Catalyst applied to continuous hydrogenation of aromatic nitro compound and preparation method

A technology for catalysts and nitro compounds, which is used in the field of catalysts and preparation for the continuous hydrogenation of aromatic nitro compounds, can solve the problems of limited catalytic activity, small specific surface area, limited active sites, etc., and achieves high atom economy and high Specific surface area and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

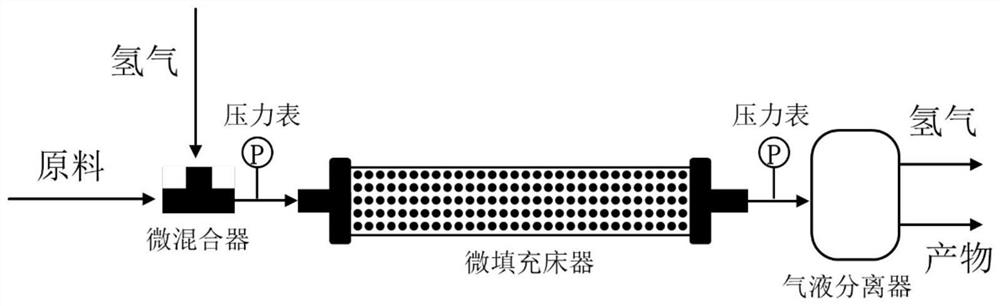

Method used

Image

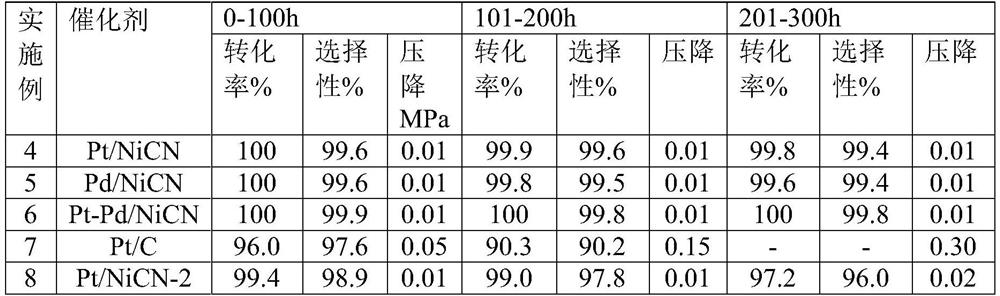

Examples

Embodiment 1

[0043] Example 1Pt / Ni / g-C 3 N 4 Catalyst preparation

[0044] Mix 20 g of urea powder and 6.2 g of nickel nitrate, add 5 g of pure water, grind, and dry to obtain a composite solid. 10 g of the composite solid was added to a 50 ml crucible, and the temperature was raised to a calcination temperature of 550 ° C at a heating rate of 10 ° C per minute in a tube furnace under helium purging conditions, and kept for 2 hours. After being naturally cooled to room temperature and after the calcination, the obtained composite carrier is molded, and the particle size is 0.4-0.6 mm. Add 1.0 g of the composite carrier into 200 g of pure water and stir. Heating in a water bath at 80° C., and adding a certain amount of chloroplatinic acid (the active metal Pt accounts for 5% of the mass of the catalyst). Stirring for 1 hour, with Na 2 CO 3 The pH of the solution was adjusted to 8.0, stirring was continued for 1 hour, and the temperature was cooled to room temperature. 0.15g NaBH 4 D...

Embodiment 2

[0045] Example 2Pd / Ni / g-C 3 N 4 Catalyst preparation

[0046] The catalyst preparation method of this embodiment is the same as that of Embodiment 1. The difference is that the active metal used is Pd (the active metal Pd accounts for 5% of the mass of the catalyst), and the obtained catalyst is recorded as Pd / NiCN.

Embodiment 3

[0047] Embodiment 3Pt-Pd / Ni / g-C 3 N 4 Catalyst preparation

[0048] The catalyst preparation method of this embodiment is the same as that of Embodiment 1. The difference is that the active metals used are Pt and Pd (the active metal Pt accounts for 2.5% of the catalyst mass, and the active metal Pd accounts for 2.5% of the catalyst mass), and the obtained catalyst is recorded as Pt-Pd / NiCN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com