Glove liner with electric heating equipment

A technology for electric heating equipment and gloves, which is applied to electric heating devices, ohmic resistance heating, ohmic resistance heating parts, etc., can solve the problems of damage to the connector 12, difficult cleaning, maintenance, and complete drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

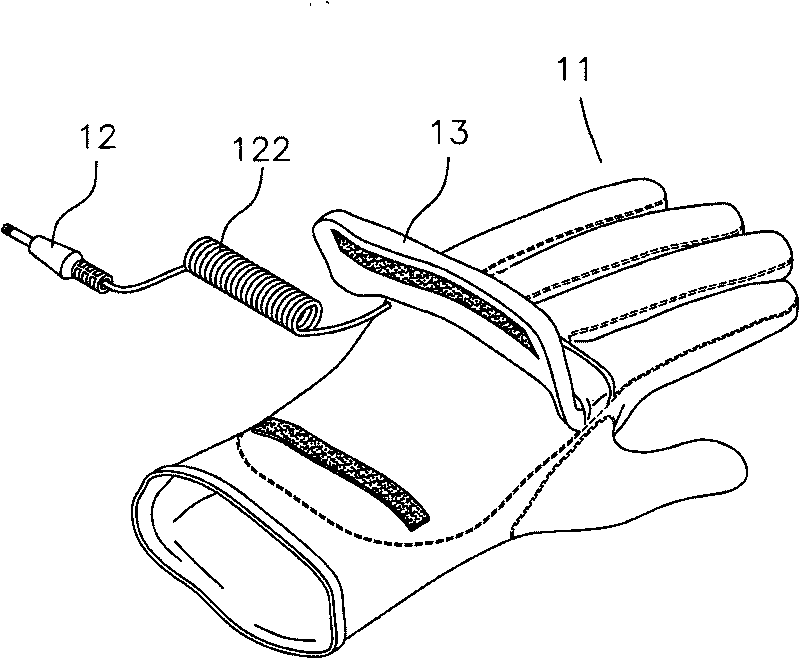

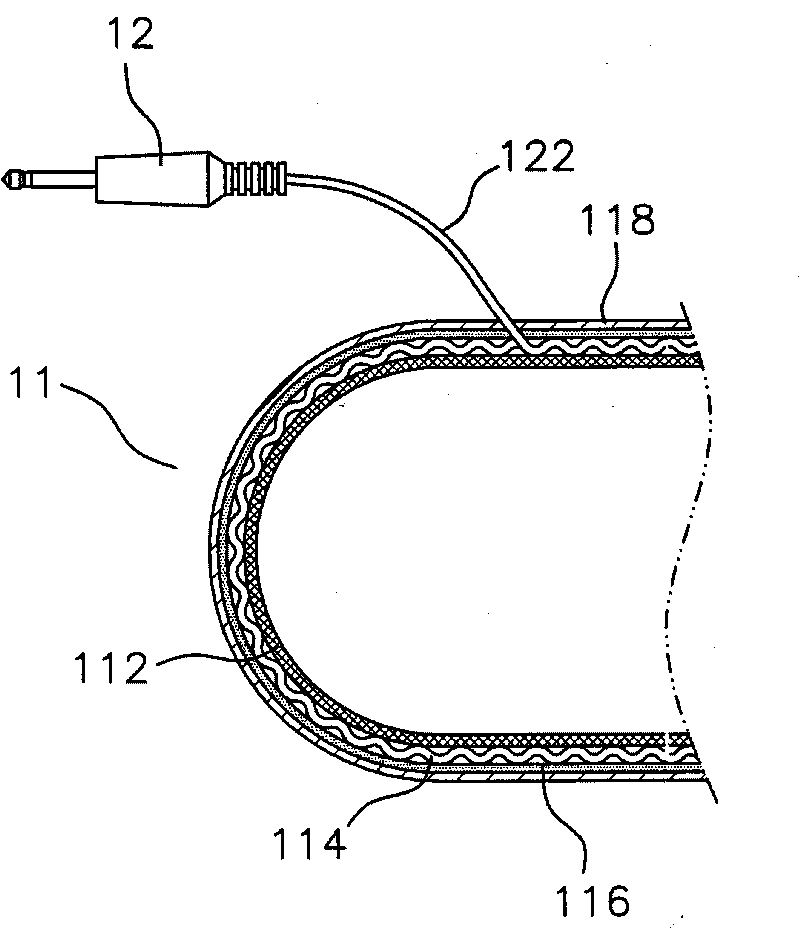

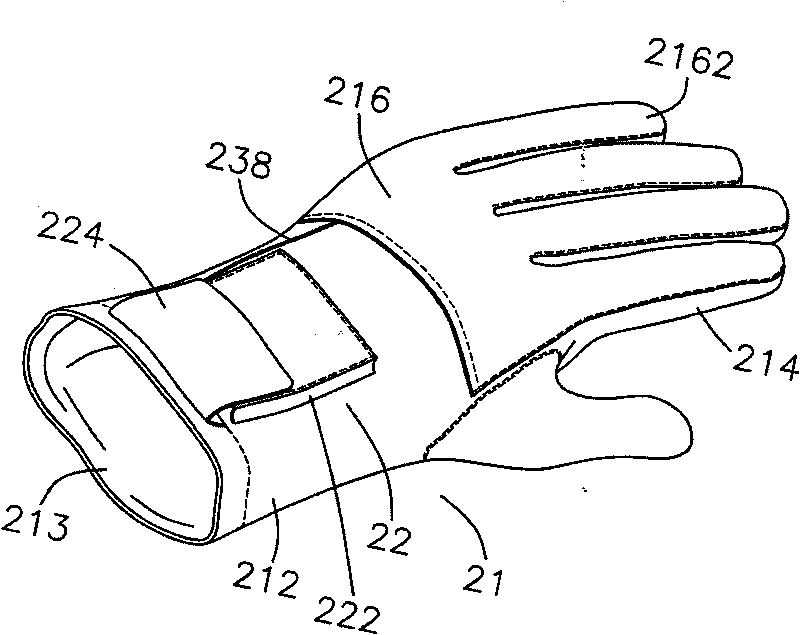

[0030] See attached image 3 , 4 The first embodiment of the glove liner with electric heating device of the present invention mainly includes a bushing 21, a containing bag 22 and an electric heating device 23, wherein the bushing 21 is made of a soft material with good heat resistance The sleeve 21 is mainly composed of a palm sleeve portion 212 and a plurality of finger sleeve portions 214 integrally connected with each other. One end of the palm sleeve portion 212 forms a sleeve opening 213, and the other end Connected with the finger sleeve portions 214 for the palm to be worn by the sleeve opening 213, the sleeve 21 is provided with an outer pocket 216 on the outside of the palm sleeve portion 212, and the outer pocket 216 has a plurality of sub-bags 2162 respectively extending thereon Outside of each finger cuff portion 214, the containing bag 22 is provided on the outside of the sleeve 21 adjacent to the cuff opening 213. It is mainly composed of a bag body 222 and a cov...

Embodiment 2

[0034] The foregoing first embodiment with slight changes constitutes the second embodiment of the present invention. The same parts will not be repeated, please refer to the attachment. Figure 5 In the second embodiment of the present invention, the cover sheet 324 is provided with a threaded hole 3242 for the wire 338 to extend through the threaded hole 3242 into the bag body 322 of the containing bag 32; in addition, the bag body 322 and the cover sheet 324 rooms can be bonded by hook and loop tape (not shown in the figure).

[0035] In summary, the present invention can indeed meet the expected purpose and has good effects through the original structure and its spatial form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com