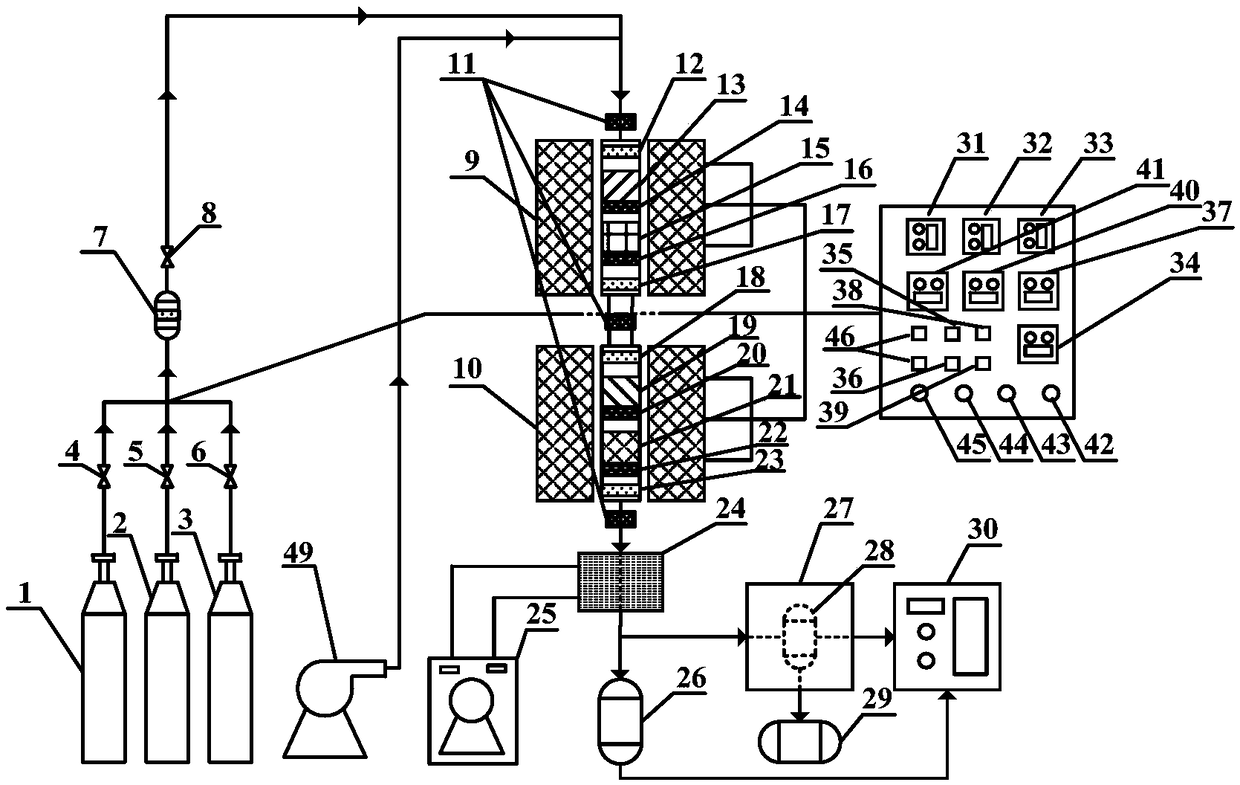

Directed catalytic cracking device and method

A catalytic cracking and process technology, which is applied in the petroleum industry, biofuels, coke ovens, etc., can solve the problems of high energy consumption costs, overall process complexity, and low process production efficiency, achieving small equipment investment and flexible sampling methods , significant incremental effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

