A kind of manufacturing technology of anti-counterfeit metal cover and anti-counterfeit metal cover

A production process and metal cover technology, which is applied in the field of anti-counterfeit metal covers, can solve the problems of precise control, unsatisfactory adhesion effect, backward traditional technology and other problems, and achieve the effect of precise positioning, superior product effect and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

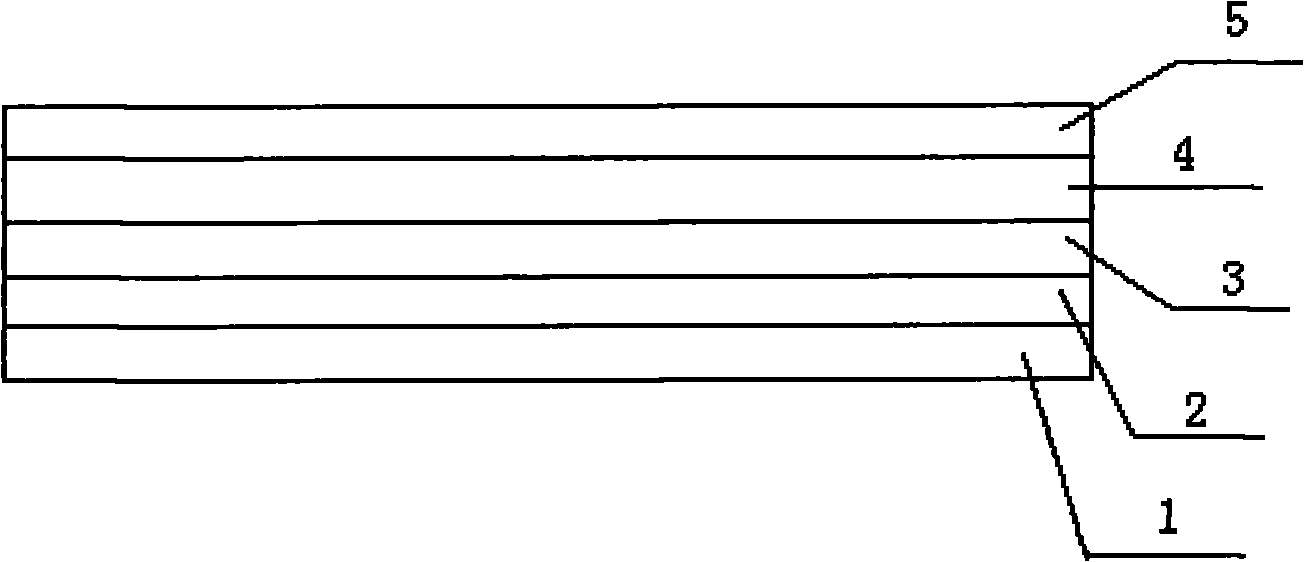

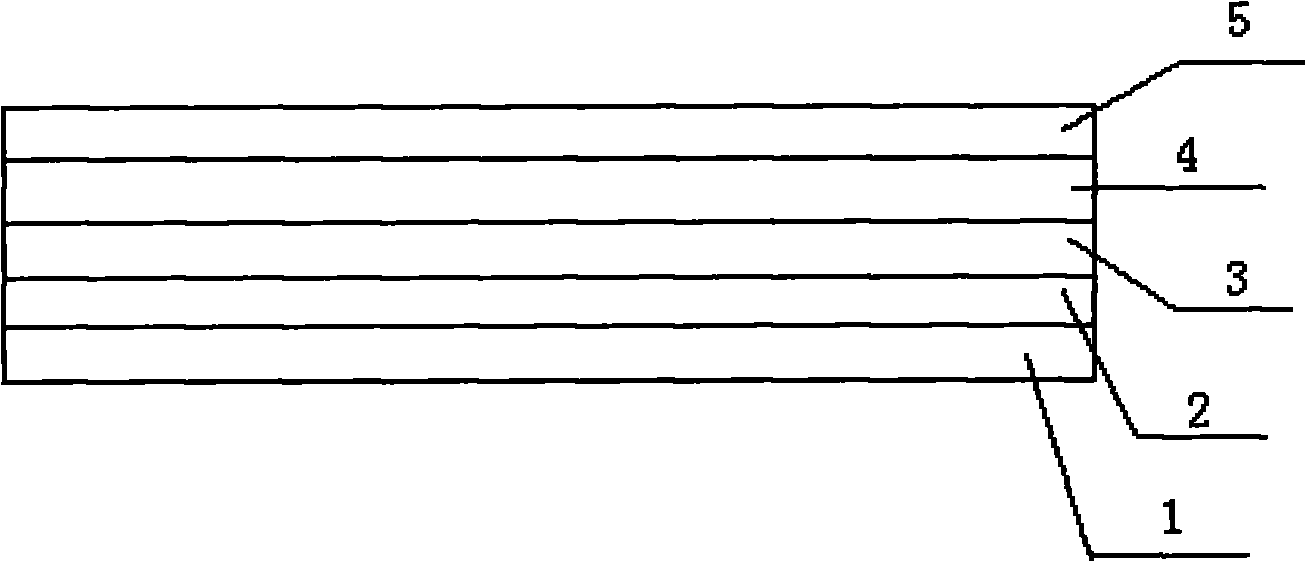

[0056] The cellulose resin is coated on the surface of the film as a transfer layer, and the acrylic resin is coated as a second information protection layer, and a holographic pattern is embossed between the second information protection layer and the information protection layer. On the holographic pattern, an information protection layer made of aluminum is vapor-deposited; composite process: an adhesive layer is further coated on the information protection layer, and the adhesive layer is made of polyurethane resin and dried and cured at a temperature of 100°C and a drying time of 30 seconds , working speed 60m / min, pressure 3kg / cm 2 , the film is attached to the metal surface, and then the film is peeled off. After peeling off, the metal obtained in the previous steps is positioned and punched in a punching machine to form an anti-counterfeiting metal cover.

Embodiment 2

[0058] The difference from Example 1 is that in this example, the transfer layer is acrylic resin, the material of the second information protection layer is polyurethane resin, and a holographic pattern is embossed between the second information protection layer and the information protection layer. It is metal copper, the adhesive layer is made of acrylic resin, and it is cured by drying at a temperature of 50°C and a drying time of 10 seconds. When compounding, the working speed is 30m / min and the pressure is 5kg / cm 2 , the film is attached to the metal surface, and then the film is peeled off. After peeling off, the metal obtained in the previous steps is positioned and punched in a punching machine to form an anti-counterfeiting metal cover.

Embodiment 3

[0060] The difference from Example 1 is that in this example, the transfer layer is polyurethane resin, the material of the second information protection layer is epoxy resin, and the holographic pattern is first embossed between the second information protection layer and the information protection layer, and then printed Color pattern, the material of the information protection layer is metal zinc, the adhesive layer is made of epoxy resin, and it is cured by drying, the temperature is 150°C, the drying time is 60 seconds, the working speed is 150m / min, and the pressure is 10kg / cm when compounding 2 , the film is attached to the metal surface, and then the film is peeled off. After peeling off, the metal obtained in the previous steps is positioned and punched in a punching machine to form an anti-counterfeiting metal cover.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com