Automatic efficient purification system for total nitrogen of water and method of automatic efficient purification system

A purification system and water body technology, applied in chemical instruments and methods, water treatment parameter control, biological water/sewage treatment, etc., can solve the problems of large investment in sewage treatment methods, poor process flexibility, and high operating costs, and achieve improved denitrification Effect, low operating cost, and improved hydraulic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

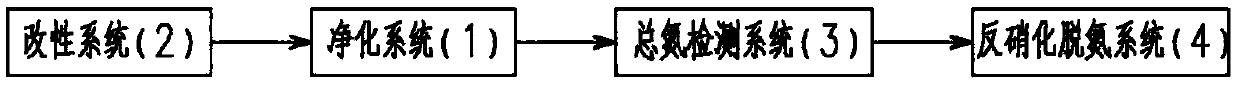

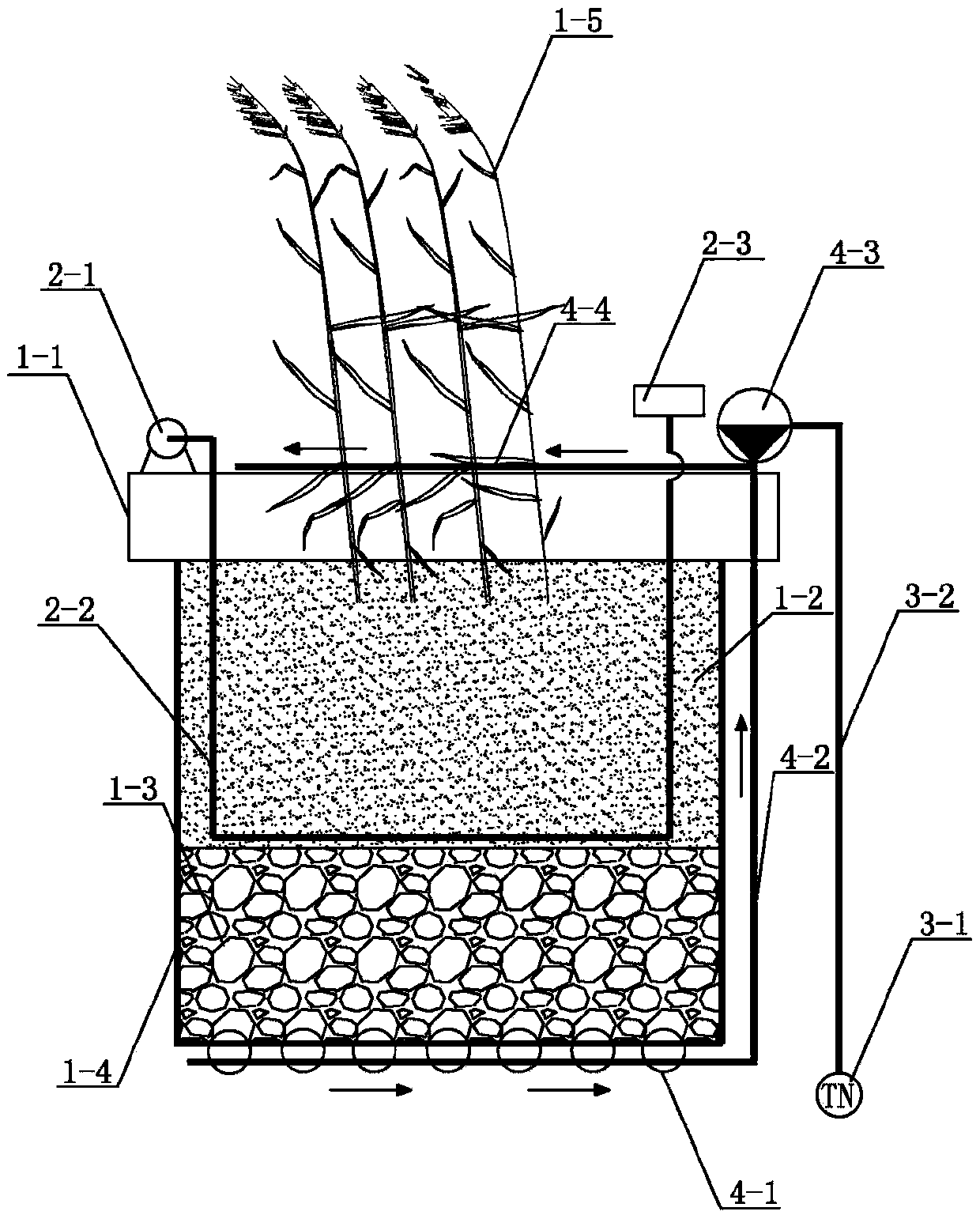

[0049] Four parts are set up in a river course: purification system 1, modification system 2, total nitrogen detection system 3, and denitrification and denitrification system 4. The purification system 1, the total nitrogen detection system 3, and the denitrification denitrification system 4 are connected in sequence, and the modification system 2 is connected to the purification system 1.

