Stress-eliminating distortion-correcting thermal treatment tooling and process of titanium alloy at high temperature

A high-temperature state and stress-relief technology, applied in the field of heat treatment, can solve the problem that deformation cannot be completely eliminated at one time, and achieve the effect of compact structure, restoring theoretical shape, and releasing welding stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

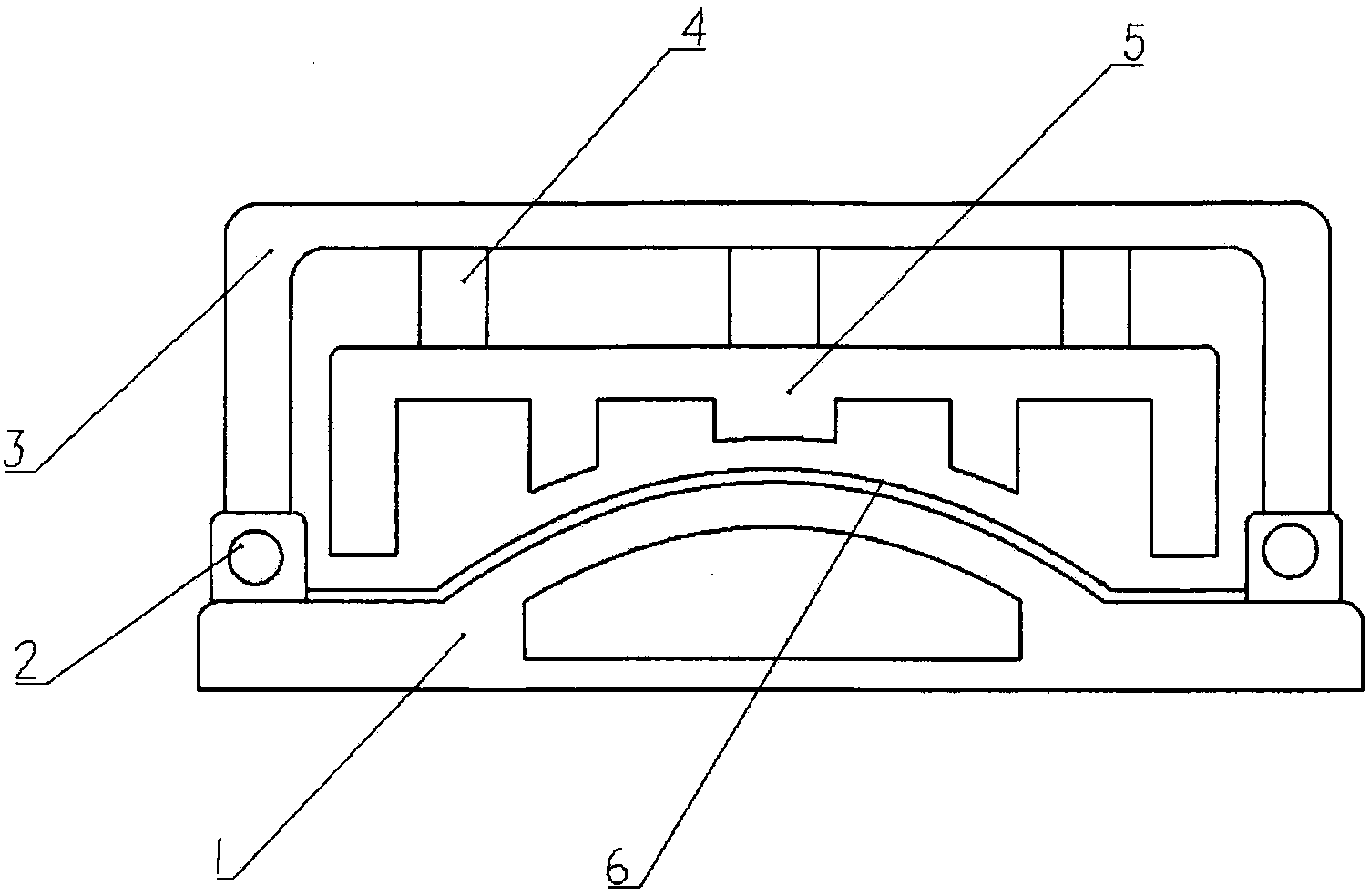

[0008] like figure 1 As shown, a titanium alloy high-temperature state stress relief correction deformation heat treatment tool, the upper surface of the clamp base 1 and the lower surface of the parts to be heat treated 6 are attached, and positioning blocks 7 are provided at both ends of the clamp base 1, inverted The fixed frame 3 of the U-shaped structure is movably connected with the clamp base 1 through the pin 2; the power strut 4 is arranged under the fixed frame 3, and the clamp 5 is connected under the power strut 4, and the lower surface shape of the clamp 5 is consistent with the parts to be heat treated The shape of the upper surface of 6 is consistent, and the lower surface of clamping plate 5 and the upper surface of part 6 to be heat treated are clearance fit, and the thermal expansion of clearance fit power prop 4; wherein the coefficient of thermal expansion of power prop 4 is greater than that of the rest of the tooling Expansion coefficient, in specific app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com