Molecular sieve ceramic membrane material for olefin purification as well as preparation method and application of molecular sieve ceramic membrane material

A ceramic material and molecular sieve technology, applied in the field of inorganic membrane materials, can solve the problem of inability to deeply purify polar oxygen-containing compounds, and achieve the effects of excellent rigidity and mechanical strength, high heat resistance, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

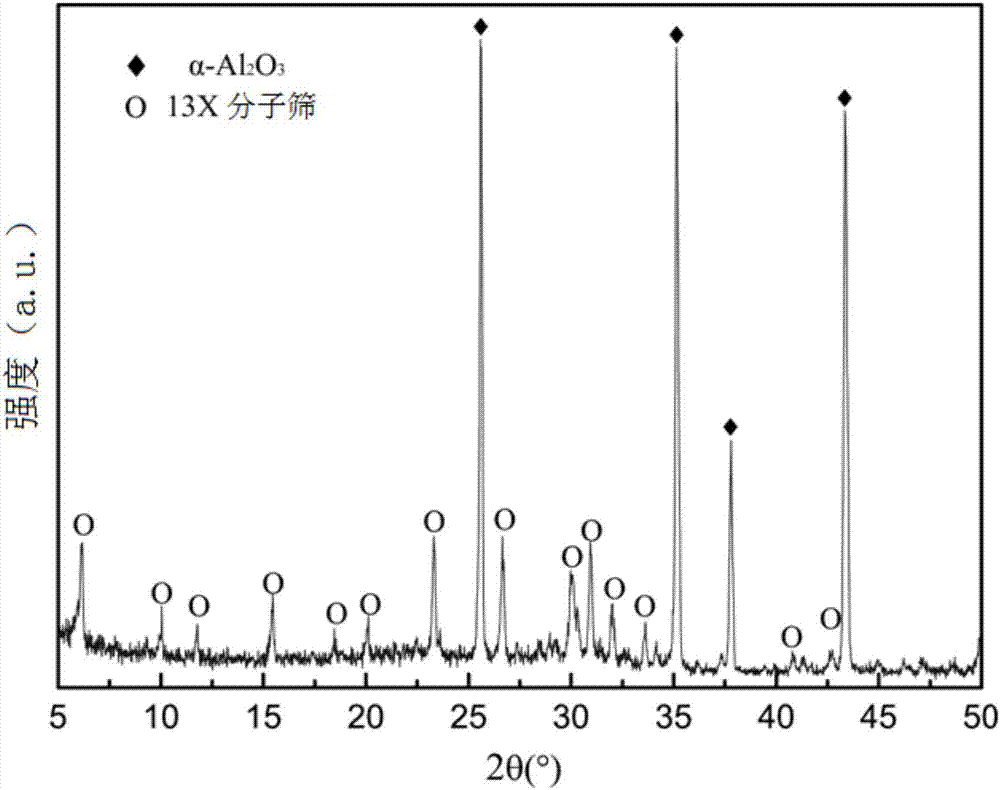

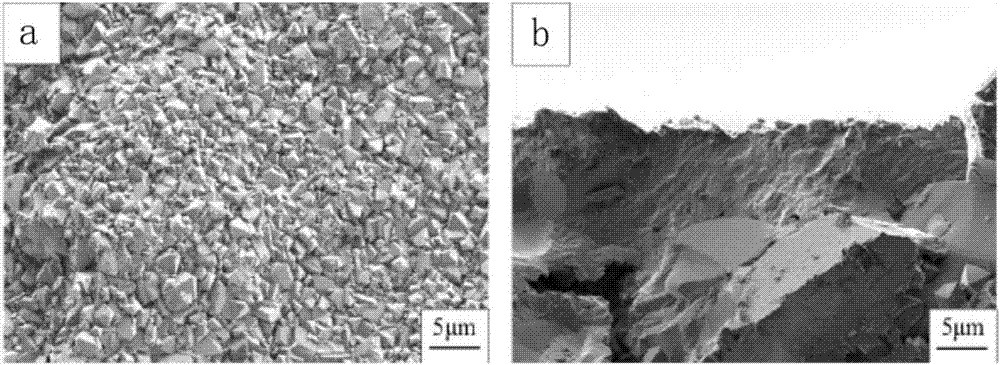

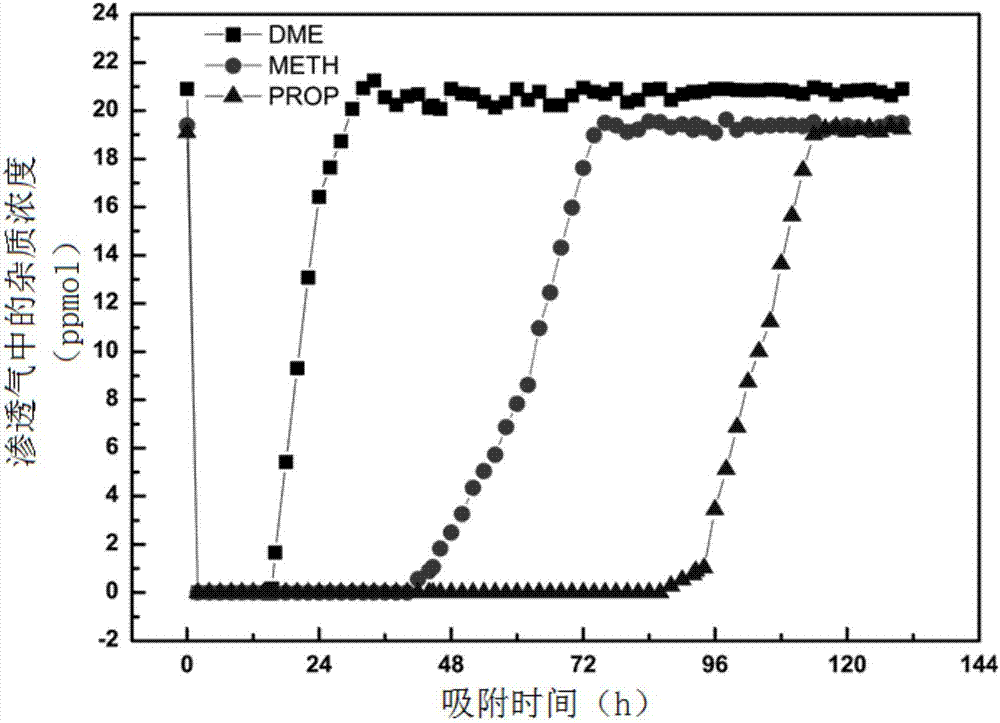

[0057] Ceramic tube pretreatment: α-Al with an average pore size of 2 μm and a porosity of 55% 2 o 3 The ceramic tube was baked in a muffle furnace at 200 °C for 1 h, cooled to room temperature naturally, and the α-Al 2 o 3 The surface of the ceramic tube was polished smooth, ultrasonically cleaned with deionized water for 2 hours, dried in an oven at 120°C for 3 hours, and cooled for later use. Will be polished smooth α-Al 2 o 3 Soak the ceramic tube in polydopamine solution: prepare polydopamine solution according to the ratio of 2mL polydopamine (2mg / L) / 100mL TRIS-HCl (10mmol / L), and then place the ceramic tube in polydopamine solution under continuous stirring Soak at 25°C for 10 hours, and finally dry for later use.

[0058] Preparation of molecular sieve seed crystal sol: mix aluminum hydroxide, sodium silicate, sodium hydroxide, and deionized water according to n(Al):n(Si):n(Na):n(H 2O)=2:3:12:300 material ratio mixed at room temperature, the specific method is: f...

Embodiment 2

