Joggling type vehicle bottom plate assembly

A car floor, tenon joint technology, applied in the superstructure sub-assembly, railway car body, vehicle parts and other directions, can solve the problems of unfavorable environmental protection, welding effects, welding deformation of the floor assembly, etc., and achieve environmental benefits. The effect of protection, reduction of manufacturing cost and avoidance of welding distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

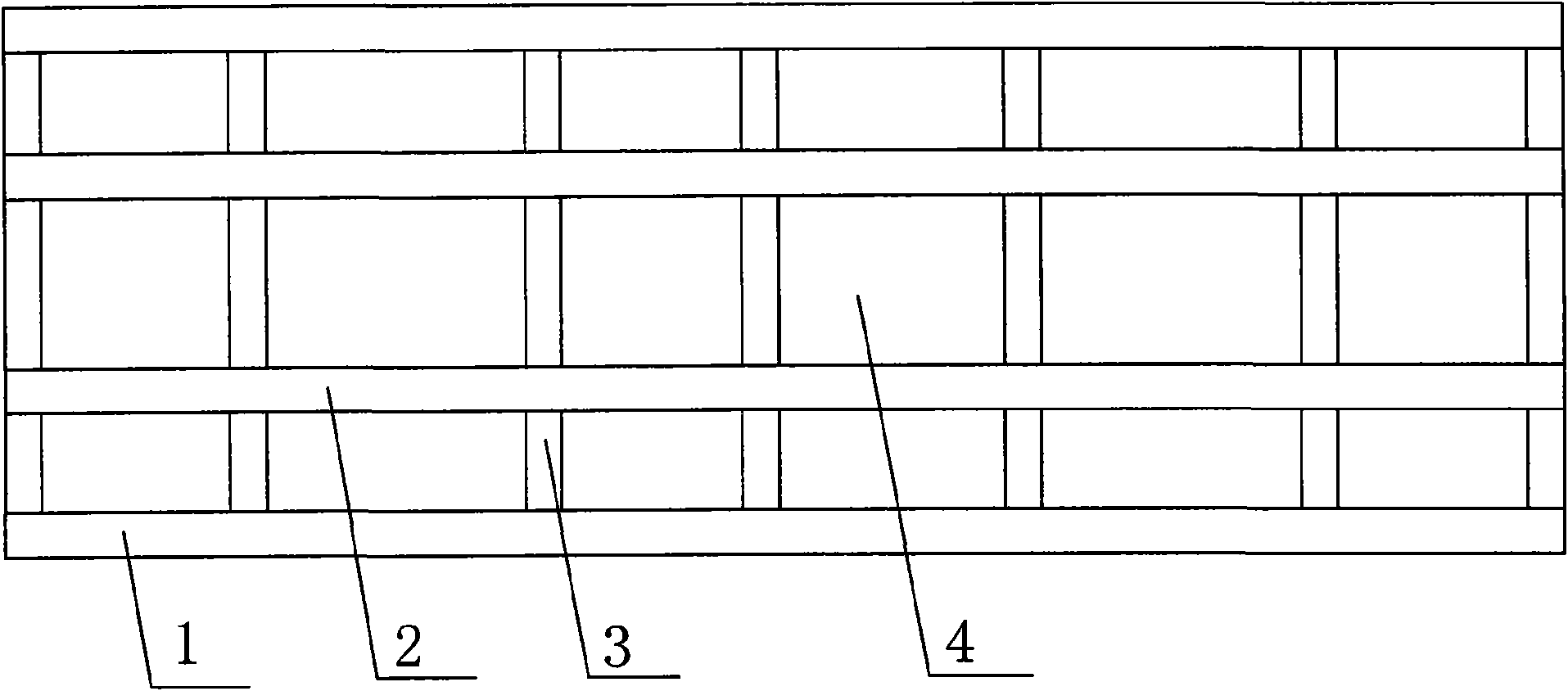

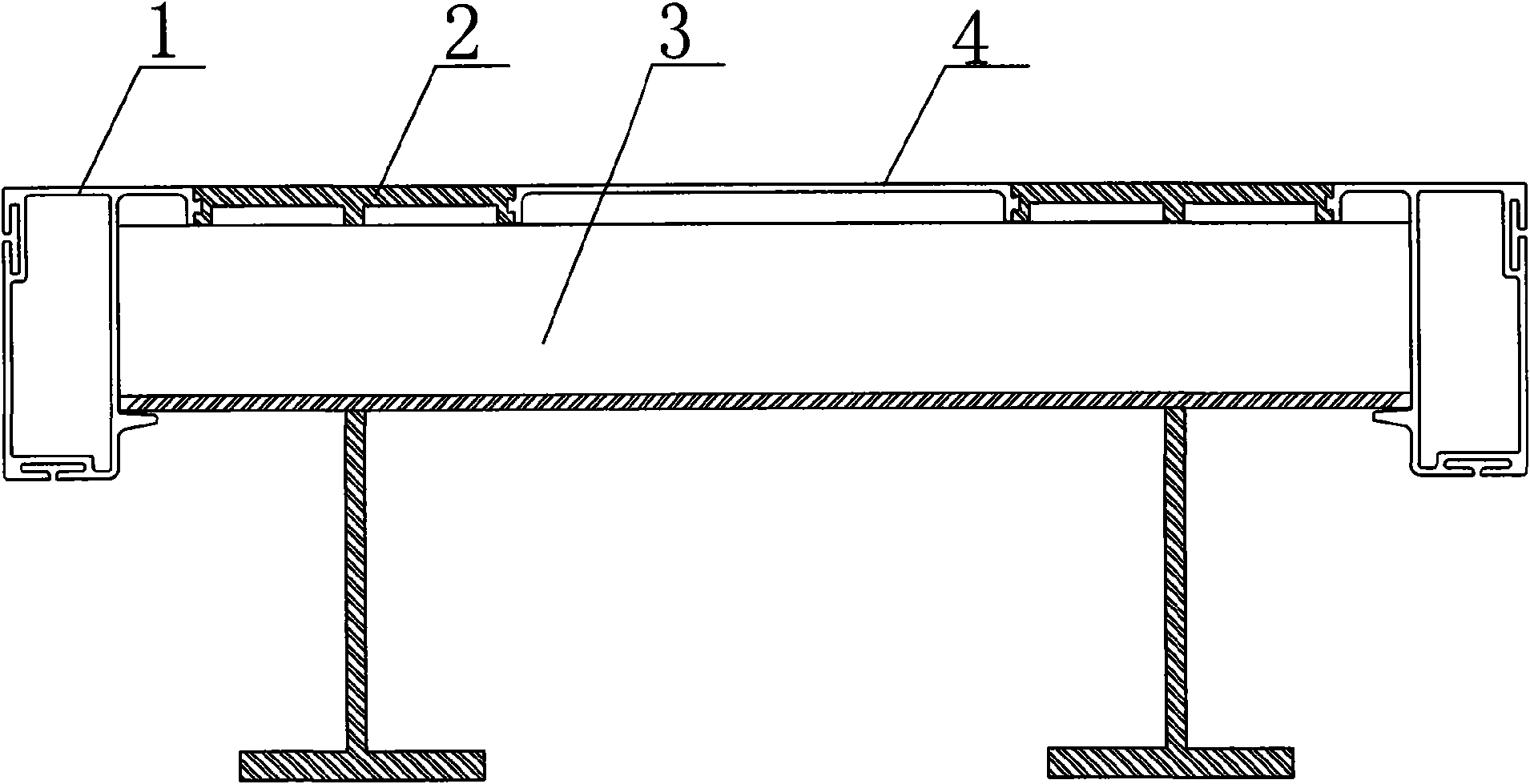

