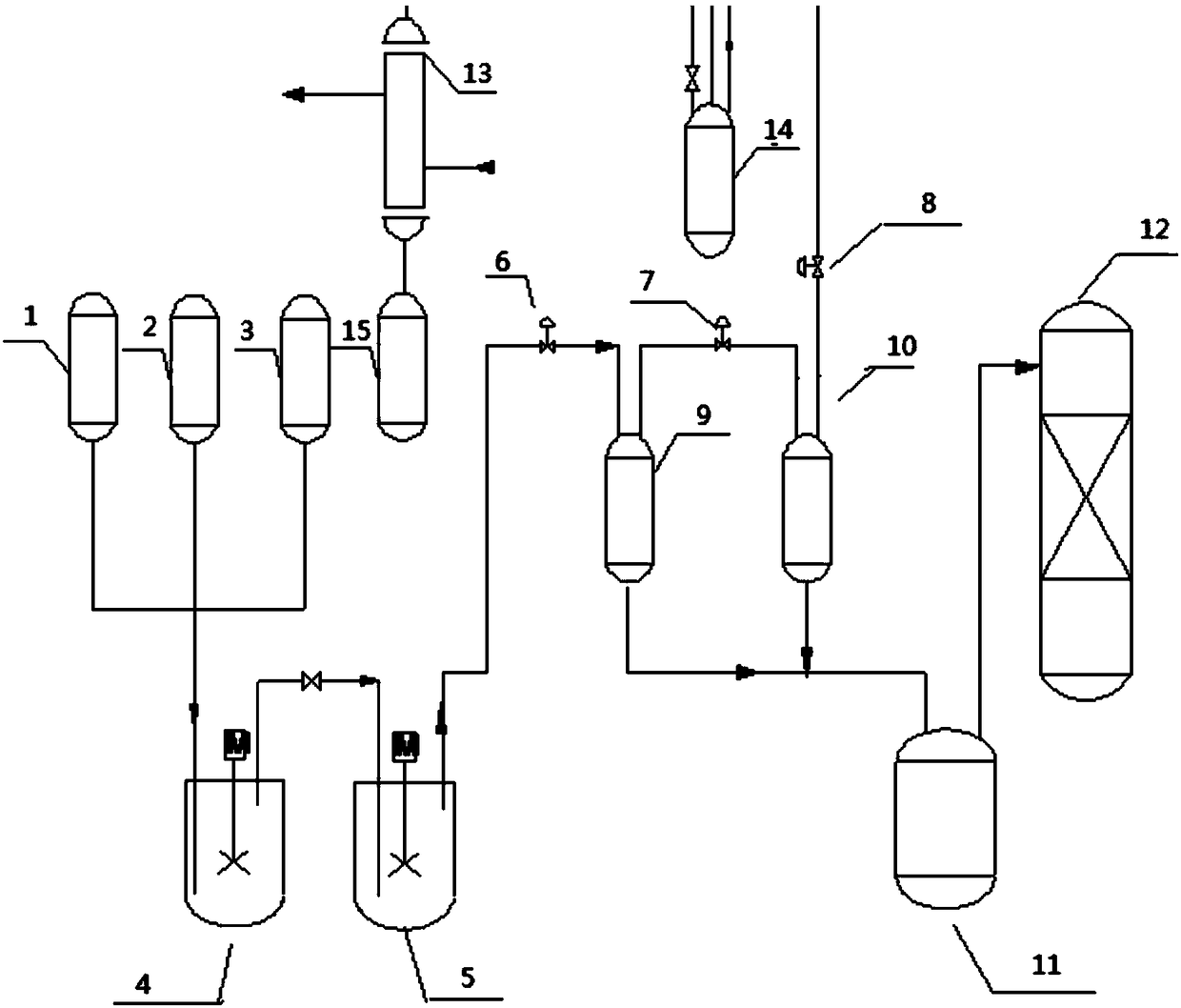

Device and method for continuously synthesizing sulfolene

A technology for sulfolene and butadiene, which is applied in the field of devices for continuous synthesis of sulfolene, can solve problems such as troublesome maintenance and treatment, reduce the degree of back-mixing, block reactors, etc., so as to reduce exhaust gas emissions and reduce equipment investment. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The temperature of reactor A is controlled at 90°C, the temperature of reactor B is controlled at 80°C, the reaction pressure is 2Mpa, the molar ratio of sulfur dioxide to butadiene is 1.2:1, the reaction residence time is 3h, the temperature of flash tank A is 65°C, and the pressure is 1.0Mpa. The temperature of steamer B is 65°C, the pressure is 0.5Mpa, the stirring speed is 300r / min, and the yield of sulfolene is 95.27%.

[0056] This embodiment implementation time is 32 hours.

Embodiment 2

[0058] The temperature of reactor A is controlled at 100°C, the temperature of reactor B is controlled at 90°C, the reaction pressure is 4Mpa, the molar ratio of sulfur dioxide to butadiene is 2:1, the reaction residence time is 3h, the temperature of flash tank A is 75°C, and the pressure is 1.5Mpa. The temperature of steamer B is 75°C, the pressure is 1.0Mpa, the stirring speed is 500r / min, and the yield of sulfolene is 98.6%.

[0059] This embodiment implementation time is 32 hours.

Embodiment 3

[0061] The temperature of reactor A is controlled at 95°C, the temperature of reactor B is controlled at 85°C, the reaction pressure is 2.5Mpa, the molar ratio of sulfur dioxide to butadiene is 1.5:1, the reaction residence time is 4h, the temperature of flash tank A is 70°C, and the pressure is 1.2Mpa. The temperature of the flash tank B is 70°C, the pressure is 0.8Mpa, the stirring speed is 400r / min, and the yield of sulfolene is 97.4%.

[0062] This embodiment implementation time is 32 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com