Method for controlling welding deformations of special type motor bedplate

A technology of welding deformation and control method, which is applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems that cannot be annealed to eliminate welding stress, cannot be used, and cannot be rooted out, etc., to achieve strong innovation and practicability , Eliminate welding stress, simple and strict quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

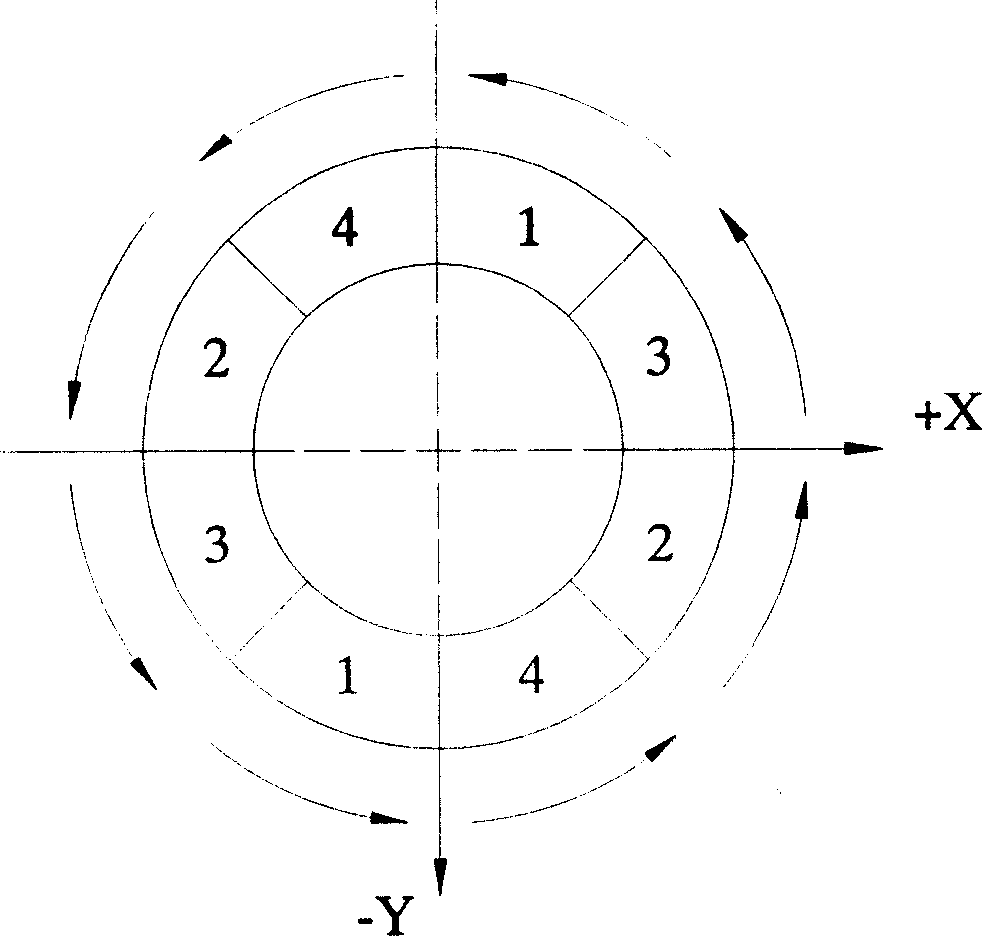

[0018] Such as figure 1 , the welding seam of the upper end ring is divided into eight equal parts along the circumferential direction according to the X and Y cross center lines. Speed symmetrical and synchronous welding.

[0019] The steps of the method for controlling the welding deformation of the special motor frame are as follows:

[0020] (1) Cold-made angle steel bracket, and a machined process flange is installed and welded on the upper end of the bracket;

[0021] (2) Use stainless steel eyebolts to hoist the machine base in the center of the bracket, fix the machine base and the upper end ring after assembly and tack welding firmly through the process flange at the upper end of the bracket, and hang them vertically;

[0022] (3) Draw X and Y cross centerlines on the outer surface of the upper end ring, draw an eighth equal line at the upper end ring weld, mark and install a dial indicator on each cross center line, adjust the dial indicator to 0 bit;

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com