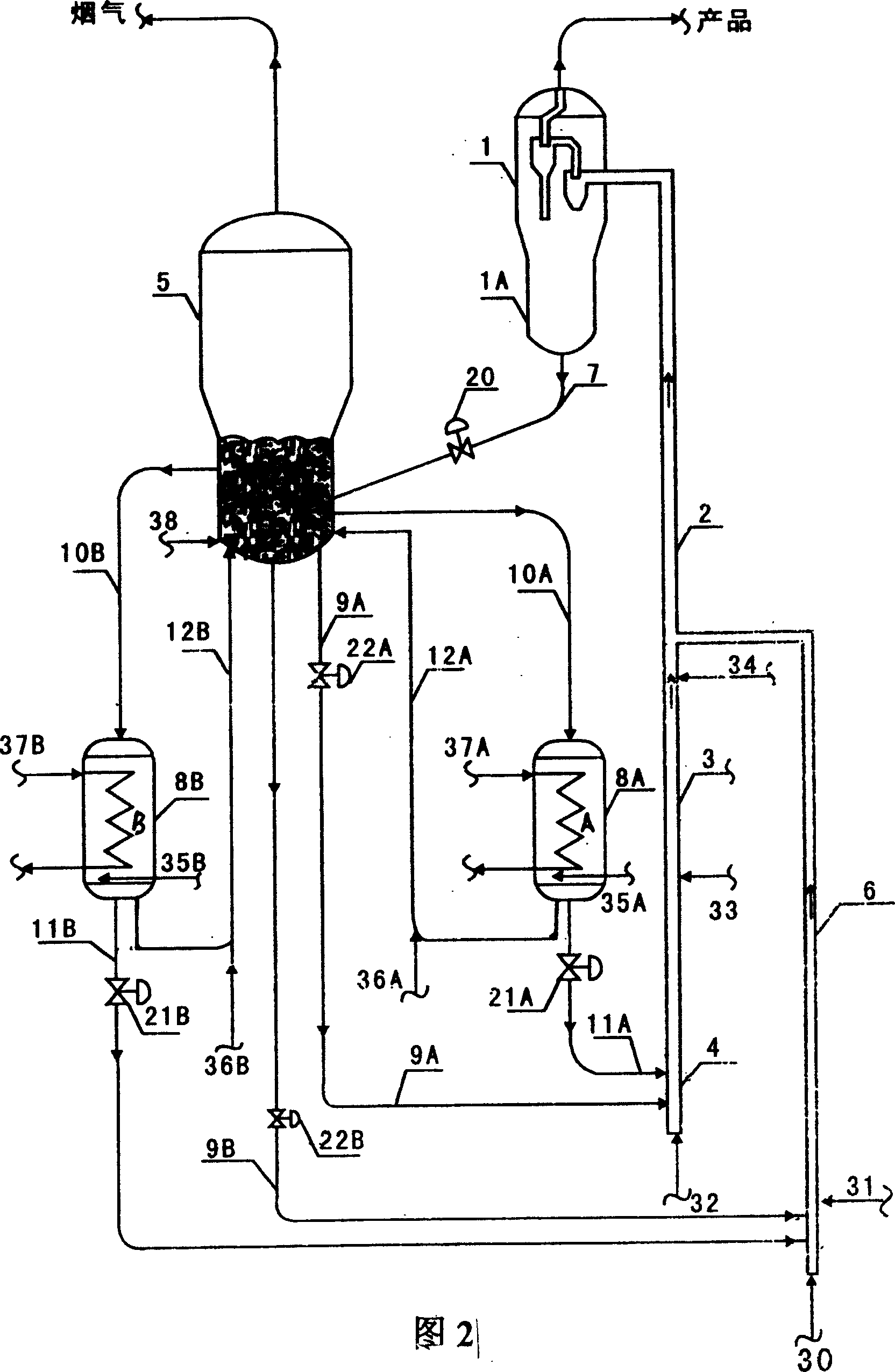

Method and device for circulating cold regenerated catalyst

The invention provides a method for circulating a cold regenerated catalyst and application thereof. A regenerated catalyst from a regenerator is cooled by a catalyst cooler to between 200 and 720DEGC, and is not mixed with a hot regenerated catalyst to directly enter a riser reactor, or is mixed with another part of uncooled hot regenerated catalyst into a mixed regenerated catalyst of which thetemperature is not lower than that of the regenerator to enter the riser reactor; and a hydrocarbon raw material undergoes contact reaction with the catalyst in the riser reactor, the reaction material flow enters a settler for the separation of the catalyst and oil gas, the separated catalyst to be regenerated is subjected to steam stripping in a steam stripping section, and then enters the regenerator for coke burning regeneration, and the regenerated catalyst is cooled and returns to the riser reactor for recycling. The method for circulating the cold regenerated catalyst has wide application, can be used for various fluid catalytic cracking processes comprising resid fluid catalytic cracking, wax oil catalytic cracking, gasoline catalytic conversion upgrading and the like, and also can be sued for other gas-solid reaction processes comprising residual oil pretreatment, fluid coking and the like.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

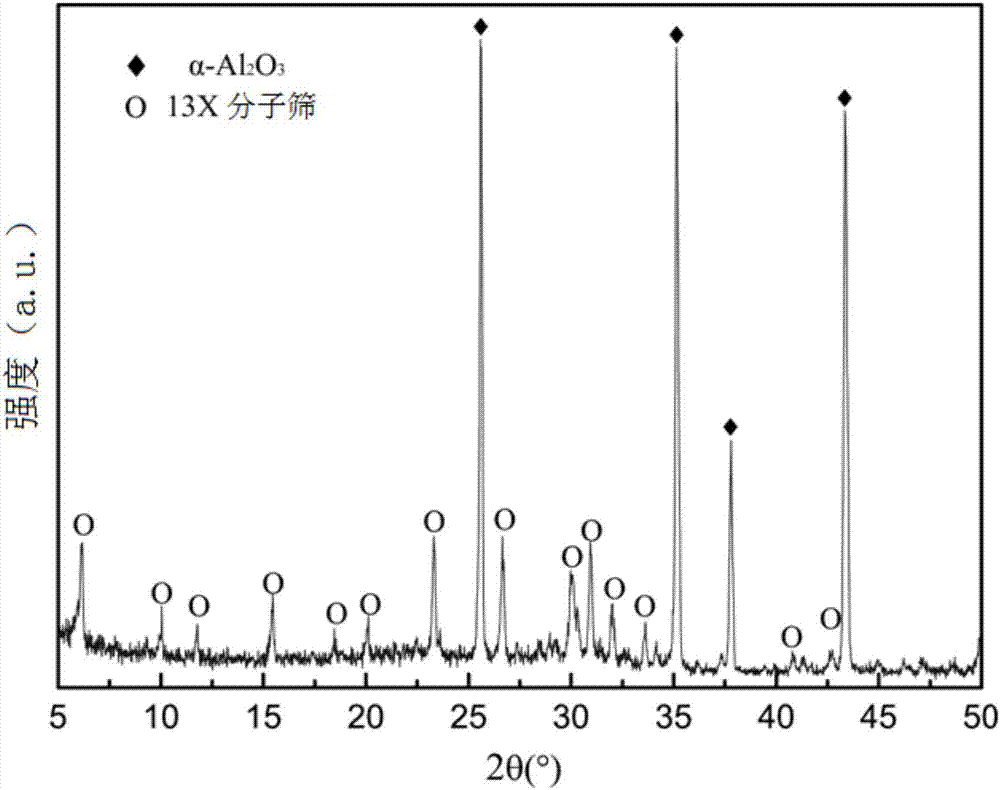

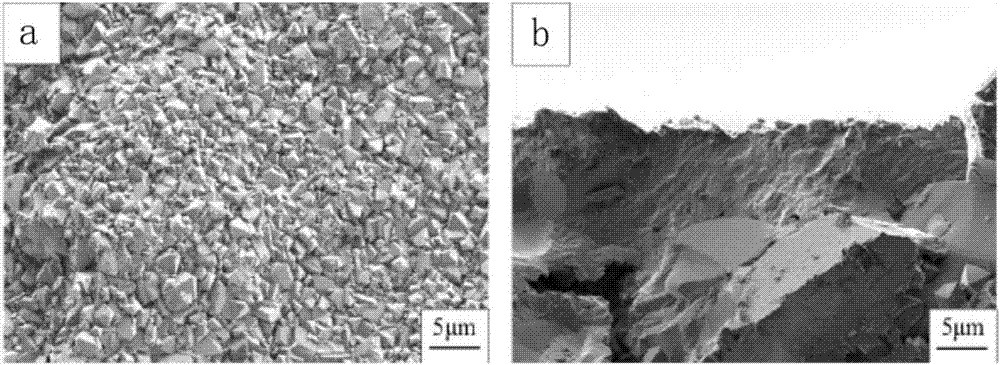

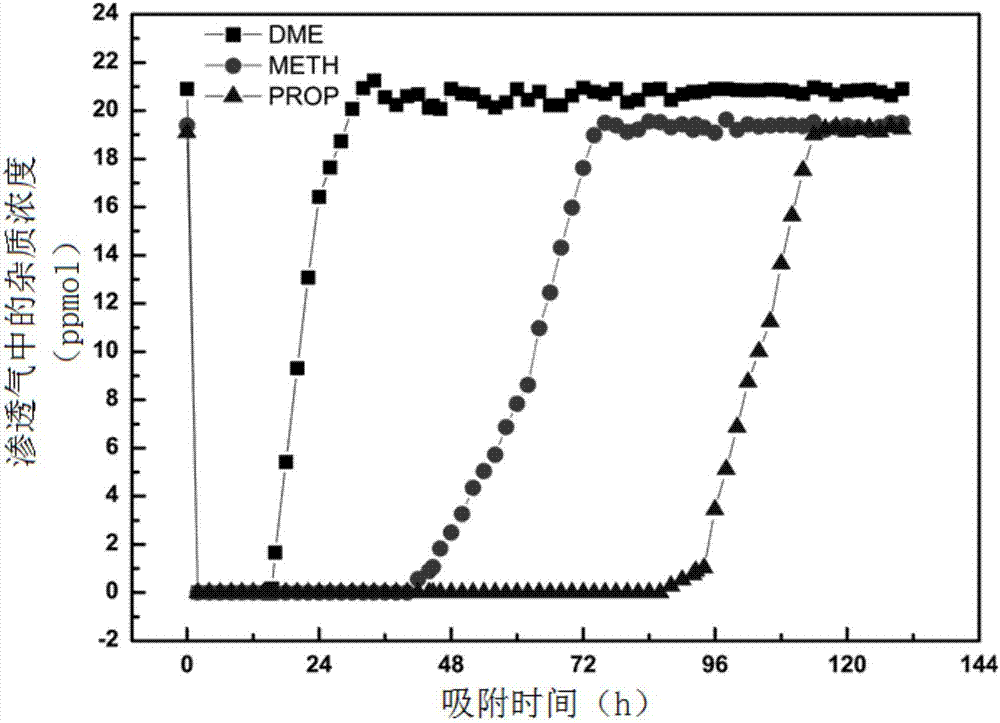

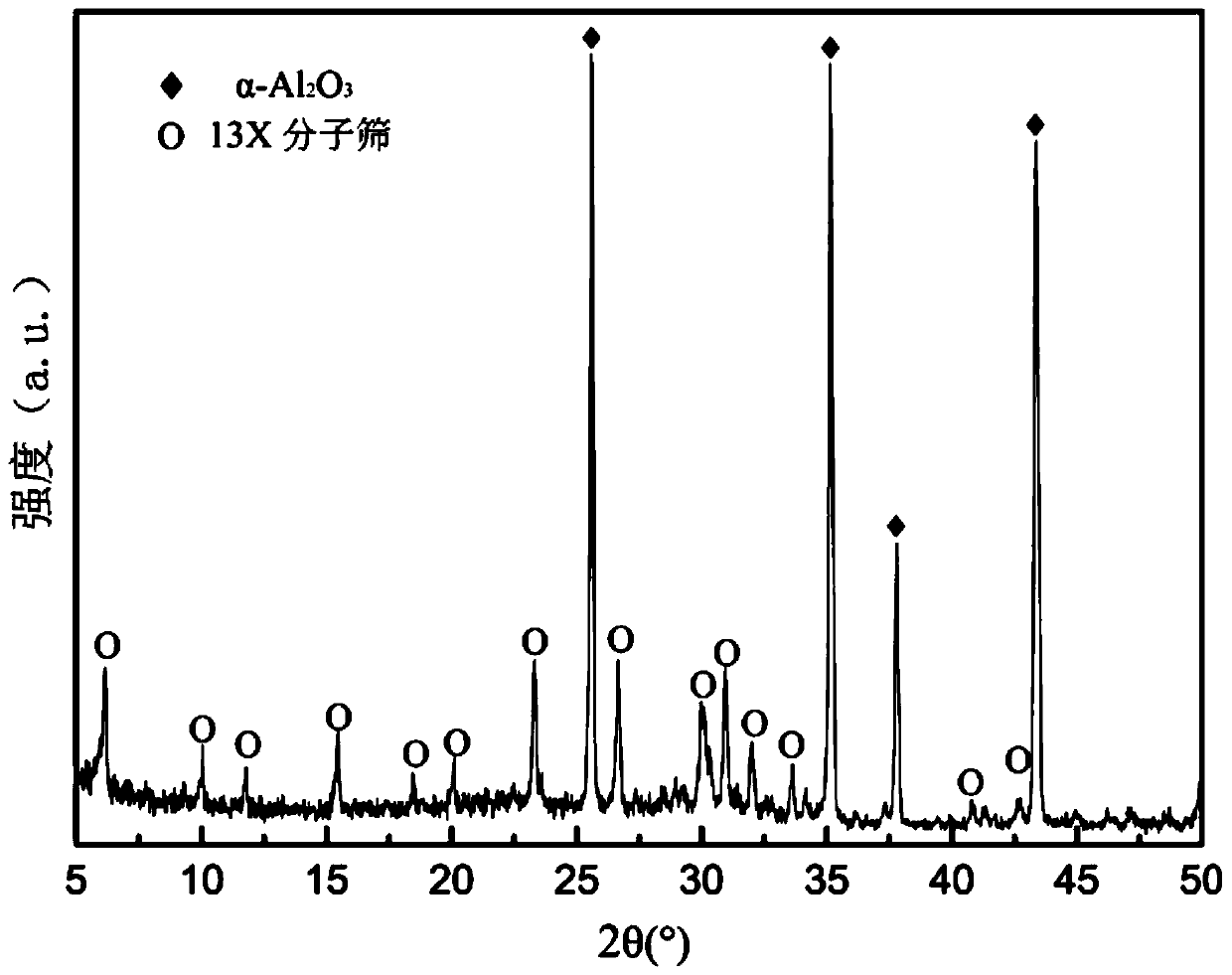

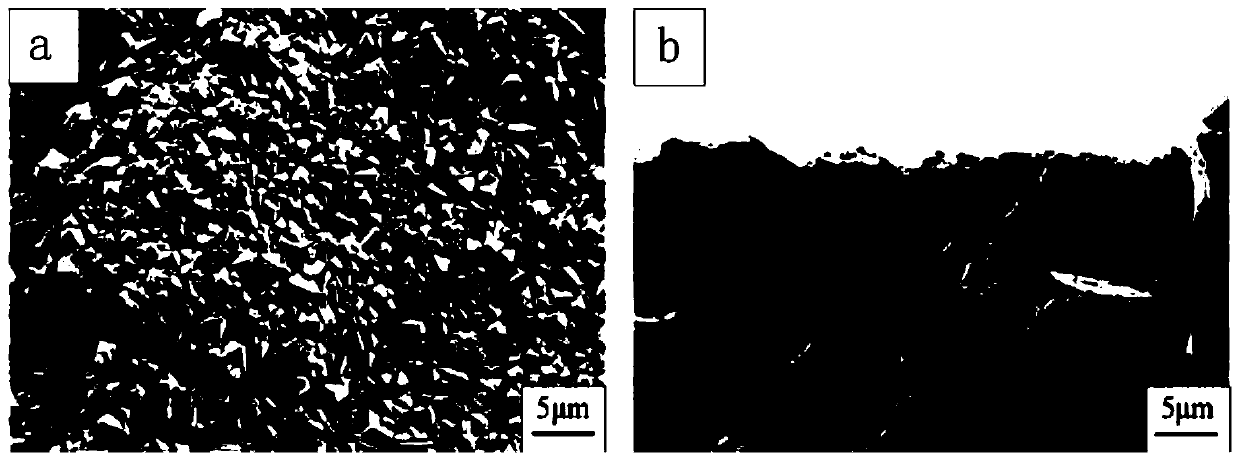

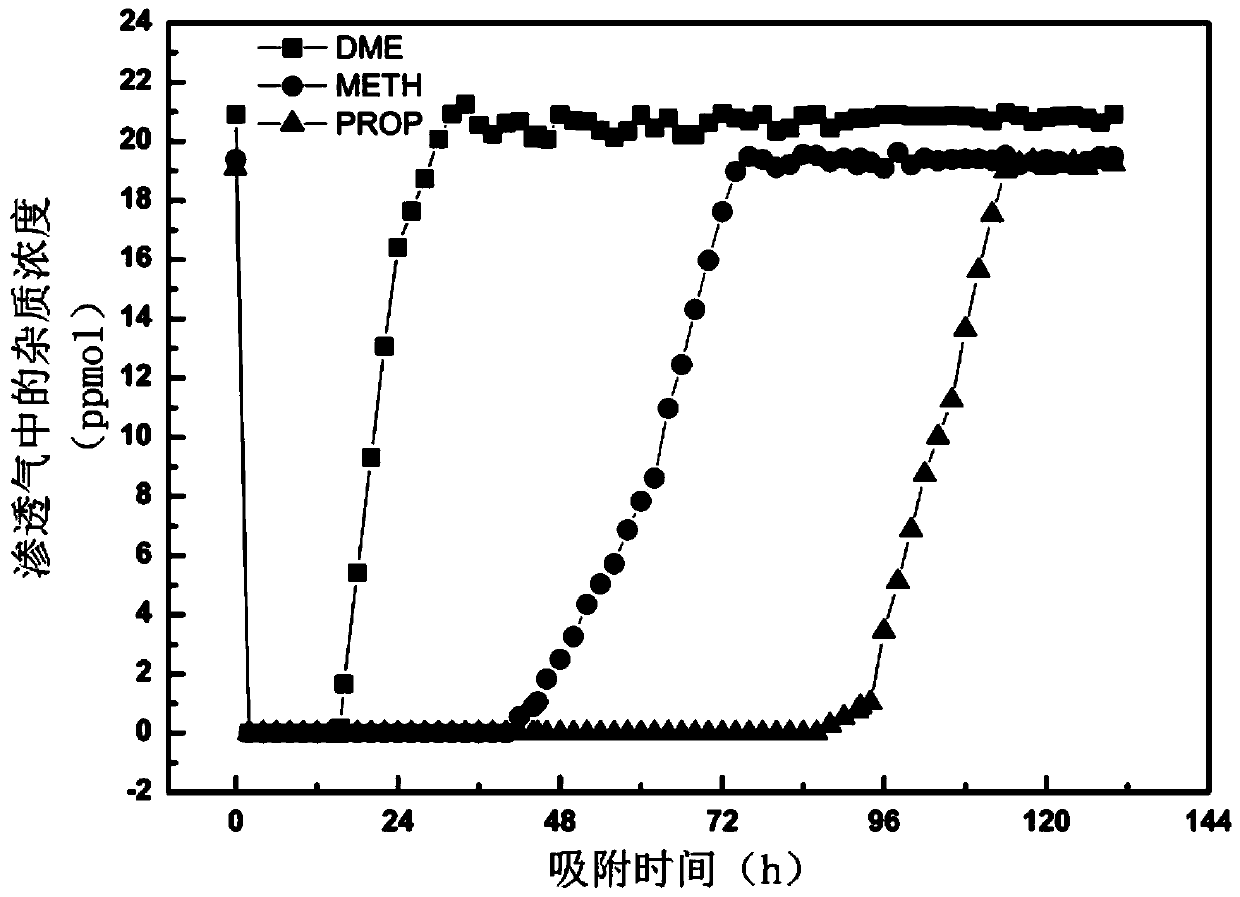

Molecular sieve ceramic membrane material for olefin purification as well as preparation method and application of molecular sieve ceramic membrane material

