A kind of catalyst for 1,2 propanediol and preparation method thereof

A catalyst, propylene glycol technology, used in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low selectivity, low reactivity, and short catalyst activity stability. and other problems, to achieve the effects of long stability, high hydrogenolysis activity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

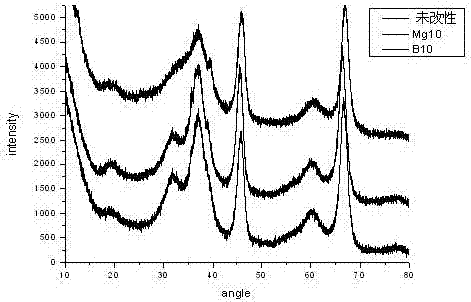

Image

Examples

Embodiment 1

[0018] Example 1 Preparation of alumina catalyst carrier

[0019] Weigh 400g of alumina (produced by Sinopec Changling Catalyst Factory), grind and dropwise add 100g of dilute nitric acid aqueous solution with a mass concentration of 10% to stir, knead, and then extrude on a extrusion machine with a plate hole diameter of 0.5mm . Bake the extruded alumina strips at 120°C for 24 hours, then roast the dried alumina strips at 540°C for 4 hours with nitrogen gas, and cut the roasted alumina into 10-20 mesh particles, which are called oxide particles. Aluminum catalyst carrier, spare.

Embodiment 2

[0020] Example 2 Preparation of 5% B 2 o 3 / Al 2 o 3 catalyst precursor

[0021] Weigh 100 g of the alumina carrier in Example 1. Weigh 8.88g of boric acid and dissolve it in 70g of distilled water to form a boric acid solution. Then add the prepared solution dropwise to the previously weighed 100g alumina carrier, stir while adding dropwise, and place it at room temperature for 8 hours after the dropwise addition is completed, then bake the alumina particles impregnated with boric acid at 120°C for 24 Hours, then bake the dried alumina strips impregnated with boric acid at 540°C for 4 hours under nitrogen to make B-containing 2 o 3 B with a mass fraction of 5% 2 o 3 / Al 2 o 3 Catalyst precursor, spare.

Embodiment 3

[0022] Example 3 Preparation of 10% B 2 o 3 / Al 2 o 3 catalyst precursor

[0023] Weigh 100 g of the alumina carrier in Example 1. Take boric acid 17.76g, be dissolved in 70g distilled water and be configured into boric acid solution. Then add the prepared solution dropwise to the previously weighed 100g alumina carrier, stir while adding dropwise, and place it at room temperature for 8 hours after the dropwise addition is completed, then bake the alumina particles impregnated with boric acid at 120°C for 24 Hours, then bake the dried alumina strips impregnated with boric acid at 540°C for 4 hours under nitrogen to make B-containing 2 o 3 B with a mass fraction of 10% 2 o 3 / Al 2 o 3 Catalyst precursor, spare.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com