Catalytic cracking method

A catalytic cracking and catalyst technology, applied in the direction of catalytic cracking, cracking, only multi-stage series refining and cracking process treatment, etc., can solve the problems of adding more equipment and complex cooling measures of regenerant, and achieve the improvement of total liquid yield, Conducive to product distribution and the effect of reducing olefin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

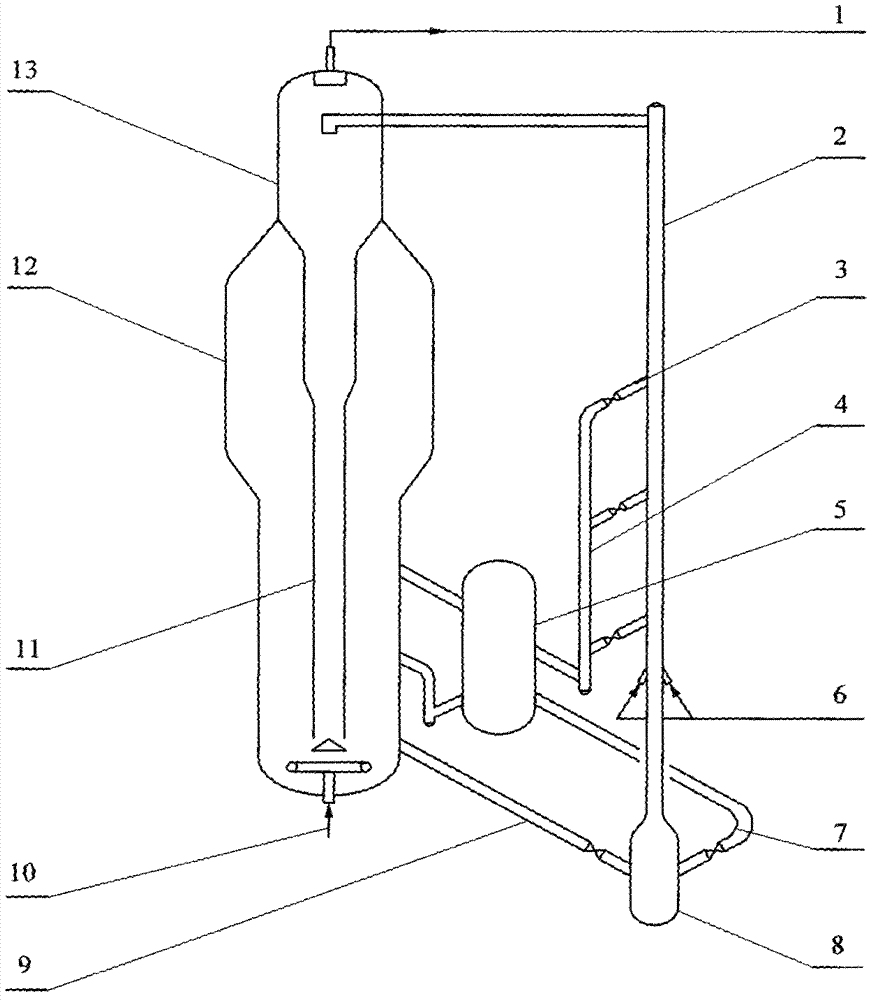

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 (comparative example)

[0037] The test is carried out on a common riser catalytic cracking test device. The feed is Luning pipeline transportation mixed heavy oil. The main properties are listed in Table 1. The treatment capacity is 30 kg / day. The reverse activity is 62, and the carbon content is 0.05w%. The main operating conditions, product distribution and main properties of the products of the riser reactor are listed in Table 2 and Table 3.

Embodiment 2

[0038] Embodiment 2 (comparative example)

[0039] By embodiment 1, the difference is that the feed is hydrogenated wax oil, the main properties are listed in table 1, and the processing capacity is 30 kg / day, and the catalyst used in the test is RSC-2006 industrial balancer, and the micro-reaction activity of the balance catalyst is 60 , the carbon content is 0.06w%. The main operating conditions, product distribution and main properties of the products of the riser reactor are listed in Table 2 and Table 3.

Embodiment 3

[0040] Embodiment 3 (comparative example)

[0041] According to embodiment 1, difference is that feed is hydrogenated heavy oil, and main character is listed in table 1, and processing capacity is 30 kilograms / day, and the catalyst used in test is MLC-500 industrial balancing agent, and the micro-reactive activity of equilibrium catalyst is 63, The carbon content is 0.03w%. The main operating conditions, product distribution and main properties of the products of the riser reactor are listed in Table 2 and Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com