Claus tail gas hydrogenation catalyst

A technology of hydrogenation catalyst and Claus tail gas, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, chemical instrument and method, etc. It can solve the problems of prolonging the loading and unloading time of the catalyst, and the specific surface area needs to be improved, so as to achieve easy ball formation, Strong anti-powdering ability and high lateral compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

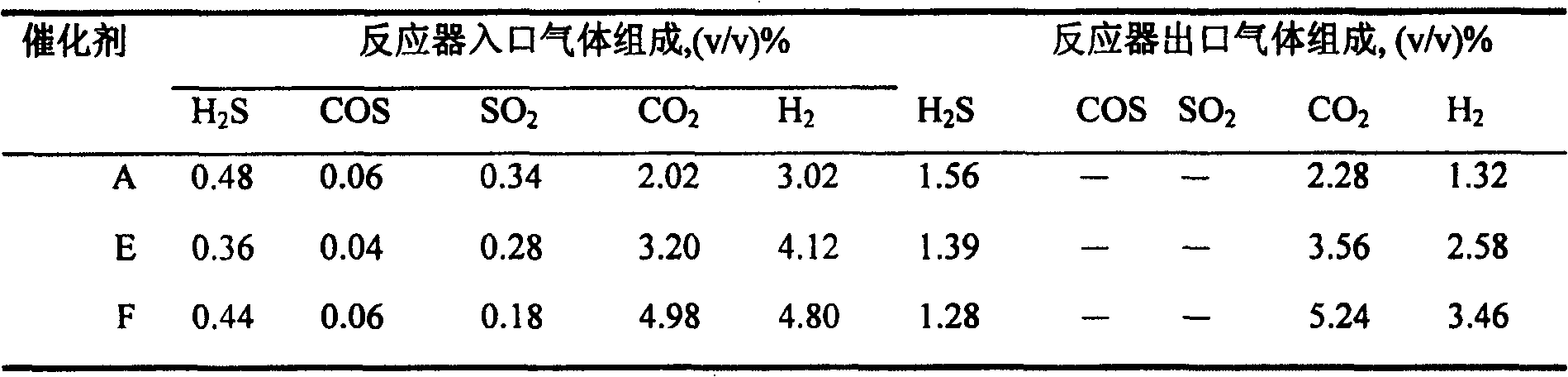

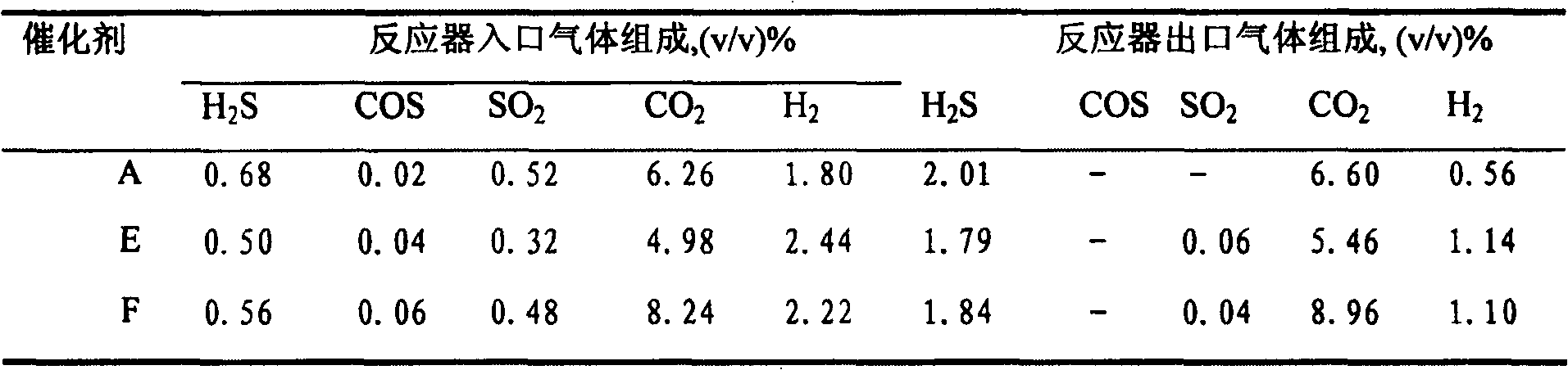

Examples

Embodiment 1

[0029] Weigh 10Kg of silicon-modified aluminum hydroxide dry rubber powder with a pore volume of 1.2 ml / g, a specific surface area of 438 m2 / g, and a silicon dioxide content of 2.5%, and place it in a roasting furnace at 600°C for rapid dehydration for 1 hour , get material 1. Take by weighing 0.43 milliliters / gram of pore volume, the specific surface area is 40Kg of aluminum hydroxide quick de-powder of 321 square meter / gram, mixes with material 1 evenly.

[0030] Prepare nitric acid with a concentration of 8% (m / m), add 4 kg of silica sol with a concentration of 25%, and make a uniform solution. Put the above-mentioned mixed materials in the rolling ball machine, slowly spray the prepared solution into the above-mentioned mixed materials, turn the rolling balls to form, sieve, sieve out 3 ~ 5mm small balls, put them in 100% water In a steam atmosphere, hydrated for 10 hours, dried at 120°C for 6 hours, and calcined at 450°C for 4 hours to obtain spherical Al with a pore v...

Embodiment 2

[0055] The preparation method is the same as in Example 1, the silicon dioxide content in the silicon-modified aluminum hydroxide dry rubber powder is 2%, the pore volume is 1.1 ml / g, and the specific surface area is 418 square meters / g. Catalyst G was prepared, and its physicochemical properties are shown in Table 4.

Embodiment 3

[0057] The preparation method is the same as in Example 1, the silicon dioxide content in the silicon-modified aluminum hydroxide dry rubber powder is 1%, the pore volume is 0.94 ml / g, and the specific surface area is 387 m2 / g. Catalyst H was obtained, and its physicochemical properties are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com