Preparation method and application of catalyst for advanced removal of organic sulfur from coke oven gas

A coke oven gas and catalyst technology, which is applied in the field of preparation of coke oven gas organic sulfur deep removal catalysts, can solve the problems of not being able to achieve fine desulfurization and difficult removal, and achieve avoidance of coke accumulation, easy operation, and improved resistance Effects of Sulfur and Poison Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

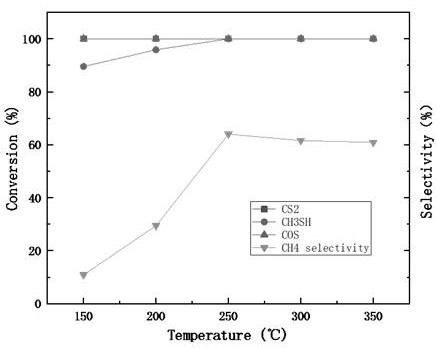

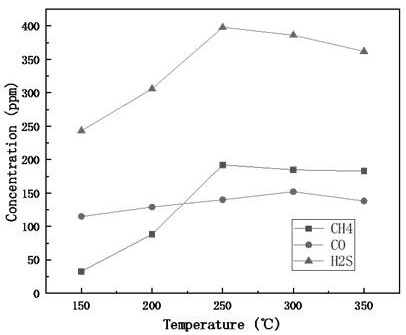

[0027] Example 1: Nano-TiO 2 (Particle size is 25nm, crystal form is anatase) Pt and Cu are supported on the carrier by wet impregnation method, and nano-TiO 2 , copper nitrate solution and platinum nitrate solution were put into the rotary evaporator, and dipped and loaded at 80°C for 20min, wherein the addition amount of copper nitrate was nano-TiO 2 4% of the mass, the amount of platinum nitrate added is nano-TiO 2 0.5% of the mass of the impregnated support carrier was placed in a blast drying oven at 100 °C for 10 h, and then placed in a muffle furnace at 500 °C for 2 h. After calcination, the catalyst was pressed, ground, and sieved. 40-60 mesh catalyst particles are obtained; the catalyst particles are packed in a fixed-bed reactor, the temperature of the heating furnace is set to 600 ° C, and then hydrogen with a volume concentration of 10% (nitrogen is used as a carrier gas) is introduced into the reactor. The catalyst particles were pre-reduced for 2 hours to obtai...

Embodiment 2

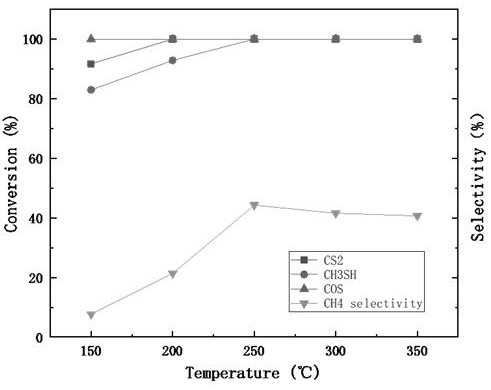

[0030] Example 2: In nanometer γ-Al 2 O 3 (particle size 5nm) Pd and Ce were loaded on the carrier by wet impregnation method, and the nano-γ-Al 2 O 3 , the cerium nitrate solution and the palladium nitrate solution were put into the rotary evaporator, and the dipping load was carried out at 70 ° C for 30min, wherein the addition of cerium nitrate was nanometer γ-Al 2 O 3 3% of the mass, the amount of palladium nitrate added is nanometer γ-Al 2 O 3 0.9% of the mass of the impregnated support carrier was placed in a blast drying oven at 150 °C for 8 hours, and then placed in a muffle furnace at 600 °C for 1 hour calcination. After calcination, the catalyst was pressed, ground, and sieved. 40-60 mesh catalyst particles are obtained; the catalyst particles are packed in a fixed-bed reactor, the temperature of the heating furnace is set to 500 ° C, and then hydrogen (nitrogen is used as a carrier gas) with a volume concentration of 8% is introduced into the reactor. The cata...

Embodiment 3

[0033] Example 3: In nano-MoS 2 (particle size: 100 nm) Ru and Cu were supported on the carrier by wet impregnation method, and the nano-MoS 2 , copper nitrate solution and rhodium nitrate solution were put into the rotary evaporator, and the dipping load was carried out at 60 ° C for 40min, wherein the addition amount of copper nitrate was nano-MoS 2 8% of the mass, the amount of rhodium nitrate added is nano-MoS 2 0.6% of the mass of the impregnated support carrier was placed in a blast drying oven at 90 ° C for drying for 12 hours, and then placed in a muffle furnace for 3 hours at 400 ° C. After calcination, the catalyst was pressed, ground, and sieved. 40-60 mesh catalyst particles are obtained; the catalyst particles are packed in a fixed-bed reactor, the temperature of the heating furnace is set to 300 ° C, and then hydrogen (nitrogen is used as a carrier gas) with a volume concentration of 5% is introduced into the reactor. The catalyst particles were pre-reduced for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com