ActiveCN107970781AReduce mass transfer resistanceReduce energy consumptionSemi-permeable membranesOther chemical processesMolecular sieveBonding strength

The invention relates to a molecular sieve ceramic membrane material for olefin purification as well as a preparation method and application of the molecular sieve ceramic membrane material. In the molecular sieve ceramic membrane material, the particle sizes of molecular sieve particles supported on the surface of the ceramic material are 0.1-3 [mu]m, and the thickness of a molecular sieve layeris 3-5 [mu]m; during preparation, ceramic material pretreatment, molecular sieve seed crystal pre-coating and sealed crystallization are sequentially carried out; and the molecular sieve ceramic membrane material is used for removing a polar oxygenated compound in a gaseous olefin flow to be 1ppm or below. Compared with the prior art, the molecular sieve ceramic membrane material prepared by the preparation method of the invention has the molecular sieve layer with higher mechanical strength, larger specific surface area and uniform thickness, in addition, the molecular sieve layer has no longitudinal or horizontal cracks, has no air pores in the surface and is high in bonding strength and not easy to fall off; and when the polar oxygenated compound in the olefin flow is adsorbed, the purification depth is 1ppm or smaller, so that not only is the mass transfer resistance lower, but also the energy consumption is lower, and the regeneration capacity is high.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

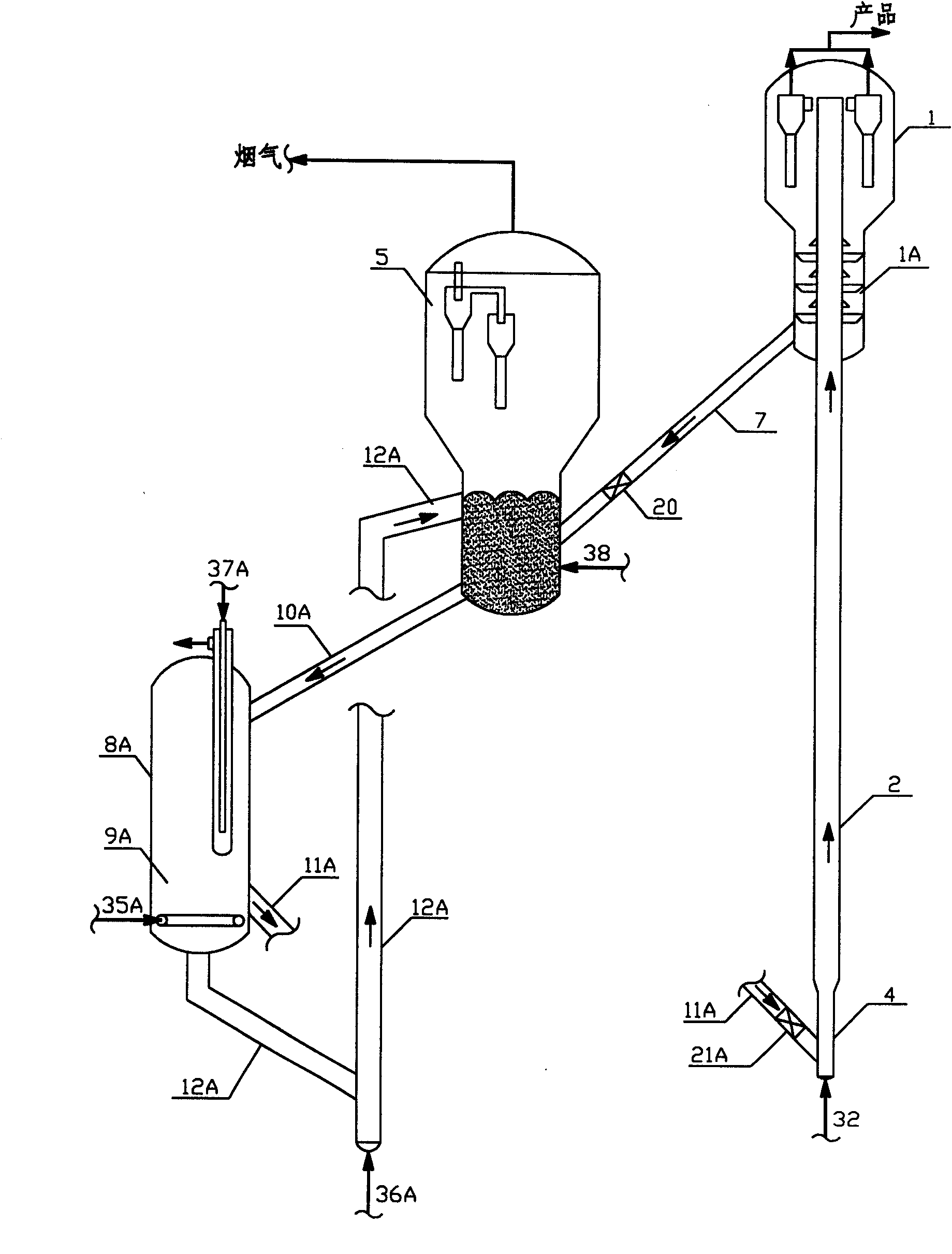

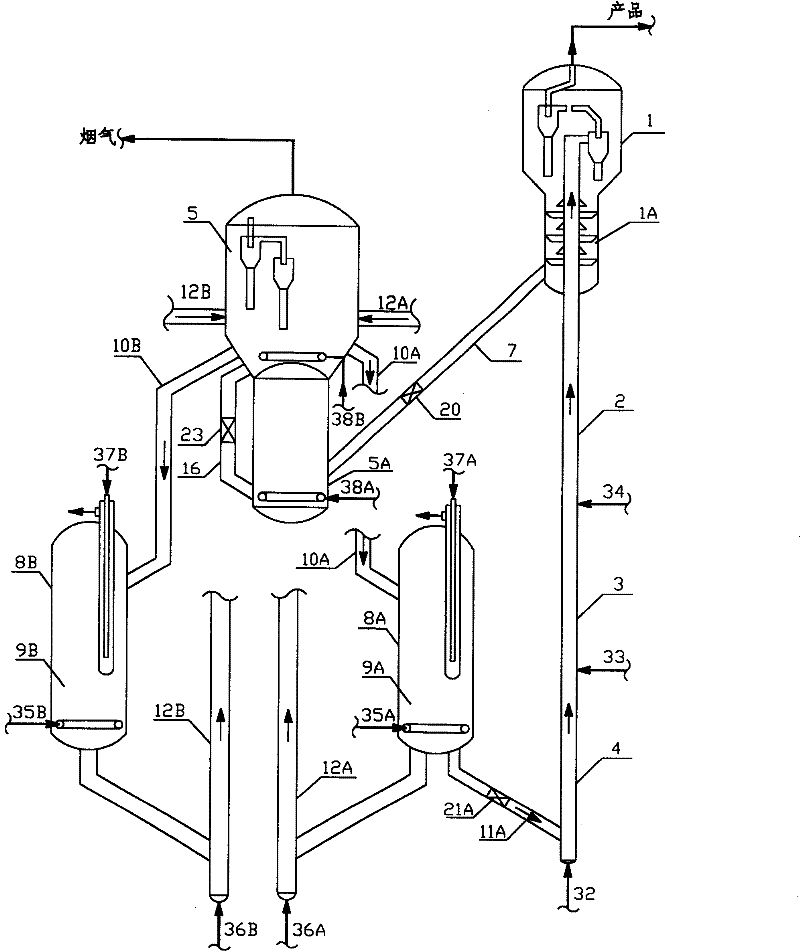

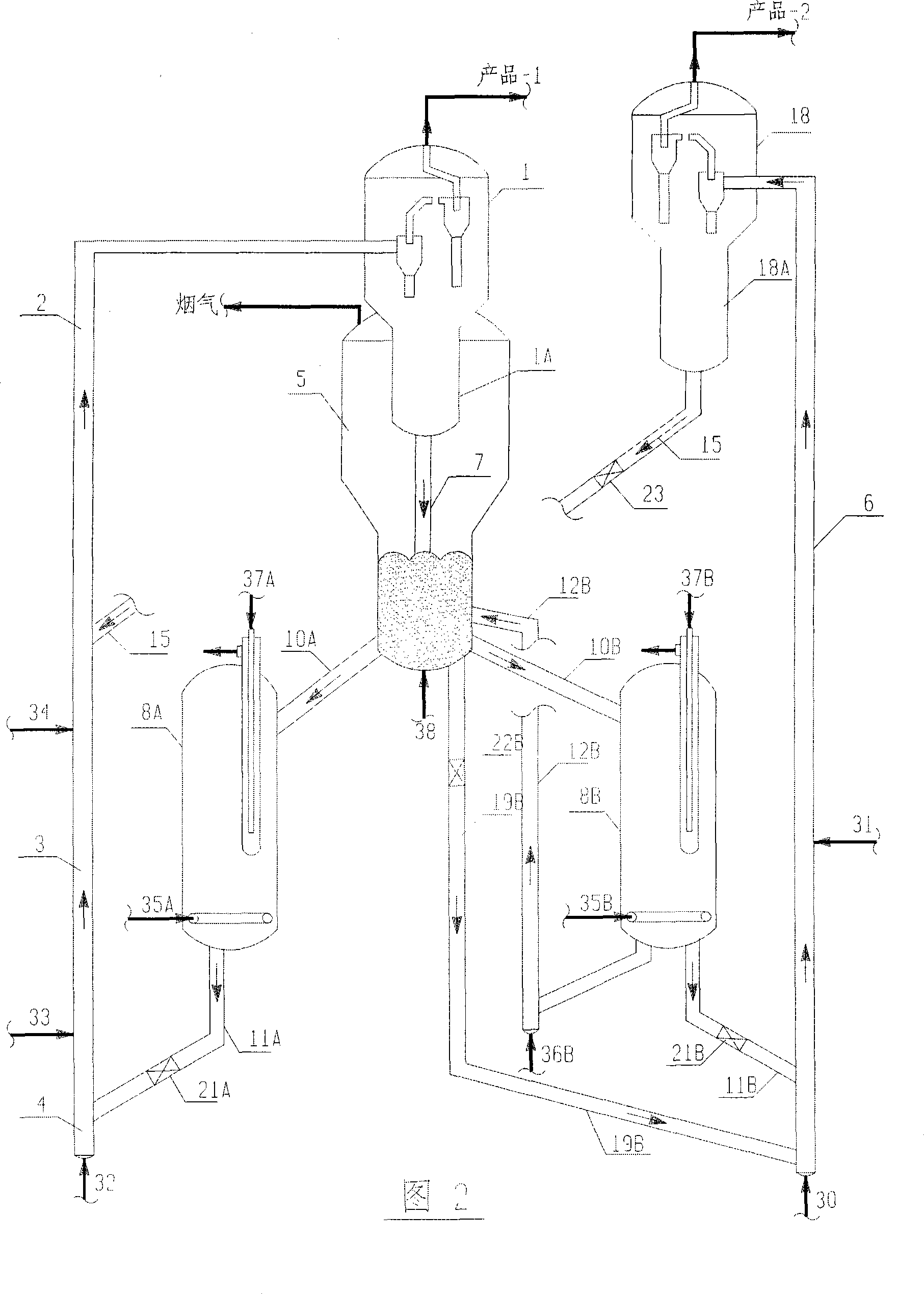

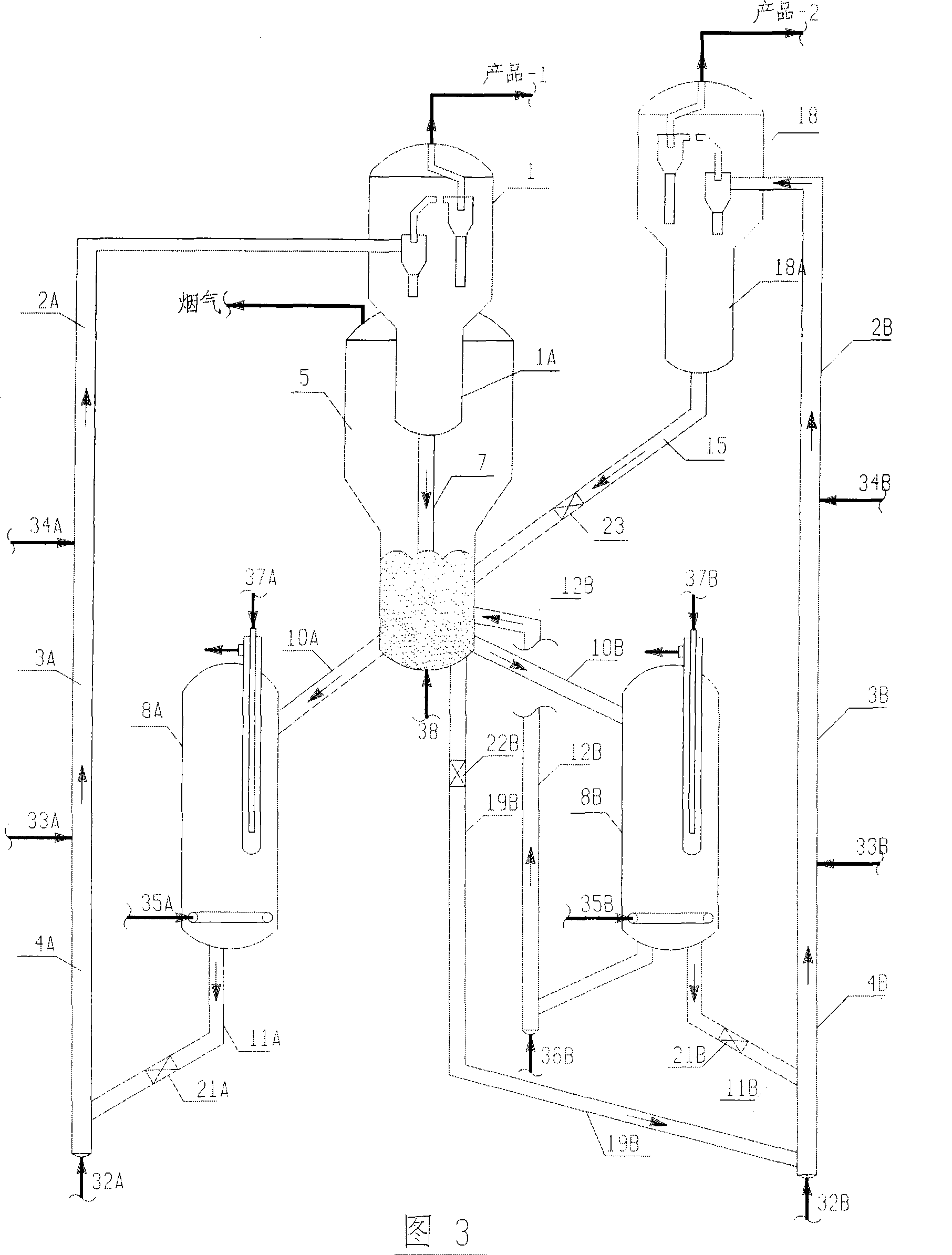

Method and device for fluidized catalytic conversion

ActiveCN101665712AReduce the temperatureRaise the preheat temperatureCatalytic crackingCatalytic transformationContact time

The invention provides a method for catalytic conversion of heavy oil, which comprises a fluidized catalytic conversion process that: heavy hydrocarbon raw materials contacts a catalyst in a riser reactor or fluidized bed reactor to react; the reaction temperature is 400 to 650 DEG C (preferably 480 to 560 DEG C); the reaction pressure is 0.11 to 0.4MPa; the contact time is 0.05 to 5 seconds (preferably 0.1 to 3 seconds); and the weight ratio of the catalyst to the raw materials ( catalyst to oil ratio) generally is 3 to 15, preferably 5 to 12. The reaction products flow in a settler for catalyst and oil gas separation; the separated catalyst to be regenerated is stripped by a stripping section and enters a regenerator for coke burning regeneration; and the regenerated catalyst is cooled or directly returns to the riser reactor to be recycled. The method can solve the problems encountered in the resid-blend ratio improvement and gasoline upgrade and update processes of the prior catalytic conversion.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

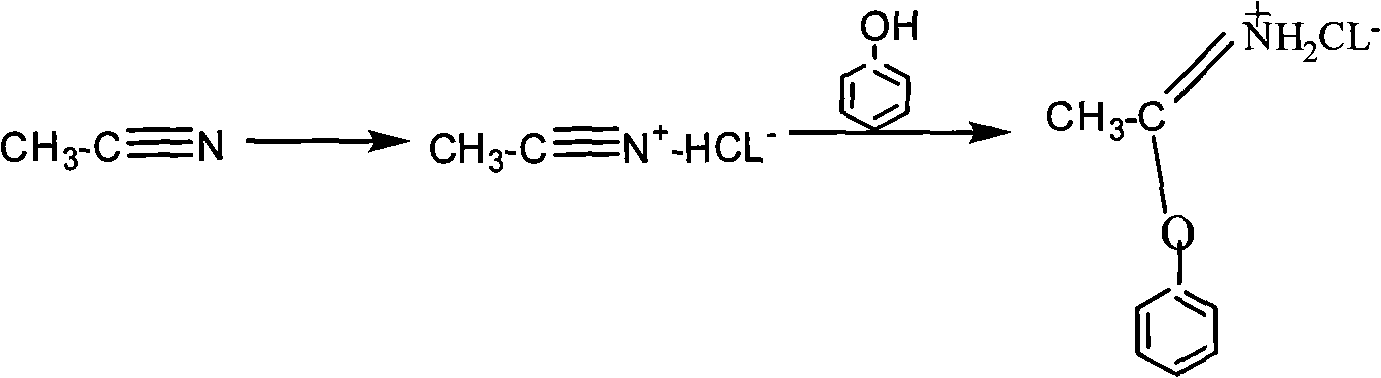

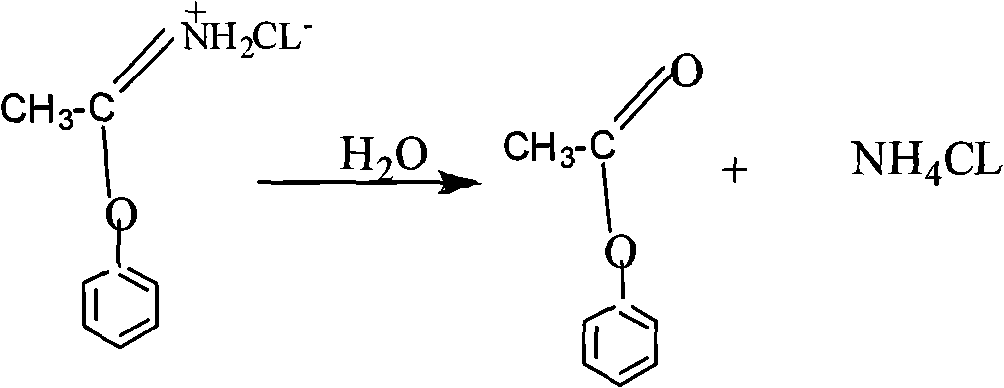

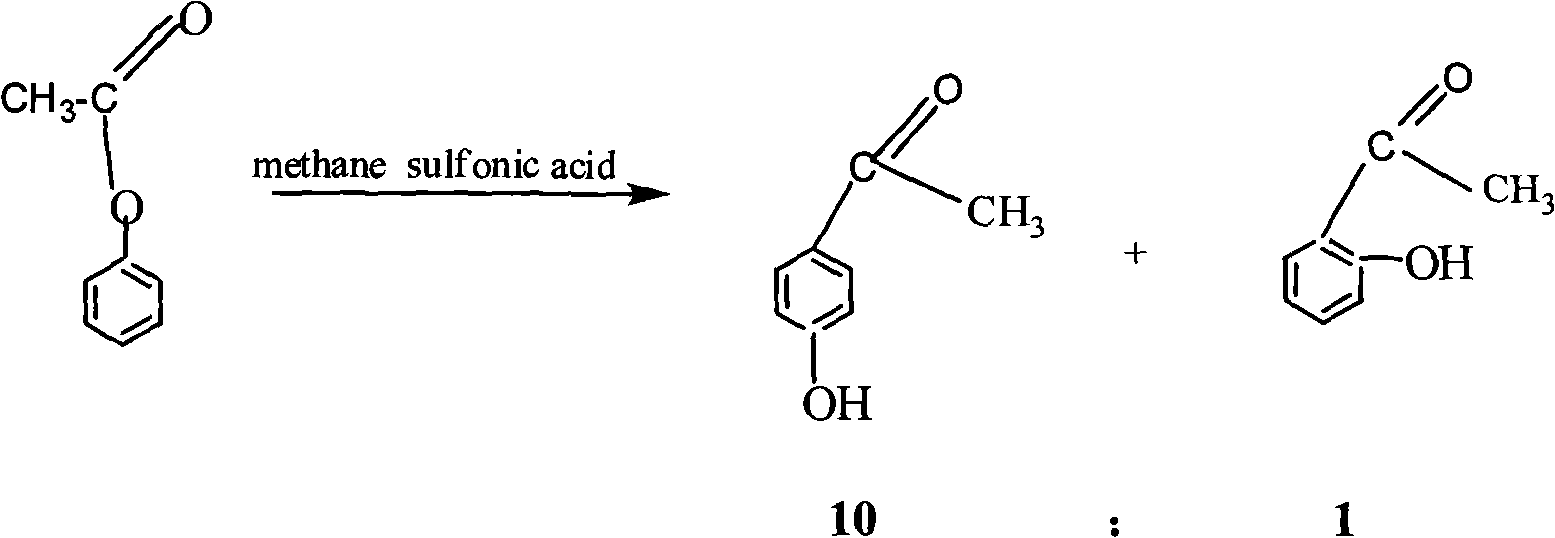

Method for synthesizing anisyl methyl ketone

InactiveCN101270039ALow priceMild experimental conditionsOrganic compound preparationCarbonyl compound preparationChemistryAcetanisole

The present invention provides a method used for synthesizing p methoxyacetophenone with phenol. The method comprises the following steps: an acylating agent and the phenol react to prepare phenyl acetate with a catalyst; the phenyl acetate is recomposed and separated to prepare acetyl phenol; the acetyl phenol is used for preparing the p methoxyacetophenone through methoxylation. Compared with the traditional synthetic method of the p methoxyacetophenone, the method has the characteristics of low price in producing the raw materials, mild experimental conditions, less by-products in the experiment and high yield of the product.

