Method for repairing defects of pipe orifice of high-alloy hollow valve shell casting

A technology for hollow valves and defects, which is applied in the repair field of nozzle defects of high-alloy hollow valve casing castings, to achieve the effect of improving repair quality, reducing internal stress and reducing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

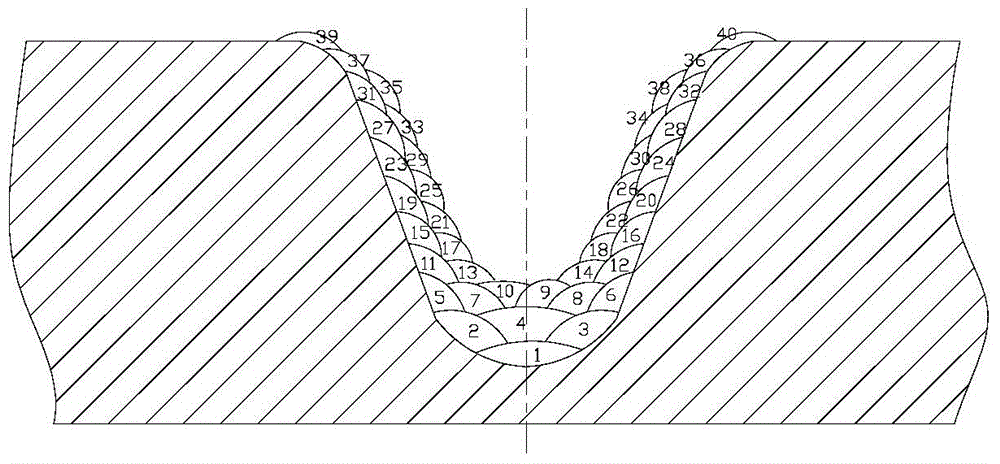

[0017] A method for repairing nozzle defects of high-alloy hollow valve casing castings, which is characterized in that: the method first carries out defect gouging from the inner side, and then removes the defects from the outer side, and then uses heating equipment to pre-heat all the upper and lower parts of the nozzle. Heat, then use the welding principle from the inside to the outside and the multi-layer and multi-pass welding sequence, the welding method with the swing width of the electrode ≤ 20mm for welding, and finally perform post-weld heat treatment.

[0018] The specific method is as follows:

[0019] 1) Excavation of defects a. In the range of 50mm from the inside of the nozzle, the defect gouging is carried out from the inside, and the rest are excavated from the outside;

[0020] b. Carbon rods with a diameter of 13mm are used for gouging. For larger defects, carbon rods with a diameter of 13mm are used for gouging at the bottom of the defect, and carbon rods ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com