Ultrasonic sensor having a deflecting element

A deflection element, ultrasonic technology, applied to engine components, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve problems such as sensor failure to achieve connection, thermal expansion characteristics difference, sensor function loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

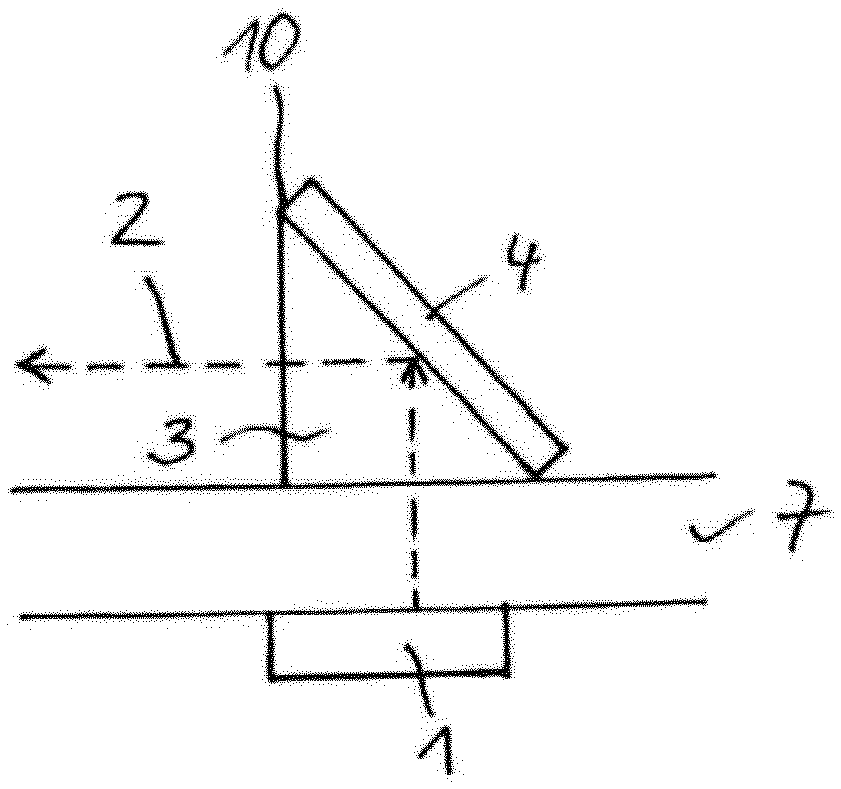

[0021] exist figure 1 In the figure, only the sonotrode 1 and the acoustic deflection element 10 of a prior art ultrasonic sensor, which also serve as a receiver, are shown. The sound pulses emitted by the sonotrode 1 pass through the bottom wall 7 of the liquid tank in which eg a urea solution is contained. With the ultrasonic sensor, the concentration of the urea solution is to be determined by ultrasonic transit time measurement. In this case, the sound pulse 2 deflected within the deflection element 10 reaches the reflector in a horizontal sound path, is reflected back there and passes through the deflection element 10 again to the sound generator 1 which also operates as a receiver.

[0022] The prior art deflection element 10 shown here has an approximately triangular-shaped plastic molding 3 , which carries a metal mirror element 4 made of stainless steel on its slope. The disadvantages of such an embodiment have already been discussed above.

