Production process of vulcanization-free gas hydrogenation catalyst

A hydrogenation catalyst and production process technology, applied in the field of coal chemical industry, can solve the problems of shortened service life, long start-up time, environmental pollution, etc., and achieve the effect of easy purification and low exhaust gas emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

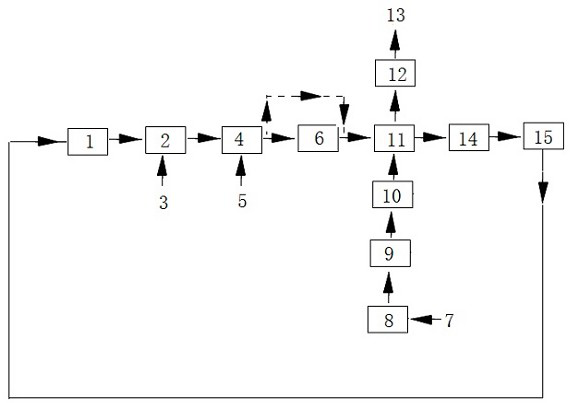

Image

Examples

Embodiment 1

[0047] Production 15 m 3 Sulfur-free FeMo prehydrogenation catalyst.

[0048] ⑴Preparation of FeMo / Al 2 o 3 Gas hydrogenation catalyst. Weigh 0.93 tons of Fe(NO 3 ) 3 9H 2 O, 0.97 tons (NH 4 ) 6 Mo 7 o 24 4H 2 O, with 4.92m 3 Dissolve in water, adjust the pH value of the impregnating solution 7 to 5.5 with phosphoric acid, select 9.34 tons of spherical Al with a strength of 120N / piece and a water capacity of 65%. 2 o 3Carrier 8, equal-volume impregnation for 1 hour and 40 minutes, drying at 100°C for 3 hours-9 (the reference number is drying instead of baking, if there is no reference number, baking and drying do not matter), 350°C roasting for 4 hours-10.

[0049] ⑵ vulcanization. The catalyst prepared by step (1) is filled in the vulcanization tower 11, and the upper layer of the hydrolysis reaction tower 6 is filled with 3m 3 Ti / Al protective agent, 12m in the lower layer 3 The hydrolysis catalyst supported by magnesia-aluminum spinel, the gas enters from th...

Embodiment 2

[0054] Production 30 m 3 Sulfur-free CoMo gas hydrogenation catalyst.

[0055] ⑴Preparation of CoMo / Al 2 o 3 Gas hydrogenation catalyst. Weigh 1.84 tons of Co(NO 3 ) 2 ·6H 2 O, 2.19 tons (NH 4 ) 6 Mo 7 o 24 4H 2 O, use 11.05m 3 Dissolve in water, adjust the pH value of the impregnating solution 7 to 6.2 with phosphoric acid, select 18.69 tons of spherical Al with a strength of 142N / piece and a water capacity of 71%. 2 o 3 Carrier 8, impregnated with equal volume for 1 hour and 40 minutes, dried at 110°C for 2.5 hours-9, and calcined at 450°C for 3.2 hours-10.

[0056] ⑵ vulcanization. The catalyst prepared by step (1) is filled in the vulcanization tower 11, and the upper layer of the hydrolysis reaction tower 6 is filled with 12m 3 Ti / Al protective agent, 18m in the lower layer 3 The hydrolysis catalyst supported by magnesia-aluminum spinel, the gas enters from the top and exits from the bottom. Prepare 1000LCS 2 , 290kg water vapor. First, the temperature ...

Embodiment 3

[0061] Production 20 m 3 Sulfur-free NiMo coke oven gas secondary hydrogenation catalyst.

[0062] ⑴ Preparation of NiMo / Al 2 o 3 Gas hydrogenation catalyst. Weigh 1.63 tons of Ni (NO 3 ) 2 ·6H 2 O, 1.68 tons (NH 4 ) 6 Mo 7 o 24 4H 2 O, with 7.74m 3 Dissolved in water, phosphoric acid adjusts the pH of the impregnation solution to 6.8, and selects 12.21 tons of spherical Al with a strength of 165N / piece and a water capacity of 78%. 2 o 3 Carrier 8 was impregnated with equal volume for 1 hour and 40 minutes, dried at 120°C for 2 hours-9, and calcined at 550°C for 2.5 hours-10.

[0063] ⑵ vulcanization. The catalyst prepared by step (1) is filled in the vulcanization tower 11, and the upper layer of the hydrolysis reaction tower 6 is filled with 6 m 3 Ti / Al protective agent, 14m in the lower layer 3 The hydrolysis catalyst supported by magnesia-aluminum spinel, the gas enters from the top and exits from the bottom. Prepare 800LCS 2 , 230kg water vapor. First, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com