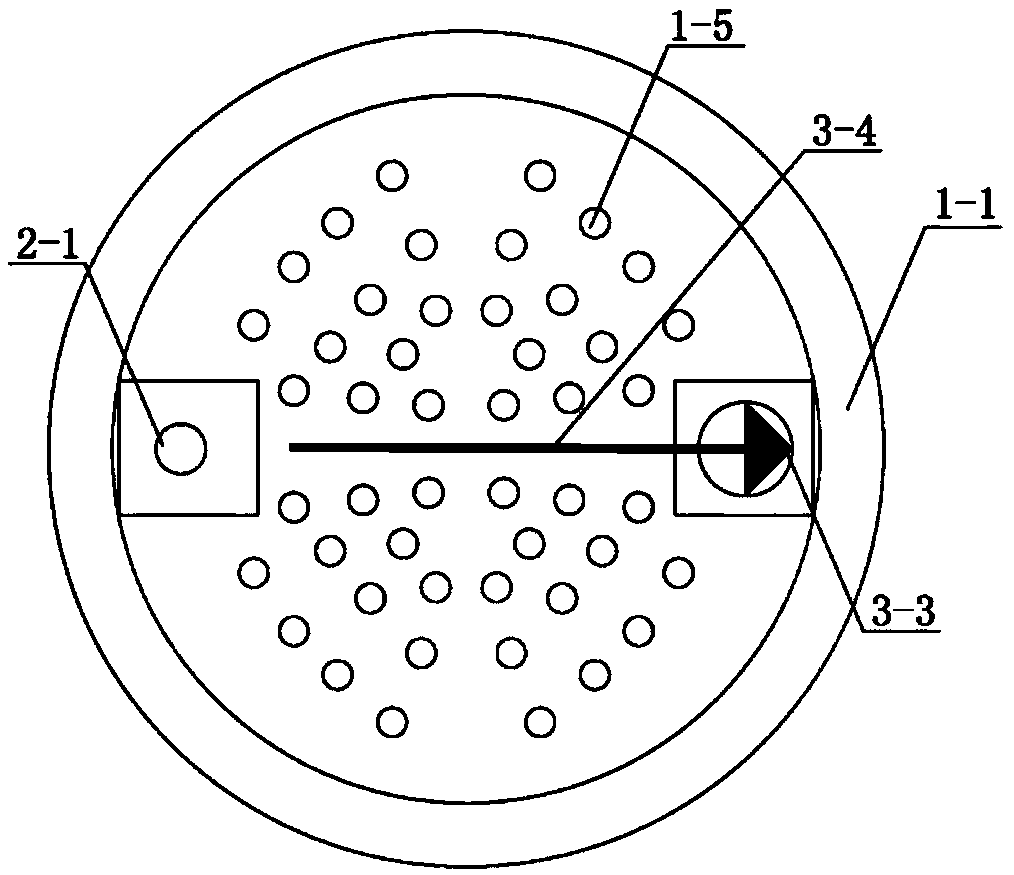

[0050] In the purification system 1, the geotextile 1-4 is arranged under the floating body 1-1 in a wrapping state, wherein the bottom and the side are arranged with the geotextile 1-4. The gravel 1-3 is located at the bottom wrapped by the geotextile and is close to the geotextile 1-4, the biochar substrate 1-2 is located on the top of the gravel 1-3, and the plants 1-5 are planted on the biochar substrate 1-2. Oxygen is supplied to microorganisms on the biochar matrix 1-2 through the action of plant roots, and nitrification is improved.

[0051] The material of the floating body 1-1 i...

Embodiment 2

[0066] Others are the same as embodiment 1.

[0067] Case 2: TN 2~5mg / L;

[0068] The PLC controller 3-2 controls the reflux pump 4-3, and the reflux ratio is 50-80%.

[0069] The water quality before and after treatment by this method is shown in Table 2.

[0070] Table 2 embodiment 2 water quality situation before and after treatment

[0071] index

Embodiment 3

[0073] Others are the same as embodiment 1.

[0074] Case 3: TN 5~8mg / L;

[0075] The PLC controller 3-2 controls the reflux pump 4-3, and the reflux ratio is 100-150%.

[0076] The water quality before and after treatment by this method is shown in Table 3.

[0077] Table 3 embodiment 3 water quality situation before and after treatment

[0078] index

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com