Purification system and purification method for treating VOCs-containing waste gas by using circulating fluidized bed.

A waste gas purification system and circulating fluidized bed technology, applied in chemical instruments and methods, combustion methods, gas treatment, etc., can solve the problems of low purification efficiency, limited application conditions and high investment costs of VOCs waste gas treatment technology, and achieve the goal of overcoming Low adsorption effect, reduced system investment and operating costs, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

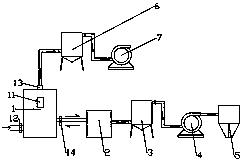

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] Such as figure 1 As shown: the present invention includes a circulating fluidized bed adsorption device 1, a gas-solid separator 11, a VOCs-containing gas inlet 12, a gas outlet 13, an adsorbate inlet and outlet 14, a regeneration device 2, a bag filter a3, a fan a4, and an incineration device 5. Bag filter b6, fan b7. Waste gas containing high, medium and low concentrations of VOCs enters the circulating fluidized bed adsorption device 1 through the VOCs-containing gas inlet 12, and the adsorbate with adsorptive properties enters the circulating fluidized bed adsorption device 1 through the adsorbate inlet and outlet 14, and the circulating fluidized In the bed-type adsorption device 1, after the gaseous state of the VOCs-containing waste gas is in close contact with the adsorbate with adsorption capacity, it is transformed into an adsorbate that carries organ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com