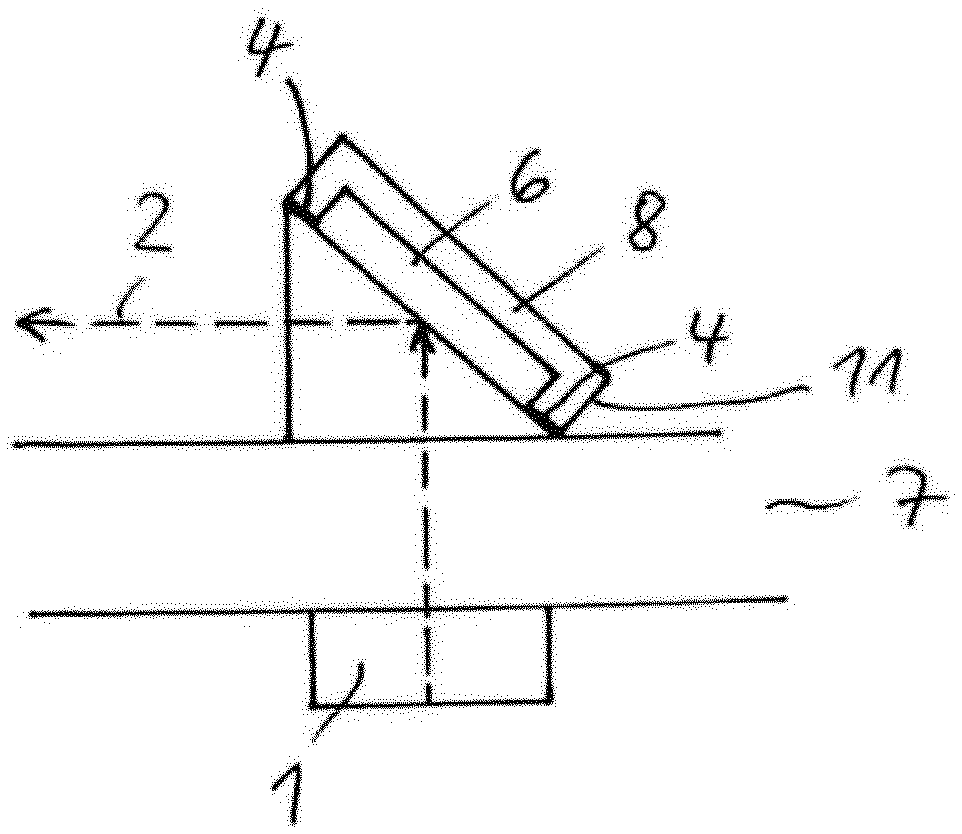

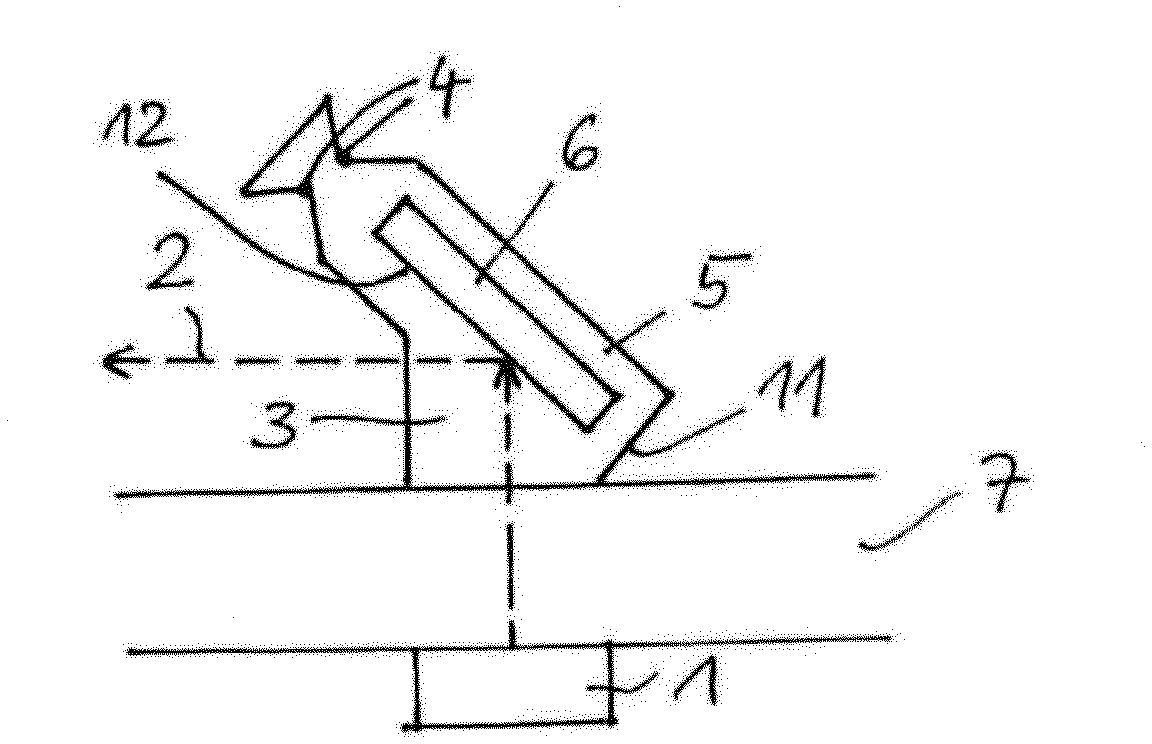

[0023] In the deflecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com