Alloy material with thermal expansion coefficient in gradient change and preparation method thereof

A technology of thermal expansion coefficient and gradient change, applied in the field of alloy materials and its preparation, can solve problems such as damage, large difference in thermal expansion coefficient, and connection failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The gradient transition alloy prepared by this process is used as a stress relief layer for the welding of alumina ceramics and stainless steel. Among them, the thermal expansion coefficient of alumina is 5.5×10 -6 , the coefficient of thermal expansion of stainless steel ≥ 16.0×10 -6 .

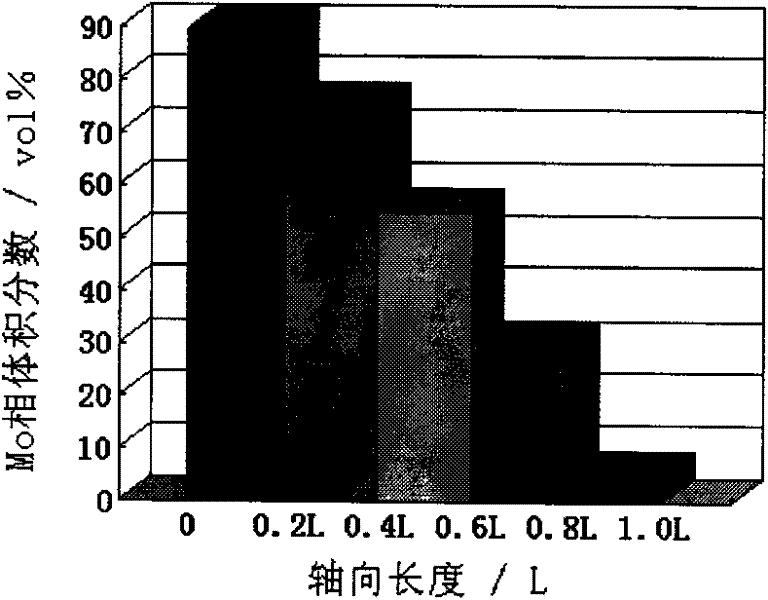

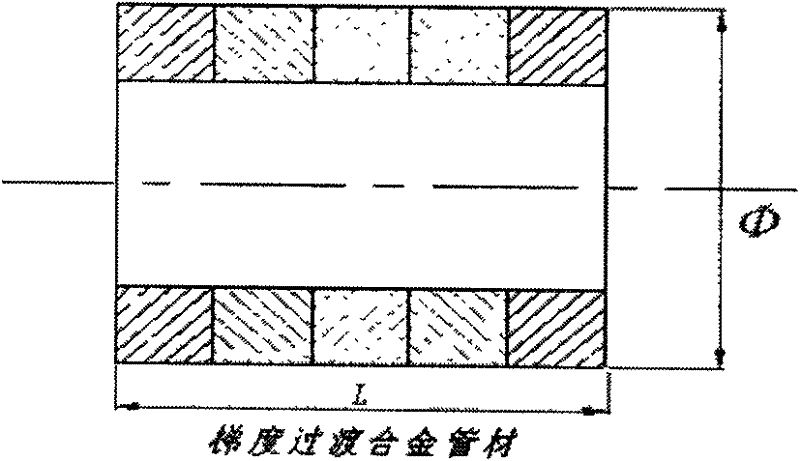

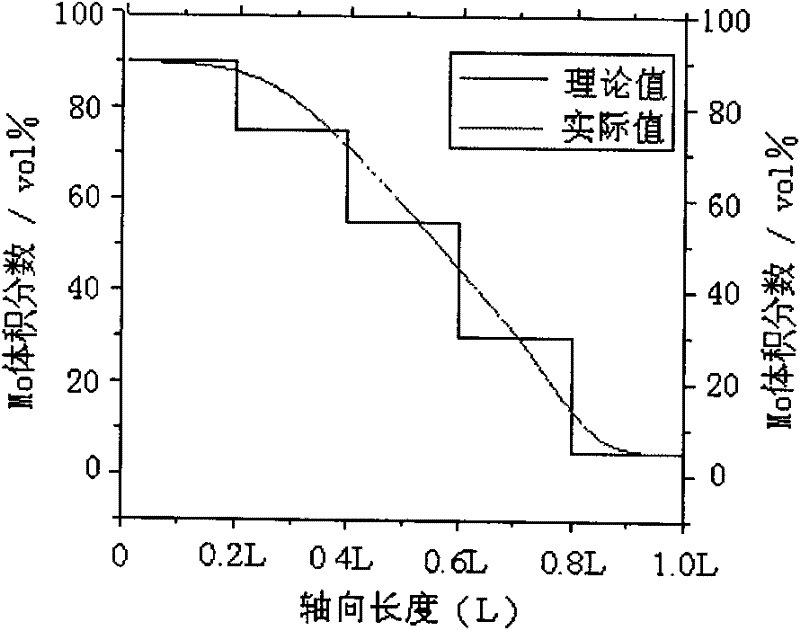

[0053] (1) Gradient transition alloy composition design

[0054] According to the size and difference of thermal expansion coefficients between alumina ceramics and stainless steel, the base material of gradient transition alloy is set to Cu, Ni, Cr ternary alloy with copper as the main body, and the mass ratio is set to 90:8:2. The coefficient of thermal expansion is about 17×10 -6 . The thermal expansion coefficient adjustment phase of the gradient transition alloy is made of high-purity, ultra-fine Mo powder, and the thermal expansion coefficient of Mo is 5.53×10 -6 . In addition, the composition of the gradient transition alloy is divided into three sections, the volume perce...

Embodiment 2

[0074] The gradient transition alloy prepared by this process is used as a stress relief layer for the welding of C / SiC composite ceramics and TC4 titanium alloy. Among them, the thermal expansion coefficient of C / SiC composite ceramics is 3.5×10 -6 , the thermal expansion coefficient of TC4 titanium alloy is 9.7×10 -6 .

[0075] (1) Gradient transition alloy composition design

[0076] According to the thermal expansion coefficient of C / SiC composite ceramics and TC4 titanium alloy and the components of the ceramics and metals to be welded, the gradient transition alloy base material is set to be two components of Ni and Fe, and the composition ratio is set to 1:1. The thermal expansion coefficient adjustment phase adopts high-purity, ultra-fine W powder, and its thermal expansion coefficient is 4.4×10 -6 . At the same time, the composition of the transition alloy is divided into two sections, the volume percentage of W in the first section alloy is set to 90vol%, and the...

Embodiment 3

[0095] The gradient transition alloy prepared by this process is used as a stress relief layer for the welding of C / C composite materials and stainless steel. Among them, the thermal expansion coefficient of the C / C composite is 3.5×10 -6 , the coefficient of thermal expansion of stainless steel ≥ 16.0×10 -6 .

[0096] (1) Gradient transition alloy composition design

[0097] According to the thermal expansion coefficient and the difference between the C / C composite material and stainless steel, the gradient transition alloy base material is set as Cu, Ni, Cr ternary alloy with copper as the main body, and the mass ratio is set at 90:8:2. The system alloy is because the thermal expansion coefficient of the Cu matrix is 17×10 -6 , which is close to the thermal expansion coefficient of stainless steel. The expansion coefficient adjustment phase of the gradient alloy adopts SiC powder and W powder. Among them, the thermal expansion coefficient of SiC powder is 4.3×10 -6 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com