HDPE flatly sealed all-steel-belt corrugated discharging tube and production technology

A production process and discharge pipe technology, which is applied to pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of short pipe life and poor construction quality, and achieve the effect of ensuring compressive performance and construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

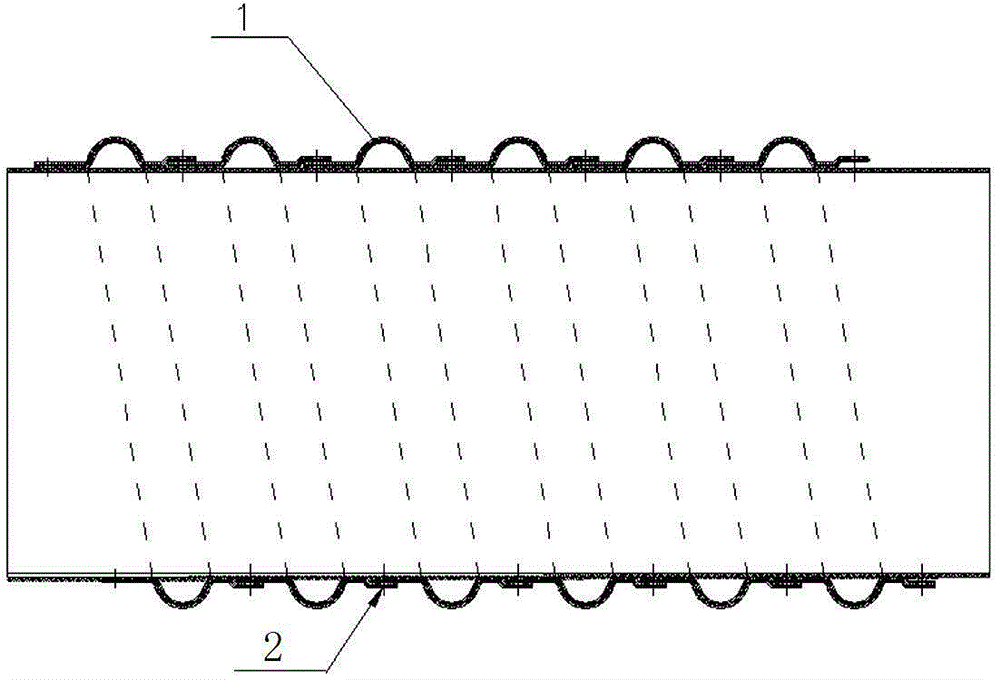

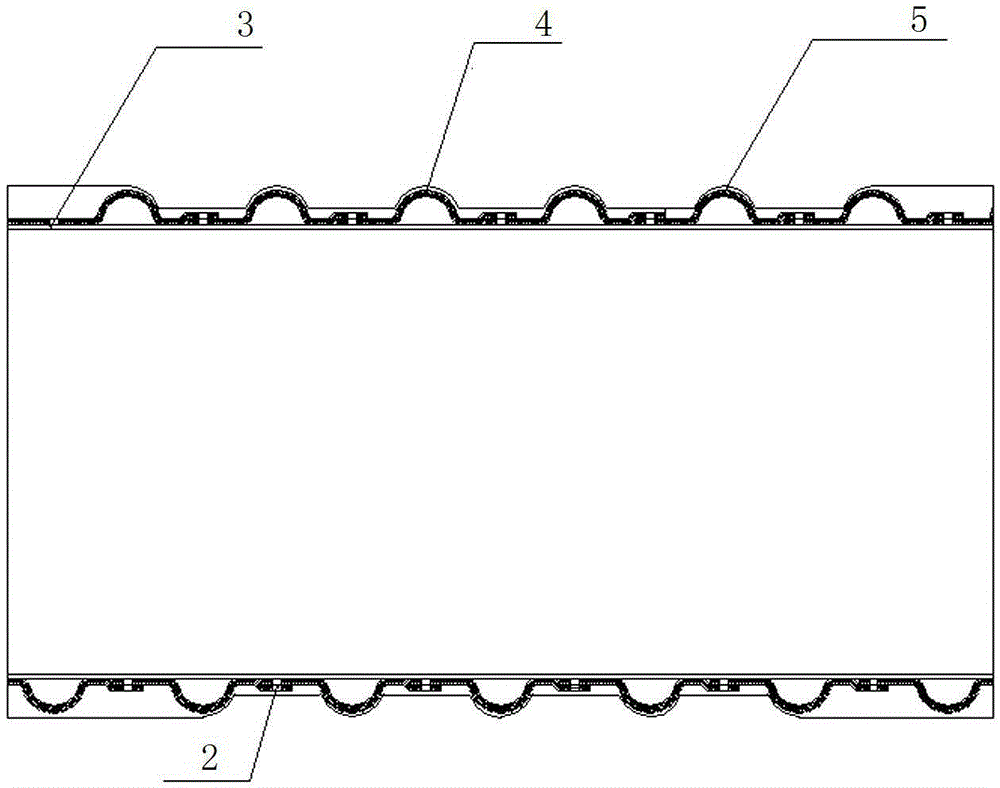

[0027] see Figure 1-4 , a HDPE flat-sealed all-steel belt corrugated discharge pipe, its pipe wall includes a polyethylene inner layer 3 tightly fitted from the inside and outside, a spiral steel belt middle layer 4 and a polyethylene outer layer 5, and a spiral steel belt middle layer 4 The concave-convex steel strip 1 raised in the middle is spirally wound from one end to the other end (see image 3 , the cross-section of the steel strip protrusion is "∩" shape), and the edges of adjacent spiral units are provided with a number of through holes 2 and overlapped with each other. The through holes 2 are filled with polyethylene and connected with the polyethylene inner layer 3 The polyethylene outer layer 4 is connected as a whole; the pipe wall surface of the discharge pipe forms a trough 7 at the steel strip lap, and forms a wave crest 6 at the steel strip protrusion; the trough at the pipe end of the discharge pipe is filled with polyethylene and Cut to form a flat struct...

Embodiment 2

[0030] The production technology of the HDPE flat seal all-steel strip corrugated discharge pipe in embodiment 1 comprises the following steps:

[0031] (1) Steel strip material selection: the steel strip is selected as 20# carbon steel sheet with a width of 30mm-150mm and a thickness of 1.5mm-5.0mm;

[0032] (2) Polyethylene material ingredients: Mix 125-140 parts by weight of 2480 polyethylene particles and 1-1.2 parts by weight of color masterbatch; specifically: start the mixer, first pour polyethylene particles into the mixer without stopping the machine, Next, add the color masterbatch and stir evenly; pay attention to the mixing and stirring, and the silo of the mixer must be kept dry and free of impurities;

[0033] (3) Confine the steel belt on the transmission shaft of the conveyor, start the transmission and pass through the punching machine and the forming machine in turn, that is, first use the forging punching method to punch holes on both sides of the steel belt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com