Owner:BAOSHAN IRON & STEEL CO LTD

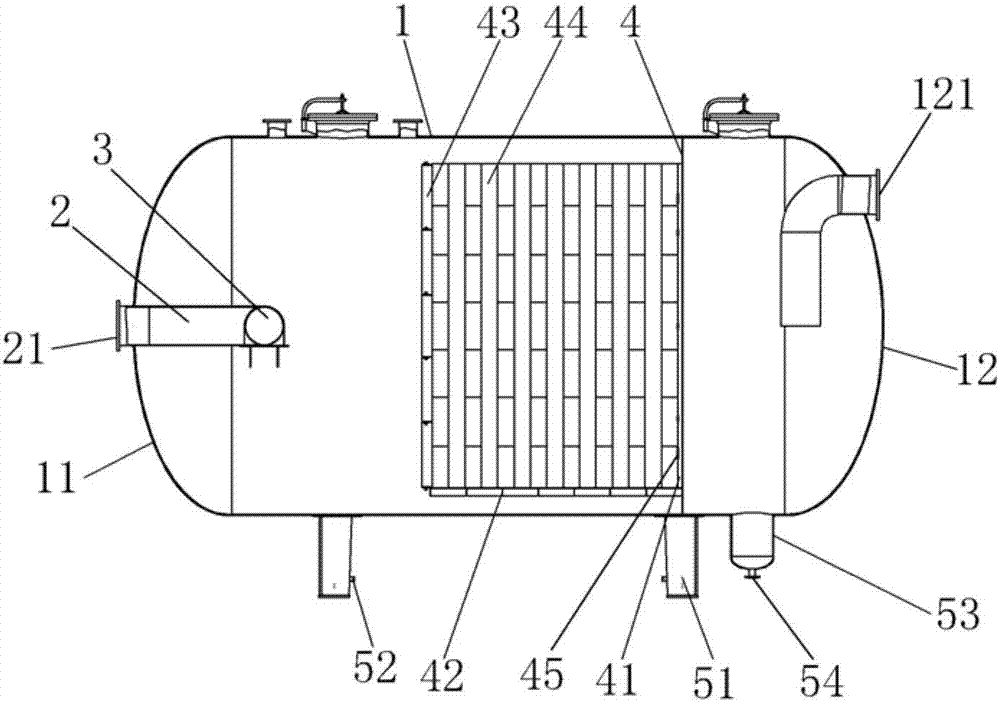

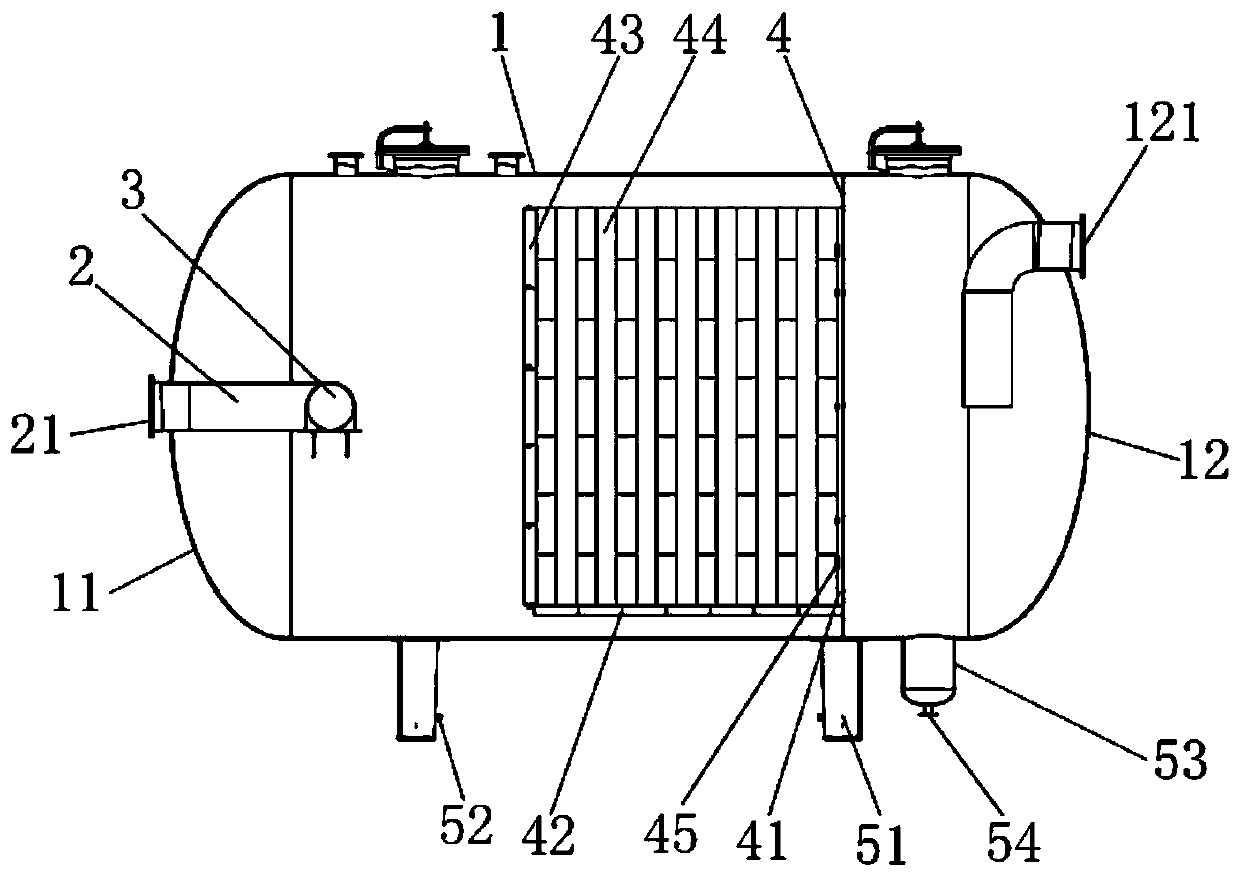

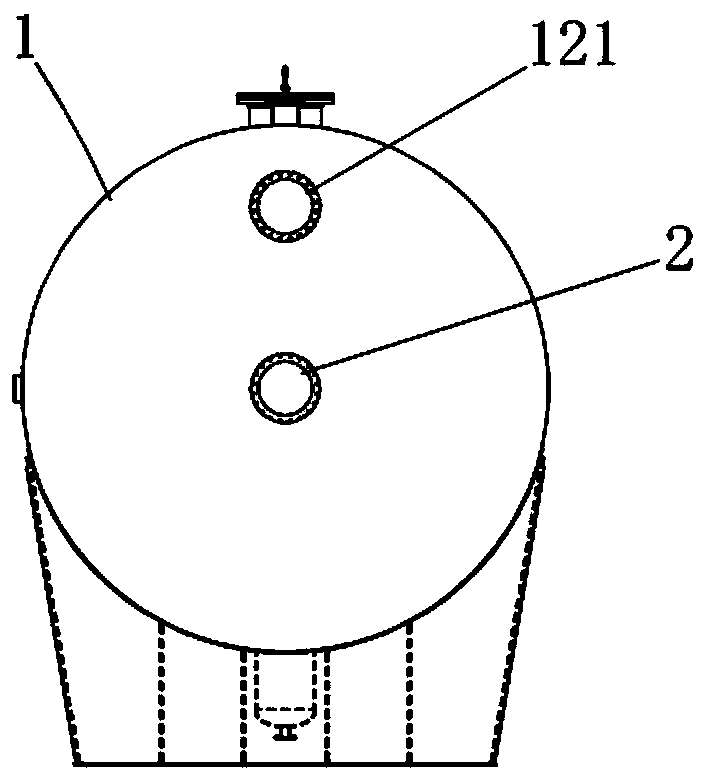

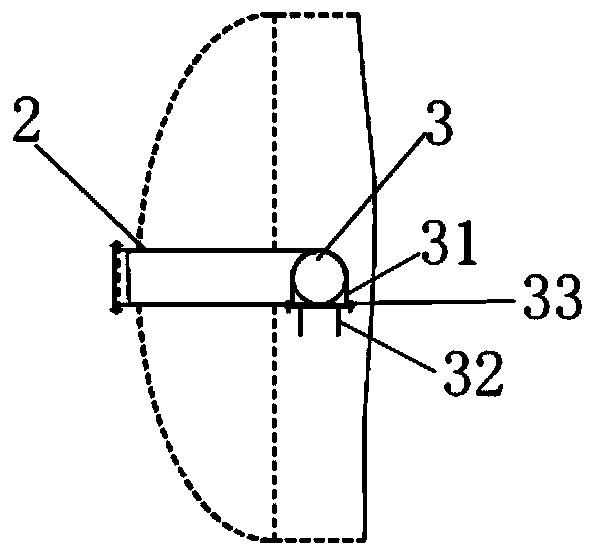

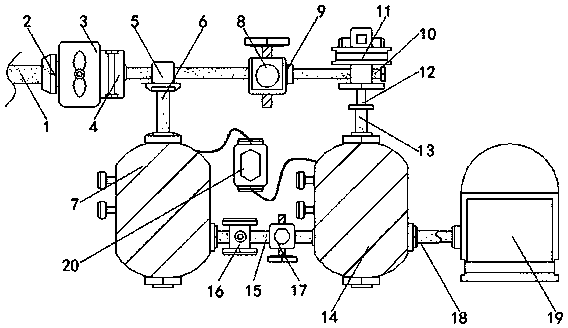

Hydrogen peroxide manufacturing technology using palladium contact agent fixed bed anthraquinone method and alkali liquor separator thereof

ActiveCN106853957AIncrease production capacityIncrease active compensation spacePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical recyclingManufacturing technologyFixed bed

The invention discloses a hydrogen peroxide manufacturing technology using a palladium contact agent fixed bed anthraquinone method. The technology is reasonable and efficient in technology, the production capacity of the catalyst is obviously improved, the generation of degraded products is reduced, the optimization for the regeneration environment of activated aluminum oxide is realized by intensifying the separation effect of an alkali liquor separator, the regeneration environment of a working solution is optimized, and a working solution heater is arranged before the working solution enters into a carclazyte bed for increasing the regeneration temperature, so that the activity of the activated aluminum oxide is improved, the regeneration effect is strengthened, the regeneration effect of the activated aluminum oxide plays roles to the maximum space, more degraded products are regenerated, the growth rate of the degraded products is controlled from the source, the compensation space of catalyst activity during production is effectively improved, the service life of the catalyst is prolonged, the heater is used for heating by using secondary steam generated by an alkali evaporator, the purpose of preheating the working solution to improve the regeneration result can be achieved, and recycling for the secondary steam of the system is carried out.

