Accurate rounding method of large-diameter metal cylinder body

A metal cylinder and large-diameter technology, which is applied in the field of precise rounding of large-diameter metal cylinders, can solve the problems of large technical equipment of the rounding device, troublesome, and inability to eliminate the stress in the calibration cylinder, so as to reduce frictional resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

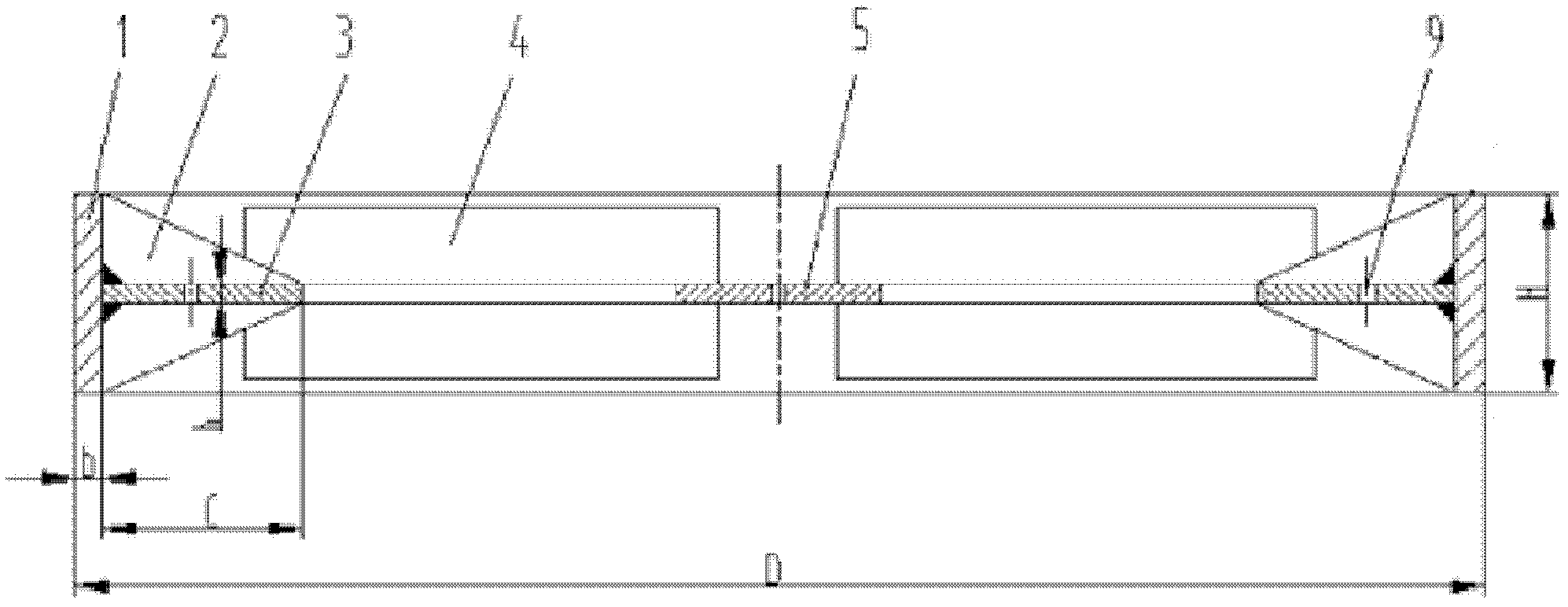

[0042] Specifications: The inner diameter of the cylinder is 4000mm, the thickness of the cylinder is 30mm, the length of the cylinder is 2500mm, and the material is Q345R.

[0043] Accuracy requirements: cylinder roundness is not greater than 1.5mm.

[0044] Make the school circle mold 10:

[0045] Structural selection of the rounding mold 10: Since the inner diameter of the cylinder is 4000mm and the wall thickness is 30mm, in order to prevent the deformation of the cylinder after rounding and the deformation in the butt welding of the cylinder and the cylinder, the rounding mold 10 The structure of the integral round-shaped mold is adopted. Its production method is as follows:

[0046] 1) Preliminary calculation according to the formula 〖1〗: the distance between the rounding molds is A=2425mm~3180mm, so the number of cylinder rounding molds 10 is 2 pieces;

[0047] 2) Making the coaming 1: Since the material of the rounded cylinder is Q345R, which belongs to carbon alloy...

Embodiment 2

[0070] Specifications: The inner diameter of the cylinder is 4000mm, the thickness of the cylinder is 40mm, the length of the cylinder is 2500mm, and the material is Q345R.

[0071] Accuracy requirements: cylinder roundness is not greater than 1.5mm.

