Device system for preparing nitric acid and using method of device system

A technology of nitric acid and dust removal system, applied in the direction of nitric acid, nitrogen oxides/oxyacids, etc., can solve the problems of reducing the height of the compressor scale absorption tower, large compressor scale, and high equipment investment, so as to reduce equipment investment and scale. , the effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

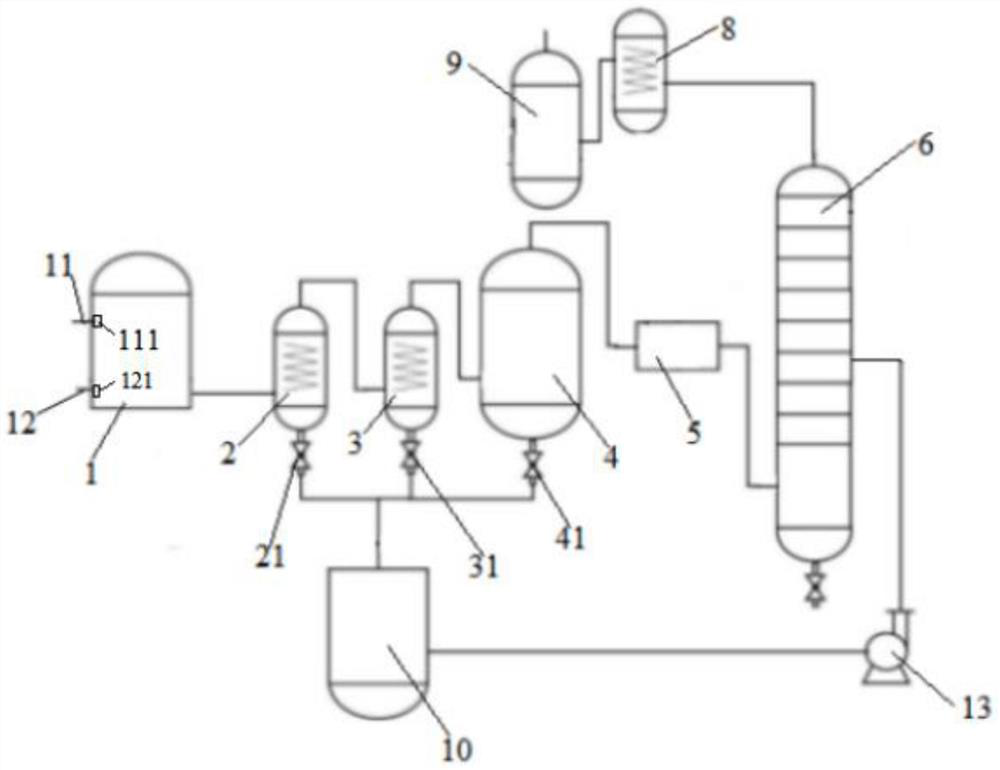

[0062] like figure 1 As shown, a device system for preparing nitric acid includes a steam mixing chamber 1, a cooler assembly, a buffer tank 4, a compressor 5, an absorption tower 6 and a tail gas treatment device in turn; wherein, the cooler assembly includes a primary cooler 2. Secondary cooler 3 ; the tail gas treatment device includes a tail gas heat exchanger 8 and a reactor 9 .

[0063] like figure 1 As shown, the steam mixing chamber 1 is used for receiving nitrate decomposition exhaust gas or NO prepared by ammonia oxidation method 2 2. Mixing reaction is carried out after the water vapor; the steam mixing chamber 1 is provided with a first air inlet 11 and a second air inlet 12, and the first air inlet 11 is used for feeding nitrate decomposition tail gas or ammonia oxidation method prepared NO 2 ; The second air inlet 12 is used to introduce high temperature steam; the steam mixing chamber 1 is provided with a first sprayer 111, the first sprayer 111 is connected ...

