Light electric steering engine anti-impact base and shell based on gradient lattice structure

A technology of dot matrix structure and electric steering gear, which is applied in the direction of rudder steering, etc., can solve the problems of increased structural wear, high acceleration amplitude, and complex frequency components, so as to achieve vibration reduction and noise reduction, improve usability, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

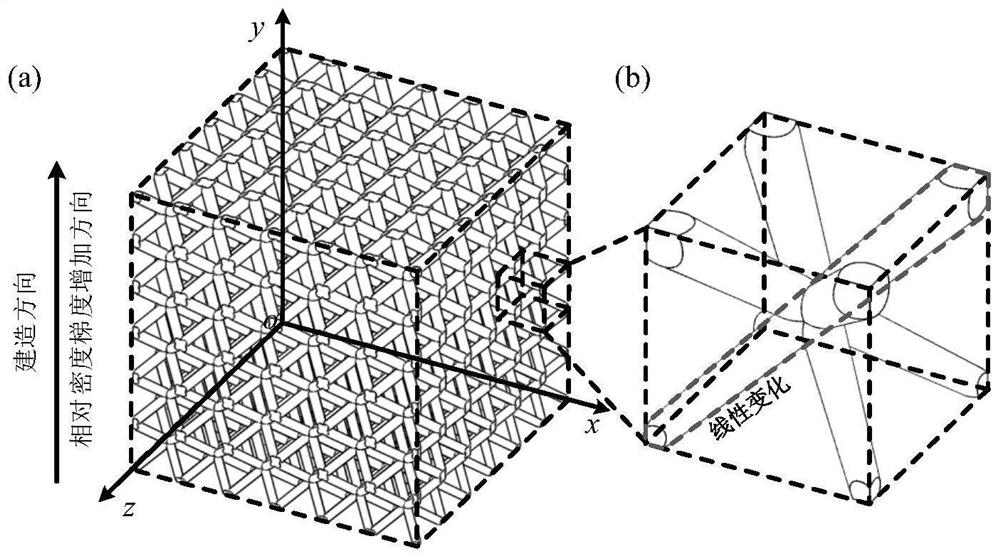

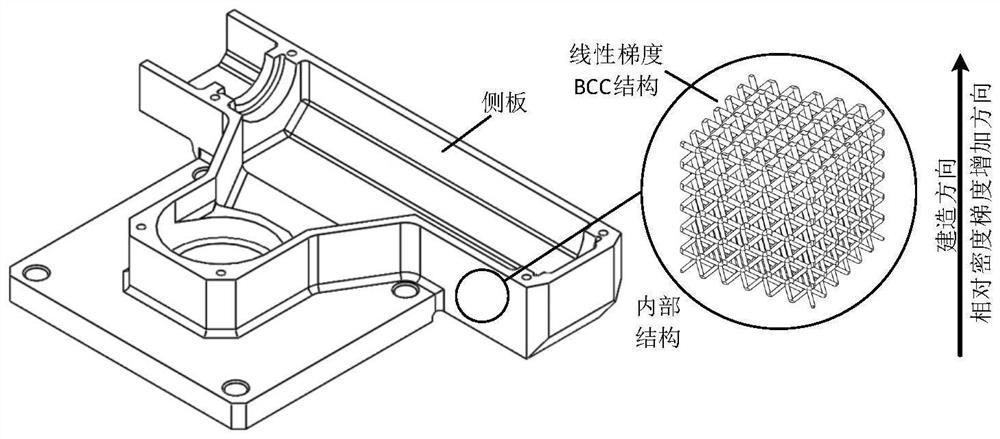

[0027] The side plate of the light-weight and energy-absorbing electric steering gear anti-shock base based on the gradient lattice structure of this embodiment is made of a gradient body-centered cubic lattice structure; the gradient body-centered cubic lattice structure is made of a body-centered cubic lattice The unit cells are periodically arranged in space; the body-centered cubic lattice structure is a truss structure that simulates the topological configuration of the crystal molecular body structure with uniform pillars of equal cross-section. The internal constituent elements are eight rods with length, and the eight rods respectively connect the body center point with the eight vertices, and the body-centered cubic lattice structure is finally formed through the periodic arrangement of the body-centered cubic lattice unit cells; The unit cell size of the structure is 4×4×4mm, the diameter of the unit cell rod varies from 0.3 to 2.2mm, the thickness is determined accor...

Embodiment 2

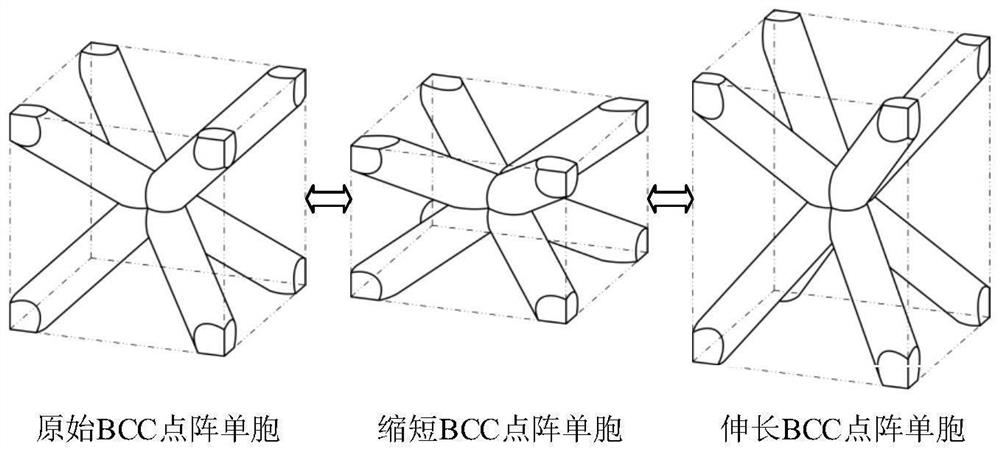

[0030] The whole of the lightweight electric steering gear housing with vibration and noise reduction based on the variant gradient lattice structure of this embodiment is made of the variant gradient lattice structure; the variant gradient lattice structure is based on the bearing and vibration and noise reduction. It is required to first determine the relative density of the structure, and calculate the rod diameter according to the geometric relationship. In this embodiment, the ratio of the rod diameter to the side length of the standard BCC unit cell is 1:5. Next, the main direction of the gradient is determined. In this embodiment, the normal direction of the casing is used as the main direction of the gradient, and along this direction, the structure is gradientd from the inside to the outside. The structure specifically includes a plurality of variant gradient unit cells that are repeatedly arranged and interconnected; the variant gradient unit cell column includes a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com