Owner:HUAQIANG CHEM GRP

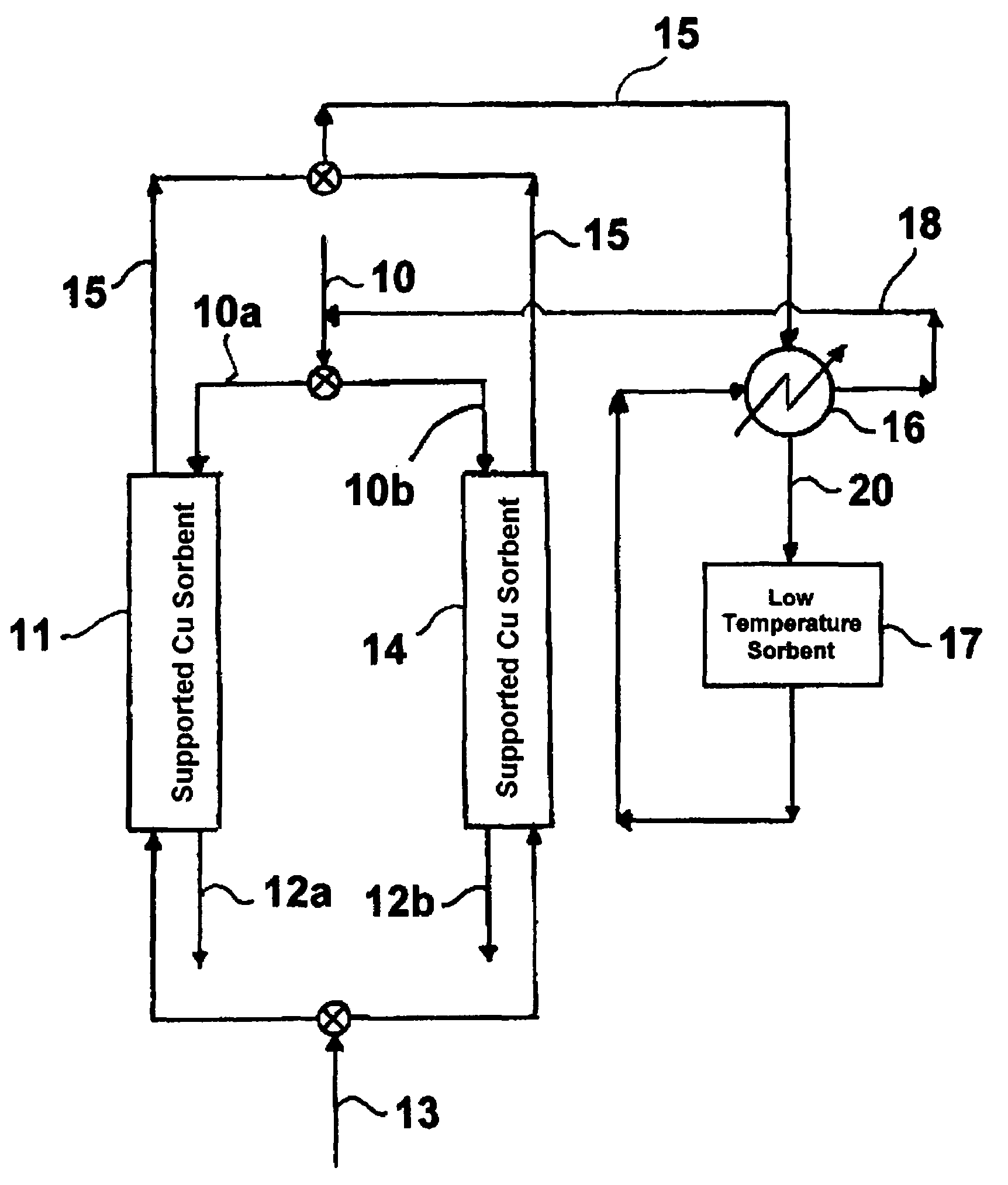

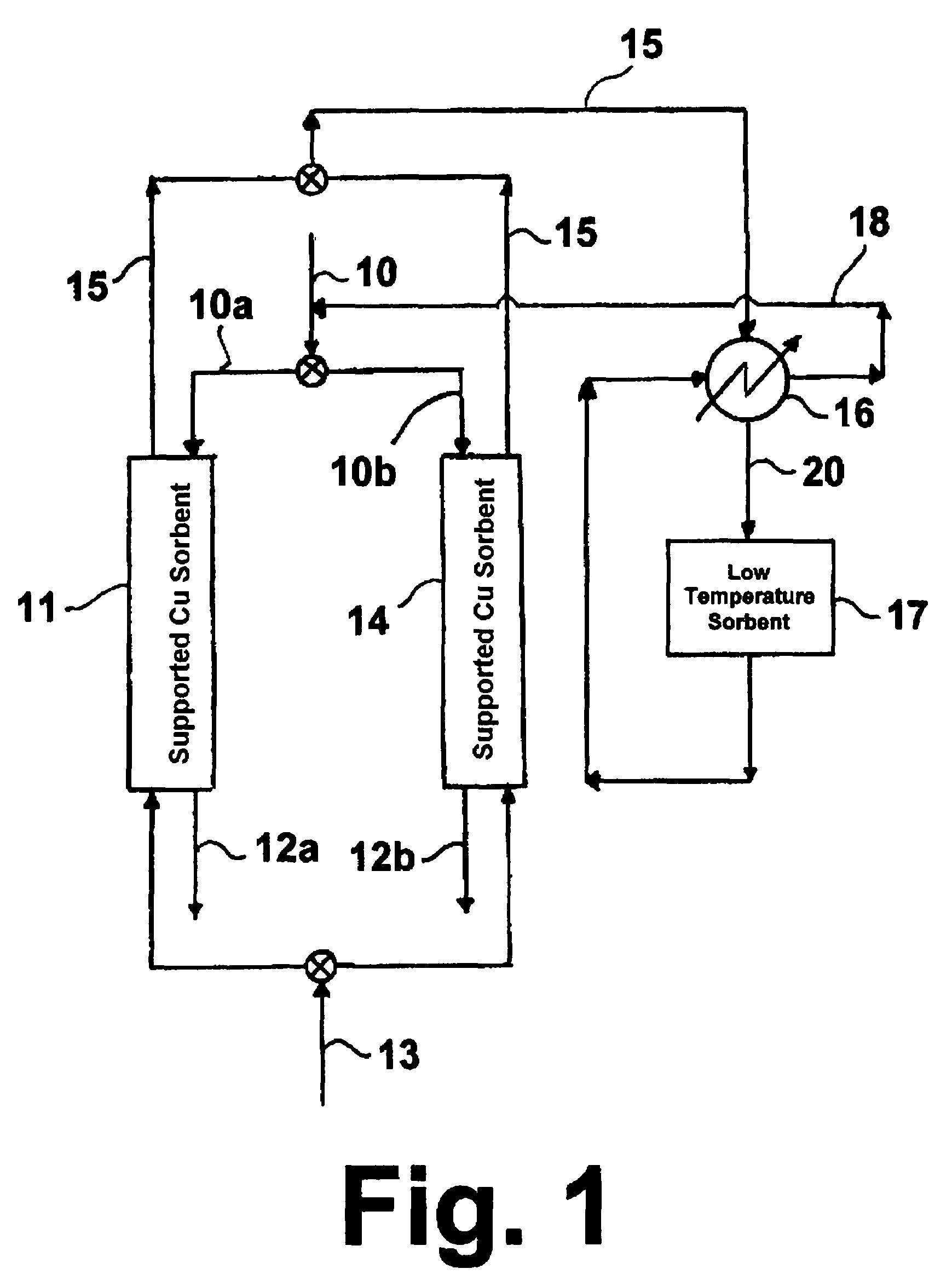

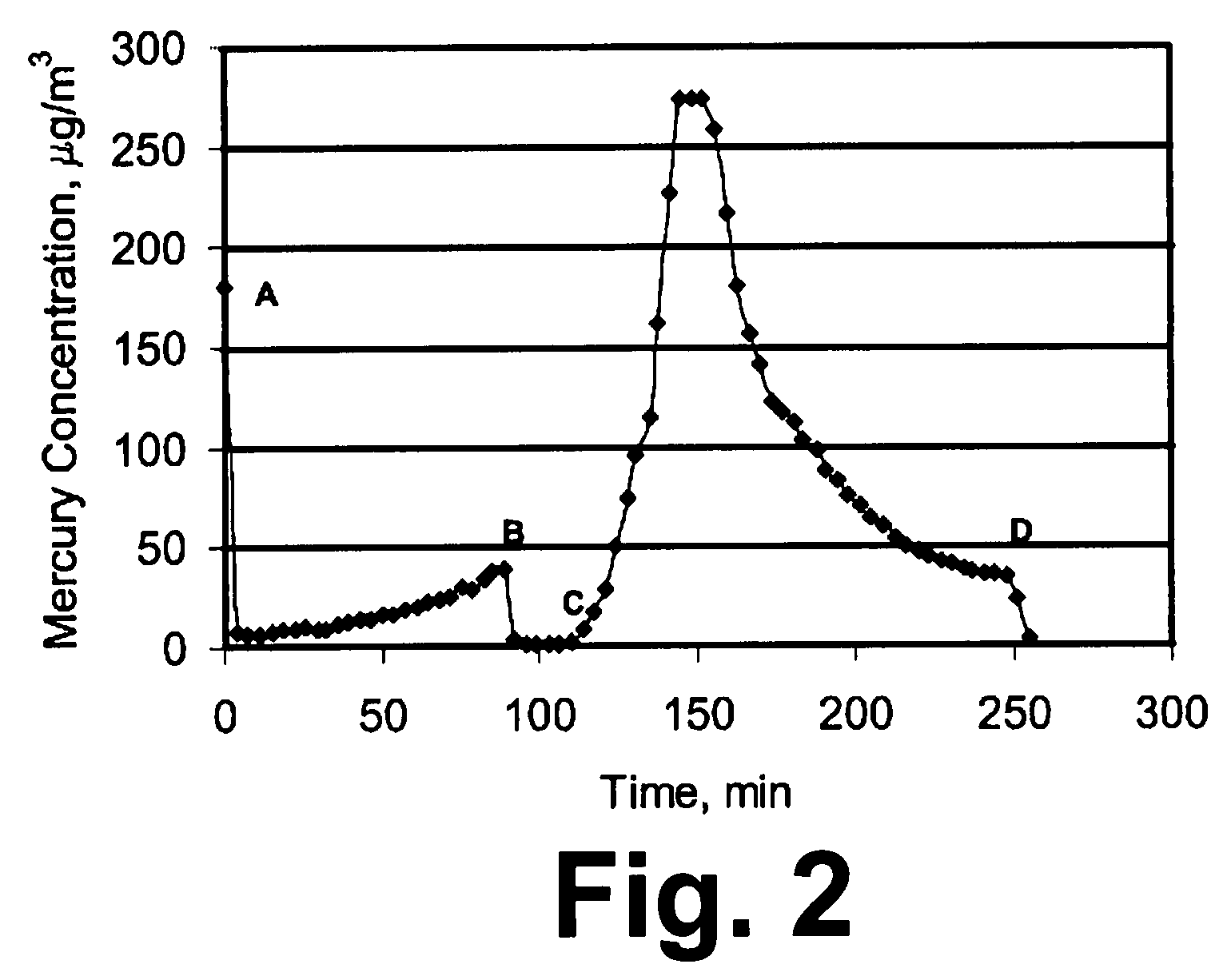

Regenerative process for removal of mercury and other heavy metals from gases containing H2 and/or CO

ActiveUS7556672B2Increase release rateRaise regeneration temperatureGas treatmentIsotope separationRegenerative processHydrogen

A method for removal of mercury from a gaseous stream containing the mercury, hydrogen and / or CO, and hydrogen sulfide and / or carbonyl sulfide in which a dispersed Cu-containing sorbent is contacted with the gaseous stream at a temperature in the range of about 25° C. to about 300° C. until the sorbent is spent. The spent sorbent is contacted with a desorbing gaseous stream at a temperature equal to or higher than the temperature at which the mercury adsorption is carried out, producing a regenerated sorbent and an exhaust gas comprising released mercury. The released mercury in the exhaust gas is captured using a high-capacity sorbent, such as sulfur-impregnated activated carbon, at a temperature less than about 100° C. The regenerated sorbent may then be used to capture additional mercury from the mercury-containing gaseous stream.

