Device for producing alkene from oxygenated compound

A compound and olefin technology, applied in the direction of producing hydrocarbons from oxygen-containing organic compounds, ethylene production, hydrocarbon cracking, etc., can solve the problems of low conversion rate, cracking condition limitation, heat imbalance of olefin cracking system, etc., and achieve high yield Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

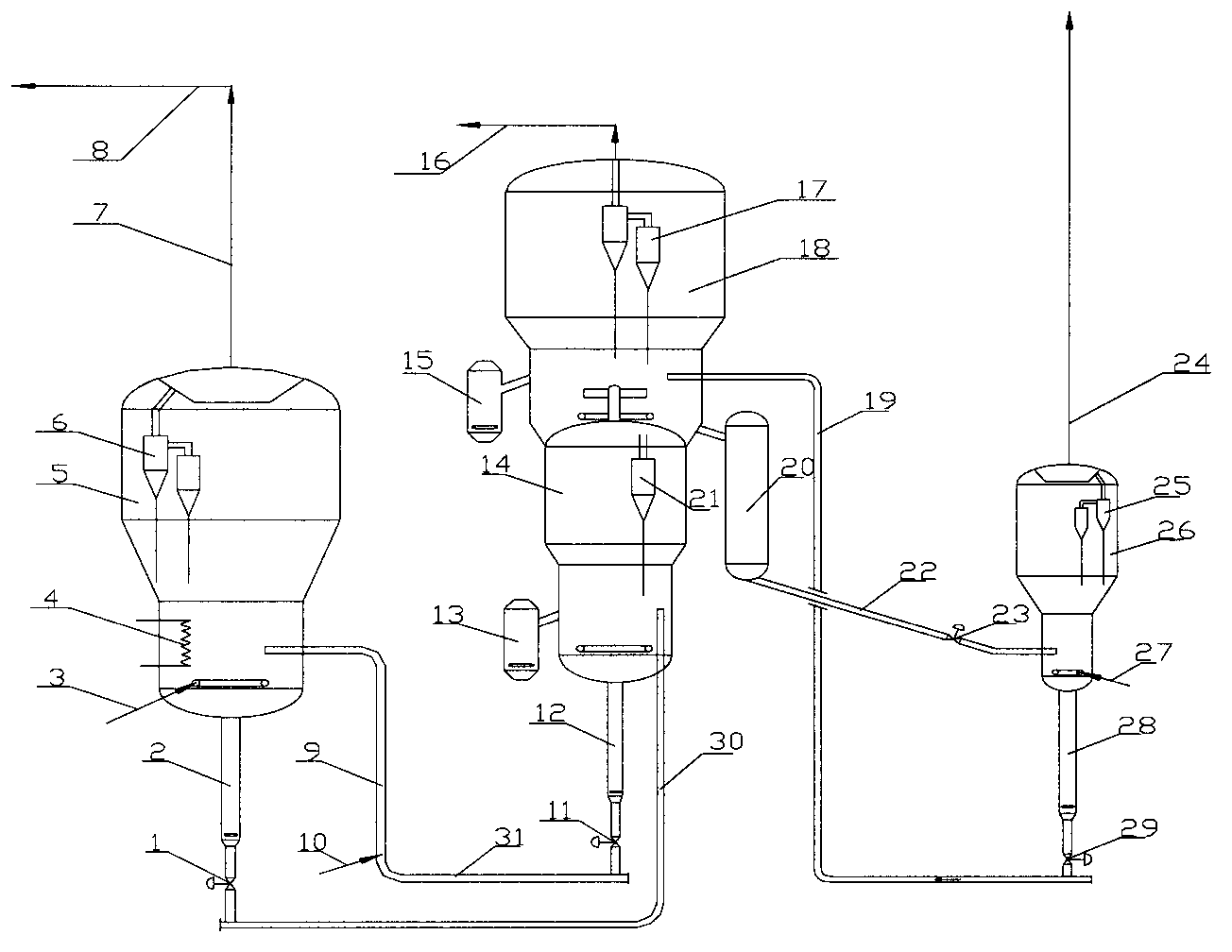

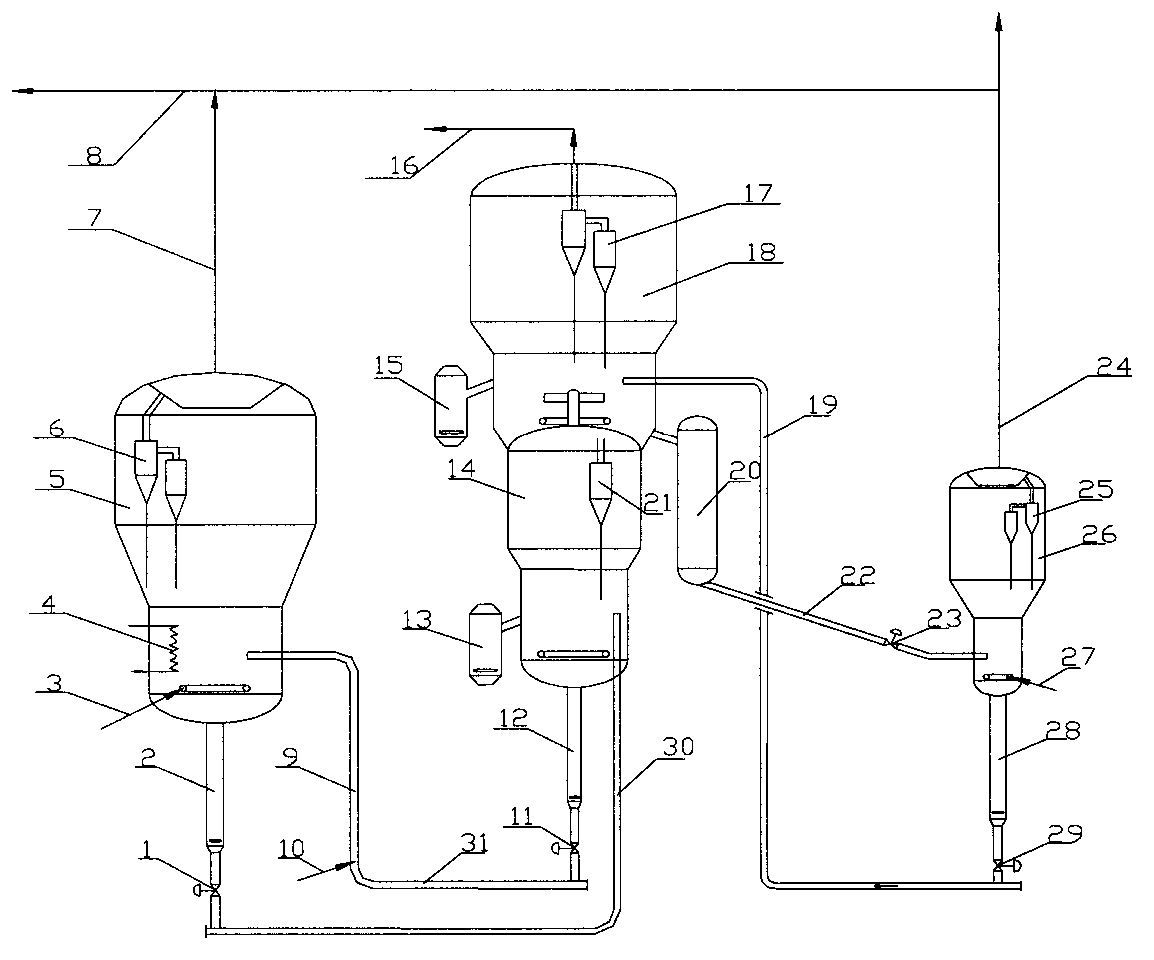

[0037] Such as figure 1 As shown, an oxygenate production olefin device is composed of a main reactor 5, an auxiliary reactor 26, a riser reactor 9, a first regenerator 14 and a second regenerator 18, and the main reactor 5 passes through the first waiting The raw catalyst delivery pipe 30, the riser reactor 9 and the first regenerated catalyst delivery pipe 31 communicate with the first regenerator 14, and the auxiliary reactor passes 26 through the second waiting catalyst delivery pipe and the second regenerated catalyst delivery pipe to the second The regenerator is connected.

[0038] The oxygen-containing compound 3 enters the lower part of the main reactor 5 and contacts and reacts with the high-temperature regenerated catalyst from the first regenerator 14. The reaction product is separated by the cyclone separator 6 of the main reactor, and the first reaction oil gas 7 is separated and passed through the quenching water washing system. The temperature of the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com