Embodiment 2

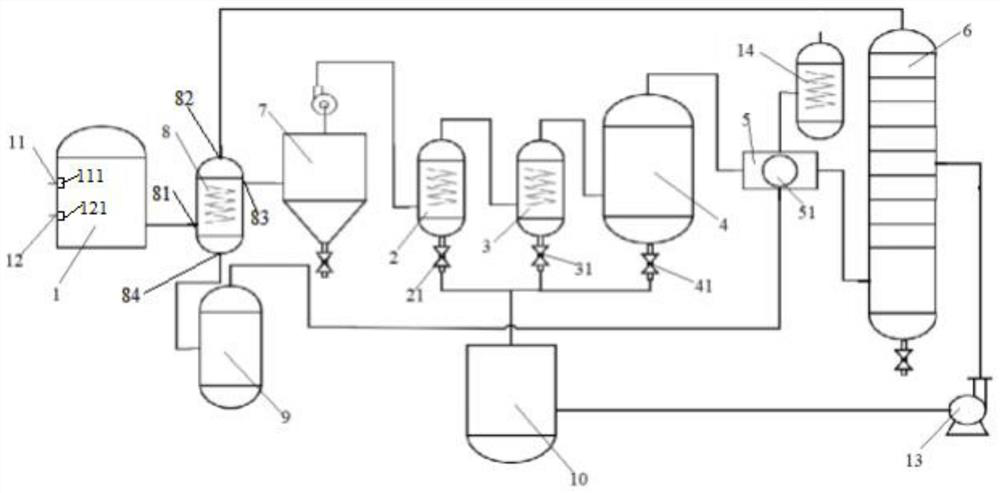

[0069] like figure 2 As shown, a device system for preparing nitric acid includes a steam mixing chamber 1, a dust removal system 7, a cooler assembly, a buffer tank 4, a compressor 5, an absorption tower 6 and a tail gas treatment device in turn; wherein, the cooler assembly includes The primary cooler 2, the secondary cooler 3; the tail gas treatment device includes a tail gas heat exchanger 8 and a reactor 9, and the tail gas heat exchanger is provided with two channels, which are the third air inlet 81 - the first An air outlet and a fourth air inlet 82 - a second air outlet, the two gas passages are used for heat exchange of different gases.

[0070] like figure 2 As shown, the steam mixing chamber 1 is used for receiving nitrate decomposition exhaust gas or NO prepared by ammonia oxidation method 2 2. Mixing reaction is carried out after the water vapor; the steam mixing chamber 1 is provided with a first air inlet 11 and a second air inlet 12, and the first air inlet ...

Embodiment 3

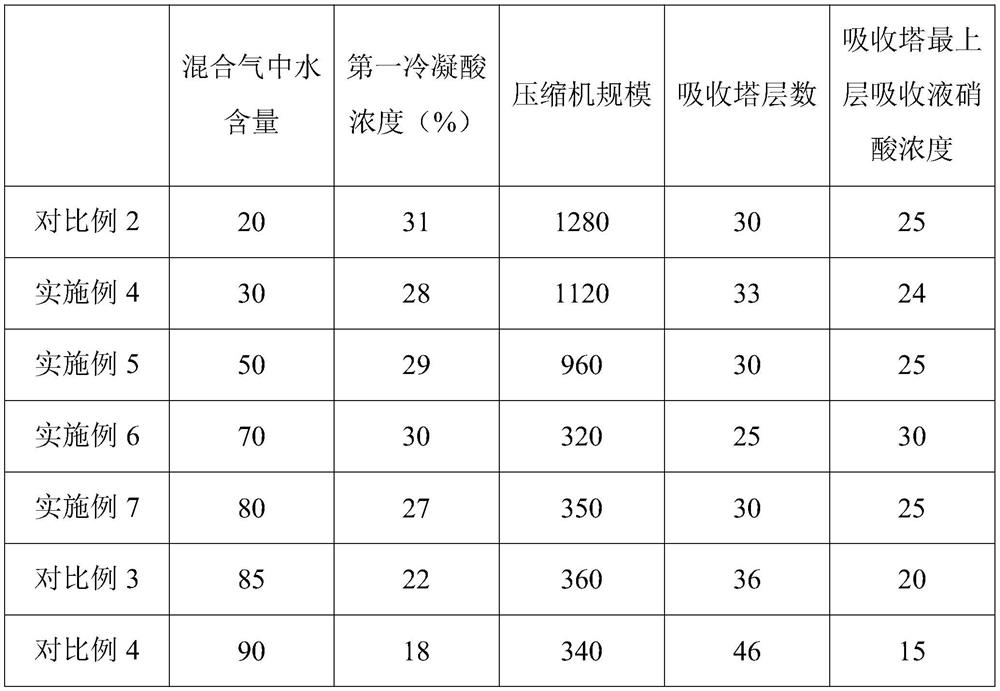

[0079] The decomposed and dust-collected gas of cobalt nitrate was introduced into the device system of Example 2, wherein the NOX concentration in the decomposed and dust-collected gas of cobalt nitrate was 80%, and the temperature was 180°C. The gas first passes through the steam mixing chamber 1, so that the water content in the mixture rises to 56%, and the temperature rises to 220°C. After that, the exhaust gas is preheated by the exhaust gas heat exchanger 8, and the temperature of the gas after heat exchange drops to 190 ° C. The gas after heat exchange is deeply dedusted by the dust removal system 7. Cooling lowered the temperature below the dew point temperature of nitric acid, which was 67°C. A large amount of 28% condensed dilute nitric acid is obtained, and the gas is cooled again through the secondary cooler 3 to make the temperature drop to 30° C. to obtain another part of dilute nitric acid, and both parts of the condensed dilute nitric acid are injected into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com