Owner:GAS TECH INST

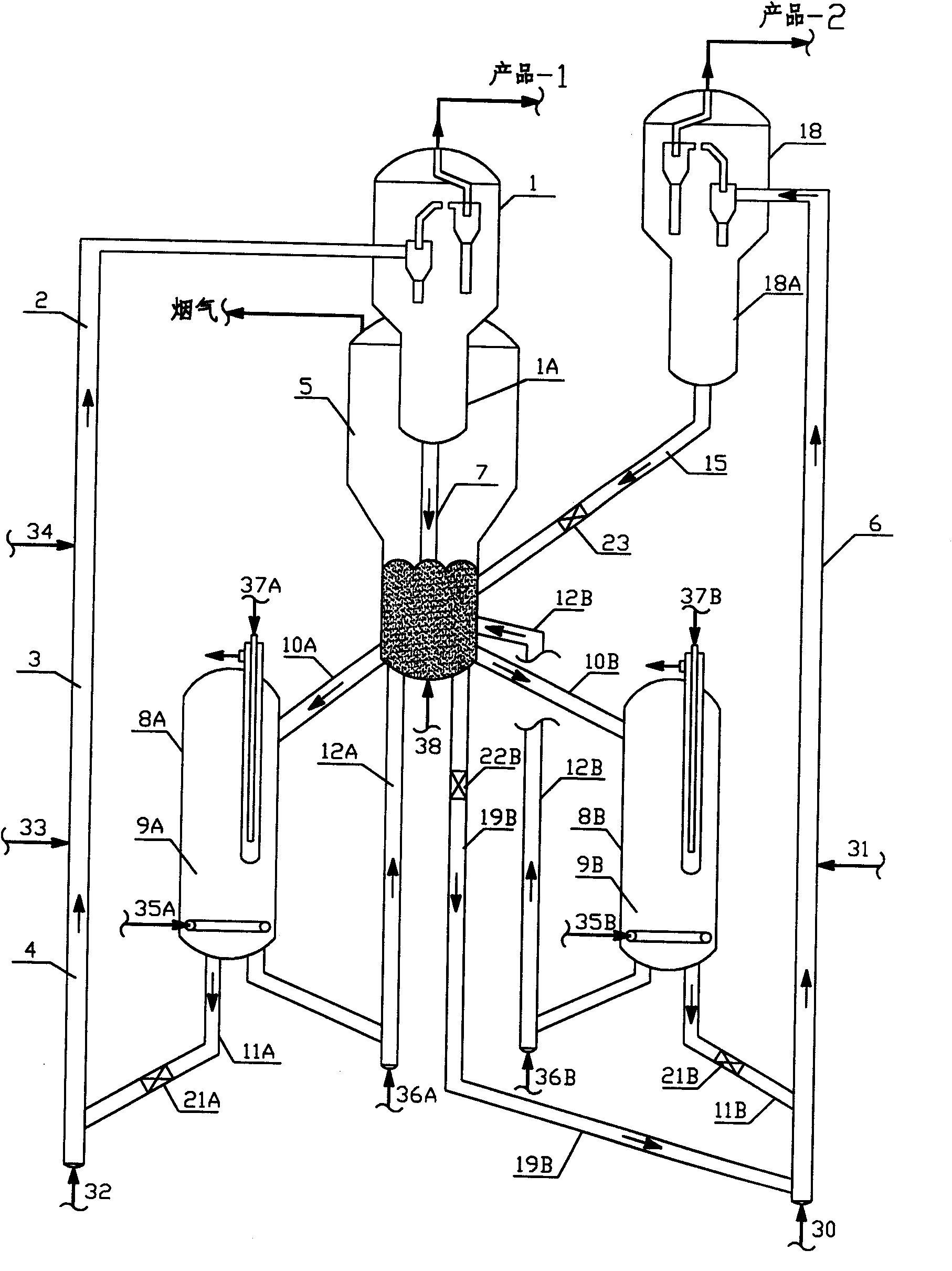

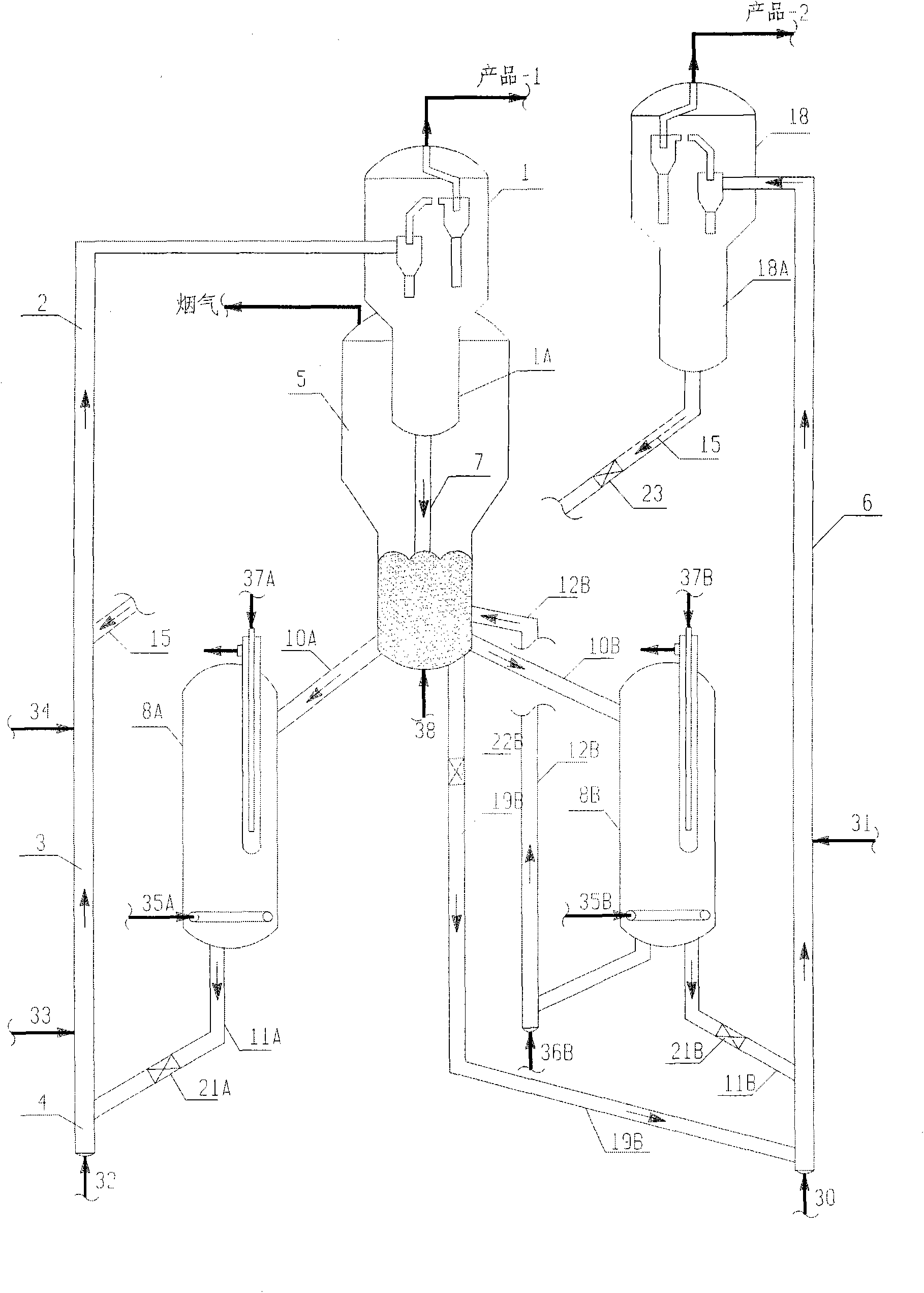

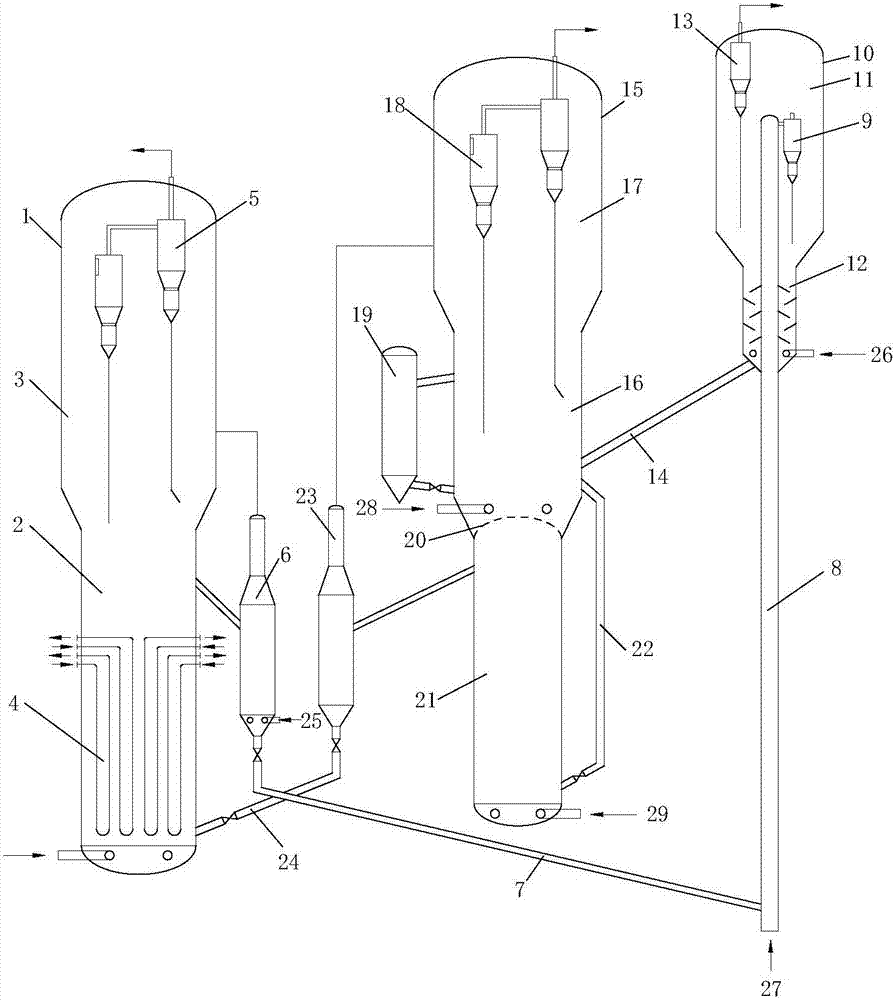

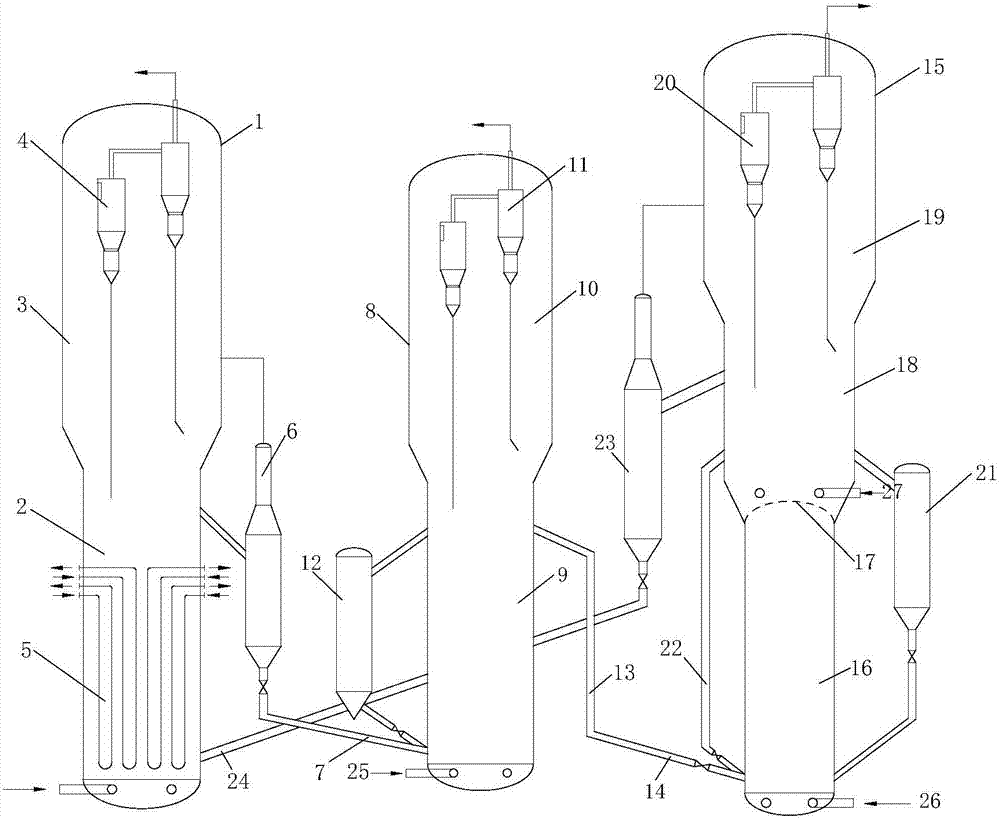

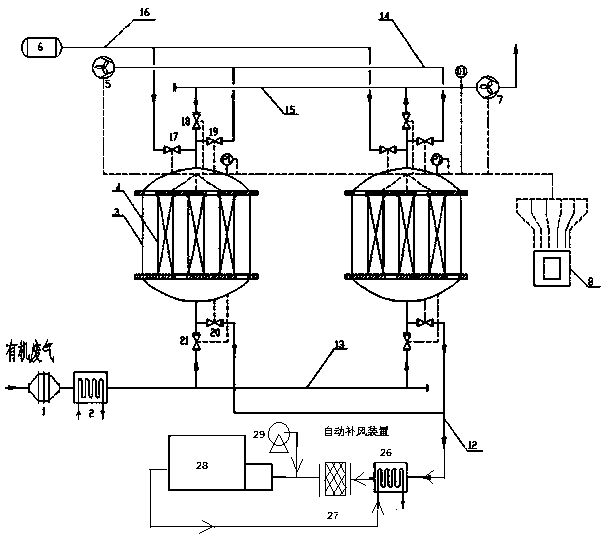

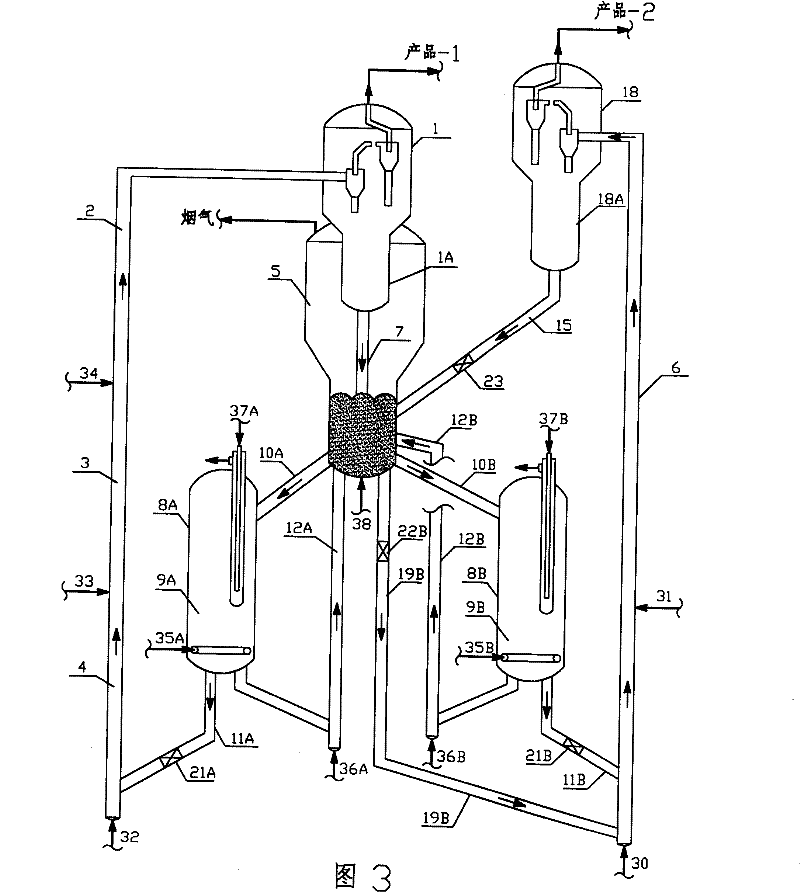

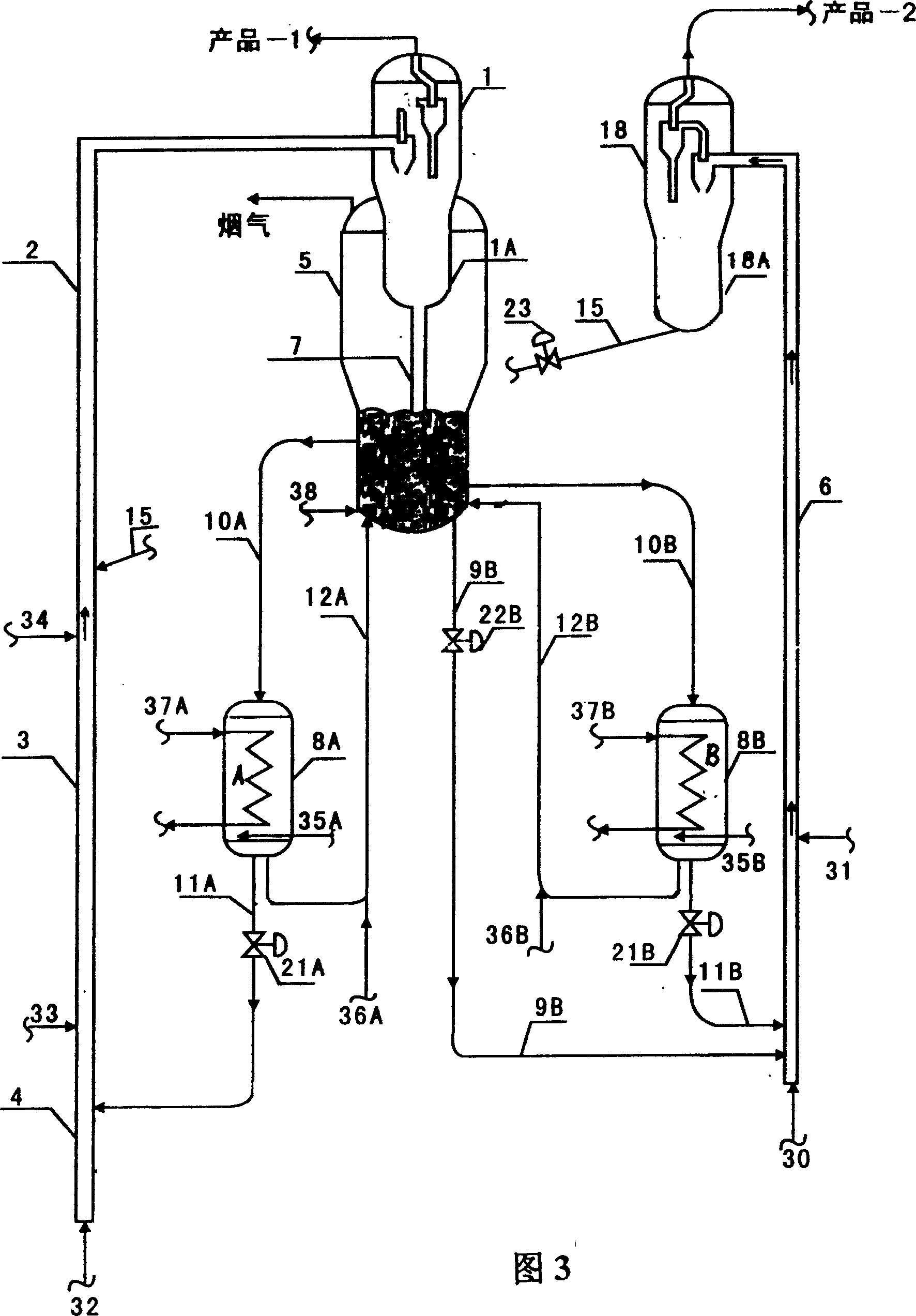

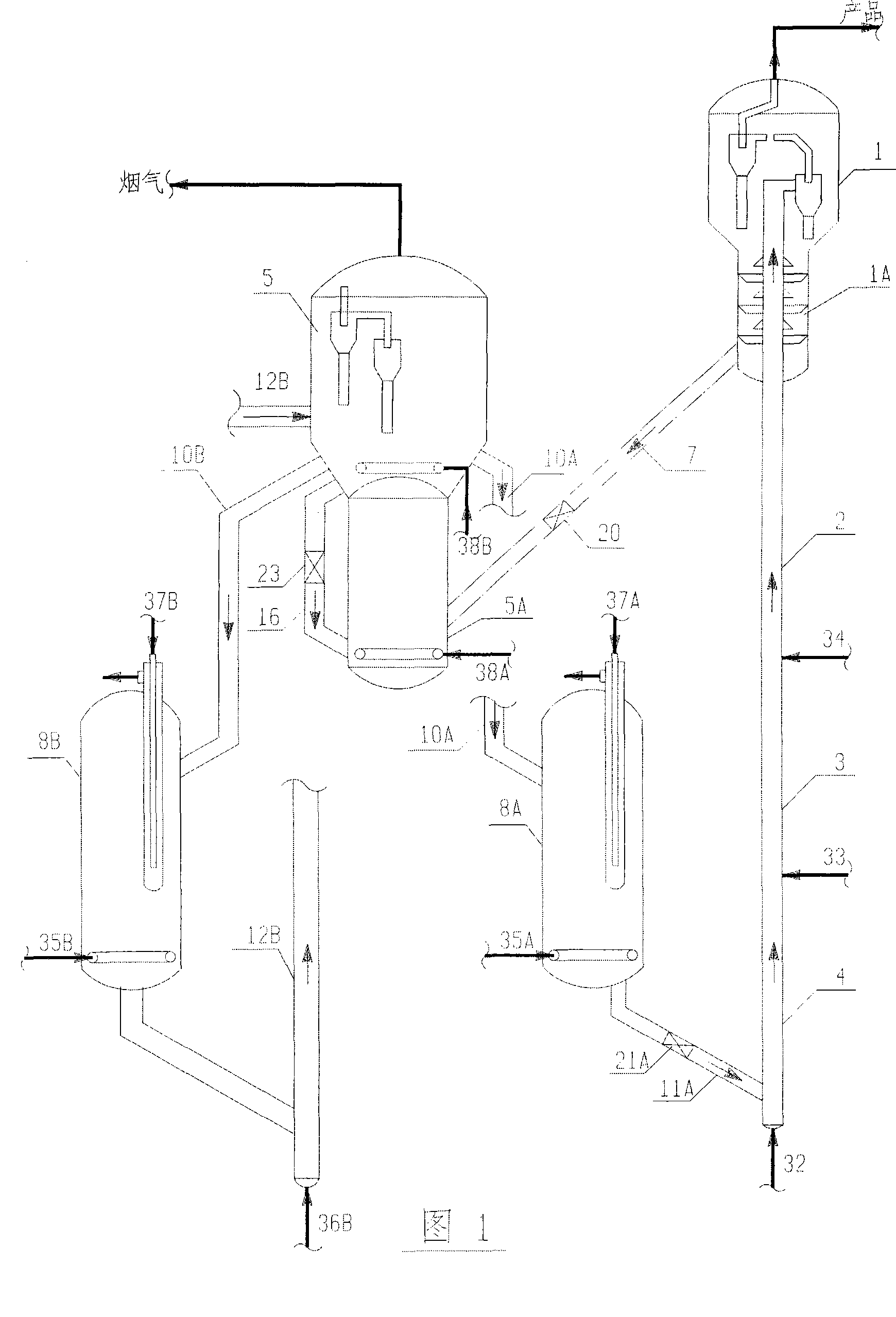

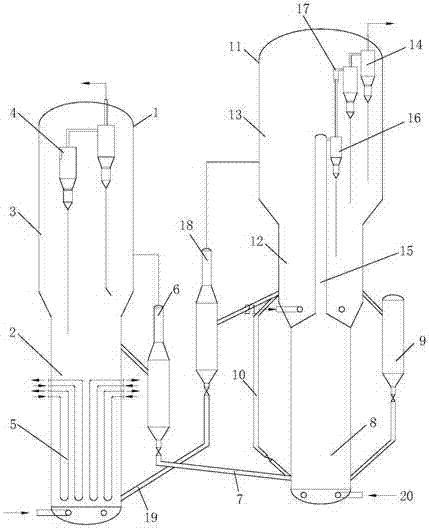

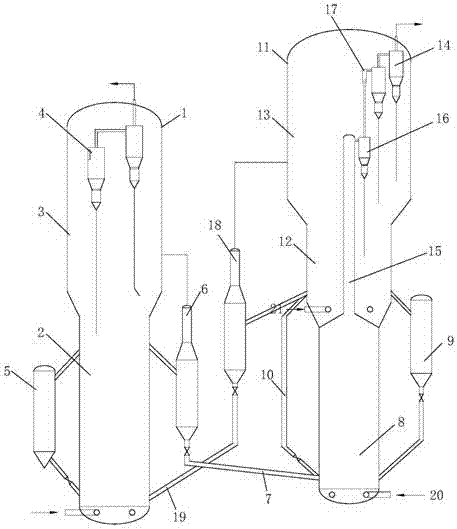

Method for producing aromatic hydrocarbons and light olefins by converting methanol or dimethyl ether

InactiveCN107540495ARaise regeneration temperatureGood hydrothermal stabilityHydrocarbon from oxygen organic compoundsEthylene productionFluidized bedMetal catalyst

The invention relates to a method for producing aromatic hydrocarbons and light olefins by converting methanol or dimethyl ether and mainly aims at solving the problems that a catalyst is gradually hydrothermally inactivated, the yield of aromatic hydrocarbons is reduced and the continuous and stable operation of a device is affected because the temperature of a regenerator is relatively high in aproduction process. The problems that the catalyst is hydrothermally inactivated and the continuous and stable operation is affected in the process of producing aromatic hydrocarbons and light olefins by using methanol or dimethyl ether are better solved by adopting the technical scheme that a circulating fluidized bed reaction-regeneration system with double strippers is adopted, methanol and / ordimethyl ether is in contact with one or more supported metal catalysts by a fluidized bed reactor to produce light olefins and an exudate rich in aromatic hydrocarbons. The method can be used for industrial production for producing aromatic hydrocarbons and light olefins by converting methanol or dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

