Anti-ionizing radiation container and preparation method thereof

An ionizing radiation and container technology, applied in the field of nuclear power, can solve the problems of poor mobility, small size, shortened lifespan, etc., and achieve the effects of reducing adverse effects, high shielding performance, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The embodiment of the present invention also provides a preparation method of the anti-ionizing radiation container, comprising:

[0058] S10, respectively providing the solution of the first resin system, the mixed solution of the second resin system and shielding filler, and the solution of the third resin system;

[0059] S20, loading the solution of the first resin system on the first fiber to obtain a first fiber prepreg, and loading the mixed solution of the second resin system and barrier filler on the second fiber to obtain a second fiber prepreg , and loading the solution of the third resin system on the third fiber to obtain the third fiber prepreg;

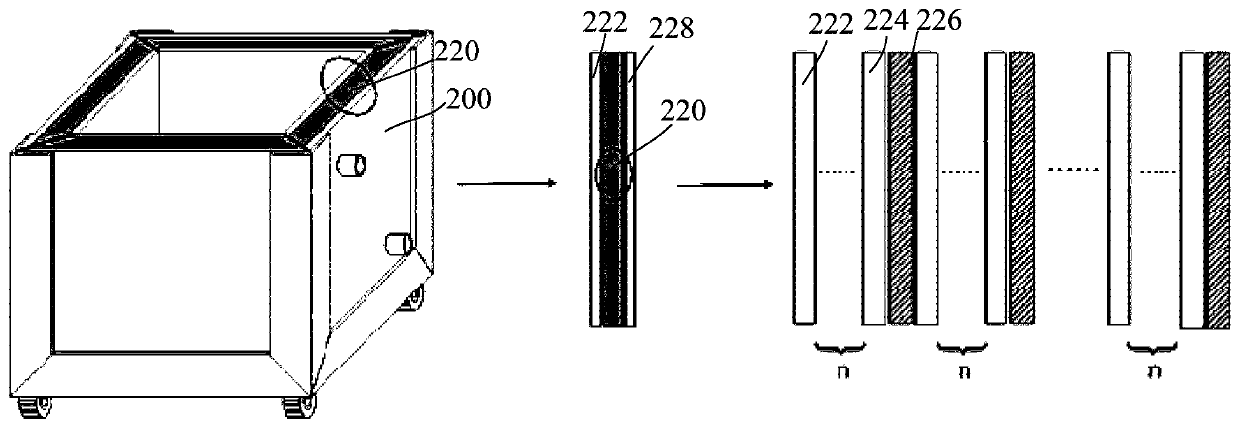

[0060] S30, laying up the first fiber prepreg on the bottom layer, then alternately stacking the second fiber prepreg and the metal layer 226 on the first fiber prepreg, and stacking the first fiber prepreg on the top layer Three-fiber prepreg, forming a preformed structure;

[0061] S40, performing curing and ...

Embodiment 1

[0097] (1) Surface modification of the metal layer 226: take a thin tungsten sheet with a thickness of 0.1 mm, and polish the surface of the tungsten sheet with sandpaper to improve its surface roughness. Place the polished tungsten sheet in a beaker filled with concentrated sulfuric acid for 30 minutes of acid etching, then rinse the surface of the tungsten sheet with clean water for 3 minutes, and dry it in an oven at 80°C for about 1 hour to obtain a surface-modified tungsten sheet.

[0098] (2) Surface modification of shielding filler: in parts by weight, take 100 parts of rare earth oxide, 100 parts of solvent and 5 parts of silane coupling agent, and the solvent is one of acetone and alcohol organic solvent or Several kinds; under normal temperature conditions, the above materials are uniformly mixed by mechanical stirring to obtain a shielding filler mixture; the shielding filler mixture is distilled under reduced pressure at 80°C to remove the solvent, and ball milled b...

Embodiment 2

[0105] Same as the steps of steps (1)-(3), (5)-(7) of Example 1, the difference is that step (4) is:

[0106] (4) Preparation of fiber prepreg: First, cut a plain basalt fiber fabric of a certain size, and apply the solution of the first resin system, the mixed solution of the second resin system and shielding filler, or the solution of the third resin system evenly on the On the fiber fabric, the fiber fabric is completely soaked to obtain the first fiber prepreg, the second fiber prepreg and the third fiber prepreg. Brush and squeeze the fiber fabric with a brush to make it evenly wet and expel air bubbles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com