An origami machine for lining paper packaging of medical gloves

A technology for lining paper and origami machines, which is applied in the field of origami machines, can solve problems such as socketing troubles, increase labor intensity, and affect work efficiency, and achieve the effects of ensuring accuracy and flatness, reducing labor intensity, and compact mechanism structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

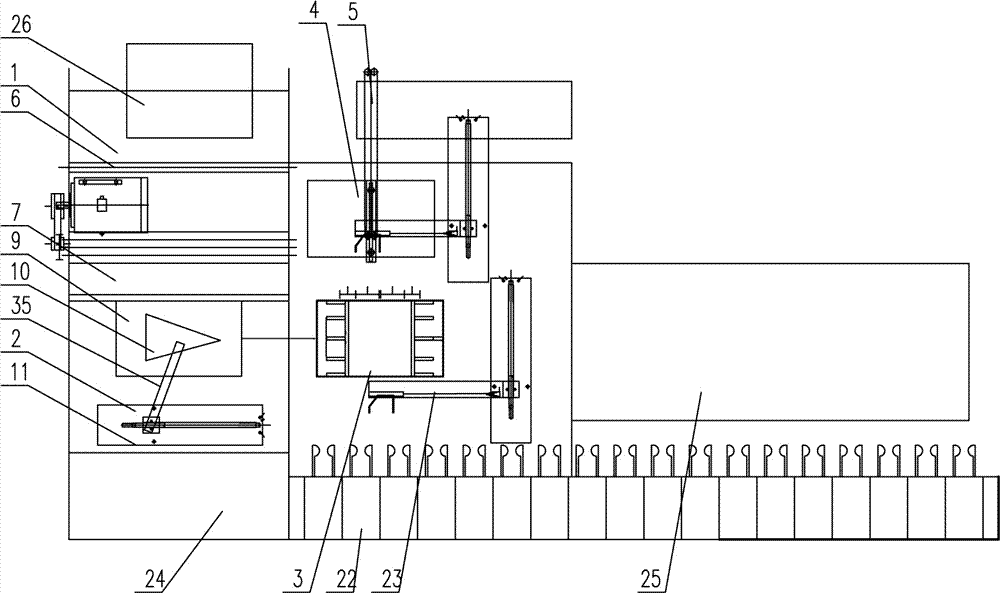

[0046] Such as figure 1 As shown, a paper folding machine for lining paper for medical gloves includes a paper feeding and cutting mechanism 1, a paper transfer mechanism 2, a sleeve feeding mechanism 22, a sleeve moving mechanism 23, a folding mechanism 3, a flattening and folding mechanism 4, and a feeding mechanism 5. Among them, the paper transfer mechanism 2 is arranged at the front end of the paper feeding and cutting mechanism 1, and the sleeve feeding mechanism, the one-folding mechanism 3, the flattening half-folding mechanism 4, and the feeding mechanism 5 are arranged in order from front to back, and are located in the paper feeding and cutting mechanism 1. , The paper transfer mechanism 2 side, in this way, compared with other similar paper folding machines, the entire mechanism has a compact structure, saves space, and is easy to operate; a pneumatic cabinet 24 and an electrical control box 25 are installed on the equipment to control the mutual movement and control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com