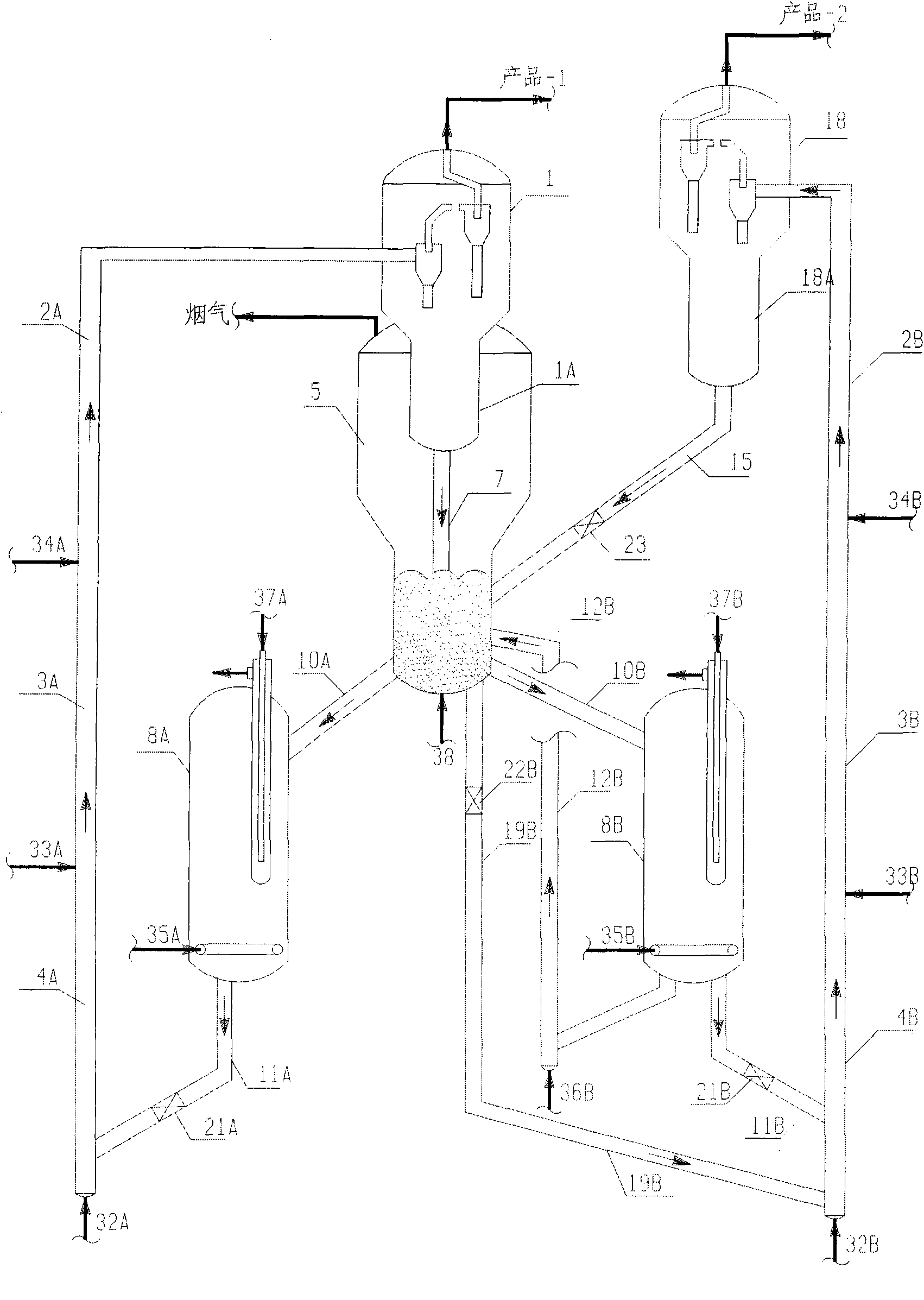

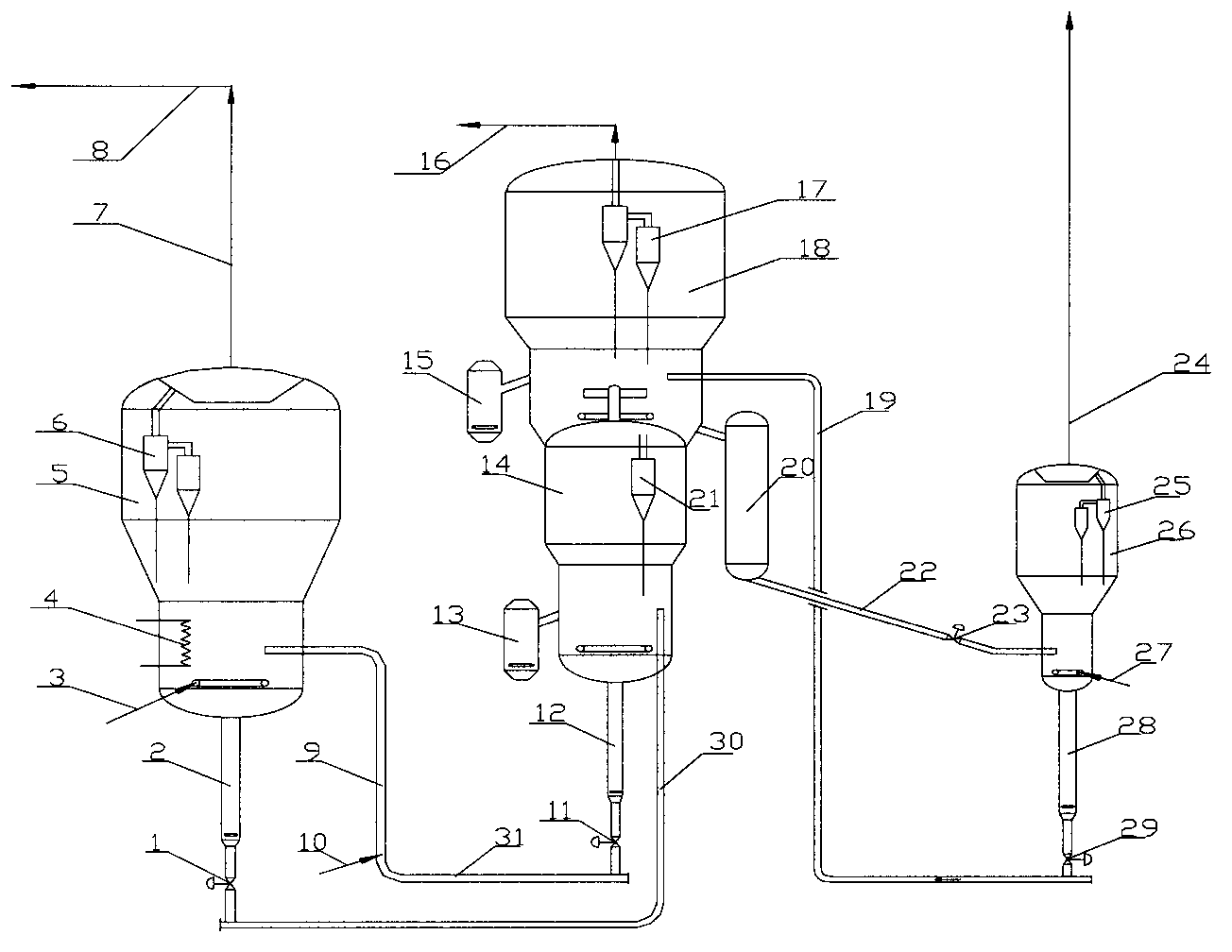

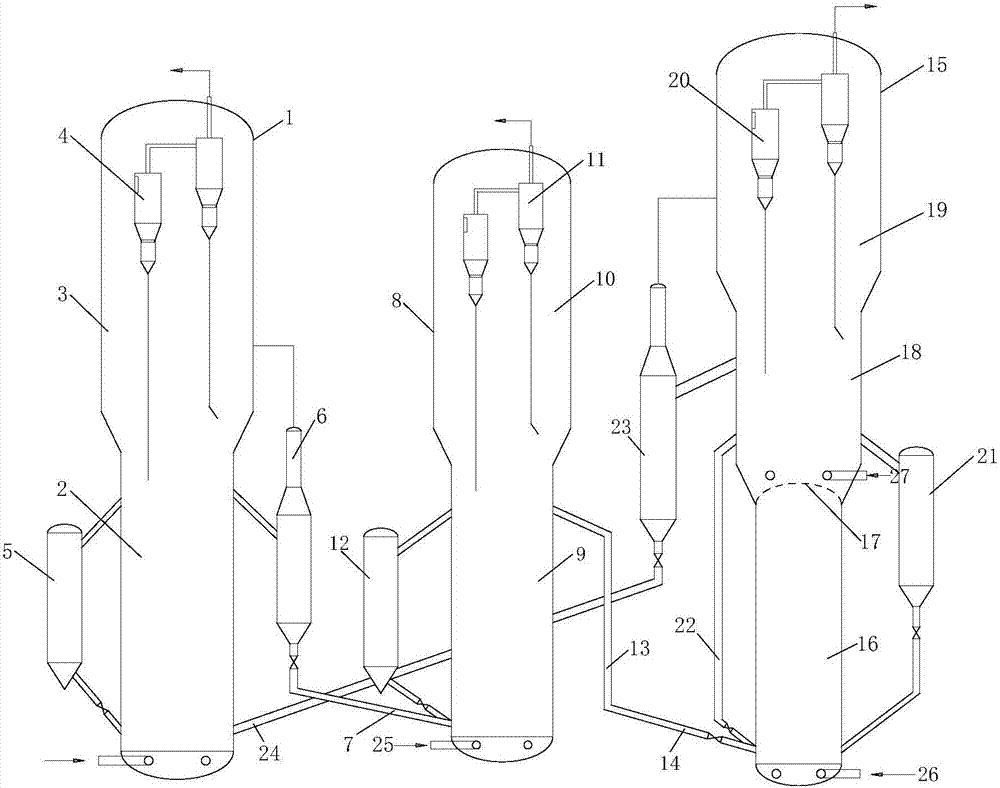

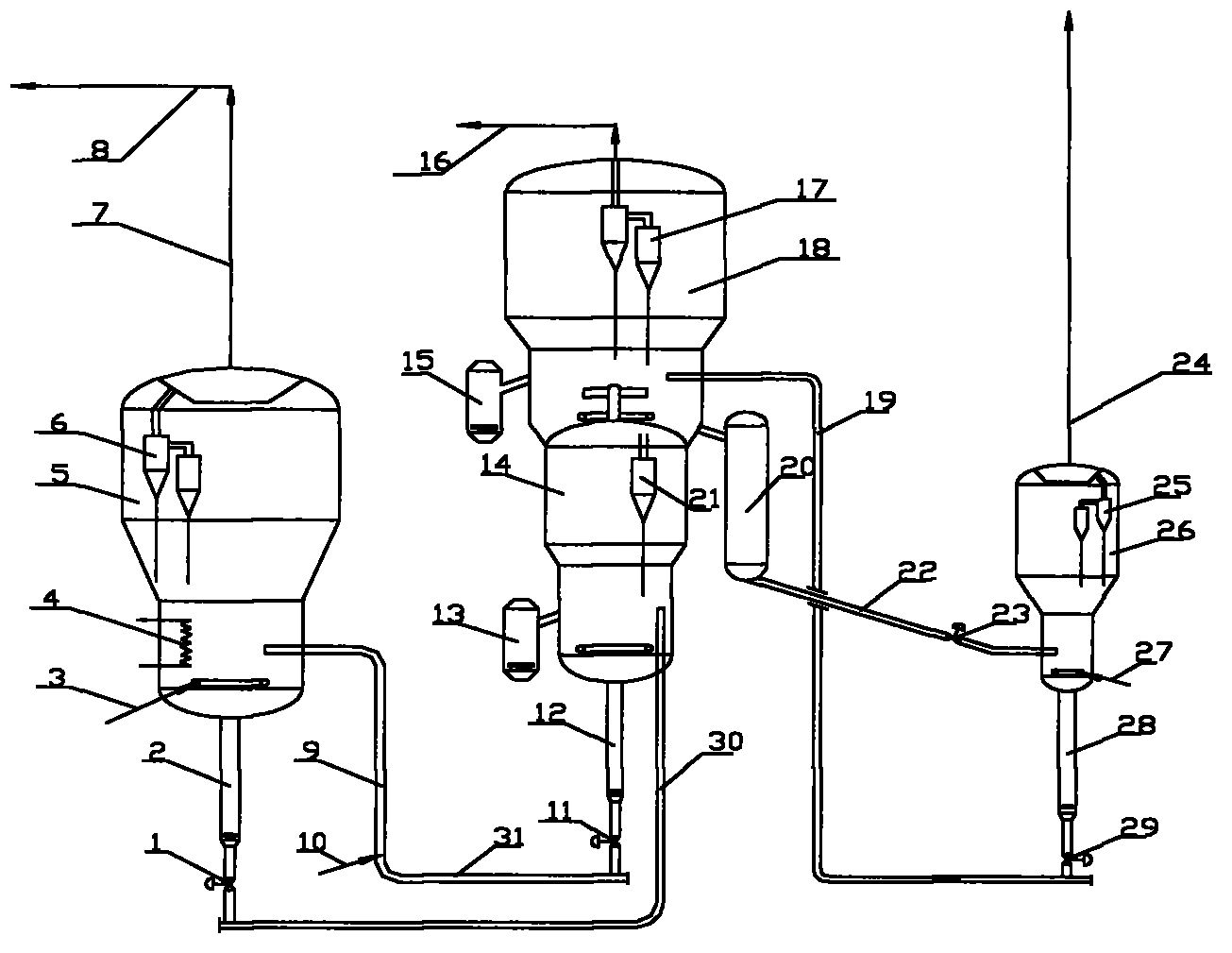

Device for producing alkene from oxygenated compound

ActiveCN103539610ALow reaction temperatureAgent / material smallHydrocarbon from oxygen organic compoundsEthylene productionProcess engineeringAlkene

The invention discloses a device for producing alkene from an oxygenated compound. The device comprises a main reactor, an auxiliary reactor, a first regenerator and a second regenerator, wherein the main reactor is communicated with the first regenerator through a first to-be-generated catalyst conveying pipe and a first regenerated catalyst conveying pipe; the auxiliary reactor is communicated with the second regenerator through a second to-be-generated catalyst conveying pipe and a second regenerated catalyst conveying pipe. According to the device disclosed by the invention, the selectivity of low-carbon alkene is high, the process flow is simple, and the investment is small.

Owner:CHINA PETROCHEMICAL CORP +1

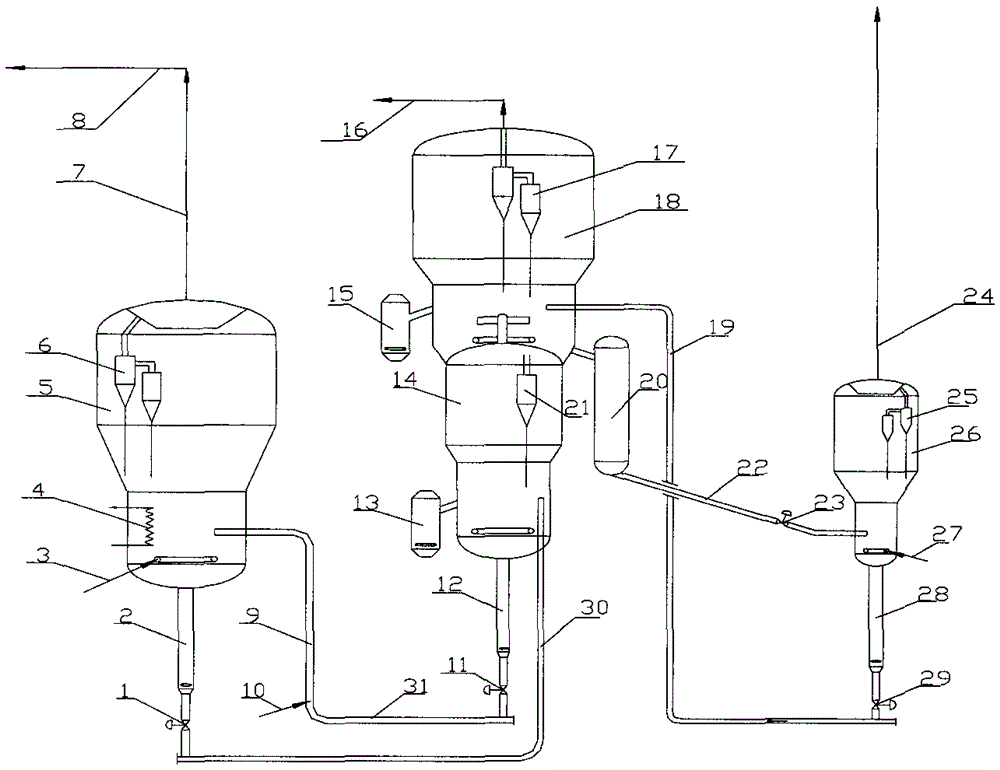

Method for producing arene and low-carbon alkene from methanol or dimethyl ether

InactiveCN107540493AQuality improvementGood hydrothermal stabilityHydrocarbon from oxygen organic compoundsEthylene productionChemistryDimethyl ether

The invention relates to a method for producing an arene and a low-carbon alkene from methanol or dimethyl ether, and mainly solves problems that in a production process, temperatures of regeneratorsare relatively high, thus hydrothermal deactivation is gradually performed on a catalyst, an arene yield is reduced, and accordingly continuous and stable operation of a device is influenced. According to the invention, through the following technical scheme: a circulating fluidized bed reaction-regeneration system is adopted, and the methanol and / or the dimethyl ether is in contact with one or more silicon loaded metal catalysts through a fluidized bed reactor to generate the low-carbon alkene and an arene-enriched effluent; and a deactivated spent catalyst firstly passes through a first fluidized bed regenerator (8), and a relatively low temperature is controlled to mainly finish a hydrogen burning process, then an obtained catalyst enters a fast bed (16) and a second fluidized bed regenerator (15), and a relatively high temperature is controlled to finish carbon burning, the problems that in the process of producing the arene and the low-carbon alkene from the methanol or the dimethyl ether, hydrothermal deactivation is performed on the catalyst, and the continuous and stable operation is influenced are better solved, and the method can be used in industrial production of producing the arene and the low-carbon alkene from the methanol or the dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

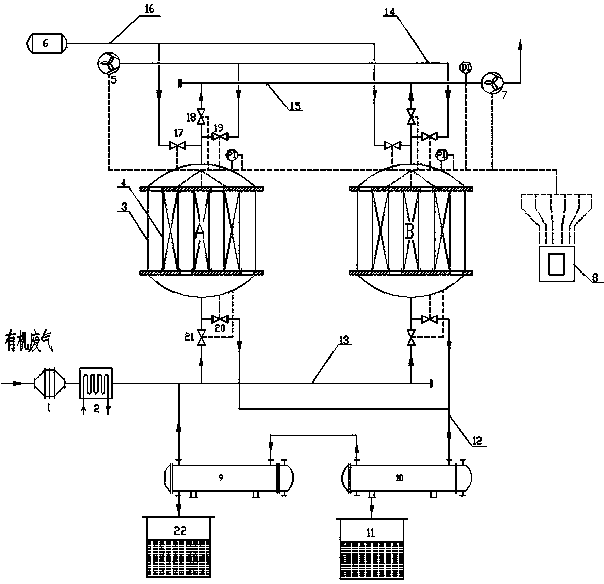

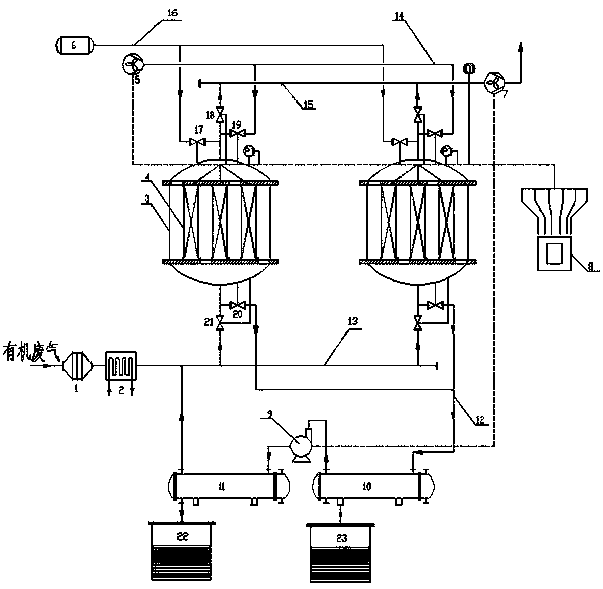

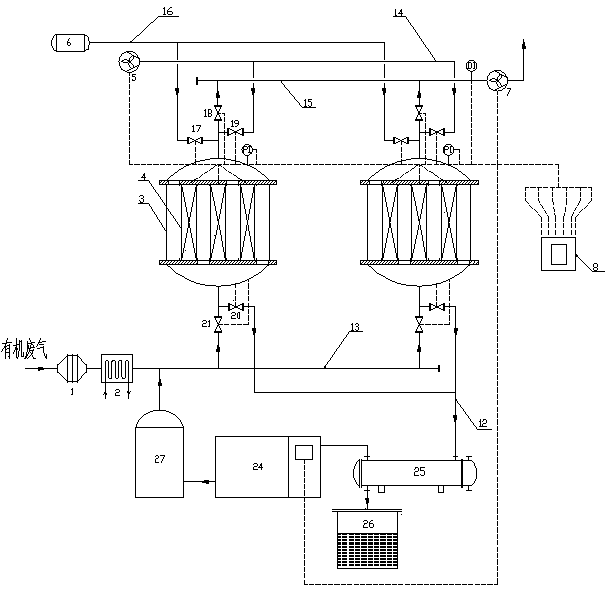

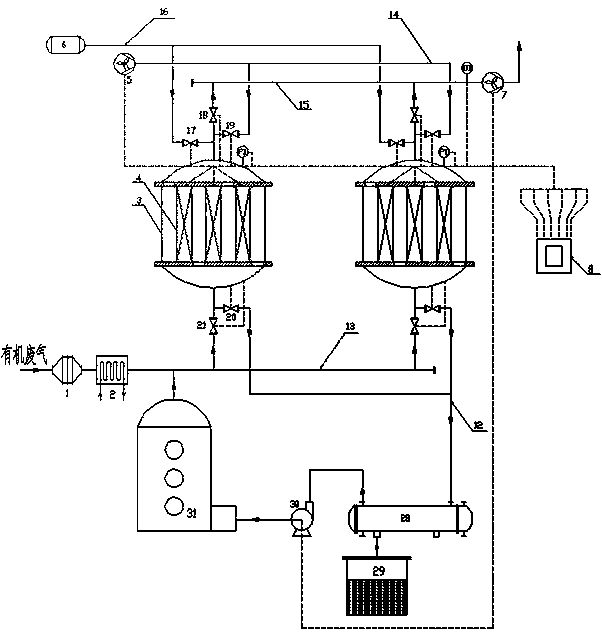

Purification system and purification method for treating VOCs-containing waste gas by using circulating fluidized bed.

PendingCN109107341AMeet the requirements of recyclingReduce dosageGas treatmentDispersed particle filtrationPurification methodsFluidized bed

The invention relates to the field of environmental engineering waste gas treatment, particularly to a purification system and a purification method for treating VOCs-containing waste gas by using a circulating fluidized bed. The purification system comprises a circulating fluidized bed type adsorption device, a regeneration device, a bag dust removal device, a fan and an incineration device, wherein one end of the circulating fluidized bed type adsorption device is connected to the regeneration device, the regeneration device is connected to the bag dust removal device, the bag dust removal device is connected to the fan, the other end of the circulating fluidized bed type adsorption device is connected to the bag dust removal device, and the bag dust removal device is connected to the fan. According to the present invention, the waste gas is converted into the fluid-state adsorbate carrying the organic matters after the waste gas contacts the adsorbate having adsorption ability, theadsorbate is captured and then is regenerated, the desorbed organic matters are subjected to harmless treatment by the incineration device, the desorbed and regenerated adsorbate is transported to thecirculating fluidized bed type adsorption device and is reused so as to meet the requirements of the recycling of the adsorbate; and the system and the method have characteristics of high VOCs removal rate, less adsorbate consumption and no emission of wastewater and other secondary pollutants, and are suitable for the treatment of high, medium and low concentration VOCs waste gas.

Owner:浙江中兵环保股份有限公司

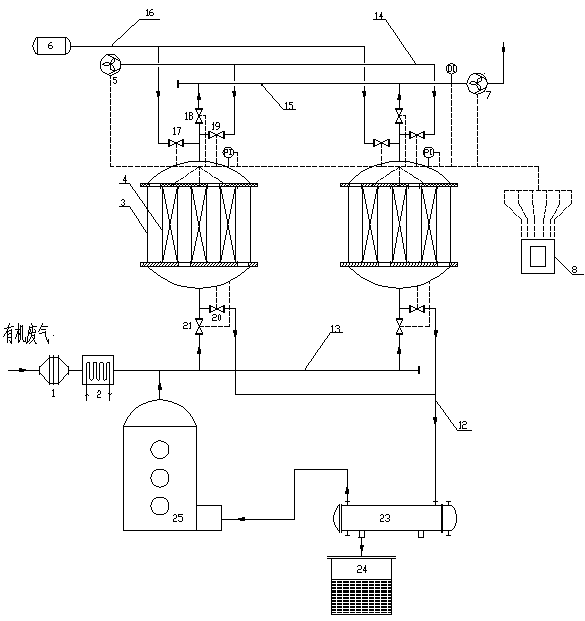

Electrified heating regenerated active carbon adsorption purification system and electrified heating regenerated active carbon adsorption purification method

InactiveCN110975515AReduce heat damageNo importGas treatmentDispersed particle separationFiberActivated carbon

The invention discloses an electrified heating regenerated active carbon adsorption purification system and an electrified heating regenerated active carbon adsorption purification method. The systemcomprises a filter, a cooler and at least more than two active carbon adsorbers, wherein an adsorption purification unit is arranged in the active carbon adsorber, and comprises an active carbon fiberbed layer, electrodes, a temperature sensor and an enclosure structure, the active carbon fiber bed layer is formed by overlapping active carbon fiber fabrics, a temperature sensor is arranged in thebed layer, the electrodes are arranged on any two opposite end surfaces of the bed layer, and the electrode adopts a mode that an electric-conducting band and an active carbon fiber fabric are overlapped layer by layer or the electric-conducting band and plural layers of active carbon fiber fabrics are overlapped. According to the invention, the electric-conducting bands are uniformly arranged inthe end surface area of the bed layer to ensure the uniform distribution of the bed layer current in the electric heating process, so that the uniform temperature rise of the active carbon bed layeris realized, organic matter desorption is thorough, regeneration is complete, and the electric heating filtering core can keep good adsorption performance for a long time.

Owner:张蕾 +1

Method for preparing olefins from oxygen-containing compound

ActiveCN103539616ALow reaction temperatureAgent / material smallHydrocarbon from oxygen organic compoundsEthylene productionOxygenSeparation system

The invention discloses a method for preparing olefins from an oxygen-containing compound. The oxygen-containing compound is put into a main reactor and contacts and reacts with a regenerated catalyst from a first regenerator, and the reaction oil gas enters a separation system; a catalyst to be regenerated enters a first regenerator for regeneration, and the regenerated catalyst is recycled; C4-C8 hydrocarbons are put into an auxiliary reactor, and contact with a catalyst from a second regenerator, and then the reaction oil gas enters a separation system for separation; next, the catalyst enters the second regenerator to be regenerated and the regenerated catalyst is recycled. The method is high in selectivity of light olefins, simple in process flow and low in investment.

Owner:CHINA PETROCHEMICAL CORP +1

Method for preparing low carbon olefin through oxygenated chemicals

InactiveCN103664449AHigh yieldRaise regeneration temperatureHydrocarbon from oxygen organic compoundsEthylene productionFluidized bedCooling down

The invention relates to a method for preparing low carbon olefin through oxygenated chemicals, which mainly solves the problem that the low carbon olefin is low in yield in the prior art. The method disclosed by the invention comprises the steps that (a) oxygenated chemicals enter a first fluidized bed reaction area so as to be in contact with a catalyst, and a generated gaseous phase material flow and the catalyst enter a second fluidized bed reaction area; (b) the catalyst in the second fluidized bed reaction area is divided into at least two parts, wherein one part of the catalyst returns back to the first fluidized bed reaction area, and the other part of the catalyst enters a lift pipe regeneration area so as to form a regeneration catalyst; (c) the regeneration catalyst is divided into at least two parts, wherein one part of the regeneration catalyst returns back to the first fluidized bed reaction area, and the other part of the regeneration catalyst is cooled down and returns back to a lift pipe regenerator. The method for preparing low carbon olefin through oxygenated chemicals well solves the problem due to the adoption of the technical scheme and can be used in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Active carbon adsorption purification system and active carbon adsorption purification method adopting vacuum electric heating regeneration

InactiveCN110975514AReduce heat damageImprove adsorption capacityGas treatmentDispersed particle separationFiberActivated carbon

The invention discloses an active carbon adsorption purification system and an active carbon adsorption purification method adopting vacuum electric heating regeneration. The system comprises a filter, a cooler and at least more than two active carbon adsorbers, wherein an adsorption purification unit is arranged in the active carbon adsorber, and comprises an active carbon fiber bed layer, electrodes, a temperature sensor and an enclosure structure, the active carbon fiber bed layer is formed by overlapping active carbon fiber fabrics, the temperature sensor is arranged in the bed layer, theelectrodes are arranged on any two opposite end surfaces of the bed layer, and the electrode adopts a mode that an electric-conducting band and an active carbon fiber fabric are overlapped layer by layer or the electric-conducting band and plural layers of active carbon fiber fabrics are overlapped. According to the invention, the electric-conducting bands are uniformly arranged in the end surfacearea of the bed layer to ensure the uniform distribution of the bed layer current in the electric heating process, so that the uniform temperature rise of the active carbon bed layer is realized, organic matter desorption is thorough, regeneration is complete, and the electric heating filtering core can keep good adsorption performance for a long time.