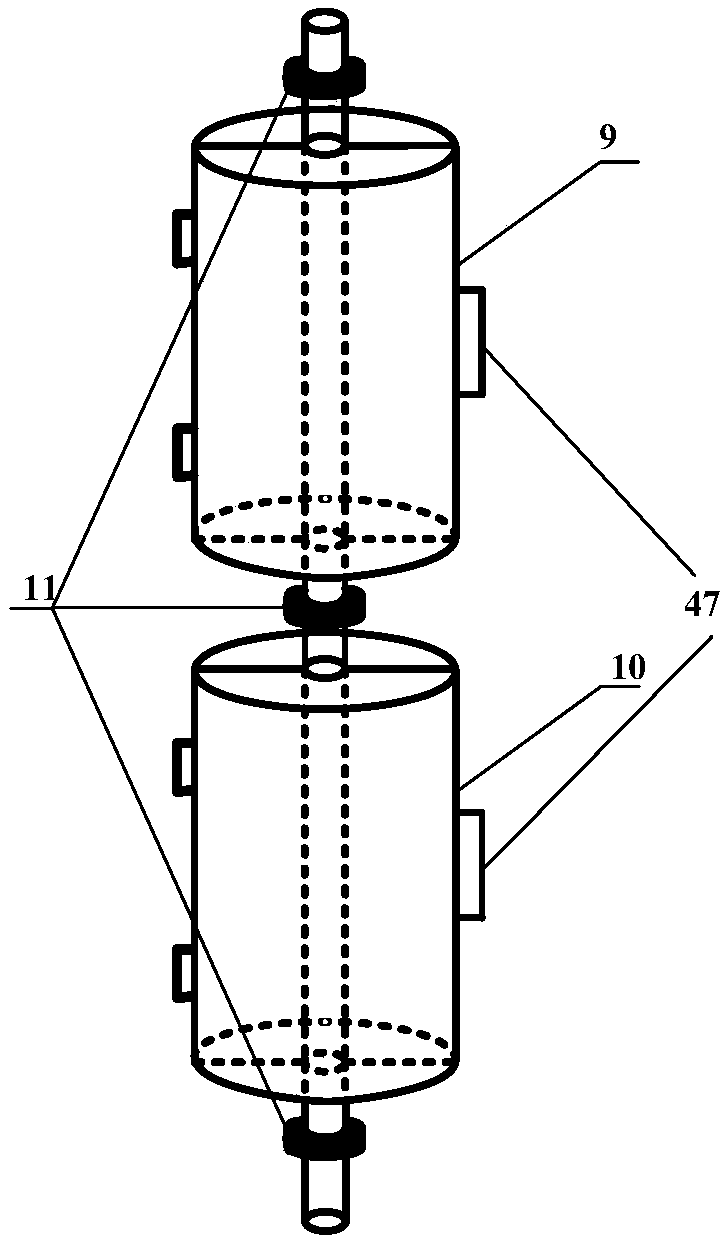

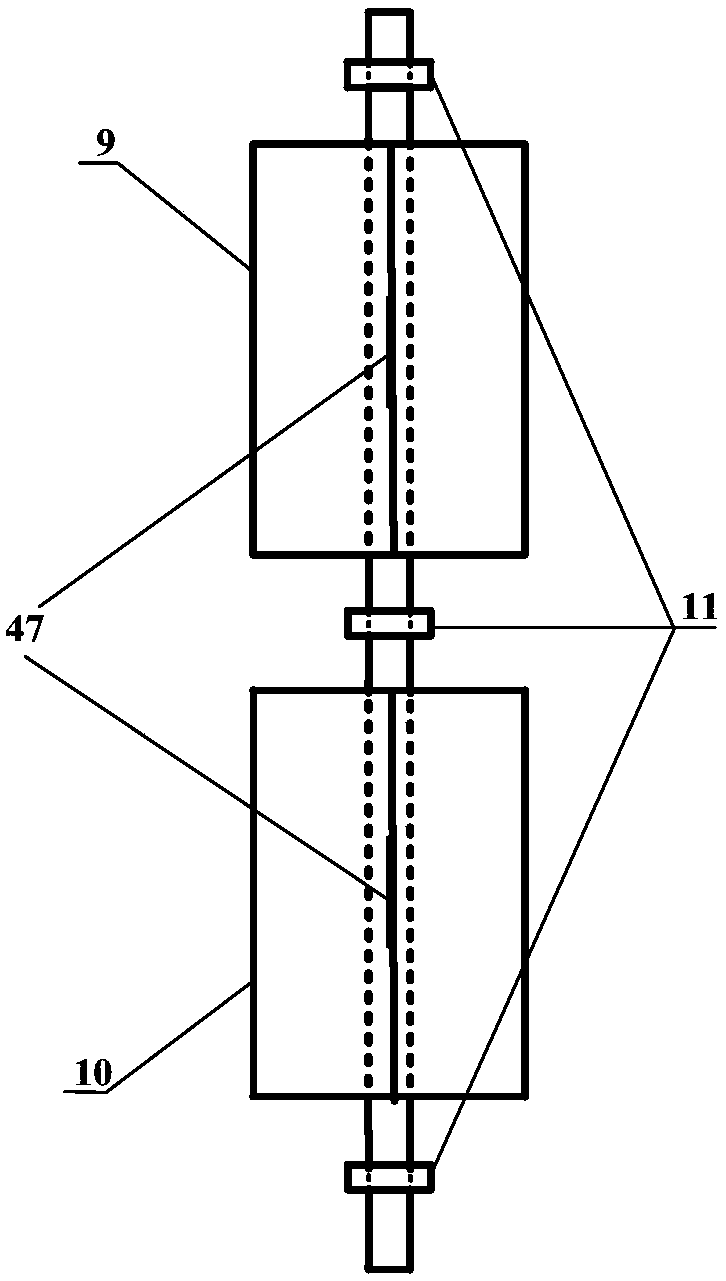

Method used

Image

Examples

Embodiment 1

[0083] The low-rank coal from a chemical plant in northern Shaanxi was used as raw material, and its industrial analysis and elemental analysis are shown in Table 1. Experiment coal 5g, reaction gas is N 2 , the catalyst activation temperature is 600°C, the catalyst used to activate the reaction gas is HY (also known as HY molecular sieve catalyst), and the amount of HY is 2g; the temperature of coal pyrolysis is 800°C, and the reaction pressure is: 0.1MPa; the catalytic cracking catalyst is al 2 o 3 , Al 2 o 3 The dosage is 2g, the temperature of the catalytic cracking section is 600°C; the catalyst used for directional regulation and control of tar products is Mo / Ni / HZSM-5, the dosage of Mo / Ni / HZSM-5 is 2g, the temperature of the directional regulation section is 500°C, and the reaction pressure is: 0.1 MPa. The yield of coal pyrolysis tar is 5.63%. The composition distribution of various products of coal is shown in Table 2. It can be seen from Table 2 that the total ...

Embodiment 2

[0090] The low-rank coal from a chemical plant in northern Shaanxi was used as raw material, and its industrial analysis and elemental analysis are shown in Table 1. Experiment coal 5g, reaction gas is CH 4 , the catalyst activation temperature is 600°C, the catalyst used to activate the reaction gas is HY, and the amount of HY is 2g; the coal pyrolysis temperature is 800°C, and the reaction pressure is: 0.1MPa; the catalytic cracking catalyst is Al 2 o 3 , Al 2 o 3 The dosage is 2g, the temperature of the catalytic cracking section is 600°C; the catalyst used for directional regulation and control of tar products is Mo / Ni / HZSM-5, the dosage of Mo / Ni / HZSM-5 is 2g, the temperature of the directional regulation section is 500°C, and the reaction pressure is: 0.1 MPa. The yield of coal pyrolysis tar is 8.81%. The composition distribution of various products of coal is shown in Table 3. It can be seen from Table 3 that the total relative content of BTXN in the catalytic crack...

Embodiment 3

[0094] The low-rank coal from a chemical plant in northern Shaanxi was used as raw material, and its industrial analysis and elemental analysis are shown in Table 1. Experiment coal 5g, reaction solution is CH 3 OH, the catalyst activation temperature is 600°C, the catalyst used to activate the reaction gas is HY, the amount of HY is 2g; the coal pyrolysis temperature is 800°C, the reaction pressure is: 0.1MPa; the catalytic cracking catalyst is Al 2 o 3 , Al 2 o 3 The temperature of the catalytic cracking section is 600°C; the catalyst used for directional control of tar products is Mo / Ni / HZSM-5, the amount of Mo / Ni / HZSM-5 is 2g, the temperature of the directional control section is 500°C, and the reaction pressure is: 0.1 MPa. The yield of coal pyrolysis tar is 9.93%. The composition distribution of various products of coal is shown in Table 4. It can be seen from Table 4 that the total relative content of BTXN in the catalytic cracking products of coal after directiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com