[0063] Ceramic tube pretreatment: α-Al with an average pore size of 0.1 μm and a porosity of 20% 2 o 3 The ceramic tube was baked in a muffle furnace at 200 °C for 1 h, cooled to room temperature naturally, and the α-Al 2 o 3 The surface of the ceramic tube was polished smooth, ultrasonically cleaned with deionized water for 2 hours, dried in an oven at 120°C for 3 hours, and cooled for later use. Will be polished smooth α-Al 2 o 3 Soak ceramic tubes in polydopamine solution: Prepare polydopamine solution according to the ratio of 2mL polydopamine (2mg / L) / 40ml TRIS-HCl (10mmol / L), and then place ceramic tubes in polydopamine solution under continuous stirring Soak at 25°C for 10 hours, and finally dry for later use.

[0064] Preparation of molecular sieve seed crystal sol: mix aluminum hydroxide, sodium silicate, sodium hydroxide, and deionized water according to n(Al):n(Si):n(Na):n(H 2 O)=2:3:12:300 material ratio mixed at room temperature, the specific method is: first...

Embodiment 3

[0069] Ceramic tube pretreatment: α-Al with an average pore size of 5 μm and a porosity of 80% 2 o 3 The ceramic tube was fired in a muffle furnace at 200 °C for 1 h, cooled to room temperature naturally, and the α-Al 2 o 3 The surface of the ceramic tube was polished smooth, ultrasonically cleaned with deionized water for 2 hours, dried in an oven at 120°C for 3 hours, and cooled for later use. Will be polished smooth α-Al 2 o 3 Soak ceramic tube in polydopamine solution: prepare polydopamine solution according to the ratio of 8mL polydopamine (2mg / L) / 100ml TRIS-HCl (10mmol / L), then place the ceramic tube in polydopamine solution under continuous stirring Soak at 25°C for 24 hours, and finally dry for later use.

[0070] Preparation of molecular sieve seed crystal sol: mix aluminum hydroxide, sodium silicate, sodium hydroxide, and deionized water according to n(Al):n(Si):n(Na):n(H 2 O)=2:12:50:300 material ratio mixed at room temperature, the specific method is: first d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com