Method for manufacturing micronanostructure on surface of block amorphous alloy

A technology of amorphous alloy and micro-nano structure, which is applied in the field of rapid fabrication of micro-nano structure on the surface of bulk amorphous alloy, which can solve the problem that the separation of mold and replica product hinders the application, it is difficult to make large-sized amorphous parts, and it is difficult to make large area. Production and other problems, to achieve the effect of reducing processing cost, low processing cost and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

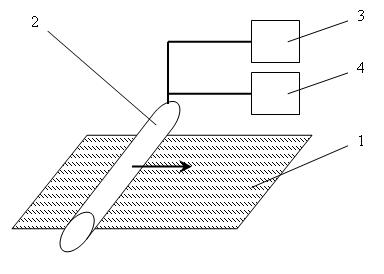

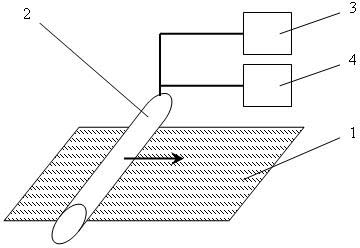

Method used

Image

Examples

Embodiment 1

[0024] The material to be surface processed is Mg 65 Cu 25 Y 10 Bulk amorphous alloy: remove the oxides on the surface of the bulk amorphous alloy by mechanical grinding, then use acetone to ultrasonically clean the grease on the surface of the bulk amorphous alloy, put the bulk amorphous alloy in a vacuum cover after drying, and pump Vacuum to vacuum degree is 1×10 -2 Pa, and then filled with argon to 500Pa, using a titanium alloy hollow roll mold with a diameter of 20mm heated to 220°C. The mold rolls Mg at a speed of 5mm / s 65 Cu 25 Y 10 The surface of the bulk amorphous alloy, the highest temperature after the surface of the bulk amorphous alloy is in contact with the roll mold is 180 ° C, so that the Mg 65 Cu 25 Y 10 The porous micro-nano structure is continuously obtained on the surface of the bulk amorphous alloy.

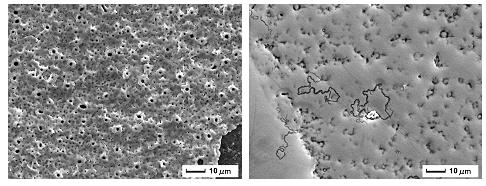

[0025] Roll mold surface and Mg after rolling 65 Cu 25 Y 10 The scanning electron micrographs of the surface of the bulk amorphous alloy are as f...

Embodiment 2

[0027] Material selection for surface processing Fe 78 Si 9 B 13 Bulk amorphous alloy: use pickling method to remove oxides on the surface of bulk amorphous alloy, then use acetone to ultrasonically clean the grease on the surface of bulk amorphous alloy, put the bulk amorphous alloy in a vacuum cover after drying, and vacuum Vacuum to vacuum degree is 1×10 -2 Pa, using a nickel-chromium alloy hollow roll mold with a diameter of 25mm heated to 380°C. The surface of the mold has been pre-processed by a laser tool to obtain a nano-columnar structure. The roll mold is rolled at a speed of 25mm / s under a pressure of 2000 Pa. Fe 78 Si 9 B 13 The surface of the bulk amorphous alloy has a maximum temperature of 330° C. after contacting the surface with a roll-shaped mold, thus obtaining a surface with a micro-nano structure.

Embodiment 3

[0029] The material to be surface processed is Zr 55 al 10 Ni 5 Cu 30 Bulk amorphous alloy: use pickling to remove oxides on the surface of the bulk amorphous alloy, then use acetone to ultrasonically clean the grease on the surface of the bulk amorphous alloy, and dry it for future use. Then put the bulk amorphous alloy into a vacuum cover and evacuate to a vacuum degree of 1×10 -2 Pa, using a nickel-chromium alloy hollow roll mold with a diameter of 30mm heated to 480°C. The surface of the mold has been pre-processed by a laser tool to obtain a nano-columnar structure, and the Zr is rolled at a speed of 50mm / s under a pressure of 3000 Pa. 55 al 10 Ni 5 Cu 30 The surface of the bulk amorphous alloy has a maximum temperature of 435° C. after contacting the surface with a roll-shaped mold, thus obtaining a surface with a micro-nano structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com