Manufacturing process of IBC battery assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

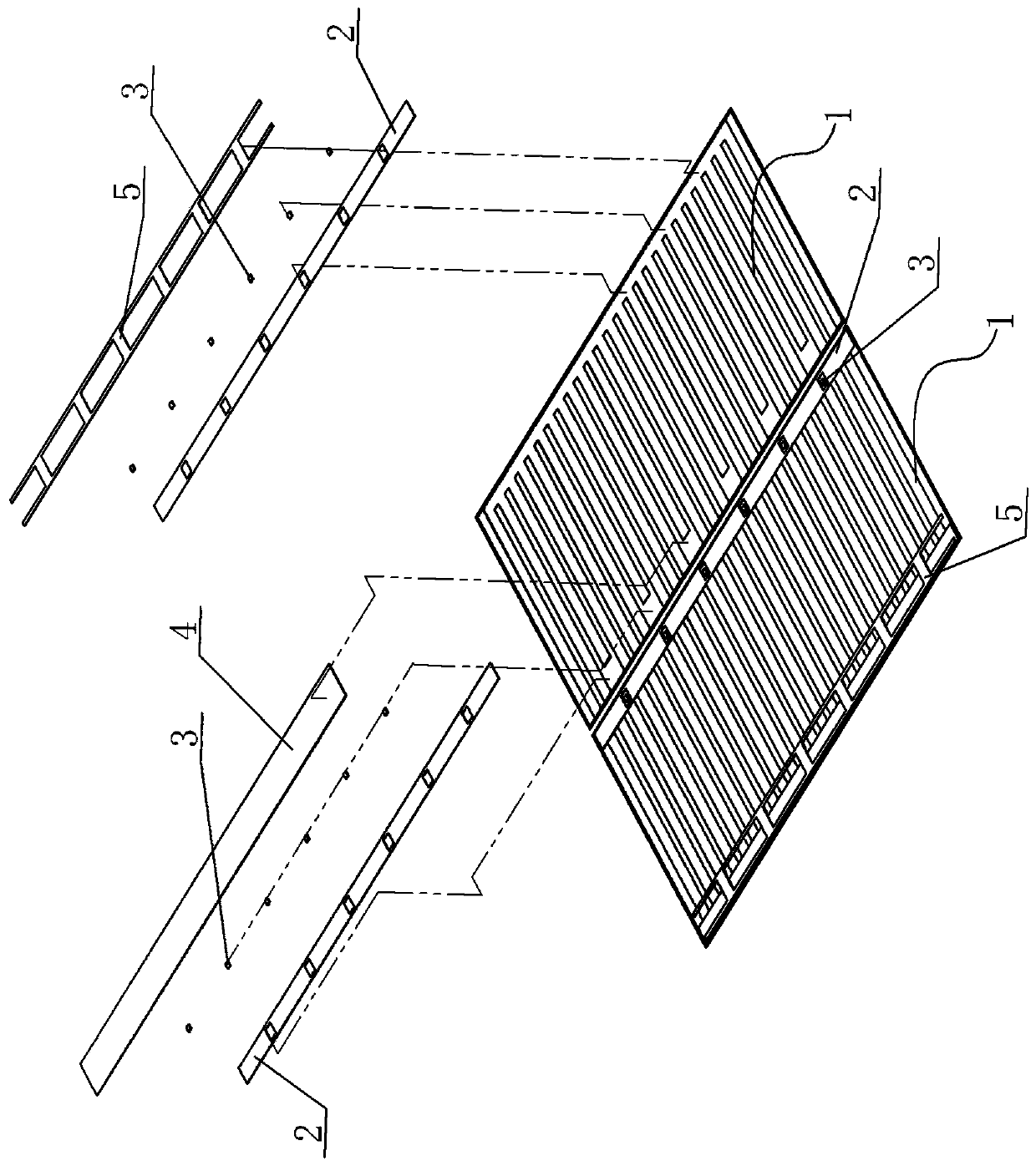

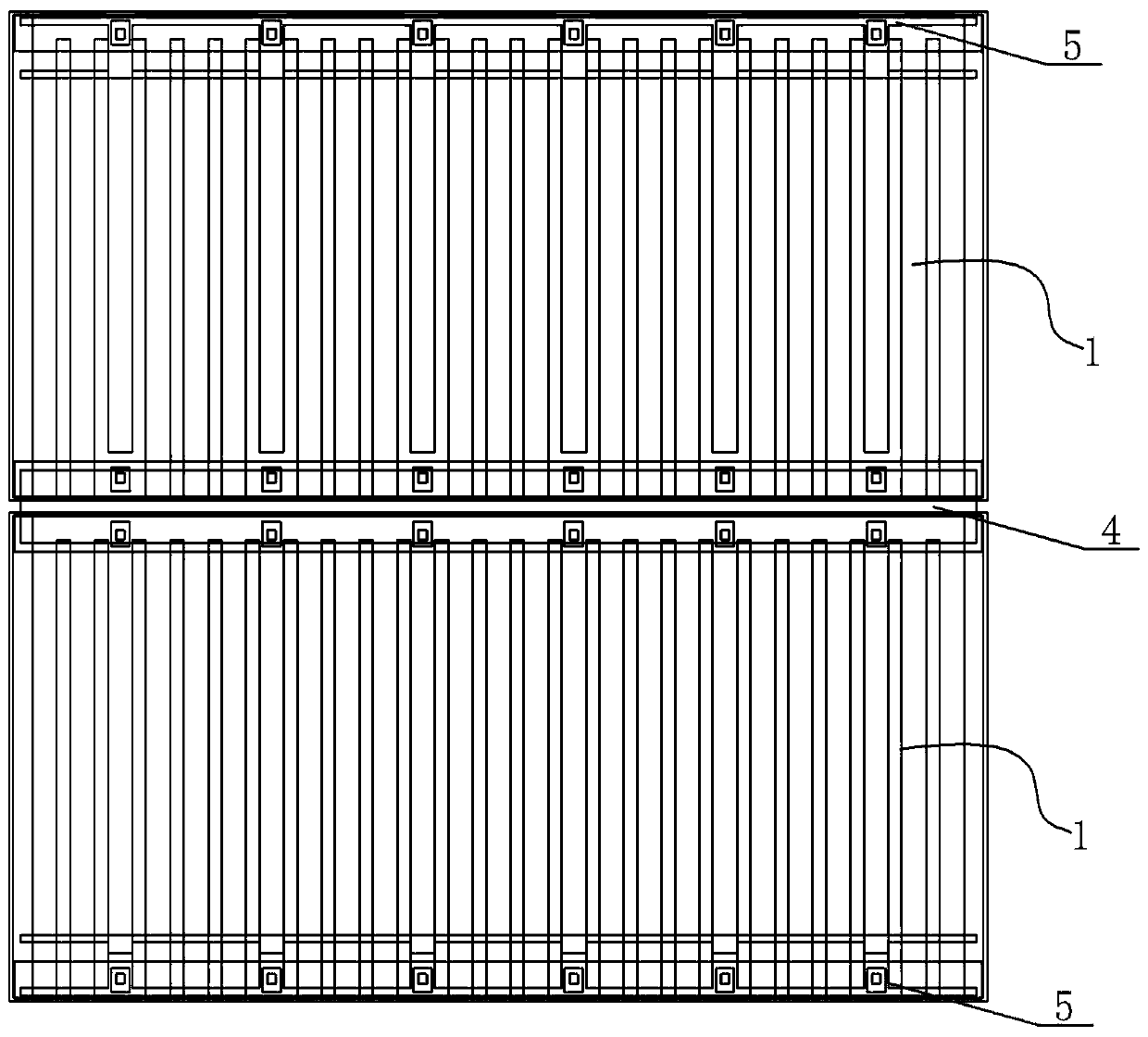

[0038] A kind of manufacturing process of IBC battery assembly, see Figure 1-Figure 2 , and its specific process steps include the following two types:

[0039] Option A:

[0040] S1. Laser cutting: First, laser cut the entire cell, and form (n-1) laser scratches on the cell, so that the cell is divided into n small cells 1;

[0041] S2. Coating insulating glue: Preset a certain number of lead-out electrodes on the two sides of n small battery pieces 1 arranged along the length direction, and apply insulating glue 2 on the outer periphery of the lead-out electrodes at the same time;

[0042] S3. Curing the insulating glue: curing the battery sheet coated with the insulating glue 2;

[0043] S4. Coating solder paste: coating the solder paste 3 on the positions corresponding to the preset lead-out electrodes on n pieces of small cells 1;

[0044] S5, arranging sheets: arranging n pieces of small cells 1 according to positive and negative series connection;

[0045] S6. Plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com