Bamboo filament cement board and preparation method thereof

A technology of cement board and special cement, which is applied in the field of bamboo silk cement board and its preparation, which can solve the problems of high material cost, high production cost, anti-corrosion, poor candle resistance, poor water resistance of wall boards, etc., and achieve good decorative effect and environmental protection performance Good, weak contraction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

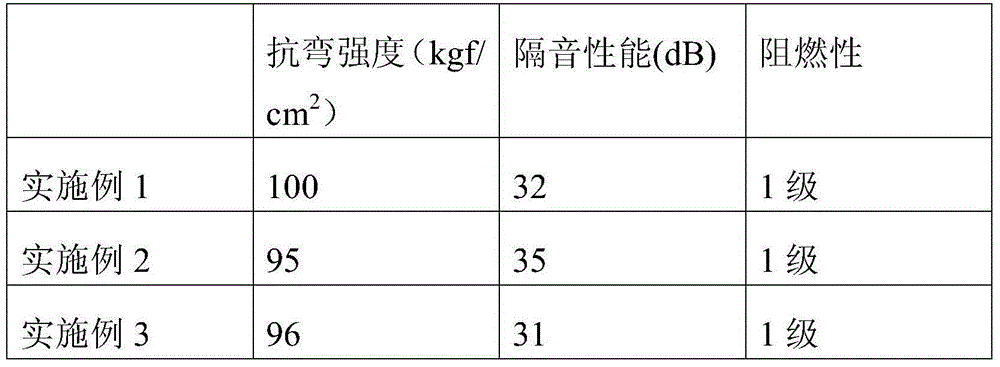

Embodiment 1

[0026] Embodiment 1 A kind of bamboo fiber cement board

[0027] A kind of bamboo fiber cement board, its preparation steps are as follows:

[0028] 1) Select 1-10 years of adult bamboo to prepare bamboo filaments, the width of the bamboo filaments is 1-5mm, and the length is 1-500mm;

[0029] 2) Bamboo silk and special cement are mixed evenly to form a slurry, which is transported to the mold; bamboo silk is 60% of the total weight of the slurry; Portland cement with a cement strength of 42.5R is 40% of the total weight of the slurry

[0030] 3) After pressing with a pressure of not less than 5 tons, it will be ready after 10 days of curing.

Embodiment 2

[0031] Embodiment 2 A kind of bamboo fiber cement board

[0032] A kind of bamboo fiber cement board, its preparation steps are as follows:

[0033] 1) Select 1-10 years of adult bamboo to prepare bamboo filaments, the width of the bamboo filaments is 1-5mm, and the length is 1-500mm;

[0034] 2) Bamboo silk and special cement are mixed evenly to form a slurry, which is transported to the mold; bamboo silk is 66% of the total weight of the slurry; Portland cement with a cement strength of 52.5R is 34% of the total weight of the slurry.

[0035] 3) After pressing with a pressure of not less than 5 tons, it will be ready after 10 days of curing.

Embodiment 3

[0036] Embodiment 3 A kind of bamboo fiber cement board

[0037] A kind of bamboo fiber cement board, its preparation steps are as follows:

[0038] 1) Select 1-10 years of adult bamboo to prepare bamboo filaments, the width of the bamboo filaments is 1-5mm, and the length is 1-500mm;

[0039] 2) Bamboo silk and special cement are mixed evenly to form a slurry, which is transported to the mold; bamboo silk is 64% of the total weight of the slurry; Portland cement with a cement strength of 62.5R is 36% of the total weight of the slurry.

[0040] 3) After pressing with a pressure of not less than 5 tons, it will be ready after 10 days of curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com