Hypersonic axisymmetric air inlet channel lip and design method thereof

A design method and intake port technology, applied to the intake port of the turbine/propulsion device, combustion air/combustion-air treatment, engine components, etc., can solve the problem of increasing the weight and complexity of the system and the total pressure loss of the intake port Large size, complex processing of the intake port, etc., to improve the starting performance, ensure the compression performance, and benefit the overall design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

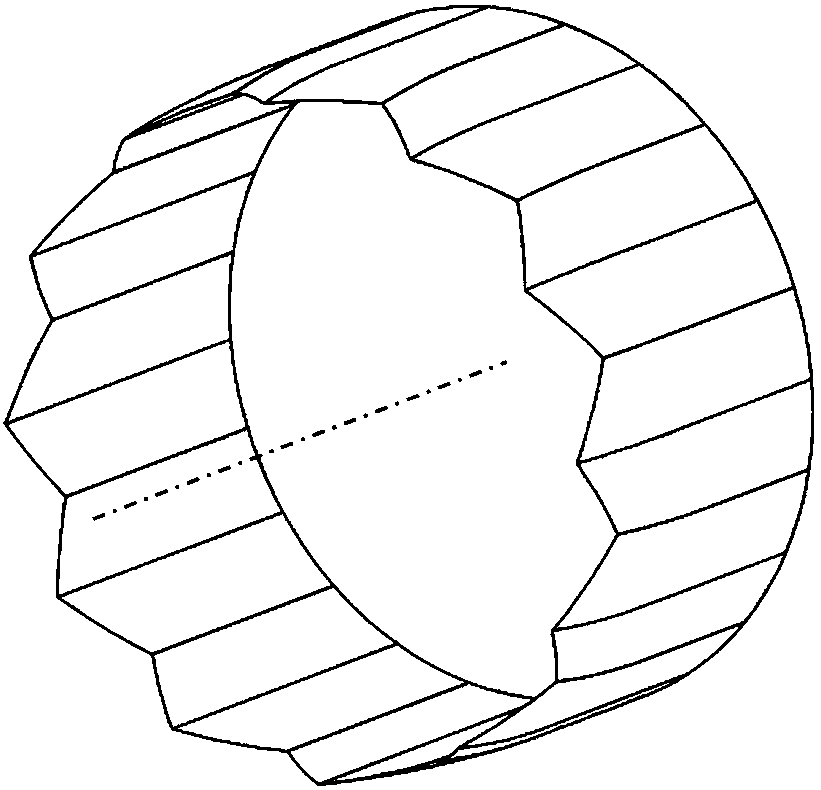

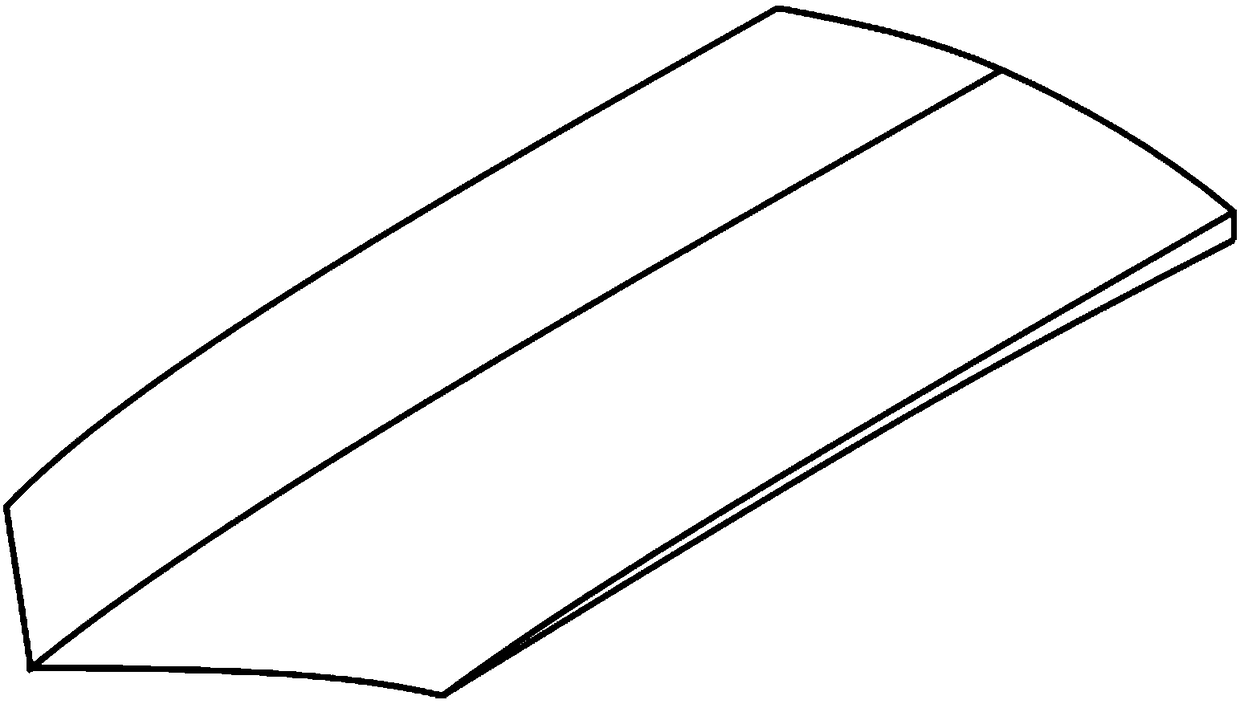

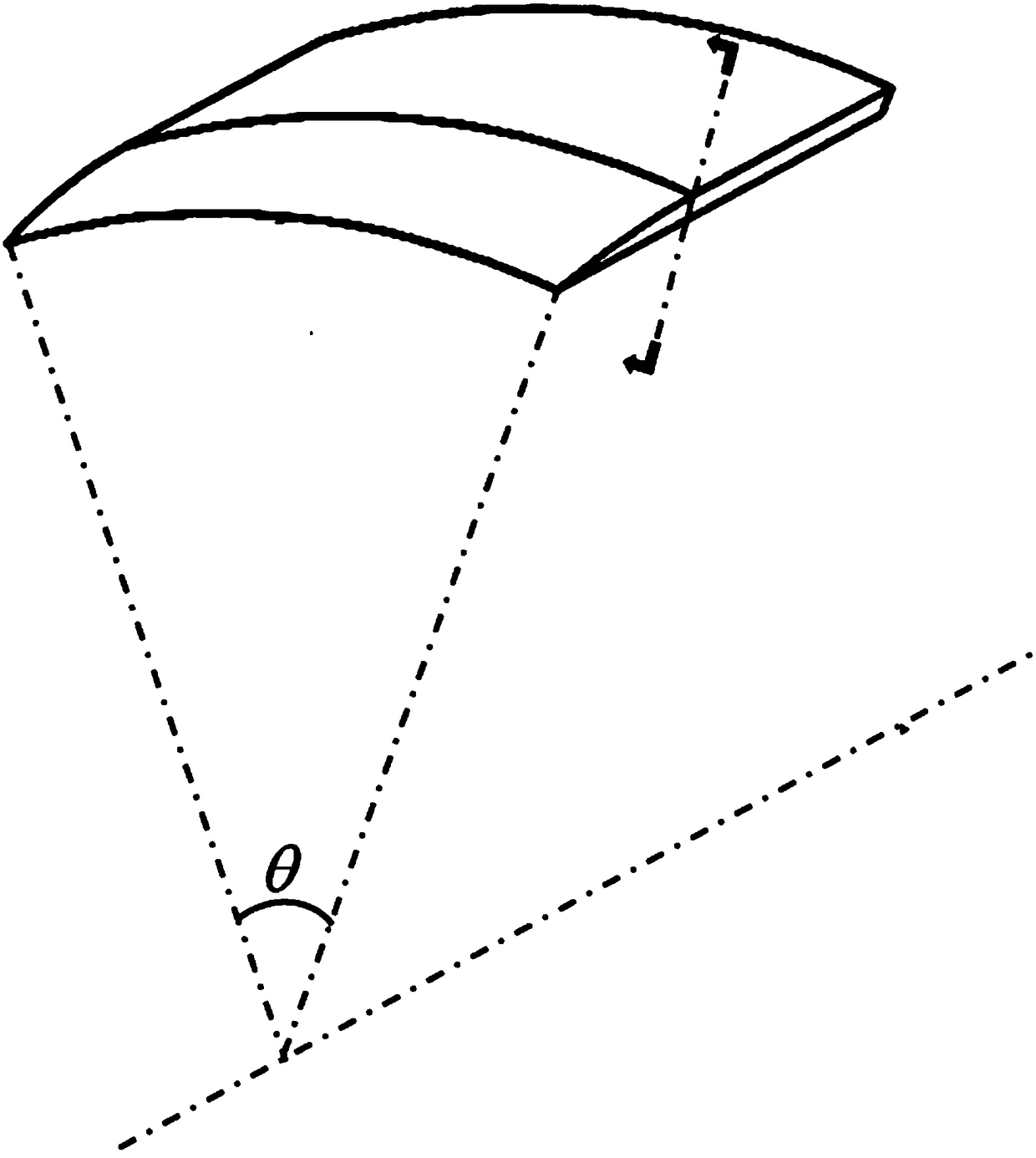

[0032] attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5A kind of hyper / supersonic axisymmetric inlet lip is shown, and described inlet is arranged on the engine of aircraft, and the front end of described inlet is provided with serrated lip, and described serrated lip includes several A piece of V-shaped sawtooth unit, the side walls of the V-shaped sawtooth unit are connected end to end to form a serrated lip, the center of the serrated lip is the axis of rotation, and the V-shaped sawtooth units are arranged in a circular array with the axis of rotation as the array axis.

[0033] A super / supersonic axisymmetric inlet lip and its design method. The design parameters of the serrated lip are: V-shaped serrated units N=15, central angle θ=24°, sweep angle λ=60°, The radius of the circle where the flat lip of the unit is located is 300mm, and the elongation length of the V-shaped sawtooth unit is calculated by taking the av...

Embodiment 2

[0037] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 6 The shown a hyper / supersonic axisymmetric inlet lip is different from Embodiment 1 in that:

[0038] A super / supersonic axisymmetric inlet lip and its design method, the design parameters of the serrated lip are: the designed sawtooth parameters are: V-shaped sawtooth units N=10, central angle θ=36°, backswept Angle λ=60°, the sawtooth forward distance is calculated by taking the average value of the given range

[0039] Taking the relative deviation ε as 1%, here is a method to determine the lip translation length x through experiment and Lagrange interpolation calculation:

[0040] First translate the elongation length a of the V-shaped sawtooth unit by x 11 =2mm,x 12 =3mm,x 13 =5mm, the corresponding relative deviation data ε is obtained through experiments 11 , ε 12 , ε 13 , it is found that the relative deviation data do not satisfy |ε 1j |≤ε, defin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com