Drying equipment for metal sheet

A technology for drying equipment and metal sheets, applied in the field of sheet metal processing, can solve the problems of uneven distribution, sheet deformation, and partial areas of metal sheets cannot be completely dried, etc., and achieves multiple air outlet directions, uniform air outlet, and good drying effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

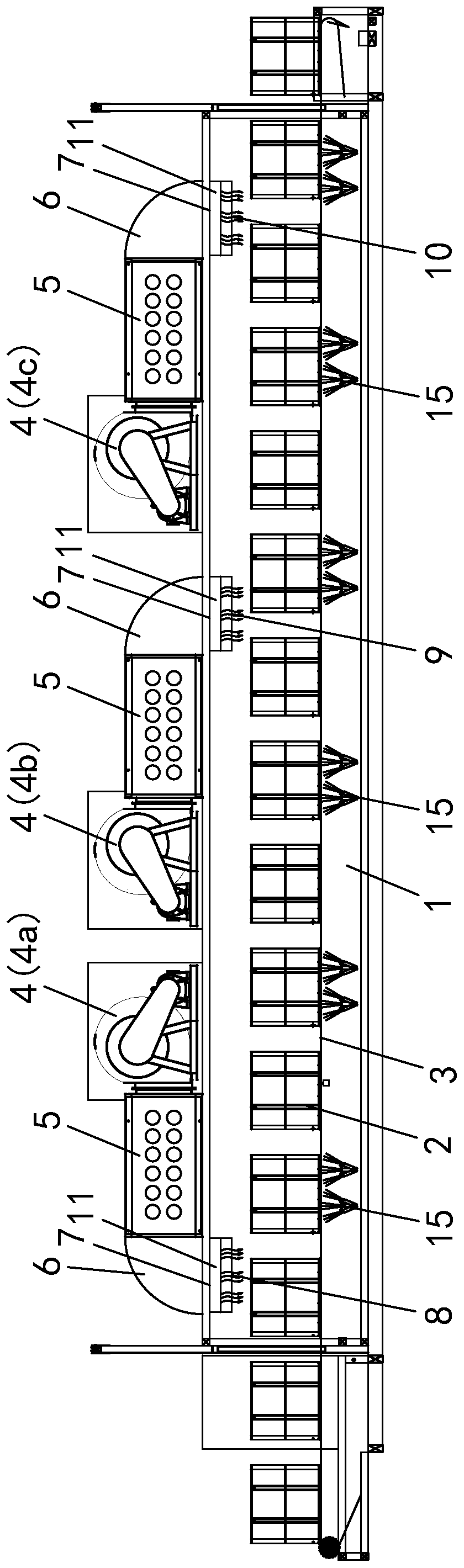

[0027] Example: see attached figure 1 As shown, a metal thin plate drying equipment includes a closed drying cavity 1, the metal thin plate is placed in a product carrier 2 after cleaning, and is sent into the drying cavity 1 through an assembly line 3 for drying. dry.

[0028] It also includes a hot air circulation motor 4, which heats the air supply through a heating box 5 and then blows the hot air into the drying cavity 1 from top to bottom through the air outlet pipeline 6; the heating method of the heating box 5 Including but not limited to existing heating technologies such as resistance wire heating and electromagnetic heating; in addition, a return air pipeline (not shown in the figure) can also be provided in the drying chamber 1, and the return air pipeline returns the hot air through negative pressure. To hot air circulation motor 4, to realize the circulation of air-flow.

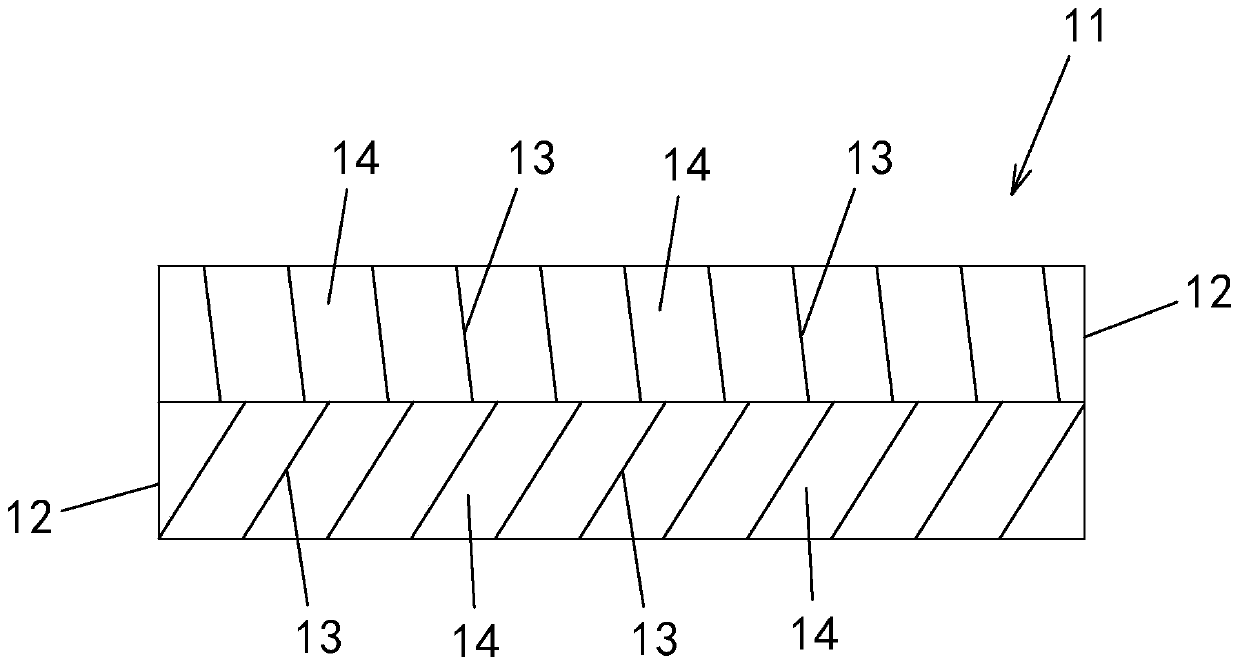

[0029] Wherein, the air outlet 7 of the air outlet pipeline 6 is provided with a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com