Dual-carbon treatment carbon capturing, recycling and reusing system and method

A carbon capture, one-way technology, applied in the field of dual-carbon treatment carbon capture and recycling systems, can solve the problems of high operating costs and complex processes, and achieve the effects of good safety performance, stable concentration and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

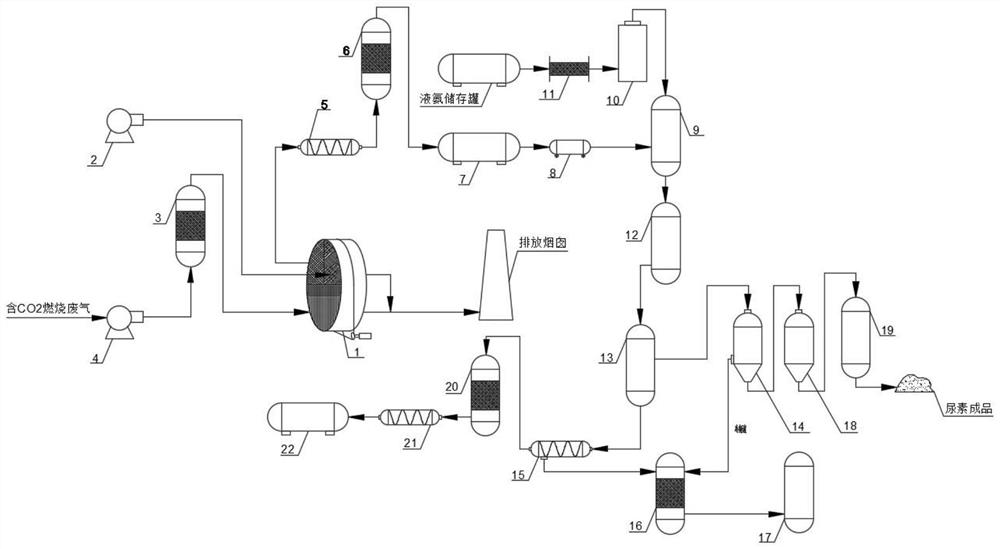

[0028] Such as figure 1 As shown, a dual-carbon governance carbon capture recovery and reuse system includes a desorption module, a synthesis module, and a decomposition module. The desorption module includes a turbine 1, and the input end of the turbine 1 is connected to a cooling fan 2 and a humidification scrubber. 3. The input end of the humidifying scrubber 3 is provided with a suction fan 4, and the waste gas pipe of the turbine 1 is connected to the discharge chimney. The turbine 1 includes a desorption area, a cooling area and an adsorption area.

[0029] The synthesis module includes a first condenser 5, which is a shell-and-tube heat exchanger. The materials go into the tubes of the first condenser 5, and water goes between the tubes to by-produce steam. The degree of condensation of ammonia and carbon dioxide is adjusted, the input end of the first condenser 5 is connected with the output end of the turbine 1, the output end of the first condenser 5 is provided with...

Embodiment 2

[0033] A carbon capture recovery and reuse method for double carbon governance, comprising the following steps:

[0034]Step 1: Use external equipment to divide the two ends of the cylindrical corrugated carbon dioxide absorbent into absorption, regeneration, and cooling areas, rotate the cylindrical honeycomb absorbent, and deliver combustion exhaust gas in the range of 50 to 80 ° C to the absorption area , at the same time, supply water vapor in the range of 150-180°C to the regeneration area, and obtain high-concentration and concentrated carbon dioxide through the separation reaction of carbon dioxide in the corrugated absorbent;

[0035] Step 2: The temperature of the urea synthesis reaction solution rises to 180--185°C, the mixed solution is evenly distributed in the stripping tube and forms a liquid film on the inner wall, and the introduced carbon dioxide gas meets the synthesis reaction solution countercurrently in the tube, Steam heating, excess ammonia and unconvert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com