Molten alloy electrode alkali metal thermoelectric conversion nuclear reactor system

A molten alloy, thermoelectric conversion technology, applied in thermal reactors, nuclear reactors, non-uniform reactors, etc., can solve problems such as unresolved alloy reduction, high operating temperature of devices, performance attenuation, etc., to improve system reliability and high performance indicators , the effect of low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

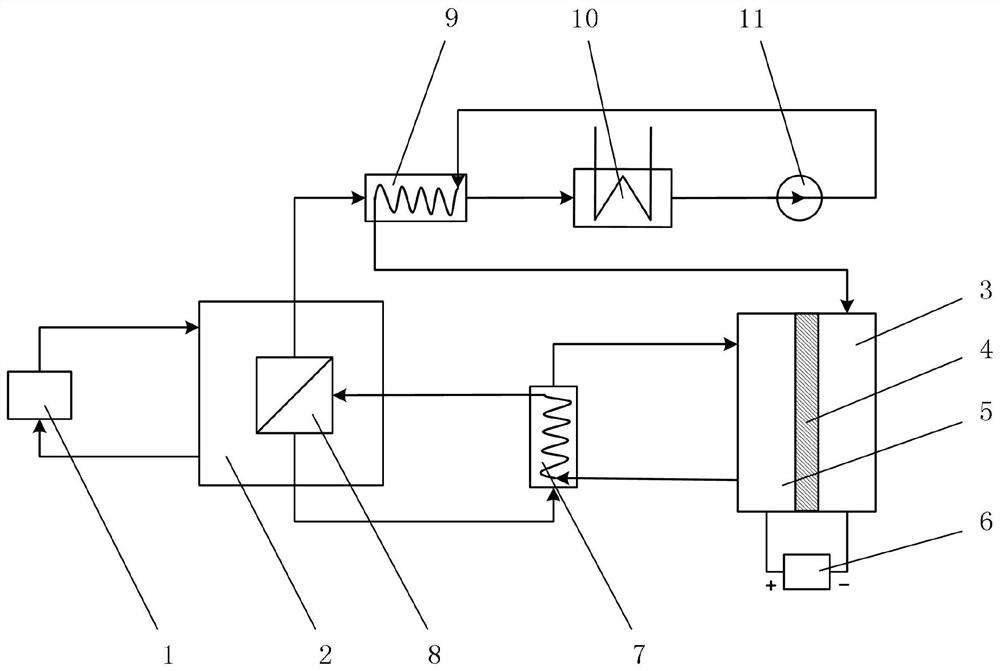

[0026] A kind of nuclear reactor system (such as figure 1 shown), including a reactor 1, a high temperature heat exchanger 2, an electrode chamber, a load 6, a first regenerator 7, a sodium distillation separation chamber 8, a second regenerator 9, a condenser 10, and an electromagnetic pump 11.

[0027] The outlet and inlet of the reactor 1 are connected to the inlet and outlet of the high temperature heat exchanger 2 respectively; wherein, the coolant (molten salt, lead bismuth or lead) absorbs heat in the reactor 1 and releases heat in the high temperature heat exchanger 2 .

[0028] The electrode chamber includes a liquid sodium electrode chamber 3, BASE4 and a molten alloy electrode chamber 5, and the BASE4 is arranged between the liquid sodium electrode chamber 3 and the molten alloy electrode chamber 5 for separating the liquid sodium electrode chamber 3 and the molten alloy electrode chamber 5.

[0029] Both ends of the load 6 are respectively connected with the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com