Assembling and welding method of side thrust device

A technology for welding and extending tubes, which is applied in transportation and packaging, ship parts, ships, etc. It can solve the problems of interfering with the normal operation of the acoustic equipment on the bottom of the ship, increasing air bubbles, and affecting the measurement accuracy, so as to shorten the welding time and save construction costs. , The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

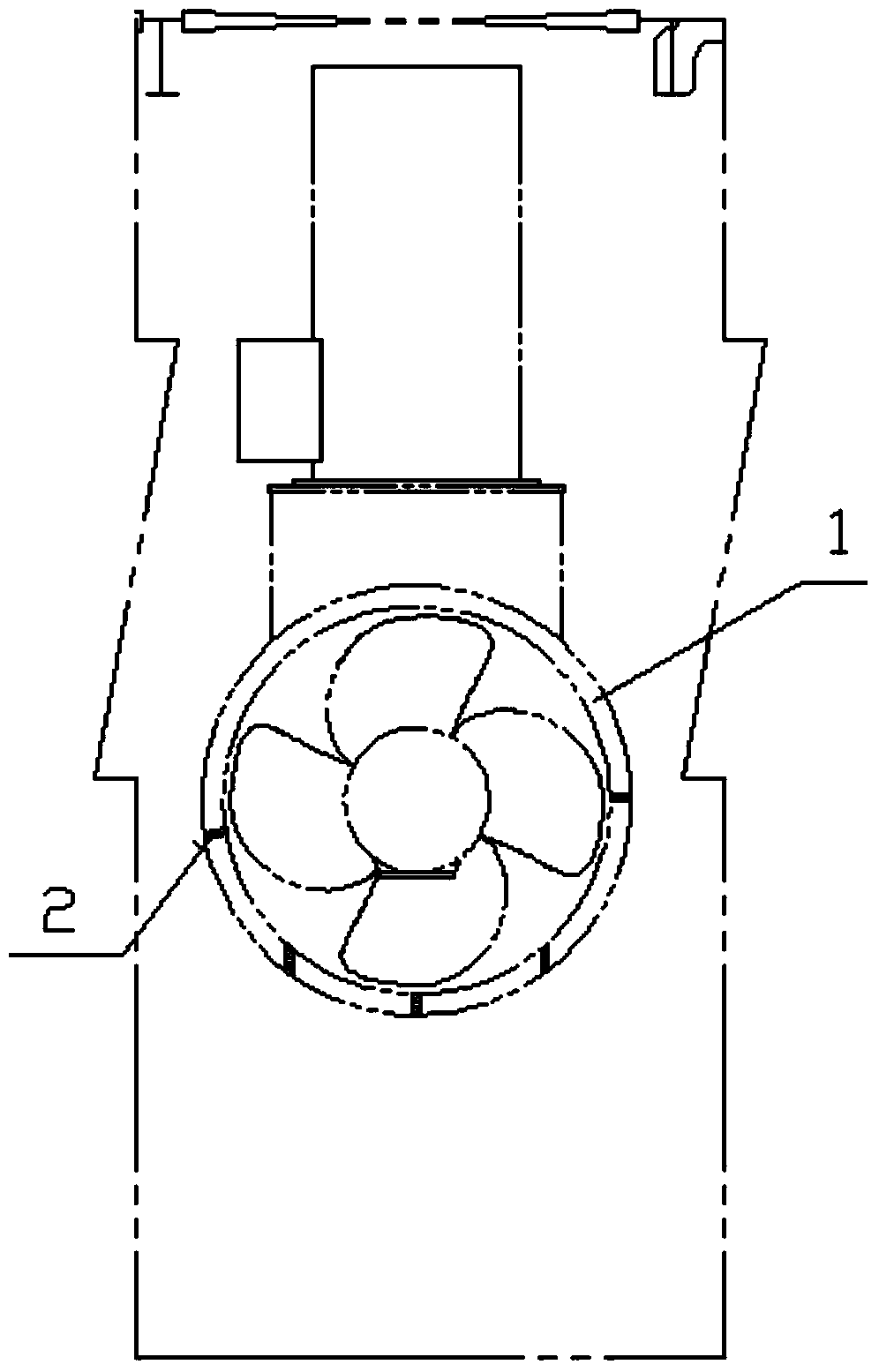

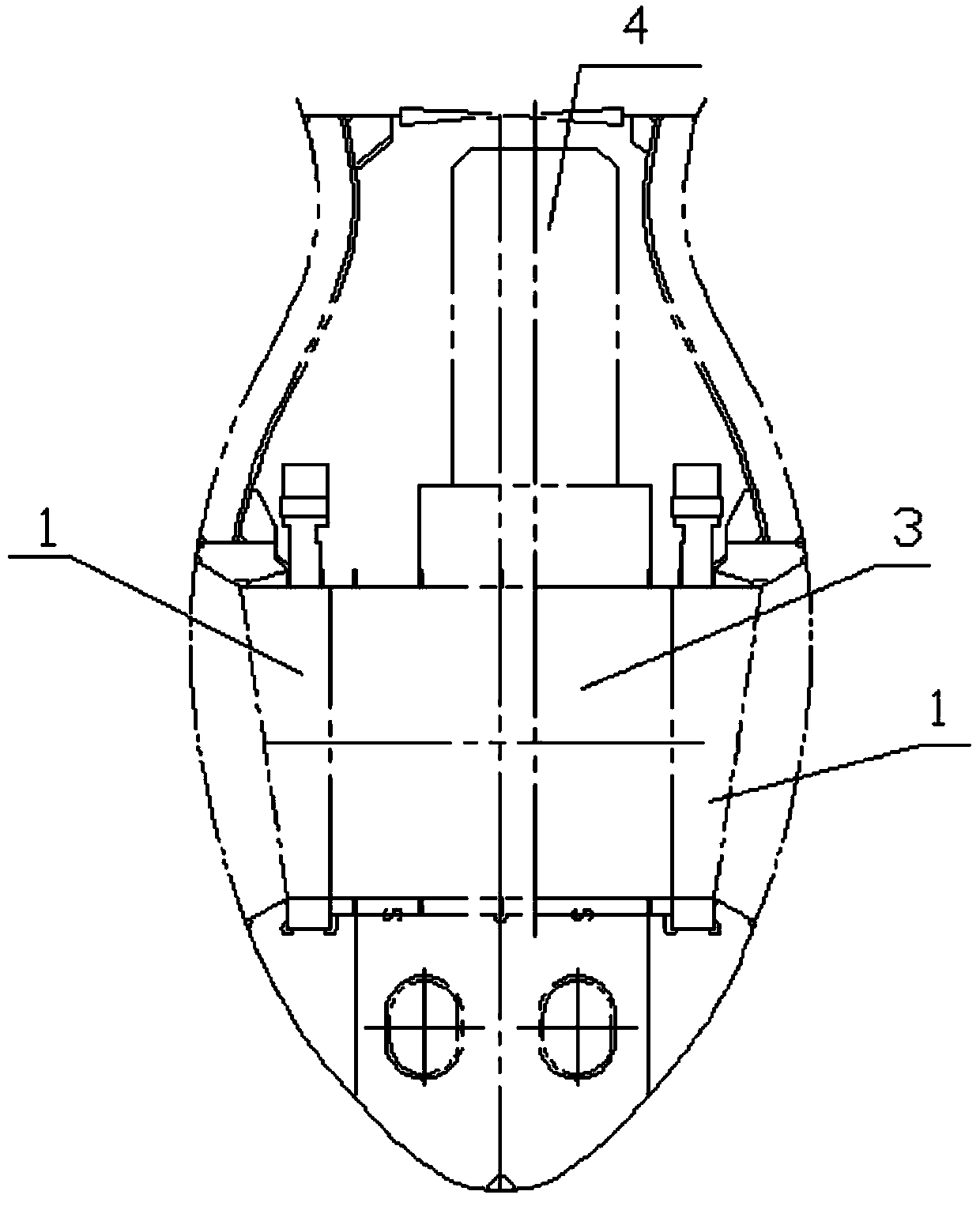

[0016] see Figure 1-Figure 4 , the embodiment of the present invention provides a side thruster welding method, including:

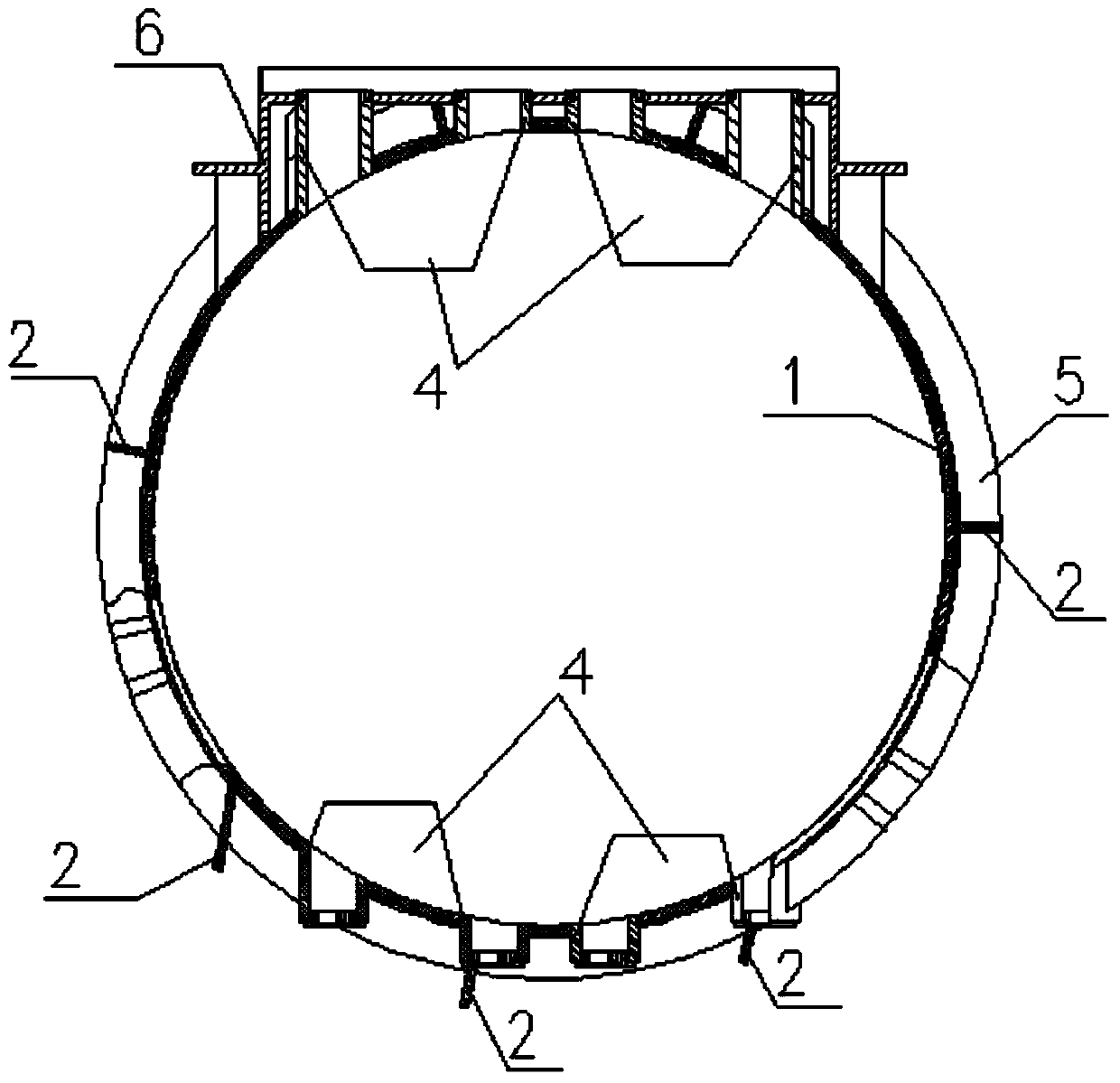

[0017] Step 10: Lofting and processing two extension tubes 1 for connecting the two ends of the lateral thrust cylinder 3, and drawing four generatrices of each extension tube 1 respectively. The four busbars are the reference positions for installing other components of the side thruster, and four busbars can be drawn at the positions of 0, 90 degrees, 180 degrees and 270 degrees on the circumferential surface of each extension tube 1 with a laser instrument.

[0018] Step 20: Based on the four busbars of the extension tube 1, install and weld the bearing seat 4, the circumferential rib plate 5, the longitudinal rib plate 2 and the motor fixing seat 6 in each extension tube 1 to form two side Push closure modules; each side push unit contains two side push modules.

[0019] Step 30: After the assembly and welding is completed, anneal the two side pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com