Owner:张蕾 +1

Porous material adsorbent regeneration technology

InactiveCN109806854AAchieve regenerationAchieve the purpose of repeated useCombustible gas purificationFilter regenerationActivated carbonEnvironmental chemistry

The invention relates to a porous material adsorbent regeneration technology and belongs to the field of sanitary appliances for daily lives. The adsorption capacity of daily odor and water vapor adsorbents, such as activated carbon and silica gel, is limited, so that after being used for a period of time, the daily odor and water vapor adsorbents reach adsorption saturation and lose efficacy, andhave to be abandoned as wastes, and thus, materials are wasted and environment is also influenced. According to the invention, the daily odor and water vapor adsorbents are filled into regeneration boxes; the regeneration boxes are placed in daily heating appliances and are used for heating and regenerating the daily odor and water vapor adsorbents; heating are performed for 10 seconds to about 2hours; odor or water molecules adsorbed on the daily odor and water vapor adsorbents are desorbed under high temperature, so that the regeneration of the daily odor and water vapor adsorbents is realized; the aim of repeatedly utilizing the daily odor and water vapor adsorbents is achieved; and not only are the materials and energy sources saved, but also greenness and environmental friendlinessare realized.

Owner:马秦生

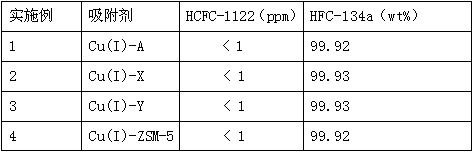

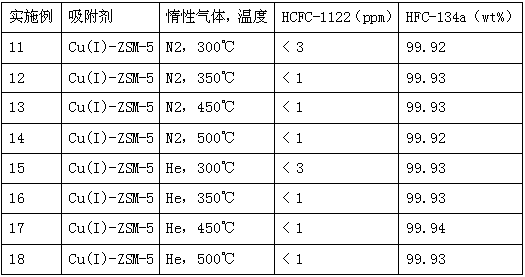

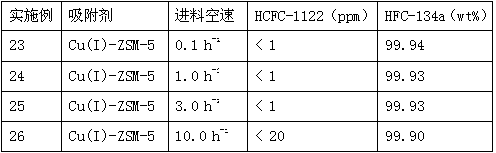

Method for removing 1,1-difluoro-2-chloroethylene in 1,1,2,2-tetrafluoroethane by adsorption

ActiveCN110002950ALarge adsorption capacityFast adsorptionHalogenated hydrocarbon preparationIon exchangeMolecular sieve

The invention discloses a method for removing 1,1-difluoro-2-chloroethylene in 1,1,1,2-tetrafluoroethane by adsorption. The method comprises the following steps: a 1,1,1,2-tetrafluoroethane crude product containing 1,1-difluoro-2-chloroethylene is in contact with a Cu(I) ion exchange modified molecular sieve adsorbent under a gas phase condition; and chemical adsorption is carried out on the 1,1-difluoro-2-chloroethylene by the adsorbent, so that the 1,1-difluoro-2-chloroethylene is removed from the 1,1,1,2-tetrafluoroethane crude product, and a purified 1,1,1,2-tetrafluoroethane product is obtained. Through adoption of the technology, the 1,1-difluoro-2-chloroethylene in the 1,1,1,2-tetrafluoroethane is high selectively removed at a lower adsorption temperature according to the characteristic that pi-complexation adsorption belongs to chemical adsorption, the adsorption capacity is large, the adsorption speed is high, and the method is environmentally friendly. The regeneration temperature of the adsorbent is not high, the regeneration performance of the adsorbent is excellent, requirements of large-scale industrial production can be met, and a good industrial application prospectis achieved.

Owner:ZHEJIANG UNIV OF TECH

Method and device for circulating cold regenerated catalyst

ActiveCN101665713BReduce the temperatureRaise the preheat temperatureCatalytic crackingEthylene productionWaxGasoline

The invention provides a method for circulating a cold regenerated catalyst and application thereof. A regenerated catalyst from a regenerator is cooled by a catalyst cooler to between 200 and 720DEG C, and is not mixed with a hot regenerated catalyst to directly enter a riser reactor, or is mixed with another part of uncooled hot regenerated catalyst into a mixed regenerated catalyst of which the temperature is not lower than that of the regenerator to enter the riser reactor; and a hydrocarbon raw material undergoes contact reaction with the catalyst in the riser reactor, the reaction material flow enters a settler for the separation of the catalyst and oil gas, the separated catalyst to be regenerated is subjected to steam stripping in a steam stripping section, and then enters the regenerator for coke burning regeneration, and the regenerated catalyst is cooled and returns to the riser reactor for recycling. The method for circulating the cold regenerated catalyst has wide application, can be used for various fluid catalytic cracking processes comprising resid fluid catalytic cracking, wax oil catalytic cracking, gasoline catalytic conversion upgrading and the like, and also can be sued for other gas-solid reaction processes comprising residual oil pretreatment, fluid coking and the like.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

Environment-friendly food drying agent and preparation method thereof

InactiveCN112602874ASimple processEasy to operateFood preservationFood ingredientsMicrosphereMetal-organic framework

The invention discloses an environment-friendly food drying agent. The environment-friendly food drying agent is prepared from the following components in parts by weight: 4-7 parts of chitosan quaternary ammonium salt modified carboxyl-containing metal organic framework, 2-5 parts of residue porous material, 2-4 parts of wood fiber powder, 3-6 parts of porous beta cyclodextrin cross-linked polymer nanofiber, 50-60 parts of silica gel, 2-4 parts of magnesium sulfate, 1-3 parts of bamboo charcoal viscose fiber and 3-5 parts of porous polysaccharide microspheres. The invention further discloses a preparation method of the environment-friendly food drying agent. The environment-friendly food drying agent disclosed by the invention is good in use safety and environmental friendliness, extremely high in moisture absorption performance, water retention capacity and oxidation resistance, stable in product quality and low in cost, and has reproducibility and degradability.

Owner:姚计化

A molecular sieve ceramic membrane material for olefin purification and its preparation and application

ActiveCN107970781BUniform thicknessStrong regeneration and reuse performanceSemi-permeable membranesOther chemical processesMolecular sieveMass transfer resistance

The invention relates to a molecular sieve ceramic membrane material for olefin purification as well as a preparation method and application of the molecular sieve ceramic membrane material. In the molecular sieve ceramic membrane material, the particle sizes of molecular sieve particles supported on the surface of the ceramic material are 0.1-3 [mu]m, and the thickness of a molecular sieve layeris 3-5 [mu]m; during preparation, ceramic material pretreatment, molecular sieve seed crystal pre-coating and sealed crystallization are sequentially carried out; and the molecular sieve ceramic membrane material is used for removing a polar oxygenated compound in a gaseous olefin flow to be 1ppm or below. Compared with the prior art, the molecular sieve ceramic membrane material prepared by the preparation method of the invention has the molecular sieve layer with higher mechanical strength, larger specific surface area and uniform thickness, in addition, the molecular sieve layer has no longitudinal or horizontal cracks, has no air pores in the surface and is high in bonding strength and not easy to fall off; and when the polar oxygenated compound in the olefin flow is adsorbed, the purification depth is 1ppm or smaller, so that not only is the mass transfer resistance lower, but also the energy consumption is lower, and the regeneration capacity is high.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

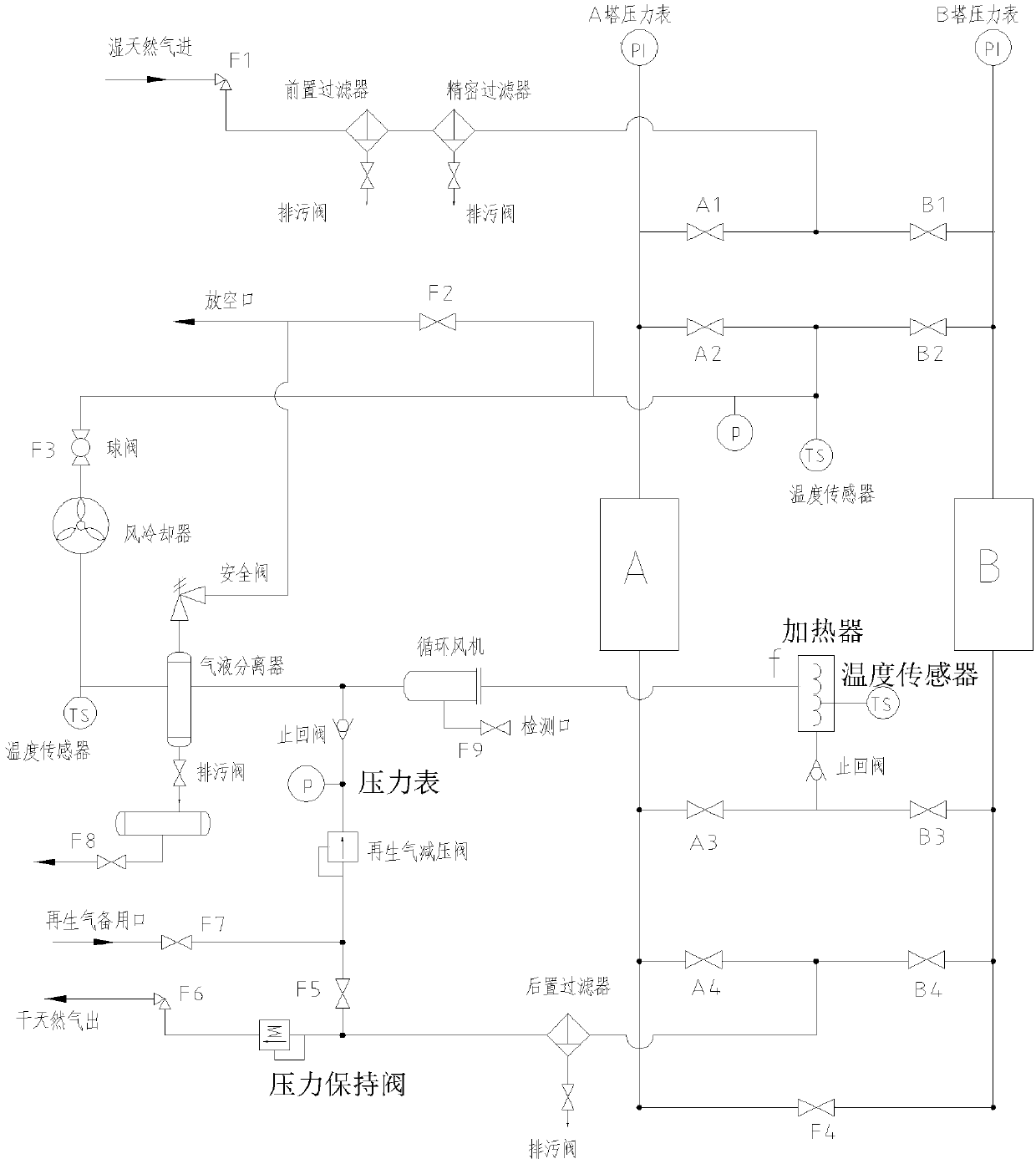

Process for drying high-pressure natural gas by using temperature-variable pressure-variable closed cyclic regeneration

The invention discloses a process for drying high-pressure natural gas by using temperature-variable pressure-variable closed cyclic regeneration. According to the process, after displacement of pipeline gas, wet natural gas enters a tower A for adsorption; at the same time, a tower B carries out pressure release, desorption of heated gas, water-gas separation and pressure equalization; and then,the working states of the tower A and the tower B are exchanged. The process provided by the invention adopts the principles of pressure swing adsorption, and carries out adsorption at a high pressureand desorption at a low pressure so as to realize pressure-reduced regeneration of an adsorbent, so energy needed in regeneration of the adsorbent is substantially reduced; the regenerated adsorbentis heated so as to increase the regeneration temperature of the adsorbent, so the regeneration of the adsorbent is more thorough, and thus, finished gas with a lower dew point can be obtained; low-pressure low-temperature natural gas separated through cooling is subjected to regeneration and blowing cooling, and blowing cooling gas is cyclically utilized, great in volume, long in blowing cooling time and thorough in blowing cooling effect, so the dew point of the finished gas is prevented from drift; and Pressure-reduced finished gas is used for heating and blowing-cooling gas, so the workingpressure of a fan and a heater is substantially reduced.

Owner:无锡联合超滤净化设备科技有限公司

Method for catalytic conversion of heavy oil and device thereof

ActiveCN1324116CRaise the preheat temperaturePromote atomizationCatalytic crackingTreatment with plural serial stages onlyCatalytic transformationGasoline

The invention provides a method of heavy raw material catalytic conversion and the device, comprising: the heavy hydrocarbon raw material passing through the first and second reaction area of the raiser reactor and contacting with catalyst for first reaction and second reaction, the reactants entering into the settler for the separation of catalyst and oil gas, steam stripping the separated catalyst through stripping section and introducing it to the reactivator for carbon burning reactivation, the reactivated catalyst returning to the raiser reactor after cooled or directly to the raiser reactor for reuse. After the heavy oil passing through the device said above, the volume content of olefin decreases by 10~40%, octane value increases 0.5~1 units, sulfur content in petrol decreases 10~30% by weight. After the poor petrol passing through the device said above, the volume content of olefin decreases by 10~60%, octane value increases 0.5~40 units, sulfur content in petrol decreases 10~50% by weight.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

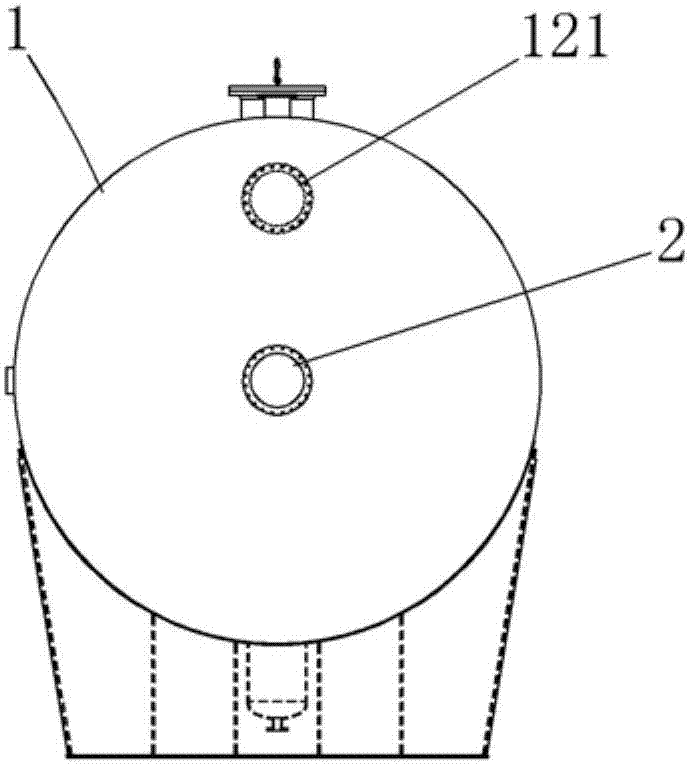

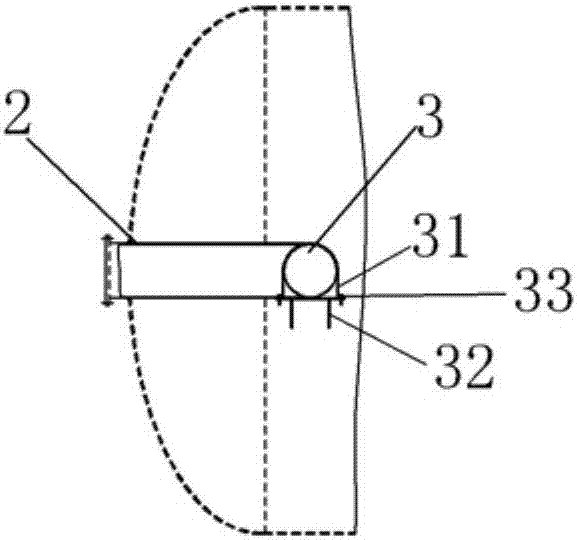

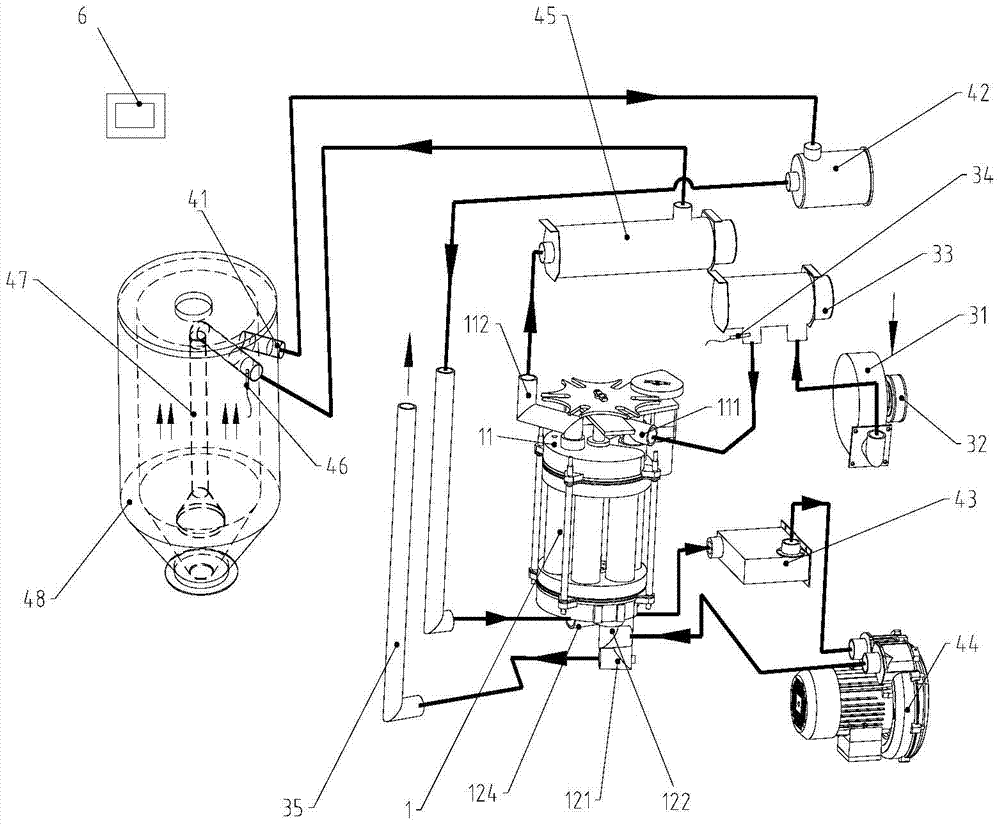

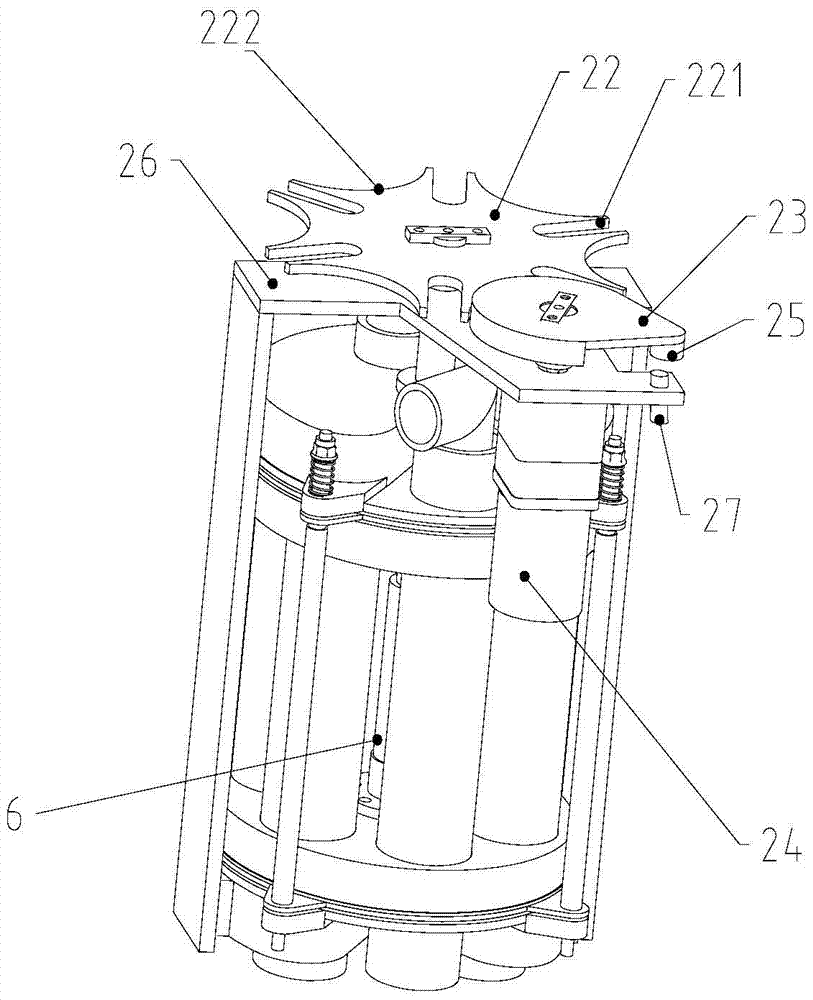

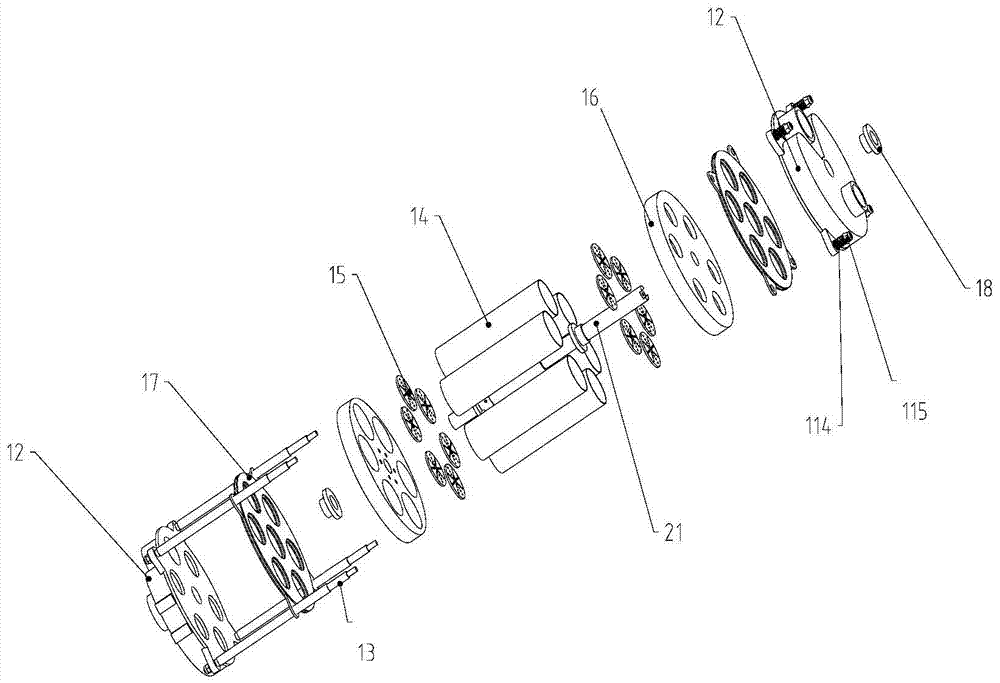

A multi-barrel molecular sieve runner intermittent circulation dehumidification dryer

