Micro-aerated biological filter

A biological filter and micro-aeration technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of long biochemical reaction time, complicated operation process, large equipment investment, etc. , to achieve the effect of less operators, small pool capacity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

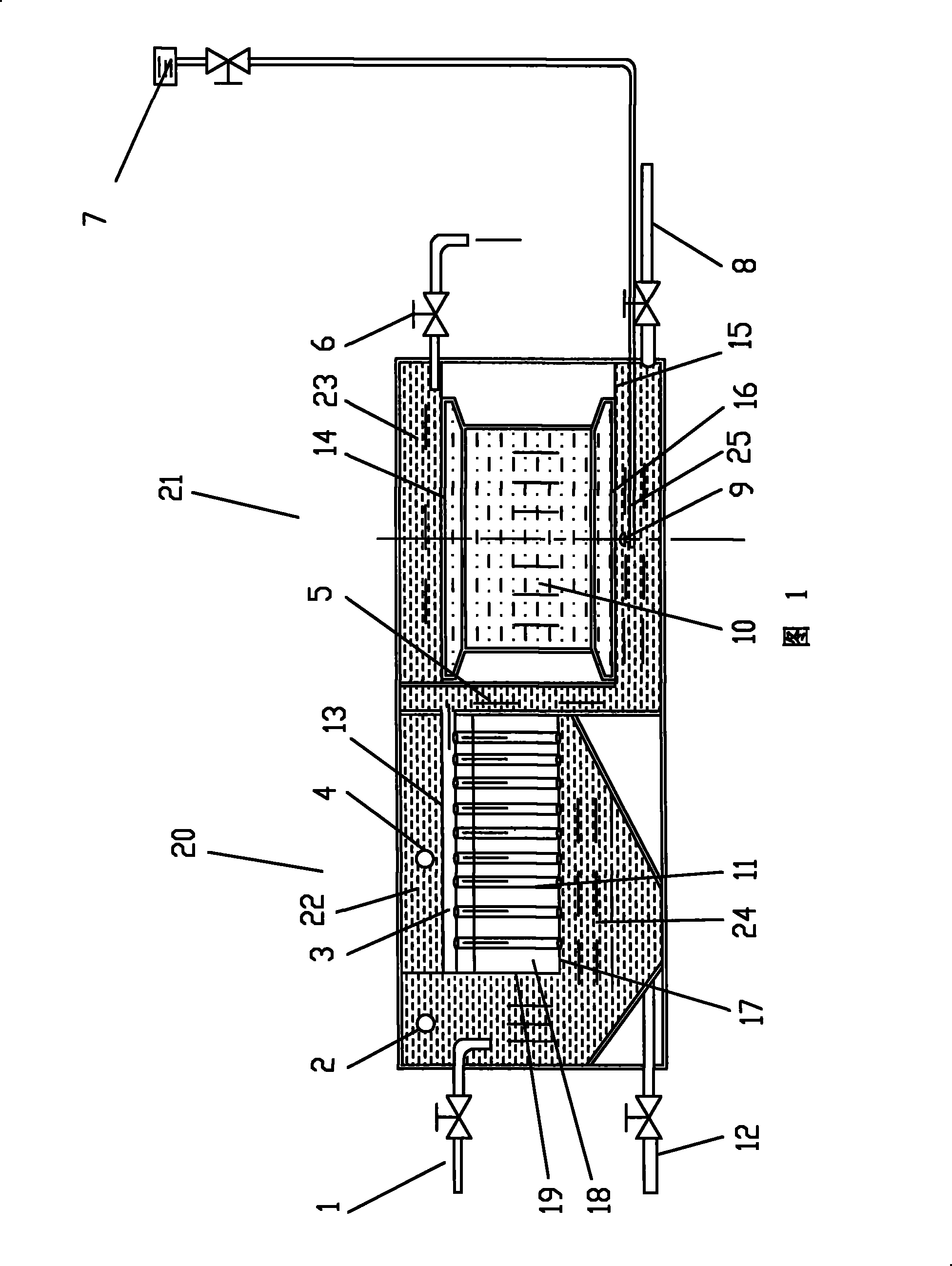

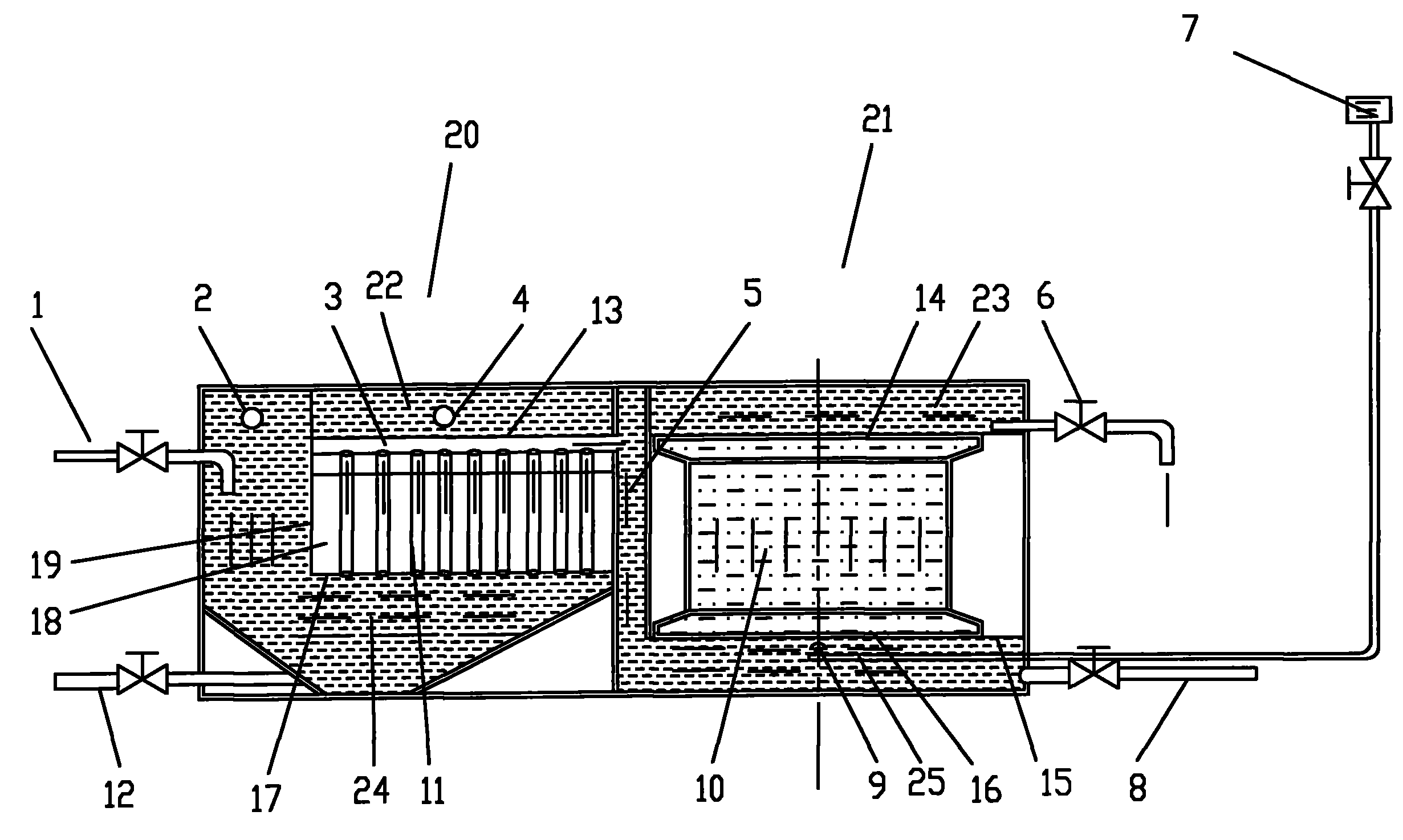

[0018] As shown in the figure: a micro-aerated biological filter, including a first filter 20 and a second filter 21, is characterized in that: a sewage inlet pipe 1 is set on the first filter 20, and a sewage inlet pipe 1 is set in the first filter 20 Filtration chamber 18, several bamboo tubes 11 parallel to each other are vertically arranged in the said filtration chamber 18, the bottom of each bamboo tube 11 communicates with the bottom of the first filter tank 20, and the top of each bamboo tube 11 communicates with the bottom of the first filter tank 20. The overflow tank 3 above the 20 is communicated; the biochemical bed 10 that can be moved out or moved in is set in the second filter tank 21, and block-shaped filter material is placed in the described biochemical bed 10, in the second filter tank 21 below the biochemical bed 10 Aeration head 9 is set, drainpipe 6 is set in the second filter tank 21 above the biochemical bed 10; in the second filter tank 21, the diversi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com