[0072] The production of circle-correcting mold 10: due to the wall thickness 40mm of cylinder 12 being circled, only differs from the wall thickness 30mm of cylinder 12 of embodiment 1 by 10mm. The production, assembly welding, stress relief treatment and mechanical processing are completely the same as those in Example 1. According to the strength calculation, the rigidity of the circle-calibrating mold 10 fully meets the cylinder body 12 circle-calibrating requirements. .

[0073] The assembly welding and stress relief treatment of the round tire set are the same as in Embodiment 1.

[0074] Manufacture of cylinder 12: According to the design requirements, the inner diameter of the cylinder is 4000mm, the thickness of the c...

Embodiment 3

[0078] Specifications: The inner diameter of the cylinder is 4000mm, the thickness of the cylinder is 50mm, the length of the cylinder is 2500mm, and the material is Q345R.

[0079] Accuracy requirements: cylinder roundness is not greater than 1.5mm.

[0080] Make the school circle mold 10:

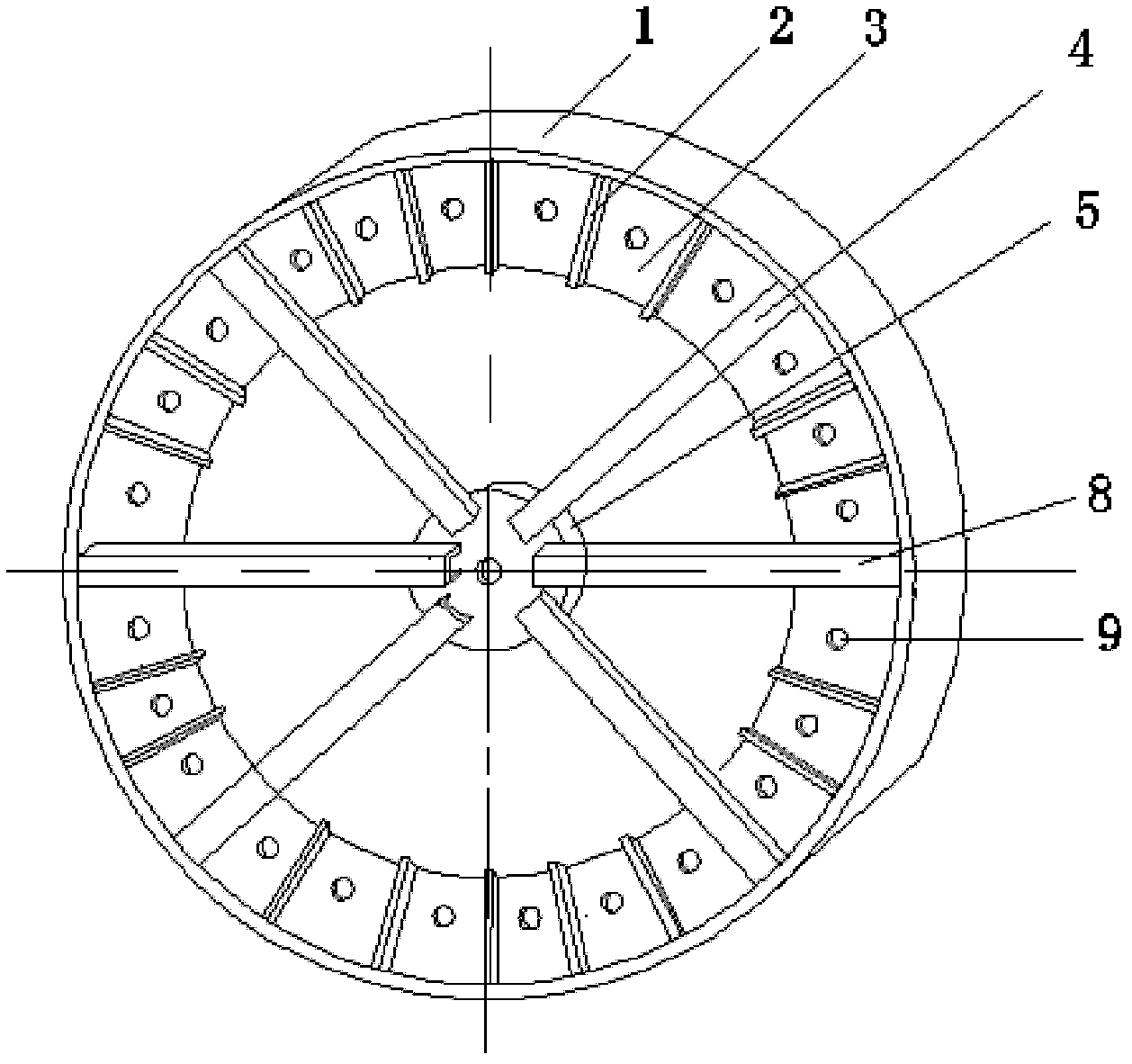

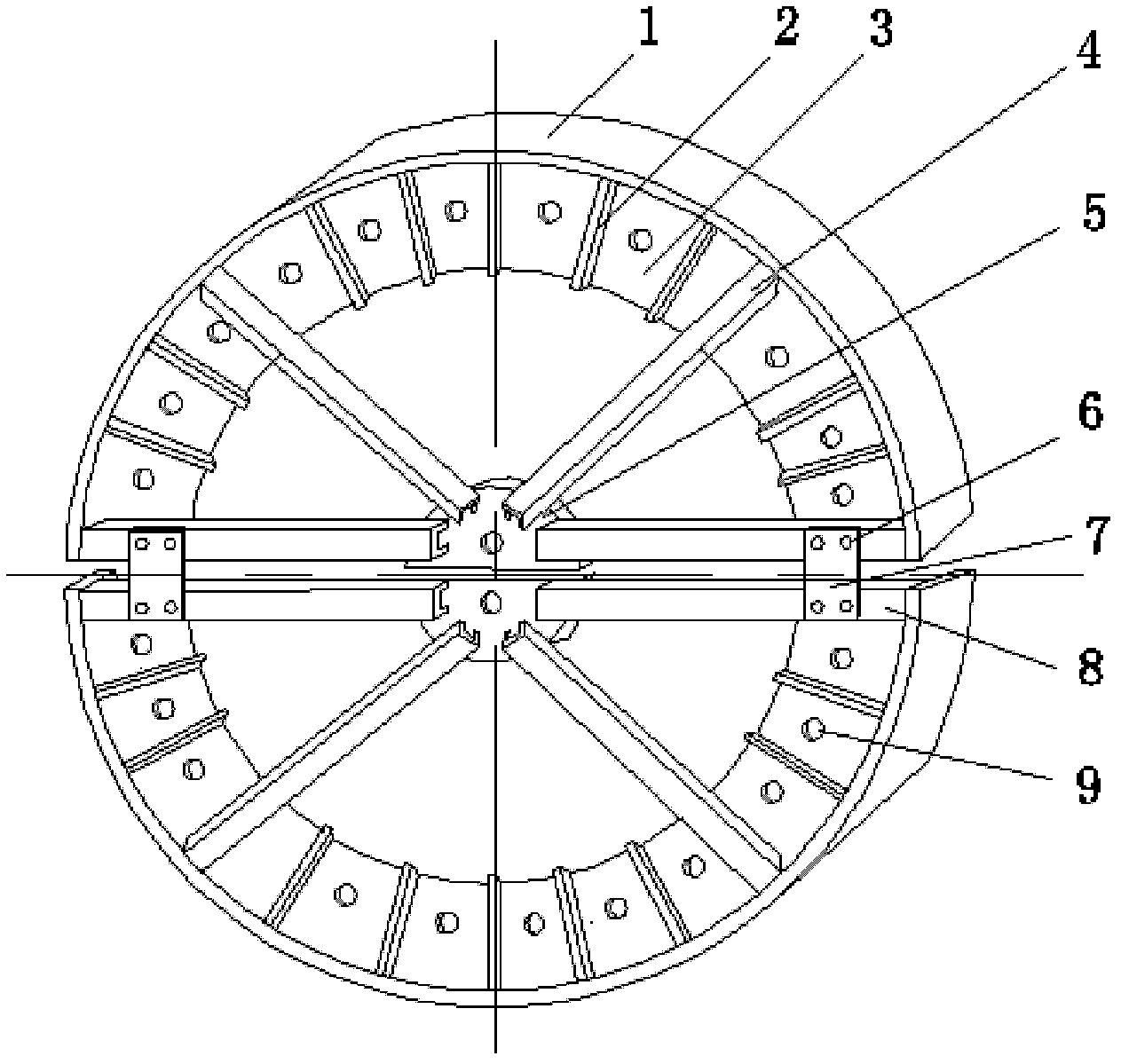

[0081] Structural selection of the rounding mold 10: Since the inner diameter of the cylinder is 4000mm and the wall thickness is 50mm, in order to prevent the deformation of the cylinder after rounding and the deformation during the butt welding of the cylinder and the cylinder, the rounding mold 10 The structure of the integral round-shaped mold is adopted. See figure 1 , which is made as follows:

[0082] 1) Preliminary calculation according to the formula (1): the distance A between the rounding molds is between 2425 and 3180 mm, so the number of cylinder rounding molds 10 is 2 pieces;

[0083] 2) Making the coaming 1: Since the material of the rounded cylinder is Q345R, which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com