Catalytic conversion method for reducing benzene content in gasoline

A catalytic conversion method and a technology of benzene content, applied in the field of catalytic conversion to reduce the benzene content of gasoline, can solve the problems such as the unspecified benzene hydrogenation rate, and achieve the effects of increasing gasoline yield, increasing octane number, and increasing octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

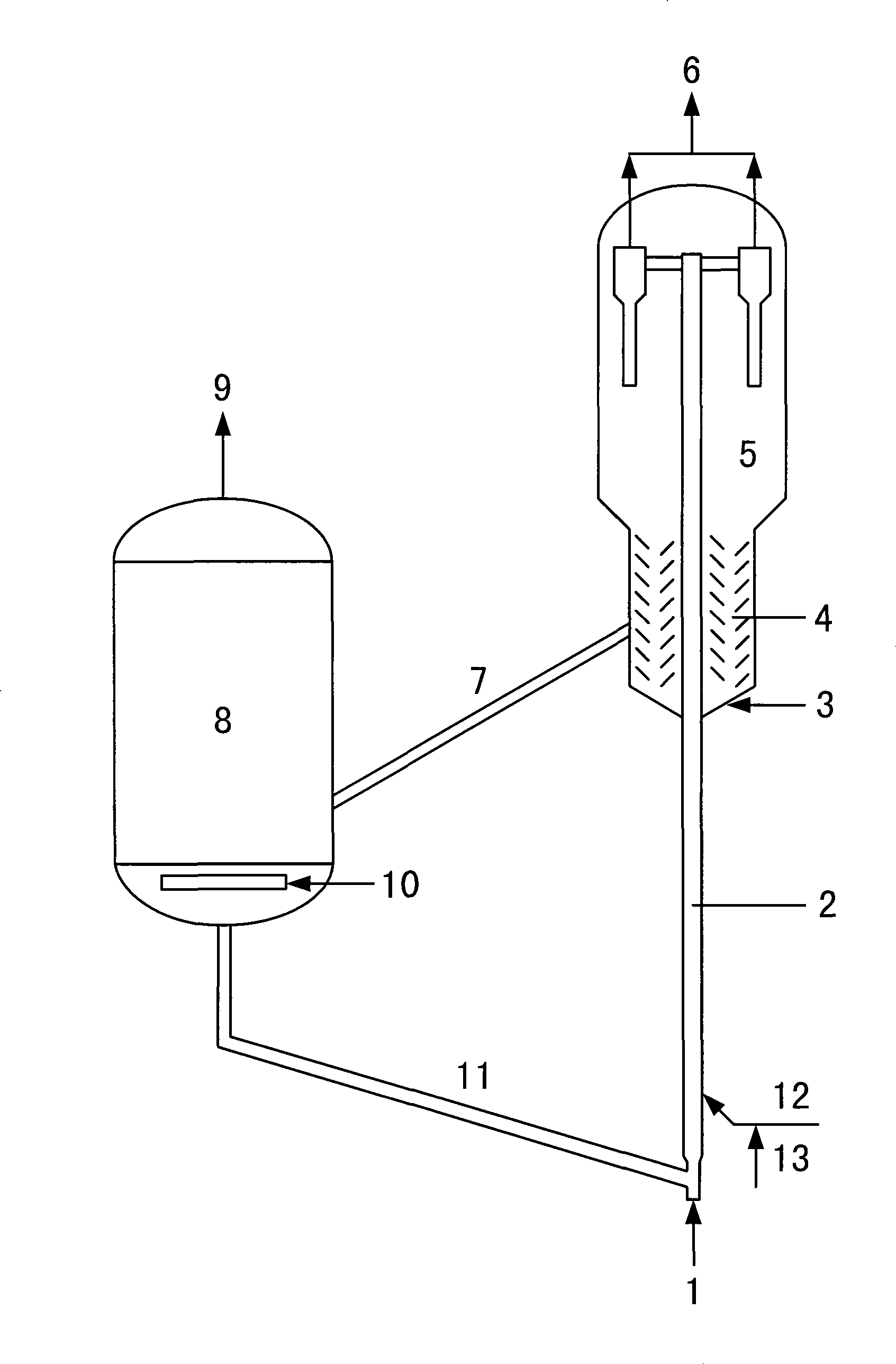

[0036] This example illustrates the situation of producing low-benzene gasoline by catalytic conversion and alkylation in a small fluidized bed reactor using the method provided by the present invention.

[0037] The gasoline raw material A listed in Table 1 was used as the raw material for catalytic cracking, and the above-mentioned catalyst was used to carry out the test of catalytic conversion and alkylation to produce low-benzene gasoline in a small fluidized bed reactor operated by continuous reaction regeneration.

[0038] Gasoline raw material A, small molecule olefin-containing gas and preheated high-temperature steam are mixed into the fluidized bed reactor. The reaction temperature is 300°C, the reactor pressure is 0.6 MPa, the weight ratio of the catalyst to the gasoline raw material is 20, and the gasoline The weight hourly space velocity of the raw material is 6 hours -1 , the ratio of agent to oil is 20, with catalytic cracking dry gas (containing ethylene 15% vo...

Embodiment 2

[0041] Feed oil B is contacted with catalyst in a small continuous fluidized bed reactor for catalytic conversion and alkylation. The main operating conditions are: the reaction temperature is 350°C, the reactor pressure is 0.5 MPa, the weight ratio of the catalyst to the gasoline feedstock is 15, and the weight hourly space velocity of the gasoline feedstock is 5 hours -1 , the agent-to-oil ratio is 15, using catalytically cracked liquefied gas (containing 35% vol of propylene) as a small molecule olefin donor, the weight ratio of the gasoline raw material to the liquefied gas is 10:1, and the water injection (accounting for raw material) is 15% by weight. The alkylation product obtained from the top of the reactor is cooled and separated to obtain gaseous products and liquid products. The regeneration temperature of the catalyst is 550°C, and the regenerated catalyst is cooled and returned to the reactor for recycling. The test conditions, product distribution and main prop...

Embodiment 3

[0043] Feed oil C is contacted with a catalyst in a small continuous fluidized bed reactor for catalytic conversion and alkylation. The main operating conditions are: the reaction temperature is 450°C, the reactor pressure is 0.3 MPa, the weight ratio of the catalyst to the gasoline feedstock is 8, and the weight hourly space velocity of the gasoline feedstock is 20 hours -1 , the ratio of agent to oil is 8, with catalytic cracking dry gas (containing ethylene 15% vol) as the small molecular olefin donor, the weight ratio of the gasoline raw material to the dry gas is 14:1, and the water injection (accounting for raw material) is 10% by weight. The alkylation product obtained from the top of the reactor is cooled and separated to obtain gaseous products and liquid products. The regeneration temperature of the catalyst is 600°C, and the regenerated catalyst is cooled and returned to the reactor for recycling. The test conditions, product distribution and main properties of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com