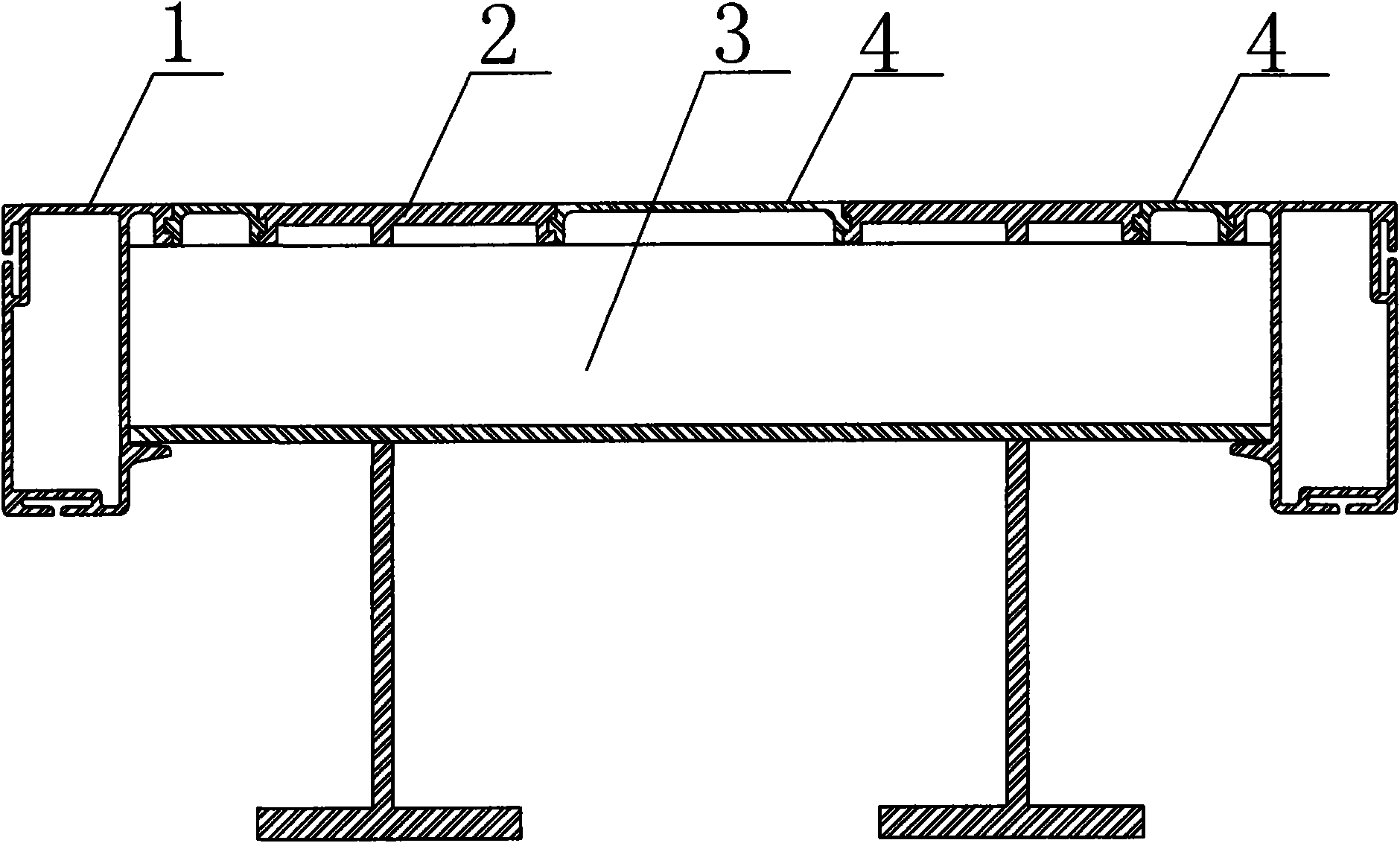

[0016] Refer to attached figure 1 , 2 , 3, 4, the present invention is made up of edge beam 1, longitudinal beam 2, beam 3, transition connecting plate 4. The side beam 1, the longitudinal beam 2, and the transition connecting plate 4 are connected together by tongue and groove along the transverse direction of the vehicle body, and their upper surfaces form a plane. Part of the side beam 1 can be used as the bottom plate. There is a tenon and groove 11 on one side of the side beam 1. There is a tenon and groove 12 for installing the hinge of the carriage on the side beam 1, and a tenon and groove 13 for installing the shackle. The side beam 1 has a limit beam 3 degrees of freedom There are tenon grooves 21 on both sides of the longitudinal beam 2, a part of the longitudinal beam 2 can be used as a bottom plate, and the web of the longitudinal beam 2 has slot holes; the transition connecting plate 4 has tenon grooves 41 on both sides. The connection relationship of each piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com