Hollow core sandwich rotary body fabric and application thereof

A rotator and sandwich technology, applied in fabrics, multi-strand fabrics, textiles, etc., can solve problems such as large loss, unstable wave transmission, complicated preparation process of rotator radome, etc., and achieve good electrical performance and wave transparency uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

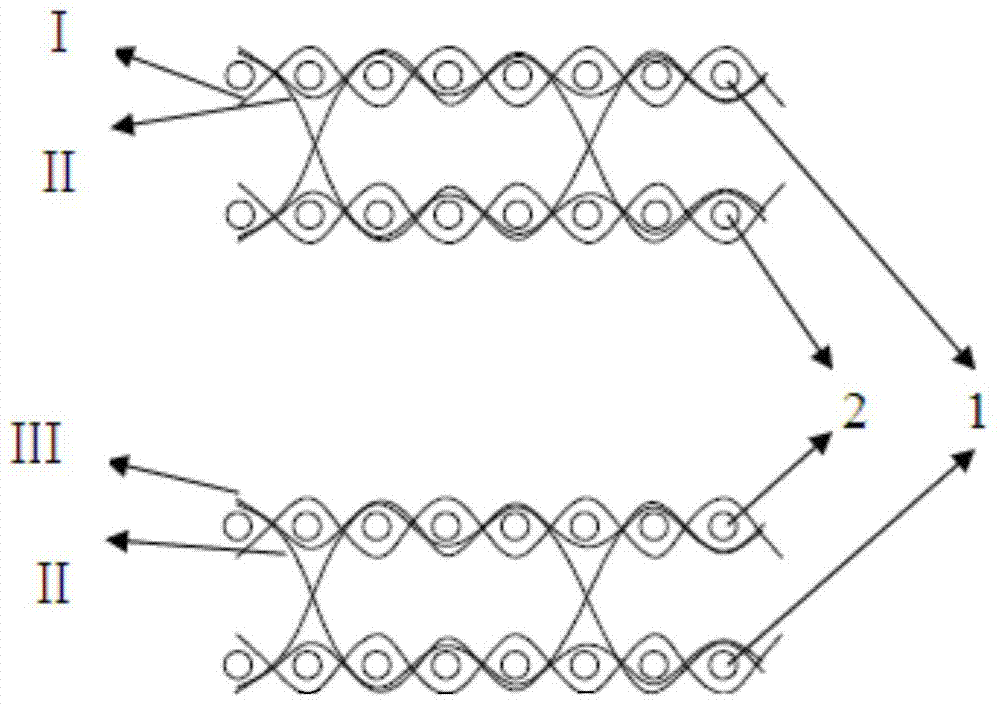

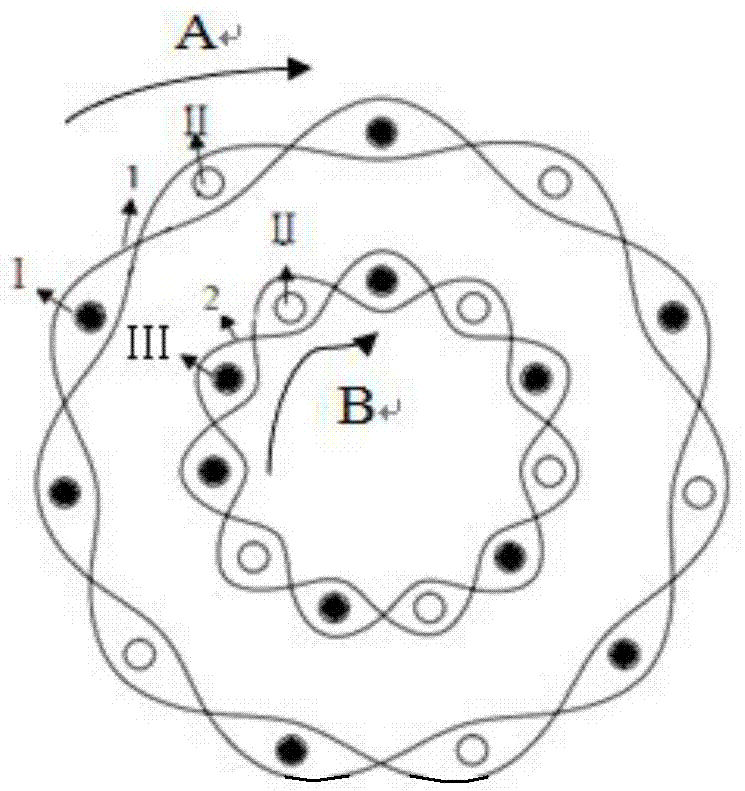

[0024] As shown in the figure, the hollow sandwich rotary fabric is interwoven by the outer warp system I, the pile warp system II and the outer weft system 1 (the ground weave is represented by plain weave), forming the outer layer of the rotary fabric; the inner layer The warp system III, the pile warp system II and the inner layer weft yarn system 2 are interwoven to form the inner layer of the rotary fabric; the pile warp system II connects the inner and outer layers of the fabric (the connection method is represented by "3 / 8W"), so that the inside and outside The fabric becomes a hollow sandwich fabric. In the inner and outer layers, the total number of warp yarns is an odd number. The outer layer weft yarn system 1 alone completes all the interweaving of the outer layer warp yarn system I and the pile warp system II. The inner layer weft yarn system 2 Complete all the interweaving of warp system III and warp system II of the inner layer alone.

[0025] The above-mentione...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com