ActiveCN105202877BDecreased dew point fluctuationsFully regeneratedDrying solid materials without heatDrying gas arrangementsParticulatesDrive wheel

Owner:苏州尚恩特科塑料科技有限公司

Process for producing hydrogen peroxide with palladium catalyst fixed-bed anthraquinone method and its lye separator

ActiveCN106853957BIncrease production capacityIncrease active compensation spacePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical recyclingAnthraquinonesPtru catalyst

The invention discloses a hydrogen peroxide manufacturing technology using a palladium contact agent fixed bed anthraquinone method. The technology is reasonable and efficient in technology, the production capacity of the catalyst is obviously improved, the generation of degraded products is reduced, the optimization for the regeneration environment of activated aluminum oxide is realized by intensifying the separation effect of an alkali liquor separator, the regeneration environment of a working solution is optimized, and a working solution heater is arranged before the working solution enters into a carclazyte bed for increasing the regeneration temperature, so that the activity of the activated aluminum oxide is improved, the regeneration effect is strengthened, the regeneration effect of the activated aluminum oxide plays roles to the maximum space, more degraded products are regenerated, the growth rate of the degraded products is controlled from the source, the compensation space of catalyst activity during production is effectively improved, the service life of the catalyst is prolonged, the heater is used for heating by using secondary steam generated by an alkali evaporator, the purpose of preheating the working solution to improve the regeneration result can be achieved, and recycling for the secondary steam of the system is carried out.

Owner:HUAQIANG CHEM GRP

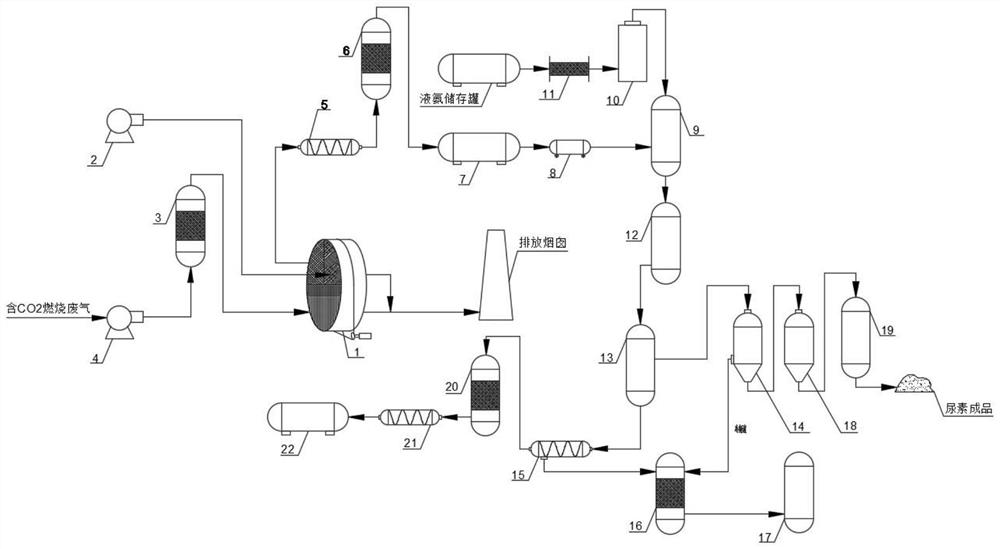

Dual-carbon treatment carbon capturing, recycling and reusing system and method

PendingCN114432839AStable concentrationImprove securityGas treatmentDispersed particle separationSorbentProcess engineering

The invention belongs to the field of dual-carbon treatment, relates to a urea preparation technology, aims to solve the problems that the prior art is only suitable for recycling carbon dioxide from low-concentration carbon dioxide waste gas, and is complex in process and high in operation cost, and particularly relates to a dual-carbon treatment carbon capturing, recycling and reusing system and method which comprises a desorption module, a synthesis module and a decomposition module. The desorption module comprises a rotating wheel machine, the input end of the rotating wheel machine is connected with an air cooler and a humidification washing tower, the input end of the humidification washing tower is provided with a suction fan, a waste gas pipe of the rotating wheel machine is connected with a discharge chimney, and the rotating wheel machine comprises a desorption area, a cooling area and an adsorption area. The safety performance is good, and the ignition phenomenon is not prone to occurring when hot airflow regeneration is adopted; calcium carbonate is adopted as an adsorbent, and the regeneration temperature can be increased; the equipment resistance is low, the operation cost is low, and the concentration of carbon dioxide in the adsorbed tail gas is stable and convenient to control.

Owner:产学研(广州)环境服务有限公司

A method for producing olefins from oxygen-containing compounds

ActiveCN103539616BLow reaction temperatureAgent / material smallHydrocarbon from oxygen organic compoundsEthylene productionOxygenSeparation system

The invention discloses a method for preparing olefins from an oxygen-containing compound. The oxygen-containing compound is put into a main reactor and contacts and reacts with a regenerated catalyst from a first regenerator, and the reaction oil gas enters a separation system; a catalyst to be regenerated enters a first regenerator for regeneration, and the regenerated catalyst is recycled; C4-C8 hydrocarbons are put into an auxiliary reactor, and contact with a catalyst from a second regenerator, and then the reaction oil gas enters a separation system for separation; next, the catalyst enters the second regenerator to be regenerated and the regenerated catalyst is recycled. The method is high in selectivity of light olefins, simple in process flow and low in investment.

Owner:CHINA PETROCHEMICAL CORP +1

Method and device for fluidized catalytic conversion

ActiveCN101665712BReduce the temperatureRaise the preheat temperatureCatalytic crackingCatalytic transformationPtru catalyst

The invention provides a method for catalytic conversion of heavy oil, which comprises a fluidized catalytic conversion process that: heavy hydrocarbon raw materials contacts a catalyst in a riser reactor or fluidized bed reactor to react; the reaction temperature is 400 to 650 DEG C (preferably 480 to 560 DEG C); the reaction pressure is 0.11 to 0.4MPa; the contact time is 0.05 to 5 seconds (preferably 0.1 to 3 seconds); and the weight ratio of the catalyst to the raw materials ( catalyst to oil ratio) generally is 3 to 15, preferably 5 to 12. The reaction products flow in a settler for catalyst and oil gas separation; the separated catalyst to be regenerated is stripped by a stripping section and enters a regenerator for coke burning regeneration; and the regenerated catalyst is cooled or directly returns to the riser reactor to be recycled. The method can solve the problems encountered in the resid-blend ratio improvement and gasoline upgrade and update processes of the prior catalytic conversion.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

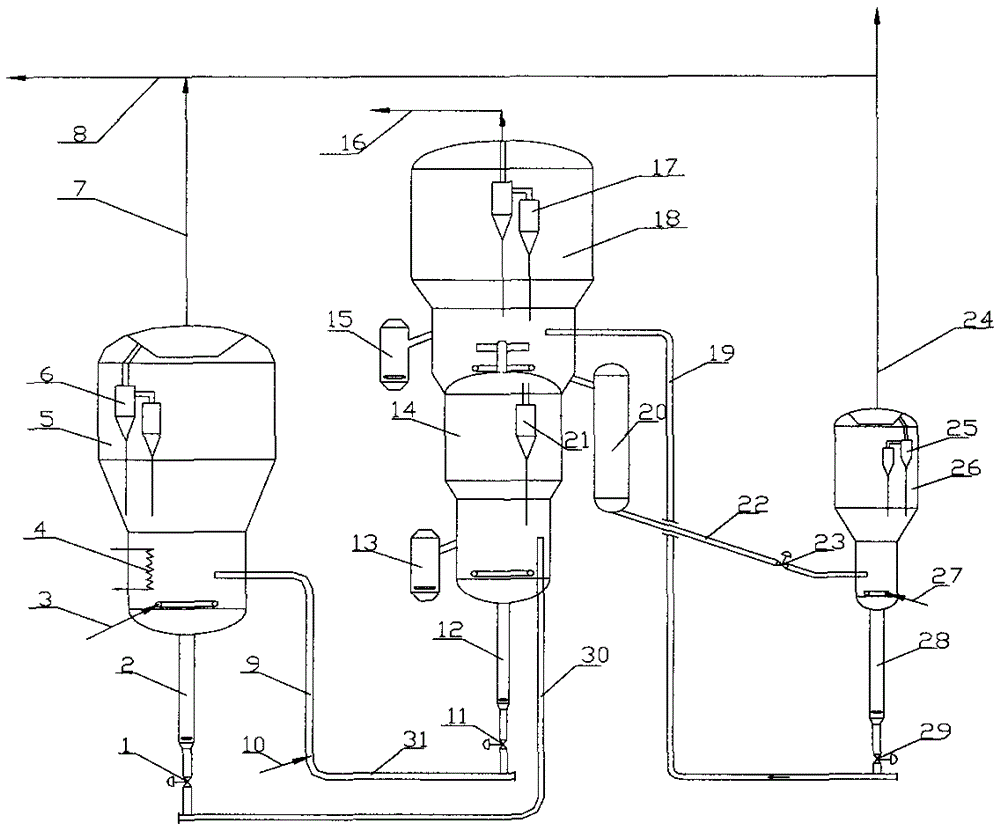

Method for preparing aromatic hydrocarbons and low-carbon olefins through conversion of methanol or dimethyl ether

InactiveCN107540498AGood hydrothermal stabilityRaise regeneration temperatureHydrocarbon from oxygen organic compoundsEthylene productionHydrogenMetal catalyst

The invention relates to a method for preparing aromatic hydrocarbons and low-carbon olefins through conversion of methanol or dimethyl ether, and mainly solves the problems that the temperature of aregenerator in a production process is high, a catalyst is gradually subjected to hydrothermal deactivation, the aromatic hydrocarbon yield is lowered and the continuous and stable operation of a device is influenced. The method adopts the following technical scheme: by using a circulating fluid bed reaction-regeneration system, the methanol and / or the dimethyl ether are / is in contact with one ormore supported metal catalysts through a fluid bed reactor to generate the low-carbon olefins and an effluent which is rich in the aromatic hydrocarbons; and a hydrogen burning process of the deactivated spent catalysts is mainly completed through a rapid bed (8) by controlling the low temperature, and carbon burning is completed through a second dense-phase fluid bed regenerator (11) by controlling the high temperature. Thus, the method favorably solves the problems about the hydrothermal deactivation of the catalysts and the continuous and stable operation in the process of preparing the aromatic hydrocarbons and the low-carbon olefins through conversion of the methanol or the dimethyl ether, and can be used for industrial production of preparing the aromatic hydrocarbons and the low-carbon olefins through conversion of the methanol or the dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Compression heat adsorption type drying machine with zero gas consumption and low dew point

InactiveCN108654327ASave energyReduce energy consumptionGas treatmentDispersed particle separationAir compressionElectricity

The invention relates to the technical field of drying machines, and discloses a compression heat adsorption type drying machine with zero gas consumption and low dew point. The drying machine comprises a gas inlet pipe, wherein a filter pipe head is fixedly mounted at the right side of the gas inlet pipe; a blower is fixedly mounted at the right side of the filter pipe head; a steam-water separator is fixedly mounted at the right side of the blower; a compressed air pipeline is communicated to the right side of the steam-water separator; a connecting pipe is communicated to the bottom of thecompressed air pipeline; a first absorption tower is communicated to one end, away from the air compression pipeline, of the connecting pipe; a wafer check valve is fixedly mounted at one end, away from the steam-water separator, of the compressed air pipeline; a pipe head is fixedly mounted at the right side of the wafer check valve; a gas guide pipe is communicated to the right side of the pipehead; an electric heater is fixedly mounted at the top of the gas guide pipe; a hot air pipe is communicated to the bottom of the electric heater; and a gas guide pipe is communicated to one end, awayfrom the electric heater, of the hot air pipe. The blowing zero-consumption gas drying machine ensures that the gas dew point of a finished product has no drift, and the drying machine is convenientfor people to use.

Owner:江苏永蓝粮食机械有限公司

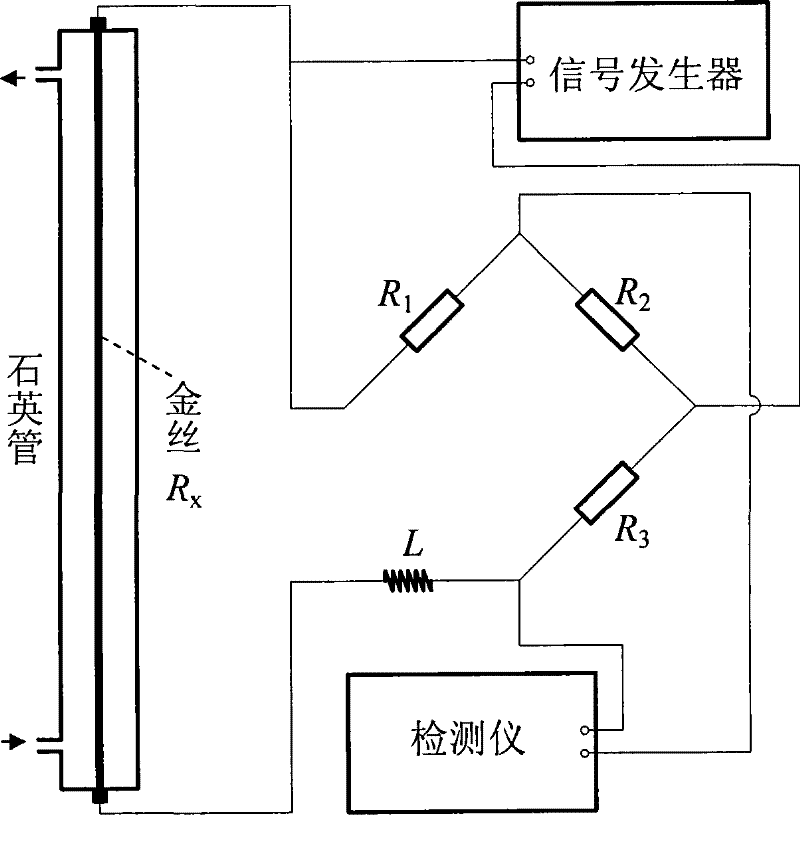

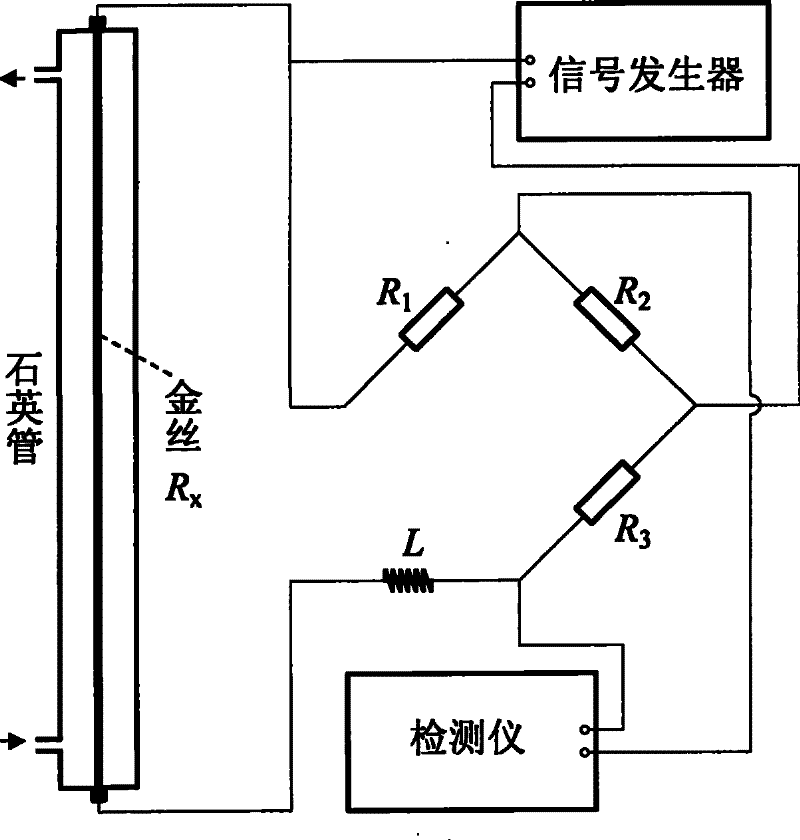

Method for measuring mercury content based on gold amalgam medium-high frequency alternating-current change

InactiveCN101403719BOmit the photoelectric conversion processGood choiceMaterial resistanceMercury pollutionAlternating current

The invention discloses a method used for measuring the content of mercury based on the change of high-frequency AC current in a gold amalgam. The method is characterized in that: under the condition of given time and temperature, when atmosphere containing the mercury passes through a mercury detector which contains golden wire at a certain flowing speed, firstly, the gold amalgam is formed on the surface of the golden wire, thus causing the surface resistance of the golden wire to be changed; by the 'skin effect' of the high-frequency AC current, the change of the high-frequency current is detected by an AC bridge; and the content of the atmosphere mercury can be obtained according to the change of the high-frequency current. In the method used for measuring the content of mercury, the mercury detector used for measurement utilizes a principle that the current is changed owning to the change of the resistance in the gold amalgam to test the content of the mercury in the atmosphere, saves the photoelectric conversion process of the cold-vapour atomic absorption method and the atomic fluorescence method, has good selectivity, strong anti-interference capability, is easy to realizethe individual detection and real-time detection of atmosphere mercury pollution so as to be adapted to the requirement of quick and online detection; and compared with a gold film detector, the mercury detector needs no complex coating process.

Owner:CHONGQING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com